Second-hand machinery for sale (2,399)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Auctions

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

7,988 km

CNC turn-mill center

TraubTNC 65

Condition: good (used), Year of construction: 2003, operating hours: 44,534 h, Functionality: fully functional, turning length: 450 mm, turning diameter: 65 mm, spindle speed (max.): 5,600 rpm, rotational speed (max.): 8,000 rpm, TECHNICAL DETAILS

Control unit: Traub TX 8F

Turning length: max. 450 mm

Machining diameter: max. 65 mm

Bar diameter: 65 mm

Dob E Rqtsulw D Ujtjut

Spindle data

Spindle speed: max. 5,600 rpm

Spindle motor: 18.5 kW

Number of spindles: 2

Tool data

Number of tool stations on the turret head: 14x VDI30

Maximum speed of the turning tools: 8,000 rpm

Drive of the turning tools 100% / 15%: 1.5 / 4 kW

MACHINE DETAILS

Dimensions: 3,450 x 2,400 x 2,100 mm

Weight: 4,800 kg

Switch-on hours: 44,533 h

EQUIPMENT

- Breuning IRCO ILS RBK 10012 bar loading magazine

- Parts collection system with belt conveyor

- Chip preparation with KNOLL belt filter system

- Chip conveyor

- HAINBUCH collets

- Tool holder (rigid and driven)

- Documentation

Auction

Auction ended

Bayern

Bayern

7,991 km

3D metal printer

ALPHALASERAL3D-METAL 200

Condition: like new (used), Year of construction: 2022, operating hours: 70 h, Functionality: fully functional, machine/vehicle number: AL-001-0007, laser power: 200 W, travel distance X-axis: 100 mm, travel distance Y-axis: 100 mm, travel distance Z-axis: 100 mm, HIGHLIGHTS

- Very fine laser spot for the finest geometries

- Powerful laser

- High powder yield

- Reliable printing process thanks to intelligent AL3D-OS software

- Small footprint 600 × 617 mm

- Closed gas circuit for reduced gas consumption

- Low energy consumption

- Unpacking station: Clean separation of the sintered component from unused residual powder + collection of the residual powder for possible reuse

TECHNICAL DETAILS

Installation space size: d = 100 mm, h = 100 mm

Resolution: 50 µm

Laser & optics

Laser type/wavelength: fiber laser 200 W CW, 1070 nm

Focus diameter: 50 µm

Scanning speed: max. 5 m/s

Process parameters: Open access to all machine and process parameters

software

Operation: 15.6" touchscreen, keyboard and mouse possible

Connectivity: Ethernet; 2 × USB

Software: AL3D-OS, offline version for project creation

Remote access: TeamViewer

External software: Autodesk Netfabb, Materialise Magics, CIM Systems Pyramis

Software interface: Open interface for external postprocessors

File format: CAD import STL

Print preparation: Simple support generation; slicer integrated in software

Materials

Material: Metal powder, grain size fraction 10-45 µm

Alloys: Iron, nickel-based, cobalt-chromium, precious metals, reactive metals (others on request)

Component density: > 99 %

Layer thickness: 10 - 50 µm

Dueb E Rsu S H E Hsqttjt

MACHINE DETAILS

Machine dimensions

Weight: approx. 180 kg

W × D × H: 600 × 617 × 1,770 mm

Unpacking station dimensions

Weight: approx. 100 kg

W × D × H: 600 × 617 × 1,770 mm

Operating hours: 70 h

Electrics & connection

Electrical connection: 230 V, 50 Hz / 60 Hz, max. 16 A

Permissible humidity: max. 70 %

Permissible ambient temperature: 15 - 30 °C

Shielding gas/argon connection: 4.5 - 6 bar inlet pressure, Ø 6 mm hose connection

Gas consumption in operation: < 5 l/min

Gas consumption purge function: 20 l/min

Unpacking station

Vacuum cleaner connection: NW32 connection

EQUIPMENT

- 3D printer

- Unpacking station

- 9 print cartridges.

Auction

Auction ended

Bayern

Bayern

7,992 km

Injection molding machine

KraussMaffeiKM200-220/220CZ

Condition: good (used), Year of construction: 2007, operating hours: 47,963 h, Functionality: fully functional, clamping force: 2 kN, No minimum price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Clamping force: 200 t

Number of aggregates: 2

Dueb E Reuzg Sboqttst

MACHINE DETAILS

Dimensions: 5,200 x 2,200 x 2,700 mm

Weight: 11,500 kg

Operating hours: 47,963 h

Find out now

+44 20 806 810 84

+44 20 806 810 84

Create listing

*per listing / month

Auction

Auction ended

Bayern

Bayern

7,992 km

Machining center

Ingersoll OPS 650

Condition: good (used), Year of construction: 2005, Functionality: fully functional, travel distance X-axis: 700 mm, travel distance Y-axis: 550 mm, travel distance Z-axis: 450 mm, spindle speed (max.): 42,000 rpm, number of slots in tool magazine: 72, swivel angle A-axis (max.): 120 °, swivel angle C-axis (max.): 360 °, Highlight: High-speed cutting spindle with 42,000 rpm, 72 tool positions

