Used Mash for sale (121)

Gargždai

Gargždai Fruit Washer Elevator Mill

ProFruit MachineryMAXIMILL 1000

Gargždai

Gargždai Fruit Washer Elevator Mill

ProFruit MachineryMAXIMILL 3000

Gargždai

Gargždai Screw conveyor

ProFruit MachineryScrew conveyor

+44 20 806 810 84

Gargždai

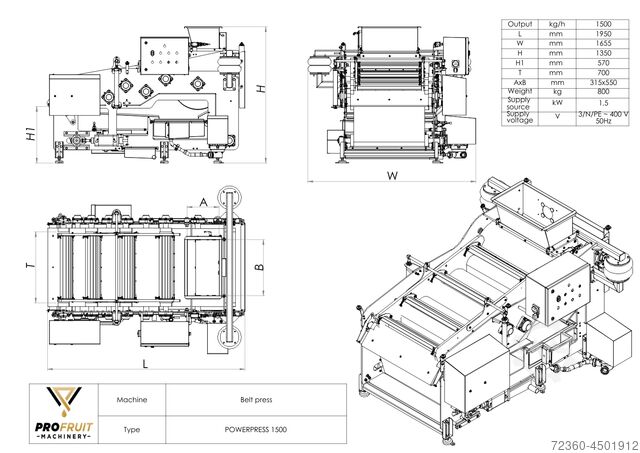

Gargždai Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Wielka Nieszawka

Wielka Nieszawka Pre-stretch pallet wrapper 2,4M type E

TM-Group

Discover more used machines

Pichl bei Wels

Pichl bei Wels Washing machine WA LC40 f. EBP420, EBP50

voranWA LC40

Pichl bei Wels

Pichl bei Wels Eccentric screw pump SP5/B2

voran Maschine GmbHSP5/B2

Pichl bei Wels

Pichl bei Wels Centrifugal mill RM5,5

voranRM5,5

Pichl bei Wels

Pichl bei Wels Elevator SA200 & centrifugal mill RM2,2

voranSA200

Pichl bei Wels

Pichl bei Wels Elevator SA400 with RM40

voranSA400

Pichl bei Wels

Pichl bei Wels Washing machine WA LC40 with RM40 f. 180

voranWA LC40

Pichl bei Wels

Pichl bei Wels De-stoning machine EP1000

voranEP1000

Pichl bei Wels

Pichl bei Wels Washing machine WA LC40 f. belt presses

voranWA LC40

Pichl bei Wels

Pichl bei Wels Washing machine WAR65 f. packing presses

voranWAR65

Pichl bei Wels

Pichl bei Wels Eccentric screw pump SP6/B2

voranSP6/B2

Pichl bei Wels

Pichl bei Wels Centrifugal mill RM1,5

voranRM1,5

Pichl bei Wels

Pichl bei Wels Elevator SA300 with RM4

voranSA300

Pichl bei Wels

Pichl bei Wels Centrifugal mill RM2,2

voranRM2,2

Pichl bei Wels

Pichl bei Wels Washing machine WA LC40 f. 100P2

voranWA LC40

Pichl bei Wels

Pichl bei Wels Washing machine WAR65 for belt presses

voranWAR65

Pichl bei Wels

Pichl bei Wels De-stoning machine EP500

voranEP500

Used Mash (121)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84