Second-hand machinery for sale (2,431)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Auctions

Auction

Auction ended

Bayern

Bayern

8,004 km

Jig

CHARMILLESRoboform 35 P Roboter Automation

Year of construction: 2001, Condition: good (used), Functionality: fully functional, Machine extensively overhauled worth EUR 18,000

Optional configuration QCRI 54/8: available, see pictures

placement automation: available, see video

Dkslien Arnxsn Iimel

Pressure flushing: 1 x through workpiece 1 x through electrode, 2 x lateral

Suction flushing: 1 x through workpiece

Central lubrication system automatically via NC in all axes

TECHNICAL DETAILS

Travel (X, Y, Z): 350, 250 300 mm

Max man. Feeding speed: 900 mm/min

Weight of electrodes: max. 20 kg

Weight of workpieces: max. 40 kg

Magazine configuration: 54/8

electrodes: 54 pieces

Electrode dimensions: 70 x 70 x 200

Plates: 8 pieces

workpiece dimensions: (4x) 320 x320 x 270 mm, (4x) 320 x 320 x 170 mm

work table: 500 x 400 mm

T-slots: 3 x 12 mm

distance of grooves: 125 mm

Available clamping systems: Erowa IST 3R Macro Megatool GPS 70

MACHINE DETAILS

Dimensions (H x L x W): 2400 x 1900 x 1690 mm

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

8,008 km

CNC lathe

MazakQuick Turn Smart 250M L

Condition: good (used), Year of construction: 2016, operating hours: 13,701 h, Functionality: fully functional, machine/vehicle number: 276209, turning diameter: 255 mm, spindle speed (max.): 4,000 rpm, travel distance X-axis: 225 mm, travel distance Z-axis: 1,125 mm, swing diameter over bed slide: 660 mm, TECHNICAL DETAILS

Chuck size: 10 inch

Maximum swing circle: max. 660 mm

Standard turning diameter: max. 255 mm

Maximum turning diameter: max. 360 mm

Largest bar passage: max. Ø 80 mm

Distance between spindle nose and turret edge: 59.5 - 1,179.5 mm

Maximum weight (bar work): max. 500 kg

Maximum weight (chuck work): max. 450 kg

Spindle

Speed: 35 - 4,000 rpm

Shape of spindle nose: JIS A2-8

Spindle bore: Ø 91 mm

Acceleration time: 2.3 s

Motor power (30-minute power/continuous power): 26/22 kW

Maximum torque (15%ED): 465 Nm

Tailstock

Quill type: MT No 4

Movement stroke (tailstock body): max. 1,075 mm

Minimum and maximum thrust: min. 1,000 N, max. 5,000 N

Tools and turrets

Djlinsu Tdi Eo Iimskl

Number of tools: 12 pieces

Outer chisel tool sizes: max. Ø 25 mm

Internal turning tool sizes: max. Ø 40 mm

Tool sizes router bits: max. Ø 20 mm

Tool sizes end mills: max. Ø 20 mm

Tool sizes for milling taps: max. M20 (3/4 UNI) × 2.5 mm

Turret

Switching time (next/opposite position): 0.23/0.62 s

Milling spindle motor power (40%ED/continuous power): 5.5/3.7 kW

Milling spindle speed: max. 6,000 rpm

Maximum torque of the milling spindle (40%ED): max. 47 Nm

Feed axes

Rapid traverse X/Z: max. 30/33 m/min

Time constant X/Z: 65/80 ms

Travel range X: max. 225 [220 + 5] mm

Travel range Z: max. 1,125 [1,120 + 5] mm

MACHINE DETAILS

Spindle center height: 1,020 mm

Overall length: 3,385 mm

Overall width: 1,720 mm

Total height: 1,820 mm

Space requirement: 5.82 m²

Mass of the machine: 6,050 kg

Mass of the machine (with steady rest): 6,250 kg

Connected load: 44.5 kVA

Voltage: 400 V

Coolant tank volume: 270/315 l

Machine package: 3.87 x 2.16 x 2.01 m, 6.62 t

Chip conveyor package: 3.54 x 0.87 x 1.35 m, 325 t

Auction

Auction ended

Bayern

Bayern

8,019 km

Wire EDM machine

MitsubishiFA20P

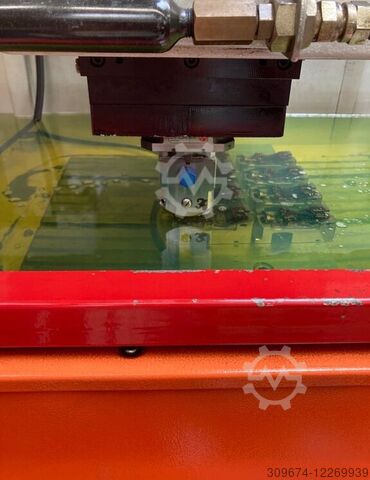

Year of construction: 2002, Condition: used, Functionality: fully functional, machine/vehicle number: J20M0036, Wire EDM machine with automatic wire threading (AT)

