Used Stone Forceps for sale (1,040)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Zheng Zhou Shi

Zheng Zhou Shi

11,505 km

Bauxite Granite Bentonite Barite Crusher

Mingyuan hard stone jaw crusher machineBauxite Granite Bentonite Barite Crusher

Call

Condition: new, power: 110 kW (149.56 HP), Year of construction: 2025, Bauxite Crusher:

Bauxite is an aluminum ore, and crushers or mills are used to break down the bauxite into smaller pieces for further processing. Jaw crushers, impact crushers, or cone crushers may be used for this purpose.

Granite Crusher:

Granite is a hard and durable natural stone. Crushers used for granite crushing typically include jaw crushers, impact crushers, and cone crushers. These crushers can handle the varying hardness of granite and produce different sizes of crushed products.

Bentonite Crusher:

Bentonite is a type of clay with excellent water-absorbing and plasticity properties. Crushers such as jaw crushers or cone crushers are used to break down the bentonite into a manageable size for further processing.

Barite Crusher:

Barite, also known as baryte, is a mineral consisting of barium sulfate. Crushers like jaw crushers and cone crushers are commonly used in the crushing process of barite. Impact crushers may also be used for shaping and processing finer particles.

For each of these minerals, the selection of the appropriate crusher depends on factors such as the hardness of the material, the required final product size, and the specific characteristics of the deposit. It's also important to consider whether a primary crusher, secondary crusher, or even tertiary crusher is needed in the processing flow.

Hedpfx Aboq Nx Apsrjnh

Additionally, for certain applications, grinding mills may be employed after the initial crushing stage to further reduce the size of the particles. Grinding mills suitable for these minerals might include ball mills, Raymond mills, or vertical roller mills, depending on the specific requirements of the process.

Remember that the choice of crushers and mills is often part of a larger mineral processing plant design, and the selection process should take into account the overall production requirements, mineral characteristics, and economic considerations.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

11,505 km

Crushing equipment

Mobile / Stationary stone crusher plantSand & aggregate production plant

Call

Condition: new, Year of construction: 2025, A sand aggregate production plant is a facility where various types of aggregates (such as sand, gravel, crushed stone, or recycled concrete) are produced for use in construction and other applications. These plants typically include various stages of processing, from raw material extraction to the final product.

Here are the key components and processes typically involved in a sand aggregate production plant:

1. Raw Material Extraction:

- Quarrying or Mining: Aggregates are often extracted from quarries, mines, or riverbeds. Depending on the type of aggregate, the extraction process may involve drilling, blasting, or dredging.

2. Primary Crushing:

Hnedjq Ngb Dopfx Abrsh

- Jaw Crusher or Gyratory Crusher: The extracted raw material is usually transported to the plant and fed into a primary crusher, where large rocks are broken down into smaller pieces.

3. Secondary Crushing:

- Cone Crusher or Impact Crusher: The crushed material from the primary crusher may undergo further reduction in size through secondary crushing.

4. Screening:

- Vibrating Screens: After crushing, the material is often screened to separate different sizes of aggregates. This process ensures that the final product meets the required specifications.

5. Washing:

- Sand Washers: In some cases, especially for sand production, washing is done to remove impurities, clay, and fines from the aggregates, ensuring a cleaner and higher-quality product.

6. Grading and Sorting:

- Classifiers or Graders: After washing and screening, the aggregates may go through additional processes to separate them based on size or quality.

7. Stockpiling:

- Stockpiles: The final aggregates are usually stockpiled for storage before being transported to construction sites or other end-users.

8. Aggregate Storage and Handling:

- Storage Bins or Silos: Larger production plants may have storage facilities, such as bins or silos, to store different types and sizes of aggregates before distribution.

9. Quality Control:

- Laboratory Testing: Regular quality control testing is performed on aggregates to ensure they meet specifications for strength, size, gradation, and other properties.

10. Environmental Considerations:

- Water Management: Some plants incorporate water management systems to recycle and reuse water used in the washing process, minimizing environmental impact.

11. Transportation:

- Conveyors or Trucks: Aggregates are typically transported from the production plant to construction sites by conveyors, trucks, or other means.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

11,505 km

Crushing equipment

Mingyuan stone crusher machinegravel & aggregate production equipment

Call

Condition: new, Year of construction: 2025, Gravel and aggregate production equipment is used to crush, screen, and process stones, rocks, and other materials for the construction industry. This equipment is essential in producing various types of aggregates, including crushed stone, gravel, sand, and recycled concrete, which are used in the construction of roads, buildings, bridges, and other infrastructure projects. Here are some common types of equipment used in gravel and aggregate production:

1. Jaw Crusher:

- Jaw crushers are primary crushers used to break down large rocks into smaller, more manageable pieces. They are essential for the initial stage of aggregate production.

2. Impact Crusher:

- Impact crushers are used to crush rocks and stones with the help of impact force. They are suitable for shaping and producing fine aggregates.

3. Cone Crusher:

- Cone crushers are often used for secondary and tertiary crushing in aggregate production. They produce well-shaped and finely graded aggregates.

4. Vertical Shaft Impact (VSI) Crusher:

- VSI crushers are designed for shaping and producing high-quality artificial sand. They are suitable for processing materials with high abrasiveness.

5. Screens:

- Vibrating screens are used to separate different sizes of aggregates. They classify the material based on particle size and ensure that the final products meet specified gradation requirements.

