Second-hand machinery for sale (2,359)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Auctions

Auction

Auction ended

Dolnośląskie

Dolnośląskie

8,235 km

Injection molding machine

KraussMaffeiKM 300-1000 C1

Condition: ready for operation (used), Year of construction: 2005, Functionality: fully functional, machine/vehicle number: 61007465, clamping force: 3,000 kN, screw diameter: 55 mm, clearance between the columns: 630 mm, injection pressure: 1,904 bar, injection weight: 476 g, opening stroke: 820 mm, Including robot - Wittmann W 731

X-axis: 800 mm

Y-axis: 1,400 mm

Z-axis: 4,000 mm

TECHNICAL DETAILS

Clamping force: 3,000 kN

Mold opening force (max.): 160 kN

Moving platen pusher force (opening): 86 kN

Moving platen pusher force (closing): 68 kN

Mold platen size (H x V): 995 x 1,050 mm

Column spacing (H x V): 630 x 630 mm

Mold opening stroke: 820 mm

Minimum mold height: 330 mm

Maximum clear height: 1,150 mm

Injection unit

Screw diameter: 55 mm

Dueb Eovzrp Io Hrhnot

L/D ratio: 20

Injection pressure: 1,904 bar

Injection volume: 523 cm³

Injection weight (PS): 476 g

Injection rate: 428 cm³/s

MACHINE DETAILS

Machine dimensions (L x W x H): 5.97 x 2.04 x 2.36 m

Total weight: 12.5 t

Auction

Auction ended

Ljubljana

Ljubljana

8,463 km

Heating tunnel

Petek ProcessTKO-1-12000-02

Condition: ready for operation (used), Year of construction: 2006, Functionality: fully functional, machine/vehicle number: 14705, temperature: 42 °C, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Capacity: 12,000 bottles/hour

Temperature range: 0-42 °C

Equipment: Heat exchanger Ipros VT20V-12/CDSC-16

CE marking: Yes

Voltage: 400 V

Frequency: 50 Hz

Power consumption: 8 kW

Dob Eevnbr Ej Hrhnsut

Packaging form: Custom-made pallet

Overall dimensions (metric): 5,000 x 2,500 x 1,800 mm - 2,000 kg

Auction

Auction ended

Germany

Germany

7,963 km

Machining Center - 5 axes

MetromP1000

Condition: ready for operation (used), Year of construction: 2007, Functionality: fully functional, machine/vehicle number: 085/2007.01, travel distance X-axis: 1,000 mm, travel distance Y-axis: 1,000 mm, travel distance Z-axis: 500 mm, controller model: Andronic 2060PKM, swivel angle B-axis (max.): 360 °, TECHNICAL DETAILS

X-axis: 1,000 mm

Dueb Eovykxrs Hrhnot

Y-axis: 1,000 mm

Z-axis: 500 mm

C-axis (table): 360°

Control: Andronic 2060PKM

Rotary table diameter: 260 mm

Spindle

Spindle mount: HSK A63

Working spindle speed range: 15,000 rpm

Feeds and speed

Feed: 1 - 5,000 mm/min

Rapid traverse X/Y: 15 m/min

Rapid traverse Z: 12 m/min

MACHINE DETAILS

Machine weight: approx. 6.0 t

Control cabinet (L x W x H): 2.4 x 0.6 x 2.2 m

Machine (L x W x H): approx. 3.5 x 2.4 x 3.2 m

Total power requirement: approx. 42 kW

EQUIPMENT

- 5-axis parallel kinematics for prototype production

Auction

Auction ended

Germany

Germany

7,963 km

Plate shears - hydraulic

WiegerAlpha 301 13/30

Condition: ready for operation (used), Year of construction: 1993, operating hours: 3,256 h, Functionality: fully functional, sheet thickness (max.): 13 mm, sheet width: 3,150 mm, distance between stands: 3,670 mm, TECHNICAL DETAILS

Max. sheet width: 3,150 mm

Max. sheet thickness: 13 mm

Stand width: 3,670 mm

Blade length: 3,150 mm

Holders: 18 pieces

Back stop

Type: Motorized

Travel path: 1,000 mm

Positioning: Yes

MACHINE DETAILS

Height above floor: 850 mm

Table size (L x W): 3,770 x 500 mm

Machine dimensions (L x W x H): 4.4 x 2.8 x 2.4 m

Duob E Hrjvykwnshnot

Machine weight: approx. 12.9 t

Total power requirement: 30 kW

EQUIPMENT

- Hydraulic sheet holding device.

