Used Bearing for sale (2,855)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Kolonia Bilew

Kolonia Bilew

8,308 km

Male thread cutting machine

STF374KV5051GAS3 FOUR ROW TAPER ROLLERBEARINGS NSK

Call

Condition: new, STF374KV5051GAS3 FOUR ROW TAPER ROLLER BEARINGS NSK

NEW, NEVER USED

Main Demensions: 374,65 x 501,65 x 250,83 mm

Weight 156 kg

3 units available

WAREHOUSE LIQUIDATION

Kwedoqpfvbopfx Ab Teu

Listing

Germany

Germany

7,870 km

Blechbearbeitungszentrum

KaltenbachKF1606

Call

Condition: used, Year of construction: 2011, machine/vehicle number: 0401-250033, The Kaltenbach sheet metal processing center is ideally suited for steel construction, the steel trade and plant engineering.

Standard sheet metal plates up to 1600 mm wide, 6 - 60 mm thick and 6000 mm long as well as sheet metal strips and flat steels from a width of 100 mm can be moved safely through the system with the gripper measuring device. The length measuring system in the X-axis consists of a double gripper measuring carriage with a hydraulic collet.

An oxy-fuel cutting unit or a plasma cutting unit from Hypertherm are available for flame cutting. Sheets with a material thickness of up to 30 mm are usually cut with the plasma unit and thicker material thicknesses with the oxy-fuel unit. Both flame cutting units are equipped with remote ignition, flame monitoring and automatic height distance control.

A powerful cartridge filter system filters the cutting gases produced during plasma cutting.

The drilling spindle has a drive power of 26 kW and a spindle speed of 150 - 2000 rpm. A 6-position tool changer ensures fast and automatic tool changes.

The drilling unit is suitable for the use of carbide and solid carbide tools, which you can obtain from Nenok including the suitable nencool micro cooling lubricant. Center punching, countersinking and thread cutting is also possible with the suitable tools.

The machine is equipped with an embossing unit for embossing letters and numbers.

The sheet metal processing center is supplied with an infeed roller conveyor for 6,000 mm long metal sheets as well as a storage table and integrated rollers on the outfeed side. On the infeed side, the roller conveyor is equipped with 3 cross tractors.

Number of drilling spindles: 1 pc.

Drilling diameter: 8 - 50 mm

Cutting system: 1

Kwedpexzfnaefx Ab Tju

Machine weight approx.: 12 t

Panel width: 1,600 mm

Panel thickness: 6 - 60 mm

Listing

Bulgaria

Bulgaria

7,824 km

SCHÜCO Profilbearbeitungscenter

SCHÜCOProfilbearbeitungscenter

Call

Year of construction: 2001, condition: ready for operation (used), travel distance X-axis: 6,300 mm, travel distance Y-axis: 600 mm, travel distance Z-axis: 405 mm, overall weight: 6,000 kg, total height: 2,065 mm, product length (max.): 8,525 mm, This 4-axis SCHÜCO Profilbearbeitungscenter was manufactured in 2001. It features a travel range of 6,300 x 600 x 405 mm, continuous 180° A-axis rotation, and a high-speed capability of 24,000 rpm. Equipped with an HSK-40E tool holder and an 8+1 tool magazine, it ensures efficient machining. Consider the opportunity to buy this SCHÜCO Profilbearbeitungscenter. Contact us for more information about this machine.

• Voltage: 380 V, 50 Hz

• Power Consumption: 21 kW

• Operating Pressure: 0.8 MPa

• Speed: 24000 rpm

• Tool Holder: HSK-40E

• Tool Dimensions Cutter/Drill: mm

• Diameter of Side Milling Cutter: 200 mm

• Tool Magazine: 8 + 1

• Quick-change System: Available

• A-axis: 180° Continuous

• Traversing Speed X / Y / Z: 80 / 60 / 20 m/min A-axis

• Speed: 10800 rpm

• Number of Clamping Blocks: 8

• Positioning of Clamping Blocks: Automatic

• Profile Clamping: Horizontal

• Air Consumption: Max. 200 NL/min

• Operating Pressure: 6 - 8 bar

Kodpfx Abex U Dfao Tewu

• Cooling Unit with Temperature Control: Available

Dimensions

Machine Depth 2235 mm

Listing

Minden

Minden

7,714 km

Precision saddle slideways mounted on roller beari

Call

Condition: used, travel 150 mm

slide width 75 mm

height 32 mm

Ksdpfovimvfox Ab Towu

threaded spindle M8 x 1 with cross crank and scale

graduation 0.1 mm

capacity approx. 1.5 kg

space requirements length - 380 mm x width - 75 mm x height

- 32 mm

weight approx. 3.6 kg

- price per unit -

Auction

Ends in

d

h

min

s

Auction ended

Gelderland

Gelderland

7,560 km

Sheet metal shear

SafanHT 310-8 TS 100

Condition: ready for operation (used), functionality: fully functional, Year of construction: 2004, machine/vehicle number: B8820, actuation type: hydraulic, working width: 3,100 mm, sheet thickness (max.): 8 mm, power: 15 kW (20.39 HP), overall weight: 9,800 kg, TECHNICAL DETAILS