New parts: Spindle from 2019 / X & Y axis from 2023

TECHNICAL DETAILS

Control system: Andronic

X-travel: 700 mm

Y-travel: 550 mm

Z-travel: 450 mm

A-axis: 120°

C-axis: 360°

Table and load capacity

Clamping surface: 850 x 700 mm

Max. Load capacity: 2,000 kg

Control and speed

Path control: Fully adapted to 3D

Travel speed: max. 30 m/min

Tool magazine

Number of tool positions: 72

MACHINE DETAILS

Dimensions (L x W x H): 2,500 x 3,200 x 2,700 mm

Weight: 7,700 kg

Djb E Reuzg E Ioqttout

SCOPE OF DELIVERY

Measuring probe (see photo)

Fixed table for conversion to 3-axis (unused, see photo)

Auction

Auction ended

Bayern

Bayern

7,992 km

Measuring system

MahrMarForm MFK 500

Condition: ready for operation (used), Functionality: fully functional, measuring length: 1,000 mm, table length: 800 mm, table load: 300 kg, table width: 400 mm, Equipment: documentation/manual, Straightness measuring device (vertical, Z-axis)

TECHNICAL DETAILS

Measuring path: 1,000 mm

Measuring path limitation: limit switch, software limit switch

Straightness deviation:

- 0.3 µm / 100 mm

- 1.8 µm / 900 mm

- 2 µm / 970 mm

Linear resolution (scale): 0.001 µm (interpolated)

Measuring spindle bearing: Air

Measuring spindle drive: Direct current

Measuring speed: 0.1 - 55 mm/s

Positioning speed: 0.1 - 55 mm/s

Straightness measuring device (horizontal, R (X) axis)

Measuring path: 120 mm

Measuring path limitation: Limit switch at 108 mm, software limit switch

Straightness deviation: 2 µm / 108 mm

Measuring speed: 0.1 - 20 mm/s

Linear resolution (scale): 0.001 µm (interpolated)

Measuring spindle bearing: Air

Measuring spindle drive: Direct current

Positioning speed: 0.1 - 20 mm/s

Automatic Y axis (Ty)

Table diameter: 800 x 400 mm

Table load capacity: 3,000 N (300 kg)

Workpiece alignment: motorized, automatic

Measuring path: 800 mm

Positioning travel: 800 (± 400) mm

Positioning speed: 0.1 - 50 mm/s

Positioning repeatability: 2 µm

Touch probe

Touch probes: T2W, T6W, T20L, T25L

Measuring range:

Duebouzg Amj E Rqttot

± 1,000 µm / 30 nm Resolution

± 200 µm / 6 nm Resolution

± 25 µm / 0.8 nm resolution

MACHINE DETAILS

Length x width x height: 1,900 x 2,225 x 3,180 mm (+ intermediate piece 200 - 800 mm)

Weight: approx. 10,000 kg (+ weight of intermediate piece)

EQUIPMENT

- computer

- software

Auction

Auction ended

Zürich

Zürich

7,993 km

Window construction machine Milling machine

SchücoPBS

Year of construction: 1999, operating hours: 17,216 h, Condition: ready for operation (used), Functionality: fully functional, machine/vehicle number: 300-251965, No minimum price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

X-axis: 6,650 mm

Y-axis: 800 mm

Z-axis: 500 mm

Feed rate X-axis: 0-40 m/min

Rapid traverse X-axis: 40 m/min

Feed rate Y- and Z-axis: 0-30 m/min

Rapid traverse Y- and Z-axis: 30 m/min

Deb E Rouzv Huoqttjut

B-axis rotation: from 0-90° continuous

C-axis rotation: from 0-360° continuous

B and C axis rotation speed: 10,000°/min

Positioning accuracy within a macro: max. 300 mm ±0.1 mm

Positioning accuracy over a length of 6,000 mm: < ±0.15 mm

MILLING UNIT

Maximum tool dimensions milling cutter, drill: Ø 50 mm, length = 60 mm

Maximum tool dimensions for side milling cutter: Ø 300 mm

Maximum spindle motor power: 7 kW

Spindle motor power for disk cutters: 7 kW

Spindle motor speed: 0-30,000 rpm

Tool change time: < 15 s (clamping-to-clamping time)

Tool holder: HSK-E-40 steep taper

Tool magazine: 9 plus 1

Total machine weight: 6.5 t

WORKING AREA

Number of clamping blocks: 8 pieces

Positioning of the clamping blocks: automatic

Maximum profile length for 3-sided processing: 6,650 mm

Maximum profile length for 5-sided machining: 6,100 mm

Maximum profile cross-section with max. tool length: 300 mm x 230 mm

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

7,988 km

Lathe - cycle-controlled

GildemeisterNEF plus 500

Condition: ready for operation (used), Year of construction: 1996, operating hours: 42,461 h, Functionality: fully functional, turning diameter over cross slide: 290 mm, turning length: 1,000 mm, turning diameter: 500 mm, spindle speed (min.): 2,800 rpm, No reserve price - guaranteed knockdown to the highest bidder at the end of the auction!