- Cutting gap lighting

- Safety light curtain at the rear

- Short stroke and continuous operation possible

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

8,005 km

Machining center

HERMLEC 600 U

Condition: ready for operation (used), Year of construction: 2002, operating hours: 28,384 h, Functionality: fully functional, machine/vehicle number: 15594, travel distance X-axis: 600 mm, travel distance Y-axis: 450 mm, travel distance Z-axis: 450 mm, swivel angle A-axis (min.): -90 °, swivel angle A-axis (max.): 20 °, TECHNICAL DETAILS

Control: Heidenhain iTNC 530

X-axis: 600 mm

Y-axis: 450 mm

Z-axis: 450 mm

A-axis rotation range: +20° / -90°

C-axis rotation range: 360°

Rotary table diameter: 280 mm

Spindle data

Spindle mount: HSK A 63

Tool changer: 30 positions

Feeds and speed

Feed range: 1 - 30,000 mm/min

Rapid traverse speed: 35 m/min

MACHINE DETAILS

Machine weight: approx. 6,500 kg

Control switch-on time: 64,299 h

Machine switch-on time: 61,676 h

Program run: 29,320 h

Djb E Hjvytgferhnjut

Spindle hours: 28,384 h

Drive hours: 37,893 hours

Auction

Auction ended

Germany

Germany

7,963 km

Single-column eccentric press

WMW BLEMA-GOTHAPEE II 160

Condition: ready for operation (used), Year of construction: 1974, Functionality: fully functional, throat depth: 400 mm, installation height: 400 mm, pressing force: 160 t, ram stroke: 140 mm, TECHNICAL DETAILS

Pressure force: 160 t

Pillar stroke: 32 - 140 mm

Pillar adjustment: 100 mm

Stroke rate: 50 strokes/min

Thrust: 400 mm

Installation height: 400 mm

Djb Eevyix De Hrhnout

Drawing depth: 63 mm

Pressure force at maximum drawing depth: 63 t

Adjustment of the ram slide: 100 mm

Operating options: single stroke / continuous stroke

Operation: foot and hand operation possible

Table and work surfaces

Table size: 1,000 x 750 mm (without clamping plates)

Pillar surface: 850 x 630 mm

Tenon hole: 400 x 360 mm

MACHINE DETAILS

Machine weight: approx. 10.5 t

Machine dimensions (L x W x H): 2.9 x 1.25 x 3.3 m

Electrical control cabinet (L x W x H): 1.06 x 0.6 x 2.0 m

Energy and operating requirements

Total power requirement: 15.5 kW

Compressed air: 6 kp/cm²

Oil filling: approx. 30 liters

Power connection: 80A

EQUIPMENT

- Clamping plates with different dimensions: 1x 1,200 x 760 x 90 mm / 1x 1,200 x 760 x 70 mm

- Tenon hole Ø 300 mm

Auction

Auction ended

Dolnośląskie

Dolnośląskie

8,235 km

Injection molding machine

BATTENFELDTM 4500/2800

Condition: ready for operation (used), Year of construction: 2001, Functionality: fully functional, clamping force: 4,500 kN, screw diameter: 75 mm, clearance between the columns: 800 mm, injection weight: 1,506 g, mold height (min.): 425 mm, opening stroke: 760 mm, TECHNICAL DETAILS

Control: Unilog B4

Clamping force: 4,500 kN

Minimum mold height: 425 mm

Maximum mold height: 770 mm

Column spacing (H x V): 800 x 800 mm

Mounting plates (H x V): 1,155 x 1,195 mm

Mold opening stroke: 760 mm

Robot interface: Euromap 12

Injection unit

Deb Esvzrn Ds Hrhneut

Screw diameter: 75 mm

Injection weight (PS): 1,506 g

Injection volume: 1,657 cm³

Specific injection pressure: 1,739 bar

MACHINE DETAILS

Machine dimensions (L x W x H): 8.3 x 1.9 x 2.4 m

Total weight: 20,400 kg

Oil tank capacity: 800 l

Auction

Auction ended

Germany

Germany

7,963 km

Shear

KingslandMulti 95D

Condition: ready for operation (used), Year of construction: 2003, Functionality: fully functional, throat depth: 625 mm, punching force: 40 t, overall weight: 2,700 kg, stroke distance: 80 mm, TECHNICAL DETAILS

Operation: via foot switch

Thrust: 625 mm

Stroke rate: 34 strokes/min

Punching force: 40 t

Stroke: 80 mm

Shearing station

Flat steel cutting: max. 380 x 20 mm / 480 x 15 mm

Bevel cutting: max. 120 x 15 mm

Holder: adjustable in length to 750 mm

Knife cutting edges: 2-way upper knife, 4-way lower knife

Profile station

Application: processing of round and square profiles, U-profiles, double-T beams, unequal-sided angles

Angle steel:

- 90° shearing: max. 150 x 15 mm

- 45° shearing: max. 80 x 10 mm

Profile cutting:

Dsb Esvyiiio Hrhnout

- Round steel: max. Ø 50 mm

- U-H profile: max. 160 x 90 mm

- T profile: max. 120 x 12 mm

Punching station

Table size: 600 x 600 mm

Max. bore: Ø 57 x 12 mm

Working stroke: 80 mm

Stroke rate: 34 strokes/min

Punching pressure: 40 t

Stop angle: 200 x 100 mm (L=600 mm)

Notching station

Table size: 450 x 450 mm

Notches/notches Material thickness: 13 mm

Notch width: 52 mm

Notch depth (V 90°): 70 - 100 mm

Angle flange: 100 x 13 mm

MACHINE DETAILS

Total power requirement: 7.5 kW

Machine weight: approx. 2.7 t

Machine dimensions (L x W x H): 1.4 x 0.8 x 1.8 m

EQUIPMENT

- Adjustable hold-down clamp

- Reusable cutting edges for longer durability

- Accessories available on request

Auction

Auction ended

Germany

Germany

7,963 km

Mandrel tube bending machine

BLMB42 CNC

Condition: ready for operation (used), Year of construction: 1990, Functionality: fully functional, wall thickness: 25 mm, overall weight: 2,800 kg, pipe diameter: 42 mm, controller model: RC 7000, TECHNICAL DETAILS

Area of application: Processing of deformable pipes, rectangular pipes, round bars and square pipes.