Sheet thickness max.: 8 mm

Working width max.: 3,100 mm

Back gauge depth: 1,000 mm

MACHINE DETAILS

Control: CNC

Power: 15.0 kW

Dimensions & Weight

Dimensions (L x W x H): 4,000 x 2,200 x 2,100 mm

Weight: 9,800 kg

Transport packages: 1

EQUIPMENT

Electric backgauge

Pneumatic sheet support system

Fixed finger guard

Motorized angle adjustment

Motorized cutting gap adjustment

Ball bearing table

Documentation

Kodpeyh Nl Isfx Ab Towu

CE marking

Auction

Ends in

d

h

min

s

Auction ended

Niedersachsen

Niedersachsen

7,585 km

Sheet metal bending machine with 4 rollers

SAHINLERSHV 4R OHS 2070 x 320

Condition: ready for operation (used), functionality: fully functional, Year of construction: 2017, machine/vehicle number: 25498, roller (bottom) diameter: 320 mm, roller (top) diameter: 320 mm, side roll diameter: 260 mm, working width: 2,070 mm, sheet thickness (max.): 25 mm, TECHNICAL DETAILS

Sheet width: 2,070 mm

Sheet thickness: 25 mm

Bending capacity: 18 mm

Top roller diameter: 320 mm

Side roller diameter: 260 mm

Lower roller diameter: 320 mm

MACHINE DETAILS

Total power supply: 26 kW

Dimensions & Weight

Space requirement: approx. 4,700 x 2,000 x 2,200 mm

Machine weight: approx. 8,100 kg

EQUIPMENT

Hydraulic lateral roller adjustment

Conical bending device

2 driven rollers

Kwedpfeygw Iksx Ab Tju

Hardened rollers

Hydraulic drop-end bearing

Mobile control panel

Foot switch

Safety device

CE marking

Listing

Chicago

Chicago

875 km

5-AXIS HEAVY DUTY PRECISION CNC ROUTER

QUINTAXQ5H

Call

Year of construction: 2009, condition: excellent (used), functionality: fully functional, QUINTAX (USA) Q5H 5-AXIS HEAVY DUTY PRECISION CNC ROUTER WITH (2) 6' X 10' TABLES

CNC FAGOR 8070

2 Tables Dim : 1830 mm x 3040 mm each 72" x 120"

Travels X = 4400 mm (longt) 173.2"

Y = 3800 mm (cross) 149.6"

Z = 1500 mm (vertical) ( Limitation under the cross rail ) 59.1"

C = +/- 360"

B = +/- 120"

Spindle speeds maxi 21.000 t/min

Tool attachment : HSK63F

Toolchanger : 20 station

Coolant installation

Double 72" (1.83 M) X 120" (3.04 M) Tables with 37 mm Steel Top Plates.

1.5 M Z-Axis Height. ..59.1"

Kwedpsyf Nugofx Ab Tou

30 kw. 40HP HSK 63F Tool Change Style Spindle, Liquid Cooled, Air Clamping including Chiller Package.

Central Lube System with Low-Level Switch.

AC Variable Speed Inverter Drive for Spindle.

Hand-held Teach Pendant.

Fagor 8070 5-Axis CNC Control includes 512 MB RAM, 40 GB Hard Drive, 11" Color Monitor, Ethernet Port; Telediagnostics; CD Drive/USB Port.

Fagor AC Digital Servo Package with Absolute Encoding.

20-Station Automatic Rotary Carousel Tool Changer.

63 x 40 mm Ball Screws and Ball Nuts.

45 mm Rails and Linear Bearings.

12" x 16" Tube Construction Plus Polymer Composite Filled Bridge Tube Supports and Base.

Dust Collection Nozzle, Hoses for 5-Axis.

Catia 5 Postprocessor.

Renishaw Toolsetting Probe.

Fagor Linear Scales on X, Y, U, V, Axis and Rotary Feedback on B and C Axis.

Continuous C- Axis.

Renishaw MP-10 Optical Probe and Software.

15 KW 20 HP Rated 170 M/3 Minute at 254 mm Water Gauge. Includes Hoses and Controls

Perimeter Light Curtain System.

additional spare new spindle included

Listing

Chicago

Chicago

875 km

Universal machining center

OkumaMU500VA

Call

Condition: excellent (used), Year of construction: 2007, functionality: fully functional, travel distance X-axis: 1,250 mm, travel distance Y-axis: 660 mm, travel distance Z-axis: 540 mm, rapid traverse X-axis: 40 m/min, rapid traverse Y-axis: 40 m/min, rapid traverse Z-axis: 32 m/min, feed rate X-axis: 32 m/min, feed rate Y-axis: 32 m/min, feed rate Z-axis: 32 m/min, controller manufacturer: Okuma, controller model: OSP P200M-H, rotary table diameter: 500 mm, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, Okuma MU500VA CNC Vertical Machining Centre (2007)

Equipped with OKUMA OSP P200M-H CNC CONTROL

20" ROTARY PLATEN

4TH AND 5TH AXIS BUILT IN TRUNION

32 POSITION AUTOMATIC TOOL CHANGER

COOLANT THRU SPINDLE

TOOL LENGTH MEASURING

Travels

X-axis (saddle left/right) – 1250mm, Y-axis (pallet front/back) – 660mm, Z-axis (spindle up/down) – 540mm, A-axis – +20~-110 deg., C-axis – 360 deg., Table surface to spindle nose – 127~667mm