6. Scalping Screens:

- Scalping screens are used to remove oversized materials before they reach the primary crusher. This helps to optimize the crushing process and prevent damage to the equipment.

7. Washing Equipment:

- Washing equipment, such as sand screws or log washers, is used to remove impurities and fine particles from aggregates. This is particularly important for producing high-quality concrete sand.

8. Conveyors:

- Conveyors are used to transport materials between different stages of the crushing and screening process. They play a crucial role in enhancing efficiency in material handling.

9. Stackers and Reclaimers:

- Stackers are used to create stockpiles of processed aggregates, while reclaimers are used to retrieve the material from the stockpile. Both are essential for efficient material storage and handling.

10. Crushing Plants:

- Complete crushing plants include various types of crushers, screens, and conveyors integrated into a single system. These plants are designed to handle large volumes of material efficiently.

Hodpfx Aoq Nxz Debronh

Listing

Germany

Germany

7,870 km

Mobile crushing plant / stone crusher

Constmach Mobile Crushing PlantMobile vertical shaft impact crushing

Call

Condition: new, Year of construction: 2025, functionality: fully functional, power: 390 kW (530.25 HP), fuel type: hybrid, color: other, Equipment: cabin, CONSTMACH V-80 mobile vertical shaft impact crusher is a fully equipped mobile sand production plant specially designed for producing high-quality fine aggregate and cubic-shaped sand. This plant delivers superior performance in 0–5 mm particle sizes thanks to the VSI 800 CR vertical shaft impact crusher technology developed with advanced engineering solutions. Its compact design, easy transportability, and high efficiency deliver excellent results, especially when processing rocks of varying hardness, such as granite, basalt, dolomite, gabbro, and limestone.

The V-80 can be fed with natural stones up to 40 mm in size after primary or secondary crushing. The plant provides a production capacity of 150 to 200 tons per hour, depending on the hardness of the stone. During production, three different fractions can be obtained simultaneously, in addition to material smaller than 5 mm. The hydraulic foot system, short assembly time, and PLC-based automation structure offer maximum ease of use for the operator. Furthermore, it guarantees long-lasting and reliable operation with Siemens – Schneider brand electronic components.

Hsdpfjxqbgdox Abrenh

V-80 Mobile Vertical Shaft Crusher Technical Specifications

Production Capacity: 150-200 tph

Maximum Feed Size: 40 mm

Feed Height: 4.5 meters

Main Configuration: VSI Crusher + Vibrating Screen

Total Motor Power: 390 kW

Electric Generator Requirement: 700 kVA

Plant Weight: 40 tons

Plant Dimensions: 18.8 (L) x 3.65 (W) x 4.4 (H) meters

Chassis Type: Single chassis with wheels, equipped with hydraulic legs

Why Choose the V-80 Mobile Vertical Shaft Impact Crusher?

At CONSTMACH, we offer our customers maximum efficiency, low maintenance costs, and quick installation advantages in rock crushing and screening processes. The V-80 model provides flexibility and operational ease in the field with both its high production capacity and mobile design. Its compact chassis, which can be transported with just a tractor, allows for quick transitions between different construction sites. Moreover, it guarantees uninterrupted production in all conditions with its dust reduction system, remote control support, and optional diesel generator integration. With its durability, energy efficiency, and world-class engineering quality, the V-80 has become synonymous with reliability and performance in sand production.

What Do We Do at Constmach?

Constmach is a leading machine manufacturer serving the construction and mining industries with a wide range of products tailored to their needs. Our product portfolio includes concrete block making machines, stationary and mobile concrete plants, stone crushing machines, stone crushing and screening plants, sand washing machines, sand making machines, asphalt plants, conveyor belt systems, jaw crushers, and mobile crushing plants. With its high quality standards, innovative production approach, and customer-focused solutions, Constmach stands out as a reliable brand in both national and international markets. Our products continue to be the preferred choice of industry professionals due to their durability, efficiency, and long-lasting performance.

Information: The prices listed in the advertisement are shared based on current information. However, due to changes in market conditions and supply processes, our prices may vary from time to time. Therefore, we recommend requesting a quote from us for accurate pricing information.

Listing

Vuren

Vuren

7,518 km

Tipper

FLIEGLSTONE MASTER

Call

Condition: used, axle configuration: 3 axles, first registration: 04/2022, loading space length: 7,200 mm, loading space width: 2,400 mm, loading space height: 1,550 mm, total length: 8,500 mm, total width: 2,450 mm, total height: 3,300 mm, suspension: air, tire size: 385/65R22,5, color: other, Year of construction: 2022, Equipment: ABS, = Additional options and accessories =

- EBS

= Notes =

Number of axles: 3, Unladen weight: 6,060 kg, Gross weight: 35,000 kg, Chassis type: Full chassis, Chassis material: Steel, Kingpin size: 2 inch, Suspension type: Full air suspension, ABS, EBS, Body year: 2022, Body material: Steel, Number of sides: 1 side, Tipper drive: PTO, Drum volume: 25, Drum capacity in: m3, Axle type: SAF

= Further information =

General information

Cab: Day

Registration number: KLEYN1

Drivetrain

Fuel type: Diesel

Transmission

Transmission: Manual gearbox

Axle configuration

Tyre size: 385/65R22.5

Brakes: Disc brakes

Suspension: Air suspension

Axle 1: Lift axle; Tyre tread left: 12 mm; Tyre tread right: 15 mm

Axle 2: Tyre tread left: 14 mm; Tyre tread right: 16 mm

Axle 3: Tyre tread left: 14 mm; Tyre tread right: 13 mm

Weights

Unladen weight: 6,060 kg

Payload: 28,940 kg

Gross vehicle weight: 35,000 kg

Environment

Emission class: Euro 0

Maintenance

APK (Dutch MOT): inspected until 04.2026

Condition

General condition: average

Technical condition: average

Optical condition: average

Damages: none

= Company information =

Kleyn Trucks is one of the world’s largest independent traders of used vehicles. Here you can choose from a constantly changing stock of 1,200 used trucks, tractors and trailers. Our range covers all European brands, model years, and price categories.