Dkolinenh R Nkj Iimsl

TECHNICAL DETAILS

x-way: 500 mm

y-way: 350 mm

z-way: 300 mm

amps: 50 A

table length: 780 mm

table width: 630 mm

table feed: 1 - 1.300 mm/min

wire feed: 15,00 m/min

Control: W21F AP-2

workpiece size: 1050 x 800 x 295 mm

workpiece weight: max. 800 kg

MACHINE DETAILS

total power requirement: 12,00 kW

machine weight: approx. 4,50 t

space requirement: approx. 3.00 x 3.50 x 2.50 m

Auction

Auction ended

Hungary

Hungary

8,621 km

Tool and Cutter Grinder

EWAGRS 12

Condition: good (used), Year of construction: 1984, Functionality: fully functional, machine/vehicle number: 1289 397, spindle speed (max.): 8,000 rpm, travel distance X-axis: 220 mm, travel distance Y-axis: 130 mm, travel distance Z-axis: 50 mm, swivel angle A-axis (min.): -10 °, swivel angle A-axis (max.): 27 °, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Motor power: 2.2 kW

Spindle speeds: 1,000 - 8,000 rpm

Spindle inclination (A-axis): -10° to +27°

Setting accuracy: 1 min

Height adjustment (Y-axis): 130 mm

Stroke range (X-axis): 220 mm

Oscillation stroke: continuously adjustable during oscillation, 0-30 mm

Oscillation frequency: 30/60 1/min

Workpiece headstock

Radius adjustment (Z-axis): 0.01 - 50 mm

Setting accuracy: 0.01 mm

Retraction of the slide (grinding in measuring position): max. 49 mm

Cross table clamping surface: 155 x 205 mm

Travel paths (X-Y): 60 mm each

Maximum swivel angle (B-axis): 260°

Doliovr Dpuon Iimekl

MACHINE DETAILS

Connection voltage: 380 V

Weight: 1,200 kg

EQUIPMENT

- Variable grinding pressure

- Projector fixed in measuring position

- 1 cabinet with accessories

- Various grinding wheels and flanges

- Coolant tank

- Documentation

Auction

Auction ended

Switzerland

Switzerland

8,020 km

Thread rolling machine

GRTZ28-500

Condition: good (used), Year of construction: 2019, Functionality: fully functional, TECHNICAL DETAILS

Rolling diameter: 6-80 mm

Width of the rolling tool: max. 150 mm

Outer diameter of the rolling tool: max. 240 mm

Center distance tool spindle - center: 190-240 mm

Pitch size range (normal): 1-12 mm

motor

Rollers: 15 kw-6

Hydraulic: 5.5 kw-4

Cooling: 0. 125 kw

Rolling force: max. 500 KN

Spindle diameter: 85 mm

Inclination angle of the spindle: +/- 10°

Volatility: 380 V, 50 HZ, 3 phase

MACHINE DETAILS

Size of the basic machine: 2600 x 2100 x 1600 mm

Size of the hydraulic station: 800 x 500 x 1250 mm

Weight of the machine: 4500 kg

Length of the workpiece: Unlimited

Dkjlietwbkqjn Iimol

Auction

Auction ended

Germany

Germany

8,021 km

CNC lathe

EMCOHYPERTURN 45

Condition: used, Year of construction: 2016, Functionality: fully functional, machine/vehicle number: BF15103648, TECHNICAL DETAILS