TECHNICAL DETAILS

Control: Heidenhain Grundig Manual Plus

Turning length: max. 1,000 mm

Rotation diameter: max. 500 mm

Turning diameter over bed: 500 mm

Turning diameter over slide: max. 290 mm

X-axis: 260 mm

Spindle data

Spindle bore: 70 mm

Spindle speed: max. 2,800 rpm

Spindle motor power: 11 kW

Dusb E Rqtjulwqhotjt

MACHINE DETAILS

Length: 2,500 mm

Width: 1,750 mm

Height: 1,850 mm

Weight: 2.65 tons

Auction

Auction ended

Germany

Germany

7,998 km

Laser Punch Press

TRUMPFTruMatic 7000 - 1600

Condition: ready for operation (used), Year of construction: 2011, operating hours: 12,748 h, Functionality: fully functional, punching force: 22 t, workpiece length (max.): 1,550 mm, workpiece width (max.): 3,050 mm, sheet thickness (max.): 8 mm, No reserve price - guaranteed knockdown to the highest bidder at the end of the auction!

Trumpf TruMatic 7000 - 1600 (large format) with additional equipment and automation

AUTOMATION

- SheetMaster with peeling system including positioning aids for large format + first additional package with 9 suction cups, incl. vacuum ejector

- Unloading monitoring

- GripMaster large format

- SortMaster pallet sorting function on four pallets

TECHNICAL DETAILS

Deb E Rqteuhygpetsut

Control system: TRUMPF Rexroth IndraMotion MTX

Punching work area: 3,050 x 1,550 mm

Laser working area: 3,050 x 1,550 mm

Combined working area: 2,500 x 1,550 mm

Control system: Siemens Sinumerik 840 D

Laser power: 3,200 watts

Wavelength: 10.6 µm

Sheet thickness: 8 mm

Workpiece weight: max. 280 kg

Punching force: 220 kN

Active blank holder: 4.5 - 20 kN

Linear magazine: 21 tools with 4 clamps

Programmable chute: 500 x 500 mm

Positioning speed X / Y / simultaneous: 100 / 60 / 116 m/min

C-axis punching: 60 rpm

C-axis thread forming: 180 rpm

Punching stroke sequence: 1200 rpm

Stroke sequence marking: 2800 1/min

Position deviation: ± 0.10 mm

Position spread: ± 0.03 mm

MACHINE DETAILS

Length: approx. 10.5 m

Width: approx. 9 m

Height: 2.5 m

Blasting time/laser switch-on time: 12,748 h

Machine switch-on time: 87,844 h

Operating voltage: 400 V / 50 Hz

Compressed air connection: 7 ± 1 bar

Laser gas consumption CO2 / N2 / He: 1 / 6 / 13 l/h

EQUIPMENT

- Sturdy, easily accessible C-frame

- Drives with maintenance-free three-phase motors

- Foot pedal clamp closing

- Ball tables

- TASC 3 laser control

- Jet pipe ventilation with compressed air

- FastLine

- FocusLine

- ControlLine

- NitroLine

- SprintLine

- ContourLine

- FlyLine

- PlasmaLine

- Additional Xp and Yp axes

- Electro-hydraulic punching head

- Rotatable mono tool holder

ADDITIONAL EQUIPMENT

- TruFlow 3200 laser incl. LensLine and optimized standby

- MultiTool function

- Thread forming function

- Marking/quick beading function

- Engraving function

- Deburring and rolling technology function

- Active die

- Spray lubrication Die incl. progr. lubricant container with level monitoring

- Repositioning cylinder

- Vibration-damped installation

- Chip conveyor with tilting container

- Brush tables with loading and unloading aid

- Blow-out device for small parts

Auction

Auction ended

Bayern

Bayern

7,999 km

Laser cutting machine

Mercury1620

Condition: ready for operation (used), Year of construction: 2005, operating hours: 25,253 h, Functionality: fully functional, laser power: 300 W, travel distance X-axis: 2,000 mm, travel distance Y-axis: 1,620 mm, travel distance Z-axis: 80 mm, No minimum price - guaranteed sale at the highest bid!

Reason for selling: Space for new machine - machine must be collected by the end of September

Under power until 12.10. Bidders are obliged to collect the machine by the deadline of 18.10.24.