Table

Table size – ø500mm, Max work size – ø730xh500, Floor to table top – 1073mm, Max load capacity – 500kg

Spindle

Spindle speed – 15000rpm, Turning specification – C-axis table 1000rpm , No. of spindle ranges – Infinitely variable, Tapered bore – 7/24 taper No.40, Bearing dia – ø70mm

Feed

Rapid traverse – X-Y: 40m/min, Z:32m/min, Rapid traverse (A-C) – 18,000 deg/min, Cutting feed rate – X-Y-Z: 32m/min

Motors

Spindle (10min/cont) – 11/7.5kW

ATC

Tool shank type – MAS BT40 Big plus, Retention knob type – MAS 2, Tool capacity – 32, Max. tool dia (w/ adjacent tool) – ø90mm, Max. tool dia (w/o adjacent tool) – ø125mm, Max. tool length – 400mm, Max. tool mass – 8kg, Tool selection – Memory random

Kwsdsyf Ncqopfx Ab Tsu

ATC

Retention knob type – MAS 2, Tool capacity – 32, Max. tool dia (w/ adjacent tool) – ø90mm, Max. tool dia (w/o adjacent tool) – ø125mm, Max. tool length – 400mm, Max. tool mass – 8kg, Tool selection – Memory random

Listing

United States

United States

0 km

Slitting line

Braner slitting lines72”x 0.5” x 60,000Lb slitting line

Call

Condition: used, 72”x 0.5” x 60,000Lb Braner Turret Type Loop Slitting Line

Braner Turret Type Loop Slitting Line is used for coil metal cross cutting with maximum width 72”, maximum 0,5” metal thcikness and 60,000Lb coil capacity

Make: Braner

Year New: 1996

Material Thickness: .060″ – .500″

Material Width: 12″ – 72″

Coil Weight: 60,000Lb

Line Speed: 120 – 250 feet per minute

Coil ID: 20″ – 24″

Coil OD: 75″

Slitting Cap: .500″ / 4 cuts – .125″ / 40 cuts

Entry L-Type Coil Car

Hydraulic Lift & Traverse

Self Contained Hydraulics

Control Panel

Mandrel Uncoiler

Powered Hold – Down Roll

Outboard Bearing Support

Hydraulic Feed-Up Drive

Water Cooled Brake

Hydraulic Peeling Table

Driven Entry Pinch Rolls

Kwedjrn Sqhjpfx Ab Tju

Adjustable Edge Guides

Entry Mechanical Crop Shear

Two Turret Type Slitting Heads

Arbor Diameter: 12″

Powered Arbor Adjustment

Powered Head Rotation

Motor: 100HP DC Drive

Lots of Knives & Tooling

Two (2) Scrap Winders

Powered Open / Close

Heavy Duty Design

Looping Pit Cross Over Table

Drag Board Tension Stand

Material Feeding Table

Recoiler

Hydraulic Drum

Powered Push Off

Hydraulic Over-Arm Separator

Outboard Bearing Support

300HP DC Motor Drive

Exit L-Type Coil Car

Hydraulic Lift & Traverse

Self Contained Hydraulics

Upgraded Siemens Digital Drives, Electrics, Controls, Knives & Tooling

Listing

Idaho

Idaho

1,123 km

Cnc lathe

HEMBRUGMikroturn 100 CNC

Call

Condition: excellent (used), Year of construction: 2004, operating hours: 1,000 h, functionality: fully functional, turning diameter over cross slide: 380 mm, turning length: 350 mm, turning diameter: 200 mm, travel distance X-axis: 240 mm, rapid traverse X-axis: 12 m/min, Hembrug Mill-Turn Machine

Model: Slantbed Mikroturn 100 CNC

Siemens 840D Control

Approximate Actual Run Time Hours: 1,000

Kwjdpfx Aowcfgbjb Tju

Hydeostatic Spindle

Hydrostatic Ways

Scale Feedback

Suspended Granite Bed

Garnite Spindle Housing

Coolant Pump

Coolant Circulation Pump

Pneumatic Bearing Purge

Hydraulic Temperature Control

Coolant Temperature Control

Return Oil Pump and Reservoir for Remote Location of Hydraulic / Cooling Unit.

Options & Additional Purchased Features:

Tailstock

Vacuum Pump for Vacuum Chucking

Programable Controlled Spray Mist

C-Axis Milling / Drilling

Renishaw Tool Touch Probe

Non-Contact Tool

Incoming Air Dryer / Filter

Thousands of Dollars of Brand New Tooling:

Live Center

Tailstock Taper Adapter

8” Micro-Centric Pneumatic Chuck

3 Sauter Straight Live tooling heads

2 Sauter 90 degree Live tooling heads

1 Special VDI offset Tooling holder

16 VDI Tool Holders for Turning, boring, and on center drilling.

Tool Pick-up Video System

Additional Backup Hard Drive with Software Fully Loaded and Tested.

Extra Siemens Control Pannel

Complete Set of Manuals

Machine Upgrades I added at additional cost.

New Digital Hard Drive

New Backup Hard Drive with software already loaded, plug and play ready, no downtime.