WORKING RANGE

Travel in X/Y/Z: 160 /+40/-30 / 510 mm

Dolett D Adoin Iimokl

Bar passage: max. 45 (51) mm

Turning diameter: max. 300 mm

Rotation diameter over bed 430 mm

Rapid traverse speed X/Y/Z 30 / 15 / 45 m/min

MAIN SPINDLE

Speed: max. 7000 rpm

Drive power: max. 15 kW

Torque: max. 100 Nm

COUNTERSPINDLE

Speed: max. 7000 rpm

Drive power: max. 15 kW

Torque: max. 100 Nm

TOOL TURRET 1

VDI size: VDI 25

Number of tool positions: 12

Driven tools: 12

Speed: max. 6000 rpm

Drive power: max. 4 kW

Torque: max. 16 Nm

TOOL TURRET 2

VDI size: VDI 25

Number of tools: 12

Of which driven: 12

Speed: max. 6000 rpm

Drive power: max. 4 kW

Torque: max. 16 Nm

EQUIPMENT

- Chip conveyor

- Parts catcher

- Accessories shown

Auction

Auction ended

Sachsen

Sachsen

8,023 km

CNC lathe

ARIXTMD 42

Condition: good (used), Year of construction: 2012, Functionality: fully functional, turning length: 160 mm, turning diameter: 140 mm, spindle bore: 42 mm, spindle speed (max.): 6,000 rpm, TECHNICAL DETAILS

Control system: Mitsubishi

Main spindle: with hydraulic brake and C axis

Machining diameter: max. 140 mm (chuck) / 42 mm (bar)

Workpiece length: max. 160 mm

Spindle clearance for bar machining: 42 mm

Collet size: 173 E/

Spindle speed: max. 6,000 rpm

Main drive power: 7.5 KW /11kW

Travel X / Y / Z: 225 / 385 / 235 mm

Travel Z1: 350 / 460 mm

Rapid traverse in all axes: 20 m/min

Driven tools: 11 tools, main spindle side

Collet size: ER 20

Axial tools: 7 pieces

Radial tools: 4 pieces

Dkslin Iiet Sd Tcomsl

Fixed tools: 16 pieces

Shank size for external machining: 8 pieces / 20 x 20 mm

Shank diameter for internal machining: 8 pieces / 25 mm

MACHINE DETAILS

Dimensions L X W X H: 3000 x 2100 x 1800 mm

Weight: approx. 4,000 kg

EQUIPMENT

- Collets: Main spindle 20 pieces each Main spindle / counter spindle 20 pieces.

- Drilling quills

- Chip conveyor

- Parts conveyor belt

- Signal lamp

Auction

Auction ended

Bayern

Bayern

8,038 km

Press brake

BystronicXPERT 400 x 4100 TANDEM

Condition: ready for operation (used), Year of construction: 2009, Functionality: fully functional, pressing force: 800 t, travel distance X-axis: 700 mm, travel distance Z-axis: 2,900 mm, stroke distance: 665 mm, travel distance R-axis: 250 mm, surfacing fence length: 8,200 mm, TECHNICAL DETAILS

Pressure: 2 x 400 t

Bending length: 2 x 4100 mm

X-axis travel: 700 mm

R-axis travel: 250 mm

Z-axis travel: 2900 mm

Stroke: 665 mm

Projection: 400 mm

Installation height: 850 mm

Clearance between the uprights: 3600 mm

MACHINE DETAILS

Total output 30 kW

Weight 76,000 kg

Equipment/accessories:

- Operator terminal with 15" TFT-LCD flat screen, network card, Windows XP and MMC-Bybend software

- Tilt adapter and double articulated arm for control system

- Pressure reference for automatic compensation of side stand deflection

- Dynamic hydraulic crowning of the lower beam, DNC-controlled

- Automatic dynamic press pressure control

- Material thickness measurement

- Tool overload protection

- Temperature monitoring

- Stainless steel scale on the upper beam

- AKAS laser system, manually adjustable in height

- Electrically monitored side safety guards

- Rear safety guard with sliding door

- Integrated hour and stroke counter

- Linear guide on the lower beam with 2 parking spaces of 250 mm each

- Double guide on the upper beam

- 2 x manually adjustable front support arms made of steel, length 1000 mm

- slim table T5, height 145 mm

- punch holder type "R" mechanical

Dkolievi I Ntjn Iimel

- 2-axis back gauge with X and R

- Inclination adapter for operator terminal

Auction

Auction ended

Bayern

Bayern

8,019 km

Horizontal machining center

Deckel MahoDMC 60 H

Year of construction: 2002, Condition: used, Functionality: fully functional, Horizontal machining center with double chain magazine.