TECHNICAL DETAILS

Laser cutting system: Mercury 1620

Laser: Rofin SCx, water-cooled, cutting head with lens

Laser power: 300 W

Table: Anodized aluminium cutting base

Work surface: 1620 x 2000 mm

Clearance height: 70 mm

Material width: 1650 mm

Z-travel: 80 mm

Dueb Eeuq I Ins Rqttst

Speed (X-Y axis): 2000 mm/s

Acceleration: 18 m/s²

Resolution (X-Y axis): 0.001 mm

Resolution Z axis: 0.1 mm

Accuracy: ± 0.05 mm on the entire work surface

Repeat accuracy: ± 0.025 mm

Laser system protection class: 1

Laser source: ROFIN ScX Series 300, closed and maintenance-free

Cooling circuit: closed incl. water recooler for laser

Cutting head: with lens, cutting nozzle, cutting gas supply

MACHINE DETAILS

Dimensions: 2390 x 4150 x 1550 mm

Weight: 2000 kg

Machine: 380 V, 50 Hz, 32 A 3P+N+T / 15 kW

Cooler: 380 V, 50 Hz, 16 A, 4 kW

Suction fan: not included in scope of delivery

Compressed air: 200 l/min, 7 bar, oil-free

EQUIPMENT

- Service set for optics

- ICARO software and user manual

- Shuttle table system

- 2 cutting tables positioned one above the other with motorized height adjustment

- Aluminum cutting base

- Vacuum / suction tray for small parts and dust; suction from below is through the tray. Extraction from above is through a specially designed slot in the upper part of the machine cover

- The cover closes/opens automatically before/after the job is completed

CONTROL

- Speed, acceleration, material thickness, laser power and frequency fully adjustable in the ICARO software

- Import HPGL, DXF, BMP, CF2 ...

- Execution of curves with constant speed

- Execution of curves with spline interpolation

- Motor load control for all X, Y, Z axes

- Position and speed control using encoders

- Control system specially developed for laser technology

- Safety standards according to European standards (CE)

The extraction system with filter is not sold.

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

7,999 km

5-axis machining center

Deckel MahoDMC 80 U duoBlock

Condition: good (used), Year of construction: 2005, operating hours: 29,839 h, Functionality: fully functional, machine/vehicle number: 11470000133, travel distance X-axis: 800 mm, travel distance Y-axis: 800 mm, travel distance Z-axis: 800 mm, rotational speed (max.): 8,000 rpm, number of slots in tool magazine: 120, TECHNICAL DETAILS

Control: Heidenhain iTNC 530

X-axis travel: 800 mm

Y-axis travel: 800 mm

Z-axis travel: 800 mm

Spindle technology: geared spindle

Spindle speed: max. 8,000 rpm

Spindle power: max. 28 kW

Spindle torque: max. 727 Nm

Swivel head: B-axis, 0.001°

Media feed-through: coolant + blast air

NC rotary table C-axis: 0.001°

Dusb E Rourky Nsqttjt

Pallet clamping surface: Ø 800 x 630 mm

Table load: max. 1,200 kg

Workpiece clamping: interface clamping hydraulics prepared

Tool magazine: Chain magazine, 120-fold

Tool holder: SK 50

Rapid traverse X-axis: 60 m/min

Rapid traverse Y-axis: 60 m/min

Rapid traverse Z-axis: 60 m/min

MACHINE DETAILS

Switch-on time: 71,261 h

Spindle time: 29,839 h

Installation dimensions: 8,600 x 7,400 x 3,060 mm

Weight: approx. 17 tons

Connected load: 76 kVA

Operating voltage: 400 V, 50 Hz

EQUIPMENT

- Distance measuring system: Direct in all axes (glass scales)

- Chip management: Chip conveyor

- Coolant supply: IKZ system with paper belt filter and high pressure, 80 bar

- Workpiece measurement: Infrared measuring probe, Hexagon

- Tool breakage monitoring: Interface prepared, mechanical

- Process monitoring: Operating mode 4

- Extraction: Electrostatic, ifs IFE 2000

- Number of pallets: 2 pieces

- Additional equipment: ROTO-Clear, rinsing gun

Auction

Auction ended

Bayern

Bayern

8,004 km

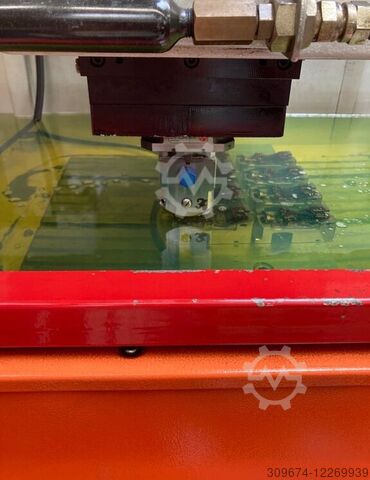

Jig

AGIE CHARMILLESHyperspark 3 HS (AT)