Why buy from Kleyn Trucks? It’s simple!

• Large, fast-changing stock

• Reliable quality

• Attractive prices

• Honest trading

• Multilingual support

• We understand our customers

• Assistance with import and transport

• (Export) license plates quickly arranged

• Expert technical services

• The safety of “recognizable quality”

• And more…

Hjdeygru Espfx Abrenh

Please visit our website for special offers and the full stock list:

Leasing through Kleyn Trucks is possible in most European countries!

Quickly calculate your leasing rate and send a request via our website.

Ask directly about our European warranty packages.

Listing

Borken

Borken

7,614 km

2250m² facing brick slips natural stone

Decor Son1550107

Call

Condition: new, 2250m² POSTEN Stone Design Decor facing bricks - Regular selling price 56.600,-

This item consists of:

2x pallet Tuscany each 63sqm = 126sqm

12x pallet Tenerife each 55sqm = 660sqm

4x pallet Nuanced 48sqm each = 192sqm

7x pallet Nuanced per 24sqm = 168sqm

14x pallet Mini Euroc per 48sqm = 672sqm

12x pallet Mini Euroc per 36sqm = 432sqm

Cover your wall with Decor Euroc and be inspired by the impressive resemblance to rustic natural stone. The Decor Euroc stones are inspired by spectacular mountains and cliffs and can be used both indoors and outdoors. The stones are made of concrete and are characterized by their robust, high-quality finish, which makes the stones colourfast and frost-resistant.

Suitable for flat interior and exterior walls

Natural appearance

Strong concrete

Product weight 1. 114 grams

Product height 13.5 cm

Product length 1 cm

Product width 28.3 cm

Brand Decor

General

Color Cream shade, White Mini,Tuscany,White Tenerife

Line Euroc

Number of pieces per pack 11

Forming rectangle

Number of m² per pack 0.5 m²

Style tile Concrete imitation

Type of tile Stone strip

Type of tile

Material Concrete

Hsdpfxotrf Rzs Abrenh

Material property Durable

Finish Untreated

Dimensions

Tile thickness 10mm

Application

Application Walls

Area of application Office, interior, living room, bedroom, kitchen

Frost-resistant Yes

Technical properties

Glazed NO

Shine NO

Color-fast Yes

Scratch-resistant Yes

Relief Yes

Full in the crowd Yes

Financing through our bank is also possible.

komplett-konzept.leasingo.de

You can find more tiles - new and used - in our store!

International shipping costs on request!

Listing

Zelo Buon Persico

Zelo Buon Persico

8,187 km

Automatic weighing and filling machine

TAG S.r.l.ARTENA STONE FRUIT

Call

Year of construction: 2022, condition: like new (used), functionality: fully functional, machine/vehicle number: TAG ARTENA-03722-1/11, The TAG Artena 16-channel Weighing and Filling Machine is a fully automated, multi-product weigher designed for accurately portioning delicate small- and medium-sized loose fruit and vegetable products into trays.

This machine is integrated at the upstream end of the production line, positioned before the packing and labelling machines. Products are loaded in bulk onto the weighing machine's conveyor belt, then directed onto the feed conveyors via a dynamic hopper and placed into trays. Trays are destacked and sorted onto the indexed conveyor. The filling process occurs in four steps, during which the trays are weighed in-line using patented technology.

The machine is controlled via a touch-screen control panel, providing a comprehensive overview of its functions.

Key product and machine performance specifications:

• Weighing and filling system for delicate fruits

• Feeding belts made from special soft material to prevent bruising of stone fruit

• 8+8 multi-product weighing units

• Enhanced product shelf-life due to reduced drop heights

• Linear combination and/or counting operation logic

• Three-way automatic dual tray/basket destacker

• Multi-format, double-lane automatic tray/basket conveyor

• Tray weight: from 300 grams up to 1,500 grams

• Tray size: from 65x65xh25 mm to 200x200xh110 mm

• Tray shapes: square, rectangular or round

• Multi-material trays: plastic, plastic-free, cardboard, and other materials

Hnodpfx Aboykam Dorjh

• Easy touch-screen control

• User-friendly interface, ready for in-line connections

• Automatic format changeover

• Production statistics

• Electrical connections for downstream machine synchronization

• Button-operated clam-shell closing device

• Two-to-one channel converger conveyor

Main construction features:

• Stainless steel frame

• Sorting belt with support surface for crate tipping

• 2 product feed elevator belts

• 8+8 multi-product weighing units (patented system)

• Clam-shell closing device

• Automatic multi-format tray destacker

• Food-grade PU motorized conveyor belts

• Tray diverters

• Synchronized step-by-step belt movement using sensors and microcontrollers

• Belt function logic managed by TAG dedicated microcontroller and software

• Electrical connections for synchronization with downstream machines (flowpack or other)

• Power supply: 220V 50Hz, 2.5kW consumption

• Compressed air circuit, minimum pressure 7 bar

• Hardwired internet connection for remote support

All line command and control functions are managed via a tablet supplied with the machine, serving as the HMI and onboard operator panel. The intuitive 3D graphic interface and 10'' touch-screen make the operation highly user-friendly.