Pipe diameter: 42 mm

Wall thickness: 2.5 mm

Djb E Hrovyib Sshnjut

Round steel (max.): Ø 20 mm

Square material (pipe): 25 x 25 mm

Rectangular pipe: 42 x 20 x 2.5 mm

Bending performance

Max. bending radius (inside): Ø 20 mm

Max. bending radius (outside): Ø 170 mm

Bending speed: not specified

Bending direction: to the left

Pipe lifting length: 3,000 mm

Control

Software: RC 7000

Programming: Manual

Operation: via control panel

MACHINE DETAILS

Machine weight: approx. 2.8 t

Machine dimensions (L x W x H): 5.1 x 0.7 x 2.0 m

Control cabinet dimensions (W x D x H): 800 x 700 x 2,000 mm

EQUIPMENT

- Various bending tools for pipe Ø 25 mm

- 12 different collets

- Various auxiliary and clamping devices

Auction

Auction ended

Germany

Germany

7,963 km

Horizontal balancing machine for rotors

SchenkH4U

Condition: ready for operation (used), Year of construction: 1970, Functionality: fully functional, workpiece weight (max.): 800 kg, rotational speed (max.): 3,600 rpm, working length: 2,600 mm, workpiece diameter (max.): 1,250 mm, TECHNICAL DETAILS

Purpose: Measuring and balancing static and dynamic imbalance of rotors

Max. balancing body weight: 800 kg (with even load distribution, 400 kg per bearing stand)

Max. balancing body diameter: 1,250 mm

Speed ranges

Measuring speed per gear:

1st gear: 190 - 650 rpm

2nd gear: 400 - 1,250 rpm

3rd gear: 700 - 2,100 rpm

4th gear: 1,200 - 3,600 rpm

Mechanical specifications

Bed length: 2,600 mm

Bearing journal diameter (min./max.): 16-95 mm / 95-180 mm

Bearing center distance min.: 125 mm

Shaft end bearing center max.: 2,070 mm

Power transmission: by means of Cardan shaft

MACHINE DETAILS

Machine dimensions (L x W x H): approx. 3.5 x 1.7 x 2.0 m

Control cabinet dimensions (W x D x H): 650 x 250 x 800 mm

Machine weight: approx. 1.5 t

Voltage: 380 V

Drive power: 7.5 kW

Djb E Hevyh Ttorhnjut

EQUIPMENT

- Schenk measuring device with digital display

- Manually movable support stands

- Accessory package with various rotor shafts and rotor mounts on request

Auction

Auction ended

Germany

Germany

7,963 km

Rebar bending machine

Schilt Engineering BVSBC 60 SP (PLC)

Condition: ready for operation (used), Year of construction: 2006, Functionality: fully functional, bending angle: 75 °, overall weight: 1,000 kg, motor voltage: 380 V, rotational speed (min.): 15 rpm, working height: 850 mm, TECHNICAL DETAILS

Max. bending angle: 75°

Bending angle options: 40° / 60° / 75°

Single and double bending of reinforcing steel: possible

Number of bending forms: 2 pieces

Bar size

Angle form: Ø 12 - 50 mm

Double angle: Ø 12 - 35 mm

Bending plate

Diameter: Ø 480 mm

Speed: 7.5 / 15 rpm

Bending pin hole: Ø 48 mm (16 pieces)

Center pin: Ø 50 x 94 mm

Counterholding strips

Number: 2 pieces

Length: 840 mm

Displacement: per handrail 100 mm

Holes: 13 pieces, Ø 48 mm

MACHINE DETAILS

Dimensions (L x W x H): approx. 1.9 x 2.6 x 1.0 m

Transport dimensions (L x W x H): 2.6 x 1.8 x 1.0 m

Working height: 850 mm

Operating voltage: 380 V

Machine weight: approx. 1.0 t

Djbjvyhiho E Hrhnjut

EQUIPMENT

- Control panel with touch screen

- Bending attachments:

2x Ø 60 mm

2x Ø 78 mm

1x Ø 96 mm

1x Ø 122 mm

1x Ø 160 mm

1x Ø 200 mm

- 1x pin for plate

- 8x counterholders of various shapes

- Bending tray

Auction

Auction ended

Germany

Germany

7,963 km

Machining Center - Vertical

UrbanBZ 3000

Condition: ready for operation (used), Year of construction: 2006, operating hours: 2,160 h, Functionality: fully functional, travel distance X-axis: 3,200 mm, travel distance Y-axis: 550 mm, travel distance Z-axis: 590 mm, controller model: Heidenhain iTNC 530, rotational speed (max.): 6,000 rpm, Equipment: rotational speed infinitely variable, Application: drilling, countersinking, reaming, thread cutting and milling of metal, aluminum, plastic and wood