Condition: ready for operation (used), Year of construction: 2008, Functionality: fully functional, machine/vehicle number: 360, travel distance X-axis: 500 mm, travel distance Y-axis: 350 mm, travel distance Z-axis: 500 mm, workpiece weight (max.): 800 kg, TECHNICAL DETAILS

Travel X / Y / Z: 500 / 350 / 500 mm

Rotation: 0 - 60 rpm

Table dimensions: 800 x 600 mm

Automatically lowerable container: 200 - 700 mm

Workpiece weight: 800 kg

Internal dimensions of work bowl: 1,090 x 730 x 490 mm

MACHINE DETAILS

Weight: 5,000 kg

Installation dimensions: 3,200 x 2,400 x 2,700 mm

Operating voltage: 3 x 400 V

Frequency: 50 Hz

Dsb Eeuh Tmie Rqtteut

Connection: 8.3 kVA

Rated current: 12 A

Auction

Auction ended

Bayern

Bayern

8,004 km

Injection molding machine

NetstalSynErgy 2000-230/110

Condition: good (used), Year of construction: 2014, operating hours: 20,209 h, Functionality: fully functional, clamping force: 2,000 kN, Machine with exemplary maintenance and servicing

TECHNICAL DETAILS

Clamping force: 2000 kN

Cylinder size AG1: 20 mm

Cylinder size AG2: 16 mm

Machine drive power: 45 kW

Flow Box DETAILS

Dob Esuh Tkzo Rqttjut

Type: LMP 105

Manufacturer: Max Petek

Serial number: S 140743

Year of manufacture: 2014

Robot DETAILS

Robot: Krauss - Maffei MH 50

Designation 6 -axis: Yaskawa

Type: DX 100

Operating hours: approx. 8900 h

Year of construction: 2014

MACHINE DETAILS

Weight: 13,300 kg

Length: 6,901 mm

Width: 2,075 mm

Height: 2,240 mm + 800 mm flow box

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

7,988 km

Gear shaping machine

LiebherrLS 120

Condition: good (used), Year of construction: 2004, operating hours: 53,371 h, Functionality: fully functional, table bore: 80 mm, rotary table diameter: 145 mm, workpiece diameter (max.): 120 mm, spindle speed (max.): 30 rpm, TECHNICAL DETAILS

Control: Siemens Sinumerik

Table diameter: 145 mm

table bore: 80 mm

Table speed: max. 150 rpm

Dujboulwlle E Rqttst

Workpiece outer diameter: max. 120 mm

Shaping head

Normal module: max. 5 mm

Bevel angle: max. 45 degrees

Stroke rate: min. 250 DH/min

Stroke rate: max. 1,500 DH/min

Shaping spindle speed: min. 0.0076 rpm

Shock spindle speed: max. 30 rpm

Drive power lifting drive: 17 kW

Stroke position adjustment range: 70 mm

Stroke length: max. 55 mm

C1 axis

Travel: Endless

Working range: Endless

Working/rapid traverse speed: 30 rpm

Reference point: -

C2 axis

Travel distance: Endless

Working range: Endless

Working/rapid traverse speed: 150 rpm

Reference point: -

X1 axis

Travel distance: 242 mm

Working range: min. - 25 mm, max. 217 mm

Working/rapid traverse speed: 3,750 mm/min

Reference point: 203.105 mm

Z3 axis

Travel: Endless

Working range: Endless

Working/rapid traverse speed: 1,500 1/min

Reference point: 270 grd

B4 axis

Travel distance: Endless

Working range: Endless

Working/rapid traverse speed: 1,500 1/min

Reference point: 270 grd

C3 axis

Travel distance: Endless

Working range: Endless

Working/rapid traverse speed: 40 1/min

Reference point: 0 grd

Z4 axis

Travel distance: 300 mm

Working range: 300 - 600 mm

Working/rapid traverse speed: 17,000 mm/min

Reference point: 525 mm

MACHINE DETAILS

Operating voltage: 400 V

Total weight: 8 t

Auction

Auction ended

Bayern

Bayern

8,004 km

Automation system for injection molding

WITTMANNW833PRO

Year of construction: 2016, Condition: excellent (used), Functionality: fully functional, Automation system of the Wittmann brand was newly installed in 2016 and used on a Netstal Synergy 2000.

All documents, operating instructions, maintenance plans, measurement diagrams etc. included as well as control modules, power supply units and control panels.

The Wittmann Picker can be used as a stand alone.