Listing

Germany

Germany

7,870 km

Stone Production Plant

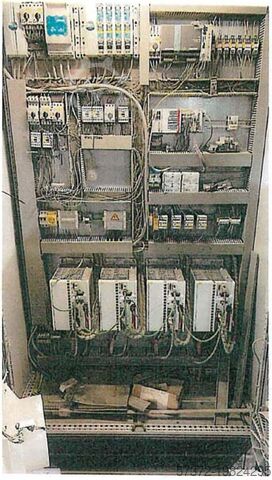

OmagTronic S22 140-90

Call

Year of construction: 2001, condition: ready for operation (used), A paving stone production line Omag, which has been continuously optimized and upgraded to the latest technical standards, is available. Overhauls: 1) Conversion for an additional hydraulic unit for additional load in 2020. 2) Conversion to servo-vibration with Siemens S7 control in 2016. 3) Conversion to digital path measurement of mould and ram in 2017. 4) New core filling carriages in 2017. Plant components: 1) Board destacker and board stacker including roller conveyor. 2) Board feeder (advance) and board conveyor (scraper) to the lifting frame. 3) Board turner. 4) Horizontal and vertical bundling units Ridder & Signode, years of manufacture: 1994 and 1983. 5) Trafo lifting platform including motors and without control, year of manufacture: 1983. 6) Doppler including hydraulic unit, year of manufacture: 2004. 7) Stone packer Omag K1400 including hydraulic unit, year of manufacture: 1997. The line has no base boards. 8) Stone finisher Omag S22 140-90, year of manufacture: 2001. Documentation available. An on-site inspection is possible.

Hnsdpfx Aow R Uziebrjh

Listing

Turkey

Turkey

9,813 km

Crushing equipment / jaw crusher

Constmach Jaw CrusherHard stone crushing machine 50-1000 t/h

Call

Condition: new, functionality: fully functional, fuel type: hybrid, color: other, Year of construction: 2025, CONSTMACH jaw crushers are designed to offer high durability and superior crushing performance, making them ideal machines for primary crushing operations in quarries and mines. They have the capacity to process a wide range of materials, from the softest limestone to the hardest types of granite and basalt. Their robust construction, high flywheel torque, and special jaw geometry ensure high-efficiency crushing of material into uniform sizes. The advanced hydraulic adjustment mechanism allows for easy adjustment of the desired output size and minimizes operator intervention.

CONSTMACH jaw crushers ensure long-lasting use with their forged chrome-nickel steel pitman structure, heavy-duty bearings, and automatic lubrication systems. The welded main frame, which has undergone thermal stress relief treatment, maintains maximum durability even under high vibration. The user-friendly maintenance design provides an uninterrupted and safe working environment during production processes. These machines can be integrated into stationary or mobile crushing plants, offering high flexibility for projects.

CJC-60 Technical Specifications

Mouth Size: 600 x 380 mm

Motor Power: 30 kW

Shaft Speed: 330 rpm

Weight: 6,000 kg

Min./Max. Adjustment: 30 - 100 mm

Production Capacity: 60 - 110 t/h

CJC-90 Technical Specifications

Mouth Size: 900 x 650 mm

Motor Power: 75 kW

Shaft Speed: 277 rpm

Weight: 11,400 kg

Min./Max. Adjustment: 50 - 150 mm

Production Capacity: 90 - 270 t/h

CJC-110 Technical Specifications

Mouth Size: 1,100 x 850 mm

Motor Power: 132 kW

Shaft Speed: 230 rpm

Weight: 33,000 kg

Min./Max. Setting: 60 - 200 mm

Production Capacity: 150 - 420 t/h

CJC-130 Technical Specifications

Jaw Opening: 1,300 x 1,000 mm

Motor Power: 160 kW

Shaft Speed: 220 rpm

Weight: 42,500 kg

Min./Max. Adjustment: 100 - 280 mm

Production Capacity: 275 - 790 t/h

CJC-140 Technical Specifications

Jaw Size: 1,400 x 1,100 mm

Motor Power: 200 kW

Shaft Speed: 220 rpm

Weight: 52,000 kg

Min./Max. Adjustment: 120 - 280 mm

Production Capacity: 420 - 850 t/h

Why Choose CONSTMACH Jaw Crushers

Hnedpfsxqhzusx Abrjh

CONSTMACH is a symbol of quality and reliability in crushing and screening technologies. Each jaw crusher model undergoes production processes that comply with international standards, ensuring maximum performance, low operating costs, and a long service life. With customizable design options tailored to customer needs and an extensive service network, it supports your business's uninterrupted production goals. In terms of reliable performance, engineering quality, and after-sales technical support, CONSTMACH is the right choice for crushing systems.

What Do We Do at Constmach?