TECHNICAL DETAILS

X-axis: 3,200 mm

Y-axis: 550 mm

Z-axis: 590 mm

Control model: Heidenhain iTNC 530

Tool and spindle data

Tool holder: SK 40

Speed range (infinitely variable): 100 - 6,000 rpm

Feed and speed

Rapid traverse range (X/Y/Z): 50 / 25 / 25 m/min

Feed speed: 0 - 5,000 mm/min

MACHINE DETAILS

Machine weight: approx. 7.5 t

Machine dimensions (LxWxH): 6.0 x 2.3 x 2.5 m

Space requirement (LxWxH): approx. 6.0 x 4.50 x 2.9 m (30 m²)

Switch-on hours: approx. 6,529 h

Program running time: approx. 2,160 h

Control switch-on time: 10,926 h

Interface: 232-C

Operating pressure: 7 bar

Connection: 3x 400V / 50 Hz

Total power requirement: 15 kVA

EQUIPMENT

Djb E Hovyg Ngjrhneut

- Mineral cast bed

- Coolant system (300 liter container)

- Position measuring system: rotary encoder / length measuring system

- Drives: X-axis (50 m/min) via pinion and rack; Y and Z axis (25 m/min) via ball screw

- Central lubrication (manually operated)

- Control cabinet with Rittal SK 3303100 cooling unit

- Heidenhain path control

- Control panel with electronic handwheel

- Workpiece clamping using clamping supports (approx. 15 bars)

- Hydraulic tool change via control

- 4x chip drawers

- Various clamping devices and clamping elements

- Barrier fence (safety fence)

- Knut measuring device

Auction

Auction ended

Dolnośląskie

Dolnośląskie

8,235 km

Injection molding machine

KraussMaffeiKM 150 - 520 C2

Condition: ready for operation (used), Year of construction: 2005, Functionality: fully functional, clamping force: 1,500 kN, screw diameter: 45 mm, clearance between the columns: 500 mm, injection weight: 250 g, opening stroke: 900 mm, Including robot - LR 100

TECHNICAL DETAILS

Control: MC 4 with color monitor, integrated control panel and plate station

Closing system: Fully hydraulic

Screw diameter: 45 mm

Suitable for: Thermoplastics

Dob Eevzrmge Hrhnout

Closing unit

Closing force: 1,500 kN

Clamping plates (H x V): 780 x 790 mm

Free space between the columns (H x V): 500 x 500 mm

Maximum opening width: 900 mm

Injection unit

Screw diameter: 45 mm

Injection volume: 275 cm³

Injection weight: 250 g

Injection pressure: 1,878 bar

Electro-hydraulic equipment

Pump motor power: 30 kW

Heating element power: 16 kW

ROBOT - Krauss-Maffei linear robot LR 100

Load capacity: < 10 kg (gripper + drives + parts)

Loading side: opposite the operator

X-axis (stroke from mold): 550 mm (servo motor)

Y-axis (vertical stroke with motor brake): 1,200 mm (servo motor)

Z-axis (lateral stroke): 1,500 mm (servo motor)

C-axis (folding axis for depositing): 0-90° (pneumatic)

Torque (Md): 30 Nm

Position measurement: encoder

MACHINE DETAILS

Net weight (with control cabinet): 7.1 t

Machine dimensions (L x W x H): 4.66 x 1.51 x 2.19 m

Auction

Auction ended

Kujawsko-Pomorskie

Kujawsko-Pomorskie

8,136 km

Lead/traction spindle lathe

PorebaTR-135 B1/5M

Condition: refurbished (used), Year of construction: 1986, Functionality: fully functional, machine/vehicle number: 1102-1284, turning diameter over cross slide: 1,000 mm, turning diameter over bed slide: 1,350 mm, turning length: 5,000 mm, rotational speed (max.): 630 rpm, workpiece weight (max.): 11,000 kg, Comprehensive overhaul in 2025 - as good as new! Guarantee: 12 months on spare parts and electrics

Highlights

- Refurbished universal lathe with the latest technology

- Powerful motor with 22/41 kW power and 21 spindle speeds

- Turning diameter of up to 1,650 mm in the bridge recess

- Versatile feed options for precise machining

- Expandable equipment with digital measuring systems, steady rests and MULTIFIX steel holders

- Meets CE / WOT acceptance conditions and Polish standards

TECHNICAL DETAILS

Center distance / turning length: 5,000 mm

Turning diameter over bed: 1,350 mm

Turning diameter over slide: 1,000 mm

Turning diameter in the bridge recess: 1,650 mm

Spindle passage diameter: 120 mm

Workpiece capacity

Max. workpiece weight between centers: 8,000 kg

Max. workpiece weight with 1 steady rest: 10,000 kg

Max. workpiece weight with 2 steady rests: 11,000 kg

Dusb E Hjvy U U Rjrhnot

Turning & feed data

Number of spindle speeds: 21

Speed range: 5 - 630 rpm

Number of feeds: 80

Longitudinal feed range: 0.07 - 10 mm/rev

Cross feed range: 0.035 - 5 mm/rev

Upper drawer feed range: 0.017 - 2.5 mm/rev

Motor & power

Motor drive for upper slide drawer: taper turning up to 450 mm length, 90° scale

Motor power: 22 kW / 41 kW (1. gear / 2nd gear)