TECHNICAL DETAILS

travel X / Y / Z: 900 / 1800 / 3000 mm

Deb E Rqtspm Htgetout

payload: 15 kg

Scope of delivery: robot, console, support V/2614-3104, adapter, conveyor system standard MB belt, SE protective enclosure incl. safety door with SIPA

MACHINE DETAILS

dimensions plant (LxWxH): 6560 x 4423 x 4154 mm

Robot weight: 560 kg

Mains connection: 3PH/N/PE

mains voltage: 400 V

tolerated voltage fluctuations: up to 10%

connected load: 11 kVA

frequency: 50-60 Hz

tolerated frequency fluctuations: up to 2%

supply line fuse: 16 A

air pressure: max 6 bar

maintenance of system functions: up to min 5 bar

Auction

Auction ended

Bayern

Bayern

8,004 km

Jig

CHARMILLESRoboform 35 P Roboter Automation

Year of construction: 2001, Condition: good (used), Functionality: fully functional, Machine extensively overhauled worth EUR 18,000

Optional configuration QCRI 54/8: available, see pictures

placement automation: available, see video

Pressure flushing: 1 x through workpiece 1 x through electrode, 2 x lateral

Suction flushing: 1 x through workpiece

Central lubrication system automatically via NC in all axes

TECHNICAL DETAILS

Travel (X, Y, Z): 350, 250 300 mm

Max man. Feeding speed: 900 mm/min

Weight of electrodes: max. 20 kg

Weight of workpieces: max. 40 kg

Magazine configuration: 54/8

Duob E Ron Arnxsqttet

electrodes: 54 pieces

Electrode dimensions: 70 x 70 x 200

Plates: 8 pieces

workpiece dimensions: (4x) 320 x320 x 270 mm, (4x) 320 x 320 x 170 mm

work table: 500 x 400 mm

T-slots: 3 x 12 mm

distance of grooves: 125 mm

Available clamping systems: Erowa IST 3R Macro Megatool GPS 70

MACHINE DETAILS

Dimensions (H x L x W): 2400 x 1900 x 1690 mm

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

8,008 km

CNC lathe

MazakQuick Turn Smart 250M L

Condition: good (used), Year of construction: 2016, operating hours: 13,701 h, Functionality: fully functional, machine/vehicle number: 276209, turning diameter: 255 mm, spindle speed (max.): 4,000 rpm, travel distance X-axis: 225 mm, travel distance Z-axis: 1,125 mm, swing diameter over bed slide: 660 mm, TECHNICAL DETAILS

Chuck size: 10 inch

Maximum swing circle: max. 660 mm

Standard turning diameter: max. 255 mm

Maximum turning diameter: max. 360 mm

Largest bar passage: max. Ø 80 mm

Distance between spindle nose and turret edge: 59.5 - 1,179.5 mm

Maximum weight (bar work): max. 500 kg

Maximum weight (chuck work): max. 450 kg

Spindle

Speed: 35 - 4,000 rpm

Shape of spindle nose: JIS A2-8

Spindle bore: Ø 91 mm

Acceleration time: 2.3 s

Motor power (30-minute power/continuous power): 26/22 kW

Maximum torque (15%ED): 465 Nm

Tailstock

Quill type: MT No 4

Movement stroke (tailstock body): max. 1,075 mm

Minimum and maximum thrust: min. 1,000 N, max. 5,000 N

Tools and turrets

Number of tools: 12 pieces

Outer chisel tool sizes: max. Ø 25 mm

Internal turning tool sizes: max. Ø 40 mm

Tool sizes router bits: max. Ø 20 mm

Tool sizes end mills: max. Ø 20 mm

Tool sizes for milling taps: max. M20 (3/4 UNI) × 2.5 mm

Turret

Switching time (next/opposite position): 0.23/0.62 s

Milling spindle motor power (40%ED/continuous power): 5.5/3.7 kW

Milling spindle speed: max. 6,000 rpm

Maximum torque of the milling spindle (40%ED): max. 47 Nm

Feed axes

Dujbsu Tdi Es E Rqttet

Rapid traverse X/Z: max. 30/33 m/min

Time constant X/Z: 65/80 ms

Travel range X: max. 225 [220 + 5] mm

Travel range Z: max. 1,125 [1,120 + 5] mm

MACHINE DETAILS

Spindle center height: 1,020 mm

Overall length: 3,385 mm

Overall width: 1,720 mm

Total height: 1,820 mm

Space requirement: 5.82 m²

Mass of the machine: 6,050 kg

Mass of the machine (with steady rest): 6,250 kg

Connected load: 44.5 kVA

Voltage: 400 V

Coolant tank volume: 270/315 l

Machine package: 3.87 x 2.16 x 2.01 m, 6.62 t

Chip conveyor package: 3.54 x 0.87 x 1.35 m, 325 t

Auction

Auction ended

Bayern

Bayern

8,019 km

Wire EDM machine

MitsubishiFA20P

Year of construction: 2002, Condition: used, Functionality: fully functional, machine/vehicle number: J20M0036, Wire EDM machine with automatic wire threading (AT)