Constmach is a leading machine manufacturer serving the construction and mining industries with a wide range of products. Our product portfolio includes concrete block making machines, stationary and mobile concrete plants, stone crushing machines, stone crushing and screening plants, sand washing machines, sand making machines, asphalt plants, conveyor belt systems, jaw crushers, and mobile crushing plants. With its high quality standards, innovative production approach, and customer-focused solutions, Constmach stands out as a reliable brand in both national and international markets. Our products continue to be the preferred choice of industry professionals due to their durability, efficiency, and long-lasting performance.

Listing

Turkey

Turkey

9,813 km

Impact crusher/sand making/stone crusher

ConstmachVertical shaft impact crusher - VSI 900

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Vertical Shaft Impact Crushers (VSI) stand out among rock crushing machines due to their high crushing efficiency and excellent particle shape production. Developed by CONSTMACH, these sand-making machines are used in the tertiary crushing stage to give cubic form to materials obtained from secondary crushers and to produce a high proportion of fine material.

The system offers superior performance in processing all types of minerals and ores, as well as hard rocks such as basalt and granite. High-quality sand is produced from materials with a maximum feed size of 45 mm. Vertical shaft impact crushers allow you to easily obtain the desired product size for different material types thanks to their variable speed rotor system.

It offers production capacity flexibility with a high reduction ratio, large feed hopper, and four different crushing chambers. In addition, high-chromium wheel shoes, anvils, and heavy-duty bearings ensure long life and low maintenance costs. The independent lubrication system and optional anvil replacement mechanism maximize uptime.

Vertical Shaft Impact Crusher Technical Specifications

Model: VSI-700-CR

Maximum Feed Size: 35 mm

Weight: 6,500 kg

Motor Power: 110 kW

Rotor Diameter: Ø700 mm

Rotor Speed: 60–70 m/s

Production Capacity: 60–100 t/h

Model: VSI-800-CR

Maximum Feed Size: 40 mm

Weight: 12,000 kg

Motor Power: 2 x 160 kW

Rotor Diameter: Ø800 mm

Rotor Speed: 45–60 m/s

Production Capacity: 150–200 t/h

Model: VSI-900-CR

Maximum Feed Size: 45 mm

Weight: 14,500 kg

Motor Power: 2 x 185 kW

Rotor Diameter: Ø900 mm

Rotor Speed: 50–60 m/s

Production Capacity: 200–250 t/h

Model: VSI-1000-OR

Maximum Feed Size: 90 mm

Weight: 15,000 kg

Motor Power: 2 x 200 kW

Rotor Diameter: Ø975 mm

Rotor Speed: 50–60 m/s

Production Capacity: 250–300 t/h

Why Choose CONSTMACH Vertical Shaft Impact Crushers?

CONSTMACH is a globally preferred brand in the production of stone crushing machines and sand making machines with its engineering quality. Our vertical shaft impact crushers offer high performance, low operating costs, and long-lasting use. Our models, which can be customized to the production needs of each facility, provide the advantages of easy maintenance and high efficiency. CONSTMACH is always the right choice for businesses seeking quality, reliability, and sustainable production.

What Do We Do at Constmach?

Hnsdpfexpvgpex Abreh

Constmach is a leading machine manufacturer serving the construction and mining industries with a wide range of products. Our product portfolio includes concrete block making machines, stationary and mobile concrete plants, stone crushing machines, stone crushing and screening plants, sand washing machines, sand making machines, asphalt plants, conveyor belt systems, jaw crushers, and mobile crushing plants. With its high quality standards, innovative production approach, and customer-focused solutions, Constmach stands out as a reliable brand in both national and international markets. Our products continue to be the preferred choice of industry professionals due to their durability, efficiency, and long-lasting performance.

Information: The prices listed in the advertisement are shared based on current information. However, due to changes in market conditions and supply processes, our prices may vary from time to time. Therefore, we recommend requesting a quote from us for accurate pricing information.

Listing

Kruibeke

Kruibeke

7,514 km

4 axis stone CNC machine for edge finishing

Igolden02P-X6E

Call

Year of construction: 2023, condition: like new (used), functionality: fully functional, 4 axis stone CNC machine for edge finishing/ tap and sink holes - fits BT40ER40/80 - 15 tool holders included - vacuum pump included - including automatic zero point determination via compressed air cylinders - excluding water installation - control cabinet dimensions 900x600x1800 mm

Hnjdpjv Dulqefx Abroh

Listing

Framrach

Framrach

8,423 km

Sorting machine for stones, rocks & gravel

ASCOVS BIG + CB - Stone classification

Call

Condition: new, Year of construction: 2026, functionality: fully functional, Technical Details of the VS BIG (Two-Deck):

• Top deck: 130 x 130 mm screen mesh

• Bottom deck: 90 x 90 mm screen mesh

• Fixed metal brake (instead of rubber brake)

• 400V power connection

Hsdpfx Aboyirx Njronh

Conveyor Belt CB 3000:

• Without standard frame with wheels

• Fixed frame at the bottom

This setup allows for efficient and precise screening directly on-site!