TECHNICAL DETAILS

x-way: 600 mm

y-way: 560 mm

z-way: 560 mm

control: Siemens Sinumerik 840D

B - axis: 360 x 0,001 °

spindle speed - stepless: 8.000 rpm

feed X/Y/Z/ axis: 1 - 60.000 mm/min

feed B axis: 9.250 °/min

Delinsnh Rn As Iimokl

rapid traverse X/Y/Z: 60.00 m/min

feed force X/Z: 9.600 N

Feed force Y: 8,000 N

drive power 40 % ED: 20,00 KW

driving power 100% ED: 13,00 kW

Tool holder: SK40

Torque at 40% / 100% ED: 191 / 124 Nm

Pallet size: 2x 400 x 500 mm

workpiece weight: max. 600 kg

tool magazine: 180

tool diameter: 90 mm

tool diameter with 2 free places: 160 mm

tool length: max. 350 mm

Tool weight: max. 3.50 / 12.00 kg

MACHINE DETAILS

total power requirement: 65,00 kW

machine weight: approx. 16,00 t

space requirement: approx. 9.00 x 4.50 x 3.50 m

EQUIPMENT

Coolant system with IKZ

Double chain magazine with 180 places

Chip conveyor

BLUM tool laser measurement

electronic handwheel

Auction

Auction ended

Sachsen

Sachsen

8,024 km

Degreasing system

bipP16-5426

Condition: as good as new (ex-display), Year of construction: 2018, operating hours: 1,000 h, Functionality: fully functional, machine/vehicle number: P16-5426-001, CONSTRUCTION

- Degreasing zone

- Finish zone

- Filter system

- Eurosorb circuit with mixer (powder container)

- Electrical system with control panel

- Pneumatics

Dkjlin Istwn Nmsimsl

TECHNICAL DETAILS

Material to be cleaned: sheet steel belts, perforated, various hole patterns

Dimensions of the material / belt width: max. 1,250 mm

Sheet thickness: 0.5 - 5 mm

Cleaning speed: max. 10 m/min

Degree of oiling: lightly oiled (< 0.5 g/m²)

Coil surface: cold-rolled, clean

Coils endless: Coil to coil is joined on the customer side without thickening

MACHINE DETAILS

Dimensions: approx. 3,300 x 2,000 x 2,000 mm (without filter and electrical engineering, without conveyor technology)

Compressed air: > 6 bar dry and de-oiled, approx. 11 m³/min

Power: 400 V / 50 Hz; ~20kW

Screed: Concrete for 10 N/mm²

Flatness: on target circle 5.0 m ± 5 mm

Noise level: ≤ 80 dB(A)

Auction

Auction ended

Bayern

Bayern

8,025 km

Machining center

PASOPS400

Condition: excellent (used), Year of construction: 2004, Functionality: fully functional, travel distance X-axis: 700 mm, travel distance Y-axis: 440 mm, travel distance Z-axis: 400 mm, controller manufacturer: Heidenhain, controller model: iTNC 530, rotational speed (max.): 24,000 rpm, TECHNICAL DETAILS

Djlju R S Hisin Iimokl

Make: PASO

Machine type: HSC milling machine

Year of manufacture: 2004

Condition: Very good (last used for milling graphite electrodes, incl. dust extraction and filter system)

Control system

Type: Heidenhain iTNC 530

Manual control unit: Heidenhain HR 410

Operating terminal: Rollbar

Working area

X-axis: 700 mm

Y-axis: 440 mm

Z-axis: 400 mm

Drive system

System: Indramat

Milling spindle

Type: IMT HSK 32

Power: 9 kW

Speed: max. 24,000 rpm

Converter

Type: S&M 21.80

Recooler

Type: Chilly 25

Tool changer

Type: Drum

Capacity: 16-fold

Cooling system

System: Minimum spray cooling system (Indutec)

Number of nozzles: 1

Coolant volume: 1 l

Dividing head

Manufacturer: Wittenstein

Type: Alpha TP10

Suction unit

Type: Volume extraction with suction cup

OTHER

The machine can be inspected under power.

Last used for milling graphite electrodes, incl. dust extraction and filter system

Control system and all air hoses were replaced in 2022 for over €10,000 (invoice available)

Auction

Auction ended

Bayern

Bayern

8,021 km

CNC lathe

GildemeisterCTX 510 V

Condition: good (used), Year of construction: 2007, operating hours: 25,000 h, Functionality: fully functional, TECHNICAL DETAILS