TECHNICAL DETAILS

x-way: 500 mm

y-way: 350 mm

z-way: 300 mm

amps: 50 A

table length: 780 mm

table width: 630 mm

table feed: 1 - 1.300 mm/min

wire feed: 15,00 m/min

Control: W21F AP-2

workpiece size: 1050 x 800 x 295 mm

workpiece weight: max. 800 kg

Duobsnh R Nks E Rqttst

MACHINE DETAILS

total power requirement: 12,00 kW

machine weight: approx. 4,50 t

space requirement: approx. 3.00 x 3.50 x 2.50 m

Auction

Auction ended

Switzerland

Switzerland

8,020 km

Thread rolling machine

GRTZ28-500

Condition: good (used), Year of construction: 2019, Functionality: fully functional, TECHNICAL DETAILS

Rolling diameter: 6-80 mm

Width of the rolling tool: max. 150 mm

Outer diameter of the rolling tool: max. 240 mm

Center distance tool spindle - center: 190-240 mm

Pitch size range (normal): 1-12 mm

motor

Rollers: 15 kw-6

Hydraulic: 5.5 kw-4

Cooling: 0. 125 kw

Rolling force: max. 500 KN

Spindle diameter: 85 mm

Inclination angle of the spindle: +/- 10°

Volatility: 380 V, 50 HZ, 3 phase

MACHINE DETAILS

Dsbstwbkqj E Rqtteut

Size of the basic machine: 2600 x 2100 x 1600 mm

Size of the hydraulic station: 800 x 500 x 1250 mm

Weight of the machine: 4500 kg

Length of the workpiece: Unlimited

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

7,988 km

Horizontal machining center

MakinoA 55

Condition: ready for operation (used), Year of construction: 2001, operating hours: 55,569 h, Functionality: fully functional, travel distance X-axis: 560 mm, controller manufacturer: Fanuc, controller model: 16 MC Professional 3, spindle speed (max.): 20,000 rpm, number of slots in tool magazine: 126, TECHNICAL DETAILS

Control system: Fanuc 16 MC Professional 3

Travel X / Y / Z: 560 / 560 / 560 mm

Spindle speed: 20,000 rpm

Torque: max. 167 Nm

Tool holder: HSK-A63 DIN 69893

Tool magazine: 126 places

Tool change time: 1 s

Max. tool diameter: 80 mm

max. tool length: 300 mm

Dueb E Retzc D Seqttst

Distance spindle head to table: 150 - 710 mm

distance table-UK-spindle: 80 - 640 mm

Pallet size: 400 x 400 mm

Pallet load: 400 kg

Pallet change time: 7 s

Rotary table indexing: 1°

Table speed: 5000 rpm

Spindle drive: 22 kW

Feed: max. 40,000 mm/min

Rapid traverse: 40,000 mm/min

MACHINE DETAILS

Total power requirement: 64 kW

Machine weight: approx. 15 t

Space requirement: approx. 9.0 x 3.0 x 2.8 m

Spindle hours: 55,569 h

Program run: 66,600 h

Switch-on time: 163,411 h

Auction

Auction ended

Germany

Germany

8,021 km

CNC lathe

EMCOHYPERTURN 45

Condition: used, Year of construction: 2016, Functionality: fully functional, machine/vehicle number: BF15103648, TECHNICAL DETAILS

WORKING RANGE

Travel in X/Y/Z: 160 /+40/-30 / 510 mm

Bar passage: max. 45 (51) mm

Turning diameter: max. 300 mm

Rotation diameter over bed 430 mm

Rapid traverse speed X/Y/Z 30 / 15 / 45 m/min

Dsbjtt D Adj E Rqttjut

MAIN SPINDLE

Speed: max. 7000 rpm

Drive power: max. 15 kW

Torque: max. 100 Nm

COUNTERSPINDLE

Speed: max. 7000 rpm

Drive power: max. 15 kW

Torque: max. 100 Nm

TOOL TURRET 1

VDI size: VDI 25

Number of tool positions: 12

Driven tools: 12

Speed: max. 6000 rpm

Drive power: max. 4 kW

Torque: max. 16 Nm

TOOL TURRET 2

VDI size: VDI 25

Number of tools: 12

Of which driven: 12

Speed: max. 6000 rpm

Drive power: max. 4 kW

Torque: max. 16 Nm

EQUIPMENT

- Chip conveyor

- Parts catcher

- Accessories shown

Auction

Auction ended

Bayern

Bayern

8,019 km

Horizontal machining center

Deckel MahoDMC 60 H

Year of construction: 2002, Condition: used, Functionality: fully functional, Horizontal machining center with double chain magazine.