Clickout

Auction ended

Ireland

Ireland

6,686 km

Stone Milling & Polishing Machine

ThibautT108L

Year of construction: 2006, condition: used, functionality: unexamined, Thibaut T108L Stone Milling & Polishing Machine with 1,260 x 3,000mm Polished Stone Bed & Accessories Head Seperated

Hnsdeyb Tfnopfx Abroh

Listing

Oberleichtersbach

Oberleichtersbach

7,890 km

Stone gripper

STC B.V.Steinzange Steingreifer

Call

Condition: excellent (used), functionality: fully functional, overall weight: 3,300 kg, Year of construction: 2010, Model: GVZ 3000-D-S

Opening width: approx. 2.60 m

Hsdpfx Abjtgpg Isrsnh

incl. CW55 adapter plate (e.g. for CAT 345)

Listing

Turkey

Turkey

9,823 km

Crushing equipment / jaw crusher

FABO Jaw Crusherhard stone crushing machine 100-250 t/h

Call

Condition: new, functionality: fully functional, fuel type: hybrid, color: yellow, overall weight: 40,000 kg, Year of construction: 2026, *All of our products are made with care and covered for 1 year warranty!

*Installation and Operator Training FREE

Fabo tracked jaw crusher FTJ 11-60 is a complete mobile system which moves on hydraulically driven tracked system with 1 km/h speeds and combination of a vibrating grizzly feeder, 1000 x 600 mm jaw crusher, foldable stockpile conveyors, control unit and electric generator.

In today's conditions and technological processes, businesses are beginning to think about how to make their field of activity more efficient. As they make it more efficient, they always take into consideration factors such as the operationally of the machines they use, their low cost and staffing needs. Our Tracked Crushers can crush with high performance even on the most demanding mine sites with its specially designed body and compact structure. Customization can be done to our tracked systems by Jaw Crusher, Primary and Secondary Impact or Cone Crusher.

All necessary equipment for the process is combined only single chassis and processing equipment is driven by electrical motors. Overall production capacity is 100-250 tph.

Advantages of Tracked Crushers;

-Heavy-duty walking tracks can reach places where ordinary machines cannot reach.

-It has the appropriate dimensions and sound level to crush construction waste in the city.

-The fuel consumption of the generator and walking track units are very economical.

-System maintenance and management is very easy with latest technology control software.

Hsdpfx Absykru Terenh

TECHNICAL SPECIFICATIONS:

-Model: FTJ 11-60

-Production Capacity: 100 – 250 tons per hour

-Maximum Feeding: 550 mm

-Crusher Type: Jaw Crusher

-SIZE: 1000x600 mm

-Generator: 275 kva

-CSS Setting: 40 – 150 mm

-Weight: 40 tons

– Low investment and operation cost

– Zero substructure preparation

– Easiness at usage and maintenance

– Easy assembly and disassembly advantages.

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

Listing

Turkey

Turkey

9,823 km

Crushing equipment / jaw crusher

FABO Jaw Crusherhard stone crushing machine 200-300 t/h

Call

Condition: new, functionality: fully functional, fuel type: electric, color: other, Year of construction: 2026, *All of our products are made with care and covered for 1 year warranty!

*Installation and Operator Training FREE

New Generation FULLSTAR Series Mobile Crushing, Screening and Washing Plants are the most preferred machines in recent years thanks to easy and cost free installation. The first crushing process is performed with Primery Jaw Crusher, we can design with secondary impact crusher or cone crusher for second crushing stage according to the requirements of our customers. FULLSTAR 110 plant has been projected for the first time in the world by Fabo and provides crushing, screening and as well as to wash 0-5 mm sand at the same time on a single chassis. Our FULLSTAR model operates in closed Crushing circuit system and allows user to obtain 4 different final fractions up to 300 T / S capacity. We are manufacturing FULLSTAR-90 and 110 models which has 3 functions at the same time by trailed-type 2 chassis with its own tires.

FABO FULLSTAR-110 is a mobile type plant which perform crushing, washing and screening operations at the same time. This type of plant is very efficient as it is produced on a single chassis, which reduces both plant operation area and manufacture cost.

TECHNICAL SPECIFICATIONS:

- Model: FULLSTAR-110

- Production Capacity: 200-300 Tons Per Hour

- 1st Crusher: Primary Jaw Crusher – 1100x850mm

- 2nd Crusher: Secondary Impact Crusher – Rotor Ø1250x1500 mm

- Maximum Feeding Size: 800 mm

- Vibrating Screen Size and Deck: 1st Chassis: 2200x5500 mm

: 2nd Chassis: 1700x4500 mm(Grizzly)

¬- Screw Washer Size: 800x8000 mm (Twins Helix)

- Total Motor Power: 560 Kw

Hsdpsykrutofx Abrsnh

- Generator (optional): 700 kvA

- Plant Dimensions: 1st Chassis: 22000 x 4700 x 4700mm

: 2nd Chassis: 17500 x 4650 x 4600mm

FULLSTAR-110 IS A COMBINATION OF:

• Bunker(Hopper)

• Vibrating Grizzly Feeder(Bypass)

• Primary Jaw Crusher

• Secondary Impact Crusher

• High Stroke Type Vibrating Screen

• Screw Sand Washer (Single Helix)

• Folding type feeding, feedback, bypass and stock conveyor belts

• Hydraulic feet

• Mobile Chassis with axles and tires

• Fully Automation System

• Dust Suppression System

• Easy walking platforms for maintenance

• Diesel Generator (Optional)

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

Listing

Wiefelstede

Wiefelstede

7,607 km

Stone cutter

Stahlmax 6 cm Steine

Call

Condition: excellent (used), Slab cutter, paving stone cutter, stone cutter, paving stone cutter

-for effortless cutting of slabs and paving stones to length through the translation of the eccentric lever

Hsdpfx Aob A Rz Asbronh

-High stability with low weight

-precise guidance of the cutting blades

-Pendulum-mounted upper blade for cutting materials with a conical cross-section (curbstones)

-max. for 6 cm stones

-Weight: 10 kg

Listing

Turkey

Turkey

9,823 km

Crushing equipment / jaw crusher

FABO Jaw Crusherhard stone crushing machine 180-300 t/h

Call

Condition: new, functionality: fully functional, fuel type: electric, color: other, Year of construction: 2026, *All of our products are made with care and covered for 1 year warranty!