New Z-Axis Heidenhain Scale

Rewound Hydraulic Pump Motor, factory motor was running too hot for my liking.

Replaced Operator Panel, back light on monitor went out, have the original, back light needs replacing.

50 Foot Extended Wiring Harness For Remote Location of Hydraulic / Cooling Unit.

Listing

Oak Forest

Oak Forest

850 km

Cnc lathe

TraubTNX 65/42

Call

Condition: good (used), Year of construction: 2007, Traub TNX 65/42 Milling and Turning Center

Mfd. 2007

Serial #7060107

Commissioned in 2010

TX 8i-S control (Mitsubishi/Traub based control with Mitsubishi drives and motors)

15 CNC axis’s

(4) X-Y-Z turrets with 10 positions each. Up to 20 tools per turret

Kwodpfxoq Npqmj Ab Tou

65 mm thru hole main and sub spindle (sub spindle has coolant flush)

Foot pedal control for clamp/unclamp of spindle chucks

Servo driven gantry receiver

Hydraulic swivel w/ pneumatic finished part and bar remnant gripper

Finished part conveyor belt

RESY paper band coolant filter

Knoll Coolant tank with BKW refrigerated coolant temperature control

20 Bar High pressure and 8 Bar Low pressure coolant pumps

Knoll chip conveyor

FMB Turbo 5-55 magazine bar feeder (new in 2010)

2) Single stick turning tool holders

2) Double stick turning tool holders

1) Cut-off tool holder

1) Overdriven double radial live ER Collet tool holder

1) Overdriven radial live ER Collet tool holder

4) Radial live ER Collet tool holders

1) Radial live End Mill tool holder

1) Angle adjustable live ER Collet tool holder

2) Radial live Shell Mill tool holders

2) Axial live End Mill tool holders

6) Axial live ER Collet tool holders

43) Additional tool holders on separate list (see supplemental attachment)

Hainbuch main spindle collet chuck

Rohm sub spindle 2 jaw chuck

2 Spare sets of spare Z-axis ball screws and bearing packs.

Listing

Warren

Warren

1,239 km

Cylindrical Grinding Machine

ToyodaGL32M-63

Call

Condition: good (used), Year of construction: 2013, TOYODA (JTEKT) GL32M-63 CNC UNIVERSAL CYLINDRICAL GRINDER

Equipped with:

CBN Grinding Wheel

Flagging

Steady Rest

Workhead Mounted Rotary Dresser

Marposs P3SE System Monitoring

Toyoda In Process Gaging

Marposs E20N Acoustic Controller

Air Gap Eliminator

Workpiece Collision Control

Coolant Pumps W/Magnetic Separator

Pendant Control

RH Workhead with Center

LH Workhead with Center

Work Rests

Worklight

Light Curtains

Stacklight

Extra Wheels

Specifications:

-Grind Center to Floor: 1,000 mm

-Swing Over Table: 320 mm

-Distance Between Centers: 630 mm

-Grinding Diameter Range: 10 - 150 mm

-Floor Space (Base machine w/auxiliary equipment): 3,400 x 5,000 mm

-Net Machine Mass (approx.): 10,500 kg

Grinding Wheel:

-Type: CBN Wheel

-Wheel Size (OD): 350 mm

-Maximum Wheel Width: 60 mm

-Surface Speed: 120 m/s

Wheelhead:

-Spindle Bearing: TOYODA STAT Bearing

Kwjdpfertrzpox Ab Tju

-Slide: V and Flat

-Feed System: Ballscrew

-Rapid Feed (on diameter): 30 m/min

-Minimum Incsrement (on diameter): 0.0001 mm

Workhead:

-Type: Dead Spindle

-Work Speed (Max): 500 rpm

-Center Taper: MT #4

Footstock:

-Type: Hydraulic

-Taper Compensation: Manual

-Maximum Center Retraction: 60 mm

-Center Taper: MT #4

Motors:

-Wheel Drive Motor: 15 kW, Belt-Drive

-Wheelhead Feed Servomotor: 1.3 kW

Tank Capacities:

-Wheel Spindle Lubrication Oil: 80 L

-Hydraulic/Lubrication Oil: 20 L

Listing

Warren

Warren

1,239 km

Bevel gear testing machine

GleasonModel 61

Call

Condition: good (used), workpiece diameter between centers: 2,286 mm, The No. 61 Angular Hypoid Tester is designed to test large bevel and hypoid gears up to 90" diameter and with shaft angles from 0 - 135 degrees. Spur, helical and internal gears can also be accommodated.

The drive or pinion spindle can be rotated in either direction at a recommended spindle speed of 600 RPM. It is mounted in a head which is vertically adjustable on a column, so that the spindle can be offset either above or below the center line of the gear spindle for testing hypoid gears. The pinion head column is adjustable angularly in a horizontal plane to permit testing of gears of any shaft angle from 0 - 135 degrees.

Specifications:

Centerline of Drive Spindle to Nose of Brake Spindle

(90 degrees shaft angle and without face plate): 38-1/2" Max. / 7-5/8" Min.

Centerline of Brake Spindle to Nose of Drive Spindle

(90 degrees shaft angle and without face plate): 60" Max. / 10" Min.

Centerline of Brake Spindle to Nose of Drive Spindle

(90 degrees shaft angle and with 54" face plate): 60" Max. / 28" Min.