Turning diameter: max. 465 mm

turning length: 1050 mm

Rotation diameter: 680 mm

Chuck diameter: 325 mm

x-path: 300 mm

Dkslin Iott Du Noimsl

z-path: 1,050 mm

C-axis: 360°

Control: Heidenhain Plus IT

Speed range: max. 3,500 rpm

Drive power: 33 kW

Torque: max. 630 Nm

Spindle bearing diameter: 120 mm

Spindle bore: 100 mm

Max. Bar diameter: 90 mm

Tailstock travel: 850 mm

Quill stroke: 150 mm

Tailstock holder: MK 5

Rapid traverse X / Z: 30 m/min

Number of tool positions: 12 positions

Tool holder: VDI 40

Driven tool stations: 12

Speed of driven tools: max. 4,000 rpm

Drive power of driven stations: 8.4 kW

Torque: max. 20 Nm

MACHINE DETAILS

Total power requirement: 50 kVA

Machine weight: 9,000 kg

Space requirement: 6.5 x 3.0 x 2.2 m

Spindle hours: 25,000 h

Auction

Auction ended

Bayern

Bayern

8,026 km

Gear grinding machine

Gleason-PfauterG 320

Condition: excellent (used), Year of construction: 2002, Functionality: fully functional, Gleason Pfauter G320 CNC generating grinding machine + Promot Automation handling unit

Functionality and machine features

Generating grinding machine with 8 numerically controlled axes for machining gears with straight and helical teeth that can be produced by generating, including a dressable worm profile wheel.

Linear and rotary main axes are hydrostatic.

High-performance machine for finishing cylindrical gears with straight or helical involute teeth.

TECHNICAL DETAILS

Control: Siemens 840 incl. control panel

Module: 0.5-7.0

Workpiece diameter: 10 - 380 mm

Number of teeth: 10 - 600

Djlin Ietu T S Ujimekl

Vertical slide stroke Z: 200 mm

Horizontal slide stroke X: 230 mm

Tangential slide stroke Y: 135 mm

Swivel angle of clamping head A: ± 45°

Stroke - tailstock center: 125 mm

Tangential slide stroke - dressing V: 180 mm

radial slide stroke - dressing U: 110 mm

C-axis (table rotation): 360°

rapid traverse speed - linear axes: 10,000 mm/min

Rotation speed: 3,000 rpm (infinitely variable)

Table rotation speed: 240 rpm

Table resolution: 0.001°

Processing feeds: stepless

Working feeds: infinitely variable

Grinding wheel diameter: 270 - 350 mm

Grinding wheel width: 104 mm

Grinding wheel bore: 160 mm

MACHINE DETAILS

Machine weight: 11,500 kg

Machine space requirement: approx. 3.7 x 2.4 x 2.75 m

Promot Automation space requirement: approx. 4.5 x 1.6 x 4.0 m

EQUIPMENT

- Promot automation

- Conveyor belt

- Cooling belt system

- Hydraulic unit

- Complete documentation

Auction

Auction ended

Bayern

Bayern

8,038 km

Laser Punch Press

TRUMPFTruMatic 6000 L - 1600

Condition: ready for operation (used), Year of construction: 2008, operating hours: 72,918 h, Functionality: fully functional, punching force: 22 t, laser power: 2,700 W, sheet thickness (max.): 6 mm, sheet thickness aluminum (max.): 4 mm, sheet thickness steel (max.): 8 mm, TECHNICAL DETAILS

Combined punching/laser operation: 2,585 x 1,650 mm

Punching mode: 3,085 x 1,740 mm

Laser operation: 3,085 x 1,650 mm

Outputs

Laser power: 140 - 2,700 W

Maximum sheet thickness: 8 mm

Cutting capacity for mild steel: 8 mm

Cutting capacity for aluminum: 4 mm

Cutting capacity for stainless steel: 6 mm

Maximum punching force: 220 kN

Active hold-down device (programmable in stages): 4.5 - 20 kN

Maximum workpiece weight: 230 kg

Speeds

Maximum positioning speed X-axis: 90 m/min

Y-axis: 60 m/min

Simultaneous (X and Y): 108 m/min

C-axis punching: 60 revolutions/min

Thread forming: 180 revolutions/min

Punching stroke sequence (E = 1): 900 1/min

Marking: 2,800 1/min

Tools

Linear magazine: 18 tools with 3 clamps

Tool change time: 1.5 - 5 s

Tool accuracy

Dkelevi I Aysin Iimsl

Position deviation: ±0.10 mm

Average position spread: ±0.03 mm

Programmable slides for punched and laser parts (max.)