*Installation and Operator Training FREE

FABO MJK Series are mobile type Jaw crushing plants that is suitable for especially hard and abrasive stones and other type of stones with hardness level is high such as basalt, granite, gabbro. This model is also suitable for concrete recycle projects or coal mining projects.

TECHNICAL SPECIFICATIONS:

-Bunker: 20m3

-Production Capacity: 180-320 Tons Per Hour

-Crusher Type & Size: Jaw Crusher – 1100x850mm

-Maximum Feeding Size: 800mm

-Total Motor Power: 150 kW

MJK-110 is a combination of:

• Bunker(Hopper)

• Vibrating Grizzly Feeder (bypass)

• Primary Jaw Crusher

• Folding type bypass and stock conveyor belts

• Hydraulic feet

• Mobile Chassis with axles and tires

Hnsdpfxjyi Sa Ho Abrjh

• Fully Automation System

• Easy walking platforms for maintenance

• Diesel Generator (Optional)

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

Listing

Turkey

Turkey

9,823 km

Crushing equipment / jaw crusher

FABO Jaw Crusherhard stone crushing machine 150-300 t/h

Call

Condition: new, functionality: fully functional, fuel type: hybrid, color: yellow, overall weight: 55,000 kg, Year of construction: 2026, *All of our products are made with care and covered for 1 year warranty!

*Installation and Operator Training FREE

Fabo tracked jaw crusher FTJ 11-75 is a complete mobile system which moves on hydraulically driven tracked system with 1 km/h speeds and combination of a vibrated grizzly feeder, 1070x760 mm jaw crusher, foldable stockpile conveyors, control unit and electric generator.

In today's conditions and technological processes, businesses are beginning to think about how to make their field of activity more efficient. As they make it more efficient, they always take into consideration factors such as the operationally of the machines they use, their low cost and staffing needs. Our Tracked Crushers can crush with high performance even on the most demanding mine sites with its specially designed body and compact structure. Customization can be done to our tracked systems by Jaw Crusher, Primary and Secondary Impact or Cone Crusher.

All necessary equipment for the process is combined only single chassis and processing equipment is driven by electrical motors. Overall production capacity is 150-300 tph

Advantages of Tracked Crushers;

-Heavy-duty walking tracks can reach places where ordinary machines cannot reach.

-It has the appropriate dimensions and sound level to crush construction waste in the city.

-The fuel consumption of the generator and the travel track units is highly economical.

-System maintenance and management is very easy with latest technology control software.

TECHNICAL SPECIFICATIONS:

-Model: FTJ 11-75

-Production Capacity: 150 – 300 tons per hour

-Maximum Feeding: 700 mm

-Crusher Type: Jaw Crusher

-SIZE: 1070x760 mm

-Generator: 300 kva

-CSS Setting: 45 – 160 mm

-Weight: 55000 tons

-Dimensions: 2900x3500x14.500mm

Hnjdpfxsyi Sams Abroh

– Low investment and operation cost

– Zero substructure preparation

– Easiness at usage and maintenance

– Easy assembly and disassembly advantages.

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

Listing

Turkey

Turkey

9,823 km

Crushing equipment / jaw crusher

FABO Jaw Crusherstone crushing machine 320-600 t/h

Call

Condition: new, functionality: fully functional, power: 200 kW (271.92 HP), fuel type: electric, color: yellow, overall weight: 51,000 kg, Year of construction: 2026, *All of our products are made with care and covered for 1 year warranty!

*Installation and Operator Training FREE

Jaw Crushers generally crushes 60 to 600 tons per hour, according to their capacity. Higher capacity jaw crushers can be produced according to customers needed. The jaw crushers are generally used to crush the hardest rocks such as basalt, granite, and gabbro. With its strong and durable jaw structure, it has been one of the most preferred crushers of the mining industry for many years. With jaw adjustment you can get the desired product and desired capacities very well. It can be easily adjusted by its hydraulic pistons.

GENERAL SPECIFICATIONS AND FUTURES:

Hnodjyi Sagjpfx Abreh

-Belt-pulley drive system

-Jaw Plates manufactured from custom made cast high manganese steel with a high level of wear resistance

-Eccentric shaft manufactured from Cr, Ni, Mo alloyed forged steel

-Adjustable jaw opening with hydraulic setting

-Utilizing toggle plates for safety purposes in case of overloading

-The surfaces which exposed to abrasion are coated with lining plates

TECHNICAL SPECIFICATIONS:

• Model: FABO CLK-130

• Type: Primary Jaw Crusher

• Inlet Dimensions: 1300 X 1100 mm

• Jaw Opening: 120-280 mm

• Max Feeding: 1000 mm

• Capacity: 320-600 Ton Per Hour

• Motor: Heavy duty GAMAK, 200 Kw Bearings: Heavy duty SKF-FAG

• Weight: 51000 kg

• Including motor and safety guards.