Centerline of Brake Spindle to Centerline of Drive Spindle

(For Spur Gears): 56" Max. / 6" Min.

Ksdpfx Absrtrzde Towu

Distance Between Nose of Brake Spindle and Nose of

Drive Spindle (for spur gears): 36-1/2" Max. / 0" Min.

Offset of Drive Spindle Either Above or Below Centerline of Brake Spindle: 10"

Range of Shaft Angles: 0 - 360 Degrees

Maximum Diameter of Gear: 90"

Diameter of Face Plate: 54"

Outboard Bearing: 3" Diameter Hole

Spindles:

RPM of Drive Spindle Pulley Set No. 1: 100 - 400

RPM of Drive Spindle Pulley Set No. 2: 250 - 600

Diameter of Taper Hole (large end): 6"

Taper Per Foot: 3/4"

Depth of Taper: 8"

Hole Through Spindle: 5-1/2"

Net Weight of Machine: 20,000#

Net Weight of Machine W/Outboard Support and Bed Plate: 24,000#

Listing

Warren

Warren

1,239 km

Double face grinding machine

GiustinaR242

Call

Condition: good (used), Year of construction: 1998, grinding wheel diameter: 915 mm, overall weight: 14,000 kg, GIUSTINA Grinder R242 to ground big bearings (up to 800mm). All machine's actions are controlled by Bosch Control.

Kwsdpfsrtr D Isx Ab Tsu

Beside controlling parts grinding process, the NC programs are also an operator guide for the machine set up and a source of information about wheel wear, thus allowing the operator to check wheels without opening the hood.

Equipped with:

Bosch CNC Control

Specifications:

Wheel Rotation Axis: Horizontal

Grinding Wheel Size (OD): 915 mm

Grinding Wheel Size, Usable Width: 65 mm

Grinding Wheel Size, Peripheral Speed: 30 ms

Spindle Motors: 75 kw

Grinding Feedrate: 0.1 - 1000 mm/min

Spindle Type: Moving Quill

Angular Contact Spindle Bearings (Precision): ABEC-7 (ISO4)

Slide Position Accuracy: 0.001 mm

Coolant Flow Rate: 600 l/min

Work Capacity (Approx) Rotary: 20 -200 Dia. In.

Listing

Canada

Canada

2,464 km

CNC Lathe - Inclined Bed Type

NILES-SIMMONSN30 - 3MC-2500

Call

Condition: used, Year of construction: 2007, turning length 2500 mm

control Sinumerik 840 D

spindle head A 11

tool numbers 48

swing diameter over bed slide 750 mm

swing over bed 780 mm

c-axis 0,1-30 1/min

diameter of quill 160 mm

taper bore MK 5

tool length - max. 500 mm

Kodpfxowwaruj Ab Towu

weight of tools max. 15 kg

weight of the machine ca. 27 t

dimensions of the machine ca. 8,4 x 4,0 x 2,5 m

Technical details:

Nominal turning length: 2,500 mm

Swing diameter over bed slide: 750 mm

Swing diameter over bed: 780 mm

Working height: 1,300 mm

Spindle head to DIN 55026: A 11

Bore through: 123 mm

Diameter in front bearing: 200 mm

Oriented spindle stop: 0-359 degrees

Drive power at 100/60 % duty cycle: 37/45 kW

Total speed range: 10-2,500 1/min

Number of speed ranges: 2

Speed range I: 10-775 1/min

Speed range II: 20-2,500 1/min

Max. torque at 60 % duty cycle: 2,500 rpm. Torque at 60 % ED: 2,083 Nm (up to

186 rpm)

Listing

Wallasey

Wallasey

6,956 km

Unused 15,000 litre Sinclair Stainless Fementer Vessel

SINCLAIR STAINLESS15m3 Fermenter Vessel

Call

Condition: used, Reportedly unused Sinclair Stainless Fabrications approximately 15,000 litre capacity vertical 316L stainless steel fermenter/bioreactor with (4) zone limpet coil jacket. Unit has a welded dished top and bottom. Internal rated -1/+3barG internal operating at 0-159degC. Internal coils rated -1/+5barG and limpet coils rated -1/+5barG operating at 0-159degC.

Mixer Drive = Nominal Speed: 100 RPM; Motor: 55KW 1500RPM 250 IE3 IP55 3PH

230/400V 50HZ; Gearbox Input Coupling: Integral w/Gearbox; External Paint

Finish: Standard Paint; Color: Blue RAL5005

Mounting = Arrangement: Structural Nozzle w/Flange

Shaft Seal = Mechanical Seal: Custom Seal - No Bearing Balanced (AES CDM C/SiC/C/SiC-AFLAS(3) - Double Mechanical Seal. )

Mounting Flange = Flange Size: DN400 [16”]; Flange Class: CL-150; Flange

Material: 316 Stainless Steel Face & Core

Shaft = Shaft Diameter: 4-1/2”; Shaft Extension: 6754 mm; Shaft Material: 316

Stainless Steel

Impellers = Impeller #1: 921 mm BT-6; Impeller #2: 959 mm W-4; Impeller #3: 959

mm W-4; Impeller #4: 959 mm W-4; Impeller Material: 316 Stainless Steel

Mixer Options = Gearbox with Food Grade Lubricants

Design Compliance = Machinery Directive 2006/42/EU

Kwsdjyln E Rjpfx Ab Tou

Specifications:

Capacity: 15,000 L

Type of stainless: 316L

Internal Pressure: -13 bar

Internal Temperature: 0°C

Jacket Pressure: -15 bar

Jacket Temperature: 0°C

Diameter: 1,800 mm

Straight Side: 5,900 mm

Legs/Lugs: Mounted on (4) legs

Weight: 6720kg

Dimensions: 2400mm diameter x 7500mm height

Listing

Écouflant

Écouflant

7,423 km

Center lathe

sidamoTP 1000

Call

Condition: good (used), Specifications:

- Conventional lathe

- Digital display (230V single-phase power supply)

- Longitudinal travel 850 mm, cross travel 205 mm, top slide travel 95 mm

- Programming of 200 auxiliary zero points

- Tool magazine for 200 tools

- Taper measurement

- Reinforced prismatic bed, made of grey cast iron, induction hardened and ground

- CAMLOCK D1-4'' type spindle nose

- Spindle hardened and ground, oil bath lubricated, mounted on 2 high-precision tapered roller bearings

- Turning accuracy < 0.015 mm at the chuck

- Gearbox gears hardened and ground, oil bath lubricated

- Backlash-free slides, adjustable via gib screws

- Quick change of feeds by mechanical gearbox

- Automatic longitudinal and cross feeds

- Simultaneous control of the spindle and leadscrew

- Lateral movement of tailstock +/- 10 mm

- Maximum swing over carriage: 212 mm

- Maximum swing in gap bed: 491 mm

Kjdpeyl Sl Ijfx Ab Towu

- Left/right spindle rotation reversal on apron control

- Jog function

- Resettable graduated dials on all axes

Listing

Dortmund

Dortmund

7,679 km

CNC turning and milling center

GILDEMEISTERCTX 600-2000

Call

Condition: excellent (used), Year of construction: 1995, Centre Height: 330 mm

Centre Distance: 2,000 mm

Working Area:

Max. Swing Diameter over Bed Cover: 650 mm

Max. Swing Diameter over Cross Slide: 360 mm

Main Spindle:

Spindle Diameter at Front Bearing: 140 mm

Spindle Bore: 107 mm

Main Drive: 58.5 kW

2-step Speed Range: 4 – 750 rpm / 750 – 3,060 rpm

Feed Drive:

Rapid Traverse X/Z Axis: 10/10 m/min

Tool Turret:

Number of Tool Stations: 12

Of which Driven Tool Stations: 6

Tool Shank Holder: VDI 50 mm

Dimensions / Weight:

Footprint (L x W x H): approx. 6,400 x 2,150 x 2,000 mm

Weight: 9,400 kg

Accessories / Special Features:

• CNC path control HEIDENHAIN TurnPlus EP 90 with color display

• Spindle orientation, C-axis

• 12-station turret, VDI 50, including 6 driven tools in turret, brand SAUTER, DIN 5482 B 20x17, max. speed 3,000 rpm

Kedox Sx Htepfx Ab Tswu

• Hydraulic 3-jaw chuck, Ø 315 mm, with various chuck jaws

• Hydraulic tailstock with drag device

• Hydraulic quill actuation

• LTA make air extraction system

• Various VDI 50 tool holders

• CE compliant

In 08 / 2025, the following parts were replaced by GILDEMEISTER service:

1 servo motor, 1 AC servo controller inverter power module for 2 axes, 1 Simodrive power module, 1 single regeneration module,

1 control insert for 1 axis, 1 control module for 2 axes of the inverter servo drive, 1 Simodrive power module for 1-axis motor.

Siegfried Volz Werkzeugmaschinen

Rüschebrinkstr. 151-153

DE - 44143 Dortmund - Wambel

Listing

Herzlake

Herzlake

7,613 km

Swap body trailer

KRONEBaustoff-Flat

Call

Condition: used, maximum load weight: 13,580 kg, overall weight: 16,000 kg, first registration: 01/2013, loading space length: 7,300 mm, loading space width: 2,480 mm, loading space height: 2,470 mm, total width: 2,550 mm, total height: 2,750 mm, Year of construction: 2013, Wagon No. G0113396 – Manufacturer: Krone. * Forklift accessible

* Fixed support legs

* Prepared for rail loading

* Lashing pockets

Kedpfx Aeylvvwsb Tswu

* Lashing options

Storage container is weatherproof, secure against unauthorized access, floor in good condition, no further repairs required. Delivery time: AVAILABLE IMMEDIATELY. Undercarriage (KTL) coating shows signs of use. Localized rust present on components of the swap body. Deformations / impact marks on some parts – see photos. Swap bodies bear lettering/markings (see pictures). Multiple units available!