TECHNICAL DETAILS

x-way: 600 mm

y-way: 560 mm

z-way: 560 mm

control: Siemens Sinumerik 840D

B - axis: 360 x 0,001 °

spindle speed - stepless: 8.000 rpm

feed X/Y/Z/ axis: 1 - 60.000 mm/min

feed B axis: 9.250 °/min

rapid traverse X/Y/Z: 60.00 m/min

feed force X/Z: 9.600 N

Feed force Y: 8,000 N

drive power 40 % ED: 20,00 KW

driving power 100% ED: 13,00 kW

Tool holder: SK40

Torque at 40% / 100% ED: 191 / 124 Nm

Pallet size: 2x 400 x 500 mm

workpiece weight: max. 600 kg

tool magazine: 180

tool diameter: 90 mm

Dujb E Rqtsnh Rn Aotjt

tool diameter with 2 free places: 160 mm

tool length: max. 350 mm

Tool weight: max. 3.50 / 12.00 kg

MACHINE DETAILS

total power requirement: 65,00 kW

machine weight: approx. 16,00 t

space requirement: approx. 9.00 x 4.50 x 3.50 m

EQUIPMENT

Coolant system with IKZ

Double chain magazine with 180 places

Chip conveyor

BLUM tool laser measurement

electronic handwheel

Trust Seal

Dealers certified through Machineseeker

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

7,988 km

Horizintal machining center

Hüller HilleNBH 170

Condition: good (used), Year of construction: 2003, Functionality: fully functional, TECHNICAL DETAILS

X-axis: 1000 mm

Y-axis: 800 mm

Z-axis: 800 mm

Control: Siemens Sinumerik 840 D

Speed range: 25 - 6000 rpm

Workpiece swivel range: 900 mm

Distance table center - spindle: 130 mm

Clamping surface plate: 500 x 630 mm (DIN 55201, form A2)

Workpiece weight per table: approx. 800 kg

Fixture height: 1100 mm

Ball screw: 63 mm

Spindle diameter: 100 mm

Torque 100% / 60% ED: max. 900/1130 Nm

Feed range X-, Y-, Z-axis: 1-36000 mm/min

Feed force X-,Y-,Z-axis 25% ED: approx. 25000 N

Rapid traverse speed X-,Y-,Z-axis: 36 m/min

Rapid traverse rotary table: 30 rpm

Dusb E Rqtotu S Systjt

MACHINE DETAILS

Space requirement: 8.00 x 3.50 x 3.50 m

Weight: 24 tons

Auction

Auction ended

Bayern

Bayern

8,021 km

CNC lathe

GildemeisterCTX 510 V

Condition: good (used), Year of construction: 2007, operating hours: 25,000 h, Functionality: fully functional, TECHNICAL DETAILS

Turning diameter: max. 465 mm

turning length: 1050 mm

Rotation diameter: 680 mm

Chuck diameter: 325 mm

x-path: 300 mm

z-path: 1,050 mm

C-axis: 360°

Control: Heidenhain Plus IT

Speed range: max. 3,500 rpm

Drive power: 33 kW

Torque: max. 630 Nm

Spindle bearing diameter: 120 mm

Spindle bore: 100 mm

Max. Bar diameter: 90 mm

Debstt Du Ns E Rqttjut

Tailstock travel: 850 mm

Quill stroke: 150 mm

Tailstock holder: MK 5

Rapid traverse X / Z: 30 m/min

Number of tool positions: 12 positions

Tool holder: VDI 40

Driven tool stations: 12

Speed of driven tools: max. 4,000 rpm

Drive power of driven stations: 8.4 kW

Torque: max. 20 Nm

MACHINE DETAILS

Total power requirement: 50 kVA

Machine weight: 9,000 kg

Space requirement: 6.5 x 3.0 x 2.2 m

Spindle hours: 25,000 h

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

7,988 km

Machining center

KIHEUNGCombi - U7

Condition: good (used), Year of construction: 2013, Functionality: fully functional, TECHNICAL DETAILS

Control: Heidenhain TNC 620

Speed: 4,000 rpm

Weight: approx. 12,000 kg

Max. Table load: 2,000 kg

Travel X: 1,600 mm

Travel Y: 750 mm

Travel Z: 900 mm

Clamping surface: 1,800 x 700 mm

MACHINE DETAILS

Gear spindle: 2-stage

Spindle power: approx. 38 kW

Tool holder: SK 50

Spindle: manually swiveling

Tool magazine: 24-fold

EQUIPMENT

Duob E Rstuwkbeqttot

Chip conveyor with coolant system

Electronic handwheel

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

7,988 km

Machining center

DAEWOOACE - HP 500

Condition: good (used), Year of construction: 2004, Functionality: fully functional, TECHNICAL DETAILS

CNC control: FANUC 18i

Duebotuwhne E Rqttjt

X-axis: 800 mm

Y-axis: 700 mm

Z-axis: 750 mm

B-axis: indexing axis

Spindle motor: 25 KW

Spindle speed: 8000 rpm

Distance from spindle nose to table center: 150 - 900 mm

Tool magazine: 60 places

Max. Table speed: 20 rpm

Tool changer: DIN SK50

EQUIPMENT

Chip conveyor

Without clamping angle

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

This may be of interest to you

Find out now

+44 20 806 810 84

+44 20 806 810 84

Create listing

*per listing / month