Size: 500 x 500 mm

TRUMPF CNC control: based on Siemens Sinumerik 840D

MACHINE DETAILS

Laser switch-on time: 72,918 h

Cutting time: 18,536 h

Space requirement (width x length): 7,900 x 9,100 mm

Height: 2,400 mm

Weight: 22,500 kg

Laser gas consumption CO2 / N2 / He: 1 / 6 / 13 l/h

Connected load: 73 kVA

Auction

Auction ended

Bayern

Bayern

8,030 km

Machining center

Deckel MahoecoMill 800 V

Condition: ready for operation (used), Year of construction: 2016, operating hours: 4,945 h, Functionality: fully functional, travel distance X-axis: 800 mm, travel distance Y-axis: 560 mm, travel distance Z-axis: 510 mm, spindle speed (max.): 12,000 rpm, number of slots in tool magazine: 30, TECHNICAL DETAILS

Control system: Siemens 840D SlimeLine

Travel X / Y / Z: 800 / 560 / 510 mm

Speed range: 12,000 rpm

Dolin Iijt Ur Srjmokl

Tool holder: SK40

Clamping surface: 1100 x 560 mm

Table load: max. 800 kg

Tool changer: 30 magazine positions

MACHINE DETAILS

Switch-on time: 15,856 h

Spindle hours: 4,945 h

EQUIPMENT

- Chip conveyor

- IKZ

- Paper belt filter

- Documentation

Auction

Auction ended

Sachsen

Sachsen

8,031 km

Centering and end processing machine

RasomaEBZ 60 - 500X

Condition: ready for operation (used), Year of construction: 2015, Functionality: fully functional, machine/vehicle number: 74005, Description of the basic machine

- Horizontal end machining center for simultaneous end machining on both sides of shaft-shaped parts

Delin Iiot Hkp Tjmokl

- Cutting to length, centering, drilling, cross drilling, chamfering, slot milling, etc.

TECHNICAL DETAILS

Control: Siemens Sinumerik 840D SL

Workpiece diameter: max. 60 mm

Workpiece length: 500 mm

Horizontal stroke: 200 mm

Transverse stroke: 200 mm

Tool carrier system left/right: fixed motor spindle / 6-position crown turret

MACHINE DETAILS

Total mass: 16 t

Voltage: 3x400V 50 Hz

Connected load: 74 kW

Auction

Auction ended

Sachsen

Sachsen

8,031 km

Straightening press

LAUFFEREPT 63

Condition: ready for operation (used), Year of construction: 1999, Functionality: fully functional, machine/vehicle number: 15914, TECHNICAL DETAILS

Dkjlin Iiotwpggsmsl

Pressing force: 630 kN

Installation height: max. 600 mm

ram stroke: max. 400 mm

throat depth: 280 mm

Table height: 850 mm

Table width: 630 mm

Table depth: 500 mm

Overtravel: 20 mm

Overtravel time: 90 ms

Safety distance: 180 mm

MACHINE DETAILS

Cooling: Type air TYPE OEKA-R4/1.0

Operating pressure: 260 bar

Oil volume: 285 l

Weight: 6000 kg

Idle noise: 69.2 dB

Drive power: 22 + 4 kW

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

8,032 km

Vertical machining center

CHIRONFZ 08 K W Magnum

Condition: refurbished (used), Year of construction: 2004, operating hours: 5,000 h, Functionality: fully functional, travel distance X-axis: 450 mm, travel distance Y-axis: 270 mm, travel distance Z-axis: 310 mm, controller manufacturer: Siemens, controller model: 840D, rotational speed (max.): 15,000 rpm, TECHNICAL DETAILS

Travel X / Y / Z: 450 / 270 / 310 mm

Drilling capacity in St 60: 16 mm (indexable insert drill)

Thread cutting Milling capacity in St 60: M12, 60 cm³/min

Speed range: 20 - 15,000 rpm

Control: SIEMENS 840D

Spindle power at 100%/25% ED: 2.2 / 7.2 kW

Torque: 23 Nm

Rapid traverse X,Y / Z: 40 / 60 m/min

Workpiece changing device: 0 / 180°

Clamping surface: 2 x 550 x 300 mm

Thread and fitting hole grid: M16 x Ø 15H7 x 50 mm

Load weight: max. 200 kg per side

Weight difference: max. 50 kg between both sides

Workpiece changeover time: approx. 2.0 s

Tool places: 24 pieces

Tool taper: HSK A 40 DIN 69893

Tool diameter: max. 50 mm

Tool diameter with free adjacent positions: max. 100 mm

Tool length: max. 160 mm

Tool weight: max. 1.2 kg

Tool change time: 0.8 s (depending on control system)

Chip-to-chip time: approx. 2.2 s (depending on control)