Dimensions are approximate. Offer subject to prior sale, prices net ex location D-59302 Oelde. Further details upon request via phone or email:

Auction

Auction starting soon

Baden-Württemberg

Baden-Württemberg

7,894 km

Thread milling machine

SCHIESS-KOPPFK 12.32 CNC

Year of construction: 1990, condition: ready for operation (used), functionality: fully functional, controller model: SIEMENS SINUMERIK 810, workpiece length (max.): 830 mm, milling spindle speed (min.): 100 rpm, milling spindle speed (max.): 4,500 rpm, mount diameter: 78 mm, TECHNICAL DETAILS

Milling spindle speed range: 100 - 4,500 rpm

Maximum workpiece length: 830 mm

Maximum workpiece diameter with double tooling: 135 mm

Spindle mount: 2 x SK 40

Spindle nose: DIN 55026 Size 5

Mounting diameter: 78 mm

Center distance: 135 mm

Front bearing diameter: 110 mm

Workpiece Slide (X-Axis)

Workpiece slide travel: 810 mm

Max. feed rate: 6 m/min

Clamping surface: 200 x 1,750 mm

Tool Post (Z-Axis)

Tool slide travel: 120 mm

Max. feed rate: 2 m/min

Tool post adjustment: 200 mm

Tailstock

Tailstock quill travel: 100 mm

Morse taper: 3 MT

Centre height: 260 mm

Quill center distance: 135 mm

Steady rest through-hole: 40 - 80 mm

MACHINE DETAILS

Drive power: 5100 W

Kodsyl U Tuspfx Ab Tewu

Control system: SIEMENS SINUMERIK 810

Dimensions & Weight

Dimensions (L x W x H): approx. 3.20 x 2.66 x 1.76 m

Machine weight: approx. 6.5 t

EQUIPMENT

Various tool holders

Steady rests

Centre points, medium

Coolant system

Listing

Pulheim

Pulheim

7,670 km

Rotary arm winder

KVK 5

Call

Year of construction: 2025, condition: new, Our KVK 5 is a semi-automatic rotary arm wrapper, which has the advantage over our wrappers with turntable that your pallets can be placed at ground level for the wrapping process. Equally ideal for light, unstable and heavy packaged goods, as there are no centrifugal forces and no load-bearing capacity to consider.

In addition, the KVK 5 model is equipped with a pre-stretch system for 250% elongation. This pre-stretching system allows you to produce up to 3.5 m of film on the pallet from 1 m of film on the roll and reduce your material consumption enormously.

With the KVK 5, there is only minimal contact tension, so that even light packages are not pulled off the pallet.

The only thing that still has to be done manually with this wrapper is applying and cutting the film.

The machine weight of almost 1000 kg shows how solid and stable this wrapper is.

With its rotating arm, it can wrap pallets up to a maximum dimension of 1.00 x 1.20 x 2.40 m.

With adjustable speeds of the rotating arm and film carriage, as well as a pre-stretching unit adjustable via potentiometer, you can adapt the automated wrapping perfectly to your product. Automatic recognition of your pallets (via photocell) is just as much a matter of course as adjustable head and foot wrapping. Programs are available for "up only" wrapping, "up & down" (cross wrapping) and "rainproof" wrapping.

In addition to an optional photocell for the detection of dark packing goods or black film, this wrapper can be supplied either for wall mounting or with the feet shown.

We recommend this model if it is important to you not to have to overcome a ramp with your goods - for example because they are too heavy or unstable. The fact that the rotating arm in this design rotates around the pallet also avoids any centrifugal force. Together with the low contact tension of the pre-stretch system, this also makes the KVK 5 ideal for very light packaged goods.

For further information we have attached the technical data sheet as PDF to this advertisement !

Kwedpfsylwz Uex Ab Tju

Trust Seal

Dealers certified through Machineseeker

Listing

Ahaus

Ahaus

7,617 km

Plate Bending Machine - 4 Rolls

ROCCIAHR4WE 2510

Call

Condition: excellent (used), Year of construction: 2014, sheet width 2600 mm

Ksdpfx Abeylpz Ho Tewu

plate thickness 10.0 mm ST

pre-bending 8.0 mm ST

diameter of upper rolls ~ 220 mm

side roll diameter ~ 170 mm

diameter of lower rolls ~ 190 mm

Control konv.

oil volume 80.0 Liter

voltage 380 V

total power requirement 5.5 kW

weight ca. 5000 kg

Dimensions (only the machine) ca. 3500 x 1550 x 1400 mm

very good condition (!!)

current new price incl. accessories approx. 120.000 Euro

special price on request

Equipment:

- robust electro-hydraulic 4-roll round bending machine

- 4-roll concept offers a wide range of bending and rounding options

- Swivel-mounted control unit

* Operation - control of all rollers or machine axes

* Digital position display of the side rollers

* Manual operation via JOY sticks

- Two central rollers are driven directly via hydraulic motors

- Conical rolling possible by tilting the rollers

- Parallelism of the side rollers via torsion shafts

- Bending on both sides

- diameters of up to 1.1 times the top roller diameter are possible

- Forged and hardened rollers with a hardness of 53-55 HRC

- Low-maintenance, stable machine concept

- Permanent lubrication of all bearings

- Sturdy welded steel construction

- electro-hydraulic hinged bearing for easy pipe removal

- pressure gauge / pressure display for the rollers

- Safety device (safety line with switch unit)

- operating instructions

* Special accessories included :

- ROCCI height-adjustable center support

* for large pipe diameters

- ROCCI electro-motorized material feed table

* motorized sheet feeding material support surface

Listing

Ahaus

Ahaus

7,617 km

Folding Machine

FALKEN // ISITANICM 2020 x 2.0

Call

Condition: as good as new (ex-display), Year of construction: 2025, sheet width 2020 mm

plate thickness 2.0 mm

distance between columns 2100 mm

Kwjdpjxab S Ssfx Ab Teu

angle adjustable from - to 130 Grad

total power requirement manuell

weight of the machine ca. 1850 kg.

range L-W-H 3100 x 725 x 1350 mm

Exhibition machine - like NEW

not yet in use (!!)