MACHINE DETAILS

Total length: 7,500 mm

Width: 2,130 mm

Height: 1,550 mm

Total weight: 13,200 kg

EQUIPMENT

- Tailstock

- Coolant pump

- Chuck protection

- Tool holder

- Chip trays

ADDITIONAL EQUIPMENT (available for an additional charge)

- 3- or 4-jaw chuck (various diameters & variants)

- Digital measuring system for 2 axes (incl. display, assembly & calibration)

- Steady rests with rollers for the following clamping ranges: 40 - 400 mm / 400 - 700 mm / 450 - 900 mm

- MULTIFIX quick-change tool holder

Auction

Auction ended

Niedersachsen

Niedersachsen

7,682 km

Laser cutting machine

TRUMPFTube TruLaser 5000 fiber

Condition: good (used), Year of construction: 2017, operating hours: 25,790 h, Functionality: fully functional, laser power: 2,000 W, sheet thickness aluminum (max.): 3 mm, sheet thickness steel (max.): 8 mm, working range: 6,500 mm, pipe diameter: 152 mm, Equipment: documentation/manual, safety light barrier, Pipe laser cutting system including LoadMaster and discharge station

TECHNICAL DETAILS

Laser power: 2,000 W (TruDisk 2001)

Control: Siemens Sinumerik 840 D

Working area

Pipe material length: 6,500 mm

Envelope circle diameter: 152 mm

Workpiece weight: 20 kg/m

Finished part length: 1,500 m

Max. speed: 170 m/min (steel), 120 m/min (stainless steel), 60 m/min (aluminum)

Accuracy: +/- 0.1 mm

Maximum sheet thicknesses

Max. sheet thickness (steel): 8 mm

Max. sheet thickness (stainless steel): 4 mm

Max. sheet thickness (aluminum): 3 mm

MACHINE DETAILS

Width: 2,800 mm

Length: 7,000 mm

Height: 16,000 mm

Weight: 17,000 kg

Operating hours: 25,790 h (total) / 20,950 h (laser)

Safety functions: Multi-beam light barriers, monitoring system for gas pressure, temperature and cooling water

Protective cabin: With certified safety windows

EQUIPMENT

- Feed station with self-centering clamping jaws

- Pipe support with automatically retractable pipe supports

- Push-through chuck, self-centering parallel clamping rollers

- High-precision drives with digital three-phase servo motors

- LoadMaster Tube 6.5 m with bundle trough

- Discharge station 3 m including scrap conveyor belt with container

- Parts storage (includes belt table and belt table extension)

- Closed beam guidance

- NitroLine

- FocusLine

- External solid-state laser TruDisk 2001 with one LLK output and excitation via Pump diodes

- Lens cutting head with 150 mm focal length

- Clamping jaws (1 set)

- Quick-change mold shells for round tubes up to 0 152 mm

- Quick-change mold shells for rectangular tubes up to HK 85 mm

- Quick-change mold shells for rectangular tubes up to HK 170 mm

Dueb E Hrevwb A Nshnot

- Guide rollers for round and rectangular tubes (1 set)

- SeamLine Tube with internal detection

- PierceLine

- Adaptive clamping technology - Feed station

- Automatic setup

- Tube diameter 15 mm LoadMaster Tube 6.5 m (12 mm semi-automatic via conveyor line)

- Set of U-shaped mold shells

Auction

Auction ended

Rheinland-Pfalz

Rheinland-Pfalz

7,797 km

LoadMaster laser cutting machine

TRUMPFLoadMaster 2040

Condition: ready for operation (used), Year of construction: 2012, Functionality: fully functional, machine/vehicle number: N0014A0234, sheet thickness (max.): 25 mm, load capacity: 1,600 kg, product length (max.): 4,000 mm, product width (max.): 2,000 mm, No reserve price - guaranteed sale at the highest bid!

Dusb E Hevxkg Herhnet

DESCRIPTION

- Easy loading for sheet thicknesses up to 25 mm

- Produce more faster

- Safe processes even with thin sheet

- 2040 = Maxi format

+ peeling device

TECHNICAL DETAILS

Usable machines: e.g. Trulaser 1040 / 3040 / 5040

Max. sheet format: 4,000 x 2,000 mm

Min. sheet format: 1,000 x 1,000 mm

Max. sheet thickness: 25 mm

Max. sheet weight: 1,600 kg

Auction

Auction ended

Woiwodschaft Pommern

Woiwodschaft Pommern

8,091 km

Forklift

Steinbock BossB1512-5A1

Condition: ready for operation (used), Functionality: fully functional, Year of construction: 1995, operating hours: 7,381 h, load capacity: 15,000 kg, lifting height: 3,520 mm, fuel type: diesel, mast type: standard, construction height: 3,380 mm, fork carriage width: 2,500 mm, fork length: 2,400 mm, TECHNICAL DETAILS