MACHINE DETAILS

Operating voltage: 400 / 230 V, 50 Hz/N/PE

Compressed air: 6 bar ±1 bar

Ambient temperature: max. 40°

Dkelot R R A Iein Iimel

EQUIPMENT

- Moving column machine with workpiece changing device Guides with long-term grease lubrication

- Digital main drive with spindle with sealing air supply

- Tool clamping monitoring

- Automatic tool changer with robust, fully encapsulated pick-up chain magazine, with mechanical collision protection as well as,

Cone cleaning via blast air

- Look Ahead with dynamic pilot control, Bellshape acceleration ramp, software limit switch, access authorization

via key switch for tool corrections, NC program changes and machine parameters

- CHIRON Powersafe software package for the targeted switch-off of installed consumers

- Definable time for variable "warm-up" program

- Thermocontrol

- Thermodrive

- Operating hours and piece counter on screen

- 230 V socket

- Socket for portable mini handwheel

- Splash guard cover

- Switch cabinet cooler

- Oil-free maintenance unit

- Installation elements

- Flushing gun

- Extraction connection Extraction Ø 150

- Machine preparation for IKZ

- CHIRON tool life monitoring

- Chip conveyor (scraper belt)

- Fixture flushing

- 4th + 5th NC axis, ready to plug in

- Documentation

Floor vehicle on site / electrician for dismantling can be provided by the seller for an additional charge.

Auction

Auction ended

Bayern

Bayern

8,026 km

High-precision rack grinding machine

MägerleMFP 260

Condition: excellent (used), Year of construction: 2008, Functionality: fully functional, Commissioning took place in 2009

TECHNICAL DETAILS

Model: MFP L 260 - 75

Control: Siemens 840D Sinumerik

Table clamping surface X / Z: 2202 / 352 mm

Longitudinal stroke: 2600 mm

Transverse stroke sanding support: 650 mm

Distance spindle to table: 806 mm

Head design: fixed, not adjustable

Grinding wheel dimension: Ø400 x 160 mm

Grinding wheel bore: 127 mm

Peripheral speed of grinding wheel: 35 / 50 m/s

Stroke speed longitudinal / transverse / vertical: 30 / 5 / 5 m/min

Resolution: 0.001 mm

MACHINE DETAILS

Machine weight: 21 t

Space requirement: 7.06 x 2.7 x 3.26 m

Drive power of grinding wheel: 75 kW

Total connected load: 113 kVA

Knoll coolant cleaning system Dimensions: 5.6 x 2.4 x 3 m

Knoll coolant cleaning system Weight: 2,000 kg

Dkolisttazfon Iimol

EQUIPMENT

- Handwheel included

- Complete documentation

Purchase price of the machine was € 1,450,000

Auction

Auction ended

Bayern

Bayern

8,038 km

Punch nibbling machine

TRUMPFTruMatic 5000 R

Condition: ready for operation (used), Year of construction: 2001, Functionality: fully functional, punching force: 22 t, sheet thickness (max.): 8 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, TECHNICAL DETAILS

Sheet thickness: 8 mm

Punching force: 220 kN

Working area: 3,000 x 1,500 mm

Control system: Siemens

MACHINE DETAILS

Machine weight: approx. 17,500 kg

Dolin Ijvi Iw Roimokl

EQUIPMENT

- Scraper alternating position control

- Thread forming

- Marking - fast beading

- Slotting

- Multishear

- Multibend

- Offset resetting

- Roller tools

- Set-up cassettes

- Ball transfer table

Auction

Auction ended

Germany

Germany

8,033 km

Vertical machining center

Deckel MahoDMC 635 V

Year of construction: 2008, Condition: good (used), Functionality: fully functional, machine/vehicle number: 1540503266A, TECHNICAL DETAILS

X axis: 635 mm

Y-axis: 510 mm

Z-axis: 460 mm

Control: Heidenaihn İTNC 530

Number of tools: 30

Tool holder: SK 40

Dkjlin Iiong Amvemel

MACHINE DETAILS

on request

EQUIPMENT

Direct path measuring system X,Y,Z

Measuring probe Heidenhain TS640

Spindle conveyor

Operating mode 4

Trust Seal

Dealers certified through Machineseeker

Auction

Auction ended

Wallis

Wallis

8,036 km

Stationary concrete mixing plant

Huggler SuhrZwangsmischer 1m3

Condition: ready for operation (used), Functionality: fully functional, Year of construction: 2009, No minimum price - guaranteed sale at the highest bid!