Special price on request

Equipment:

- heavy/manual swivel bending machine, with counterweight

- long service life thanks to robust welded steel construction

- universally applicable for metalworking shops and craft businesses

- quick and easy bending process using a bow handle

- all bearings and guides in a stable design

- easy adjustment of the upper beam for efficient work

- manual adjustment of the lower beam

- manually adjustable angle fixed stop with analogue degree display

Listing

Ahaus

Ahaus

7,617 km

Lathe-conventional-electronic

KNUTHDL 425/4000 S

Call

Condition: ready for operation (used), Year of construction: 2017, turning length 4000 mm

turning diameter 850 mm

turning dia. in gap 1150 mm

turning diameter over slide 520 mm

turning speeds 5.0 - 630 U/min

quill: 6 MK

quill travel 250 mm

spindle bore 100 mm

workpiece weight max. 4000 kg

bed width 600 mm

travel -x axis 500 mm

travel -z axis 3700 mm

rapid traverse X 1800 mm/min

rapid traverse Z 3640 mm/min

feeds X : 0.04 - 4.8 mm/min

feeds Z : 0.08 - 9.6 mm/min

feeds Z1 : 0.02 - 2.4 mm/min

engine output 20.0 kW

weight of the machine ca. 6800 kg.

dimensions 6150 x 1500 x 1500 mm

good / well-maintained condition (!!)

original price at the time approx. 65.000 euros

special price on request

Description:

- particularly heavy, heavily ribbed and wide machine bed

- in a rigid one-piece monoblock design

- induction-hardened and ground guide prisms

- guarantee long-term accuracy and minimal wear

- solid headstock

- with high-precision, tapered roller bearing main spindle

. and 100 mm spindle bore

- excellent smooth running at maximum spindle speed

- joystick switch for X and Z feed directly on the support

- manually switched 4-stage countershaft gear,

Kwsdpfx Abexabh Tj Tou

- powerful main spindle motor enables exact adjustment of the speed

. and high torque for heavy machining

- rapid traverse for X and Z axes enables quick positioning of the support

. and reduces idle times

- adjustable overload clutch in the lock case protects the feed mechanism

. against damage and failures

- central, handy control for feeds and thread pitches

- the feed gear offers a wide range of

. diametric, inch, module and metric threads

- support and top slide are designed for large cutting forces

- higher working precision

- user-friendly functions

Scope of delivery:

- SINO position indicator

- TOS 3x jaw chuck .. Ø 400 mm

- 4-jaw faceplate chuck Ø 800 mm

- 4-way tool holder

- Fixed steady rest 40-350 mm

- Follow-on steady rest 30-120 mm

- Fixed centering point

- Reducing sleeves

- Chuck protection

- Coolant device

- Machine leveling feet

- Work light

- Operating tools

- Operating instructions

Clickout

Langenfeld (Rheinland)

Langenfeld (Rheinland)

7,672 km

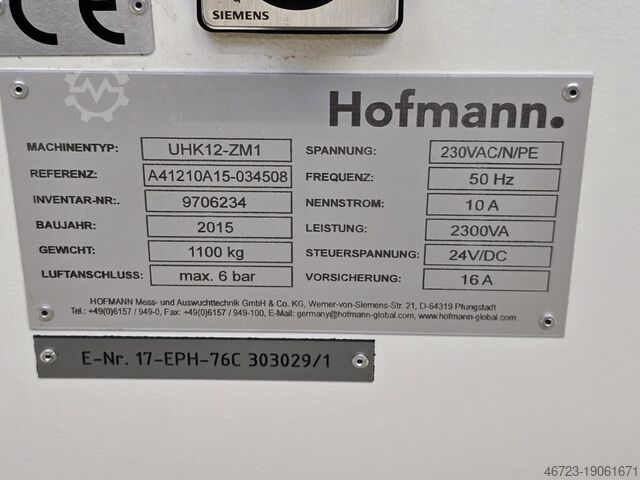

Balancing machine

HofmannUHK 12 - ZM1

Condition: good (used), Year of construction: 2015, Lot consists of:

(1) CNC Crankshaft Control Balancing Machine

Position consists of:

(1) CNC crankshaft control balancing machine

Kodpfxjwg A Sio Ab Tewu

Technical Details/Technical Details:

English:

max crankshaft length 800mm, max dia 300/200mm, max weight 50kg, bearing dia 30 - 80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH,:1.3x1x1.5m

Parts Gantry System and/or Cranes are not included in the scope.

German:

Maximum crankshaft length 800mm, maximum diameter 300/200mm, maximum weight 50kg, bearing diameter 30-80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH: 1.3x1x1.5m

Parts gantry system and/or cranes are not included in delivery.

We make it easier for you to find: "bearing"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Bearing (2,855)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you