Load capacity: 15,000 kg

Load center: 1,200 mm

Lift height: 3,520 mm

Mast type: Standard

Overall height: 3,380 mm

Fork & structure data

Fork carriage width: 2,500 mm

Fork length: 2,400 mm

Fork width: 200 mm

Fork thickness: 100 mm

Dimensions & weight

Overall length: 5,400 mm

Overall width: 2,650 mm

Net weight: 22,700 kg

Engine & drive

Fuel type: Diesel

Dueb E Hevy A U Sorhnet

Engine type: Perkins

Drive type: Diesel

Gearbox: Clark

Tires

Front: Pneumatic tires 12.00-20

Rear: Pneumatic tires 12.00-20

Condition

Overall condition: Ready for use and fully functional

Technical condition: Very good

EQUIPMENT

- Perkins diesel engine with Clark gearbox

- Side shift and tine adjustment device for flexible handling

- Full cabin with heating for comfortable working

- Pneumatic tires front and rear for optimal traction

- Side shift

- Tine adjustment device

- Heating

- Full cabin

Auction

Auction ended

Bourgogne-Franche-Comté

Bourgogne-Franche-Comté

7,690 km

Machining center

HOMAGBOF 611 / 34 /13 / 2R

Condition: ready for operation (used), Year of construction: 2005, Functionality: fully functional, travel distance X-axis: 3,740 mm, travel distance Y-axis: 1,150 mm, travel distance Z-axis: 300 mm, TECHNICAL DETAILS

Number of axes: 4 processing axes + A-axis

Spindle power: 15 kW

Model: HSK F63

Working surface

Dobjvwatys E Hrhnsut

In X (single processing, workpiece length): 3,740 mm

In X (pendulum processing, workpiece length): 1,830 mm

In Y (workpiece width): 1,550 mm

In Z (workpiece thickness): 300 mm

Work tables: Double

Use of tables: simultaneous or alternating

Feeding system

Model: HOMAG OPTIMAT TBP 370 gantry loader

Type of feeding: Automatic panel feeding through spreader beam

Usable dimensions:

Panel width: 400 - 1,600 mm

Panel length: 400 - 2,000 mm

Panel thickness: 16 - 36 mm

Maximum panel weight: 60 kg

Drilling group

Total number of spindles: 16

Number of vertical spindles: 12

Number of horizontal spindles: 2 + 2

Tool magazine

Turret: 12 positions

Auction

Auction ended

Dolnośląskie

Dolnośląskie

8,235 km

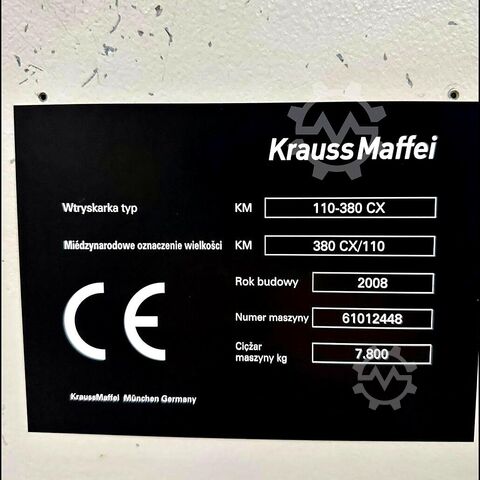

Injection molding machine

KraussMaffeiKM 110 - 380 CX

Condition: ready for operation (used), Year of construction: 2008, operating hours: 42,000 h, Functionality: fully functional, machine/vehicle number: 61012448, clamping force: 1,100 kN, screw diameter: 35 mm, clearance between the columns: 470 mm, injection weight: 140 g, ejector stroke: 150 mm, opening stroke: 600 mm, TECHNICAL DETAILS

Control: MC5 with color monitor, integrated control panel and 3 USB ports

Screw diameter: 35 mm

Deb Eevzrkfj Hrhnsut

Design: Scuff protection for thermoplastics

Non-return valve: Yes

Nozzle: Open nozzle

Clamping unit

Mold clamping force: 1,100 kN

Mold opening force: 70 kN

Mounting plates (H x V): 745 x 770 mm

Column spacing (H x V): 470 x 470 mm

Mold opening stroke: 600 mm

Mold height: 300 mm

Plate opening stroke: 900 mm

Ejector stroke: 150 mm

Ejector force: 22.6 / 9.9 kN

Injection unit

Screw diameter: 35 mm

Injection pressure: 2,429 bar

Injection volume: 154 cm³

Injection weight (HP): 140 g

Screw revolutions (standard/option): 390 / 490 rpm

MACHINE DETAILS

Working hours: approx. 42,000 h

Machine weight (with control cabinet): 5.8 t

Machine dimensions (L x W x H): 4.5 x 1.6 x 2.1 m

Pump motor power: 18 kW

Heating power: 10.97 kW

Cylinder heating zones: 5

Drying cycles according to Euromap: 1,850 / h

Oil tank capacity: 489 l

Auction

Auction ended

Hungary

Hungary

8,507 km

Pelletizing/pellet production line

Radviliskis Machinery FactoryOGM 1.5

Condition: ready for operation (used), Functionality: fully functional, Year of construction: 2017, operating hours: 1,500 h, power: 200 kW (271.92 HP), Complete pellet production line for the production of feed pellets/straw pellets/fertilizer pellets from agricultural raw materials, whereby the pellet press and hammer mill are also suitable for the production of wood pellets.

Hammer mill is completely new (built in 2021) and has only been in operation for 2 hours. Valid ATEX certificate!