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

Listing

Portugal

Portugal

7,265 km

Stone milling machine

CEIStoneCUT®MILL MASTER

Call

Condition: used, Year of construction: 2018, functionality: fully functional, StoneCUT® MILL MASTER Cutting and Milling Machine

- CNC cutting and milling machine with 6 interpolated axes

- Steel frame with concrete foundations

- Z-axis travel: 2,000 mm

- 40 HP motor (S6), ISO 50

- Continuous blade operation, 1,000 mm diameter (optionally up to 1,200 mm for short periods)

- Automatic tool tilting, 5th axis (0–140°)

- Automatic tool changer: 15 positions for milling tools + 1 blade position

- 1 × Easystone Premium Software license with virtual milling module

- Automatic lathe (6th axis) for parts up to 3,000 mm × 1,400 mm

- Remote control panel

Hnodsyb Suhopfx Abrjh

- Effective working area with 1,000 mm blade: 3,500 × 2,000 mm

- Vision system for slab positioning and defect detection

Operating modes

- As a cutting machine (like existing StoneCUT machines, connected to the same server)

- As a 5-axis milling machine

- As a 6-axis lathe

- Ready for diamond wire cutting upgrade

- Automatic lubrication system

- Anti-corrosion protection: sandblasted, metallized, and epoxy painted

- Installation and operator training included

2. Diamond Wire Cutting Upgrade

- The mechanical structure and electrical wiring are pre-configured to accommodate a diamond wire cutting tool as an upgrade.

- The diamond wire tool and corresponding software are not included in this offer.

Trust Seal

Dealers certified through Machineseeker

Listing

Schermbeck

Schermbeck

7,632 km

Stone cutting saw

HusqvarnaHusqvarna TS 400 F Steintrennsäge NEU

Call

Year of construction: 2026, condition: new, functionality: fully functional, Husqvarna TS 400 F Masonry Saw NEW

Husqvarna TS 400 F Masonry Saw – NEW | 125 mm Cutting Depth | 400 mm Blade | 230 V Electric Motor

Item No.: 965 14 81 01

Hnodpfeya Huysx Abrjh

Technical Specifications:

Manufacturer: Husqvarna

Model: TS 400 F

Condition: NEW

Operating Weight: 100 kg

Blade Diameter: 400 mm

Bore Diameter: 25.4 mm

Max. Cutting Depth: 125 mm

Motor: Electric

Voltage: 230 V

Water Tank: 40 litres

Starting System: Direct start

Highlights & Features:

- Includes 400 mm cutting blade – ready for immediate use

- Robust slurry collection tray for clean operation

- High-performance water pump for effective cooling

- Adjustable cutting table with angle stop

- Precise cuts in concrete, stone, and tiles

- Ergonomic design for comfortable operation

- Stable construction – ideally suited for tough job site conditions

- Made by Husqvarna – proven professional quality

Fields of Application:

✓ Structural and interior construction

✓ Paving and natural stone processing

✓ Tiling and stonemasonry businesses

✓ Landscaping and garden construction

✓ Refurbishment and renovation works

✓ Construction companies and municipalities

Location: Warehouse D-46514 Schermbeck (NRW) – Inspection & collection possible

Delivery: Nationwide & international delivery upon request

Other sizes & models available!

➡️ Masonry saws with various cutting depths & blade diameters – also available with 400 V or diesel drive

Buy Husqvarna Masonry Saw | TS 400 F NEW | Masonry Saw with Blade | Cutting Table with Angle Stop | 400 mm Masonry Saw | 125 mm Cutting Depth | Husqvarna TS Series | Electric Masonry Saw | Professional Stone Cutting Technology

Your reliable partner for cutting and separation technology:

Claudio Macagnino Construction Machinery & Commercial Vehicle Trading GmbH

➡️ Contact us now & secure immediately available new equipment!

We are happy to offer a virtual viewing of the machine via video call upon request.

Listing

Bitburg

Bitburg

7,719 km

Stone and tile bridge saw

ACHILLITAG80 - WS

Call

Year of construction: 2013, condition: excellent (used), Robust and compact bridge saw with fixed bridge for cutting stone tiles and slabs up to 800 mm long:

Special design of the beam for maximum cutting precision;

Hnedpei Akvvsfx Abreh

Water collection tray with built-in water circulation system for cooling the blade;

Robust and compact design.

Roller conveyor front

Roller conveyor rear

Saw blade size: 350 mm

Motor power: 2 KW

Voltage: 230 Volt

Weight: 173 kg

Mobile

Location: ex stock 54634 Bitburg

- immediately available -

Listing

Hilzingen-Duchtlingen

Hilzingen-Duchtlingen

7,991 km

Stone cutting saw

Fuhrer und BachmannT

Call

Condition: excellent (used), Stone cutting saw with diamond blade

Hnodsw Evznepfx Abrjh

Listing

Wiefelstede

Wiefelstede

7,607 km

Stone cutter

StahlAL 50

Call

Condition: excellent (used), Slab cutter, paving stone cutter, stone cutter, paving stone cutter

-for effortless cutting of slabs and paving stones to length through the translation of the eccentric lever

-High stability with low weight

Hsdpfxeb A I Sfs Abrsnh

- precise guidance of the cutting blades

-Pendulum-mounted upper blade for cutting materials with a conical cross-section (curbstones)

-Working length: 500 mm

-Weight: 100 kg

We make it easier for you to find: "stone forceps"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Stone Forceps (1,040)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you