The system is a modular system and can therefore be quickly dismantled and reassembled.

TECHNICAL DETAILS

Storage components

Ring-pan mixer: 1 m³

Pre-silo: 4.5 m³

Gravel silo: 2 pieces, 6 components each

Cement silo: 2 pieces, 3 chambers each

Chemical scale: Finke with 3 chambers

Software and maintenance

Software: Version from 2022, updated to the latest operating system

Base plates: Renewed in 2023

Mixer

Type: Forced action mixer

Model: Huggler

Capacity: 1 m³ hardened concrete

Gravel silo 1

Components: 4

Capacity K1: 20 m³

Capacity K2: 32 m³

Capacity K3: 32 m³

Capacity K4: 20 m³

Gravel silo 2

Components: 2

Capacity K5: 20 m³

Capacity K6: 20 m³

Cement silo 1

Type: 2-part silo

Cement 1 capacity: 20 t

Cement 2 capacity: 40 t

Cement silo 2

Type: 1-piece silo

Cement 3 capacity: 60 t

Admixture

Admixture weigher: Finke

Number of chambers: 3

Chamber capacity: 6 components, conveying system by pump

Year of construction

Gravel silo 1 and cement silo 1: 2009

Dolieu Rc Nnon Iimokl

Gravel silo 2 and cement silo 2: 2013

Other

Heating: Gravel silos equipped with electric heating

Pre-silo: 4 m³ hardened concrete

Control system: PC control system, conversion in 2022

Floor sealing plates: Renewed in 2023

Plant: Compact construction site plant with plug connections

Auction

Auction ended

Sachsen

Sachsen

8,038 km

Vertical machining center

HURCOVMX 50

Year of construction: 2003, operating hours: 4,689 h, Condition: reconditioned (used), Functionality: fully functional, 2023 comprehensively overhauled:

- Spring assembly spindle renewed

Dkelinjl D Rubo Iimjl

- Rotating union renewed

- trackball renewed

- Life support battery renewed

- Graphic card regenerated

- X-axis bearing new

- backlash X-/Y-axis 0,015mm

TECHNICAL DETAILS

X travel: 1270 mm

Y travel: 660 mm

Z travel: 610 mm

speed: max. 8.000 rpm

table load: max. 1300 kg

table size: 1500x660 mm

tool changer: 24-fold/double arm

tool holder: SK 40 DIN69871

Control: Ultimax 4 control

MACHINE DETAILS

spindle hours: 4.689 h, machine ran only 1 shift

drive: 15 kW

machine weight: approx. 9 t

space requirement: approx. 4,8 x 4,5 x 2,95 m

EQUIPMENT

- Coolant system

- Cooling through the spindle (IKZ) 20bar

- chip conveyor

- machine light

- 2x color screens (working)

- Removable electronic handwheel

SOFTWARE

- Pocket milling with islands

- Synchronous tapping without compensating chuck

- DXF software

- 3D contouring software

- Ultinet

- Advanced Velocity Control

- Plunge Ramp/Helix

Auction

Auction ended

Bayern

Bayern

8,037 km

Plasma cutting machine

MicroStepSPL 3001.15 PG

Condition: ready for operation (used), Year of construction: 2004, Functionality: fully functional, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, No minimum price - guaranteed sale at the highest bid!

TECHNICAL DATA

Travel X x Y: 3,000 x 1,500 mm

Dslin Iisuxr Txomekl

Auction

Auction ended

Bayern

Bayern

8,038 km

Press brake

EHTEHPS 32-80

Condition: reconditioned (used), Year of construction: 1990, Functionality: fully functional, Conversion 2009:

- motorized die shift 111-112: mechanically and electrically NEW

- Backgauge X-R: mechanical and electrical NEW

- Automatic punch clamping: mechanical and electrical NEW

- CNC control: mechanical and electrical NEW

- Safety valves NEW

- Measuring rulers NEW

- Control valves Y1 - Y2 NEW

- Main hydraulic pump NEW

TECHNICAL DETAILS

Pressure: 320 t

folding length: 8050 mm

Stand width: 7550 mm

Control system: Cybelec ModEva 12S

EQUIPMENT

Dkjlinjvc Axvs Iimel

- CNC-controlled backgauge x-direction and R-direction

- Motorized die displacement M1 and M2

- 2 x pneumatic bending aids at the front

- Pneumatic sheet holding unit

- Automatic tool clamping at the top

- motorized crowning

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

This may be of interest to you