SCOPE

- Pellet press

- Conveyor belt

Dujb E Hrhov Ak S Denet

- Elevator

- Pellet cooler + sieve

- Buffer container with discharge for the ground material

- 2 cyclones (centrifugal separators) with rotary valve

- Fan for cooler extraction

- 1 new ring die and various used spare parts

- Feeder table for bale shredder

- Bale shredder including control

- Hammer mill (new) including control

- Centrifugal separator

- Scheuch dust filter including control

- Discharge screw

- BigBag station for dust filter

TECHNICAL DETAILS

System throughput: 1.3 t/h (depending on material)

Hammer mill throughput alone: 2 t/h (depending on material)

Pellet press output: 75 kW

Feeder table length: 10 m

Bale shredder output: 35 kW

Hammer mill output: 75 kW

Output Dust filter: 20,000 m³/h

Dust filter manufacturer: Scheuch

Dust explosion report: 2023, according to EU ATEX Directive 2014/34

MACHINE DETAILS

Hammer mill dimensions: 2,350 x 970 x 1,200 mm

Auction

Auction ended

Rheinland-Pfalz

Rheinland-Pfalz

7,797 km

Bending machine

TRUMPFTruBend 7036

Condition: ready for operation (used), Year of construction: 2012, operating hours: 67,352 h, Functionality: fully functional, working height: 1,150 mm, stroke distance: 120 mm, pressing force: 36 t, feed length X-axis: 240 mm, back gauge travel distance R-axis: 80 mm, distance between stands: 932 mm, The brake was converted to the new variant in 2017. PCCS was renewed in 2021.

TECHNICAL DETAILS

Max. pressing force: 360 kN

Mounting height: 300 mm

Clearance between the columns: 932 mm

Arm reach: 150 mm

Working height: 1,150 mm

Control: TRUMPF TASC 6000

Speeds and axis data

Y-axis working speed: 220 mm/s

Y-axis maximum stroke: 120 mm

Inertia run time: max. 90 ms

Minimum safety distance: 180 mm

Reverse speed: 220 mm/s

Djb E Hjvxkchorhneut

X-axis speed: 1,000 mm/s

R-axis speed: 330 mm/s

Z-axis speed: 1,000 mm/s

X-axis positioning speed: 0.04 mm

R-axis positioning speed: 0.06 mm

Travel path X-axis: 240 mm

R-axis travel: 80 mm

MACHINE DETAILS

Space requirement: 1,805 x 1,330 x 2,380 mm

Machine weight: approx. 2,600 kg

Total connected load: approx. 6 kVA

Operating hours: 67,352 hours at 8851,728 strokes

EQUIPMENT

- Back stop system (6 axes)

- Foldable comfort support table at the front

- Comfort footrest

- Work area lighting at the front (LED)

- Swiveling control unit

- BendGuard safety device with block laser

- Automatic tool clamping at the top and bottom

Trust Seal

Dealers certified through Machineseeker

Auction

Auction ended

Dolnośląskie

Dolnośląskie

8,235 km

Injection molding machine

ENGELVictory 330/60 Tech

Condition: excellent (used), Year of construction: 2007, Functionality: fully functional, machine/vehicle number: 164225, clamping force: 600 kN, screw diameter: 35 mm, clearance between the columns: 450 mm, mold height (min.): 600 mm, plate width: 720 mm, TECHNICAL DETAILS

Closure system: Hydraulic

Closure force: 600 kN

Plate size (table size): 720 mm

Distance between the columns: 450 mm

Mold height: 600 mm

Opening stroke: 900 mm

Ejector stroke: 115 mm

Ejector force: 125 kN

Injection system

Screw diameter: 35 mm

Injection volume: 154 cm³

Injection pressure: 2,400 bar

Dujbjvzrhde E Hrhnst

MACHINE DETAILS

Total weight: 5,300 kg

Auction

Auction ended

Rheinland-Pfalz

Rheinland-Pfalz

7,798 km

Punch nibbling machine

TRUMPFTruPunch 5000

Condition: ready for operation (used), Year of construction: 2010, operating hours: 57,504 h, Functionality: fully functional, punching force: 22 t, sheet thickness (max.): 8 mm, travel distance X-axis: 2,500 mm, travel distance Y-axis: 1,250 mm, AUTOMATION

- SheetMaster - loading and unloading in parallel with main time

- Toolmaster 70 - setting up in parallel with main time

- GripMaster with scissor lift table

- Good part conveyor

TECHNICAL DETAILS

Travel paths X / Y: 2500 / 1250 mm

Sheet thickness: 8 mm

Punching force: 220 kN

Active hold-down clamps: 4.5 - 20 kN

Workpiece weight: 200 kg

Control: Siemens Sinumerik 840D

Part flap: 500 x 500 mm

Speed X / Y / simultaneous: 100 / 60 / 116 m/min

C-axis: 500 rpm

Stroke sequence punching / marking: 1600 / 3000 1/min

Position deviation Pa: ±0.1 mm

Position spread Ps: ±0.03 mm

Linear magazine: 21 tools with 3 clamps

Tool change time for single tool / multi-tool: 3 / 0.3 s

Djb E Hrsvxi Sujhneut

MACHINE DETAILS

Space requirement: 6,760 x 6,100 mm

Average power consumption: 9.5 kW

Operating hours: 57,504 h

EQUIPMENT

- Stable, easily accessible C-frame

- Moving ball roller tables

- Linear magazine for tool stations and clamping clamps

- Foot switch for clamp closing

- Good parts container

- Hydraulic single tool holder, 360° rotation

- Manually adjustable holding down force

- Programmable holding down device - active/passive/repositioning

- Spray lubrication of punch

- Punch slug extraction

- Level monitoring for thread forming and tool lubrication

- CE marking

- Multi-beam light barriers

- Quick shutdown of hydraulics

- Bulge detection

ADDITIONAL EQUIPMENT

- Function MultiTool

- MultiBend function

- Thread forming function

- Roller technology function

- Marking

- Multishear

- Adaptive stroke calibration

- Active die

- Repositioning cylinder

- Spray lubrication of die with level monitoring

- Repositioning cylinder

- Sensor for parts chute

- Vibration-damped installation

- Chip conveyor with tilting container

- Blow-out device for small parts

Auction

Auction ended

Dolnośląskie

Dolnośląskie

8,235 km

Injection molding machine

DEMAGMulti 80/420-80h/120v (800 - 80 h/120v)

Condition: ready for operation (used), Year of construction: 2005, Functionality: fully functional, machine/vehicle number: 7154 - 0118, clamping force: 800 kN, clearance between the columns: 750 mm, opening stroke: 500 mm, plate length: 590 mm, plate width: 600 mm, TECHNICAL DETAILS

Control: NC 4 control, DIAS

Closing system: Hydraulic

Closing force: 800 kN

Distance between columns: 420 mm x 420 mm

Plate dimensions: 590 mm x 600 mm

Mold size (min.): 250 mm

Bar width: 420 mm

Maximum opening distance: 500 mm

Maximum distance between plates: 750 mm

Two-component system

Horizontal system: Nitrided screw, diameter 18 mm

Vertical system: Bimetallic screw, diameter 25 mm

MACHINE DETAILS

Motor power: 18.5 kW

Heating power: 8.8 kW

Machine dimensions (L x W x H): 3.9 m x 1.4 m x 1.9 m

Weight: 4,100 kg

Dueb E Hrhevzrf Njnjt

EQUIPMENT

- Two-component injection molding machine with hydraulic closing system

- Complete machine history available

Auction

Auction ended

Rheinland-Pfalz

Rheinland-Pfalz

7,798 km

Laser Punch Press

TRUMPFTruMatic 6000 - 1300

Condition: excellent (used), Year of construction: 2010, operating hours: 44,973 h, Functionality: fully functional, punching force: 22 t, laser power: 2,700 W, sheet thickness (max.): 8 mm, travel distance X-axis: 2,585 mm, travel distance Y-axis: 1,280 mm, number of slots in tool magazine: 21, AUTOMATION

- SheetMaster

- GripMaster

- TrumaSort R4

ADDITIONAL EQUIPMENT

- Laser TruFlow 2700

- MultiTool function

- Thread forming function

- Marking/fast beading function

- MultiBend function

- Rolling technology function

- Repositioning cylinder

- Bulge detection

- Chip conveyor

TECHNICAL DETAILS

Punching working area: 2,585 x 1,280 mm

Laser working area: 3,085 x 1,370 mm

Combined working area: 3,085 x 1,280 mm

Control: Siemens Sinumerik 840 D

Laser

Laser power: 140 - 2,700 watts

Wavelength: 10.6 µm

Sheet thickness: 8 mm

Workpiece weight: max. 200 kg

Punching

Punching force: 220 kN

Active hold-down clamps: 4.5 - 20 kN

Linear magazine: 21 tools

Programmable slide: 500 x 500 mm

Positioning speed X / Y / simultaneous: 90 / 60 / 108 m/min

C-axis punching: 60 rpm

C-axis thread forming: 180 rpm

Punching stroke sequence: 900 rpm

Signing stroke sequence: 2800 rpm

Position deviation: ± 0.10 mm

Position scatter: ± 0.03 mm

MACHINE DETAILS

Duebovxivme E Hrhnot

Length: approx. 7.5 m

Width: approx. 8.1 m

Height: 2.4 m

Weight: 16 t

Laser switch-on time: 29,826 h

Cutting time: 6,054 h

Machine switch-on time: 44,973 h

Compressed air connection: 7 ± 1 bar

Consumption of laser gas CO2 / N2 / He: 1 / 6 / 13 l/h

EQUIPMENT

- Stable, easily accessible C-frame

- Drives with maintenance-free three-phase motors

- Programmable hold-down device for repositioning

- Sensor-monitored part slides for punching and laser station, ejection cylinder on laser slide

- Laser unit: High-frequency excited CO2 laser, vibration-insulated, including cooling unit and laser control DIAS 3

- HI-Las high-pressure cutting

- Fast processing with SprintLas

- ContourLas for producing small holes

- Programmable cutting gas pressure setting

- Laser cutting head: 5'' lens, quick-change device, distance control

- Multi-beam light barriers, quick hydraulic shutdown, extraction and compact dust extractor, protective device against scattered radiation on the cutting head

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

This may be of interest to you