Used Internal Threading Machine for sale (69,531)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Siedlce

Siedlce

8,431 km

Threading machine

CORMAKRGE16PW

Call

Condition: new, Year of construction: 2025, The electric threading machine is a compact and efficient threading device, used both in large production plants and small workshops. Thanks to the high-torque servo drive and swivel head, it enables fast and precise thread cutting. Equipped with a blow-through cooling system, the threading machine ensures optimal visibility of the drilled hole. The threading arm has 2 operating modes: automatic and manual.

Description of the RGE16PW threading machine

The electric threading machine is a versatile threading device that is used in both large production plants and small workshops. Its main advantage is shortening the time of threading operations, making the process much more effective.

The threading machine has a simple and compact design, equipped with a swivel head, which increases the possibilities of its use. The device is driven by a high-torque servo drive, which ensures strong and reliable operation. In order to operate the device, the threading arm is equipped with a touch control panel with a menu available in Polish. This intuitive panel allows you to easily program threading parameters such as rotational speed, threading direction and thread cutting depth.

The standard equipment of the threading machine includes a micro-spraying system, which is used for constant cooling with minimal consumption of cooling lubricant. In addition, the device is equipped with a chip blower, which ensures optimal visibility of the drilled hole.

The tapping arm is equipped with a quick-mount holder that allows easy and quick attachment of taps to through and blind holes. Additionally, the device has a rotating motor unit that allows thread cutting at any angle ranging from 0° to 90°. Compared to manual threading, the threading machine offers greater accuracy and reliable threading while maintaining a right angle (90°).

Collets for taps are equipped with adjustable overload clutches. The couplings in the sleeves are pre-adjusted to standard torque values for specific tap sizes, but these settings can be corrected using a special key included in the set. It also includes a large radius swivel arm that makes it easier to position the tap on the workpiece, ensuring precise and efficient thread cutting. It is intended for cutting threads in various materials such as steel, stainless steel, aluminum and non-ferrous metals.

Codpfsvvlkzex Afnopu

An electric threading machine is a reliable and effective tool that speeds up the threading process, improving the precision and quality of threads. Thanks to its versatility and ease of use, it is used in various industries, from industrial production to craft workshops.

Thanks to the use of modern technologies and solid construction, the threading machine ensures not only time savings, but also long-term efficiency and durability. It is an indispensable tool for professionals who require fast, precise and reliable threading in their work.

The set includes tap holders:

M3, M4, M5, M6-8, M10, M12, M13, M16

The machine is sold without a work table, vice and taps

Technical parameters

Power 0.6 kW

Power supply 230V

Weight 30 kg

Max. arm reach 1080 mm

Max. Rotational speed 375 rpm.

Listing

Siedlce

Siedlce

8,431 km

Threading machine

CORMAKRGE30PW

Call

Condition: new, Year of construction: 2026, The electric threading machine is a versatile threading tool, ideal for both large factories and small workshops. It has a simple and compact design with a movable head and a high-torque servo drive, which ensures strong and reliable operation. The threading machine offers easy and quick tap mounting, adjustable thread cutting angle and adjustable collets. The threading machine model is equipped with an oil dispenser and a blower to blow away chips. The machine has a touch control panel with a menu in Polish. The threading arm has 2 operating modes: automatic and manual. It is intended for threading various materials.

Characteristics of the RGE30PW threading machine

The electric threading machine is a versatile device for creating threads that is used in both large factories and small workshops. Its main advantage is the reduction of the time needed for the threading operation, which makes the entire process more efficient.

The threading machine has a simple and compact design, equipped with a movable head, which increases its versatility. The device's drive is based on a strong servo drive, which guarantees strong and reliable operation. To enable operation, the threading arm is equipped with a touch control panel with an intuitive menu in Polish . This panel allows you to easily program threading parameters such as rotational speed, threading direction and thread cutting depth.

The standard equipment of the threading machine includes a micro-spraying system that effectively cools the tool with minimal lubricant consumption. In addition, the device is equipped with a blower that removes chips, ensuring good visibility of the drilled hole. The threading machine arm has a quick-mount holder, enabling easy and quick mounting of taps in both through and blind holes. The threading head can be adjusted both vertically and horizontally by 90°, as well as to the right or left by 180°. Compared to traditional manual threading, the threading machine offers greater precision and reliability while maintaining a right angle (90°).

Codpfx Ajvughxjfnjpu

The threading machine's collets are equipped with adjustable overload clutches. The threading machine set includes DIN tap holders with sizes from M6 to M30, which provides a wide range of applications for various thread sizes. They are set to standard torque values for various tap sizes, but it is possible to adjust these settings using a special wrench that is included in the kit.

The electric threading machine is designed to create threads in a variety of materials such as steel, stainless steel, aluminum and non-ferrous metals. It is a reliable and efficient tool that speeds up the threading process, improving the precision and quality of threads. Thanks to its versatility and ease of use, it is widely used in various industries, from the manufacturing industry to craft workshops.

The set includes DIN tap holders:

M5-6, M8, M10, M12, M14, M16, M18, M20, M22-24, M27, M30

The machine is sold without a work table and taps.

Technical parameters

Power 1.2 kW

Power supply 230V

Libra 50 kg

Max. arm reach 1200 mm

Max. Rotation speed 156 rpm

Listing

Siedlce

Siedlce

8,431 km

Threading machine

CORMAKRGE36PWx1700

Call

Condition: new, Year of construction: 2026, Characteristics of the RGE36PWx1700 threading machine

The electric threading machine is a versatile device for creating threads that is used in both large factories and small workshops. Its main advantage is that it shortens the time required for the threading operation, which makes the entire process more efficient.

The threading machine has a simple and compact design, equipped with a movable head, which increases its versatility. The device is driven by a strong servo drive, which guarantees strong and reliable operation. To enable operation, the threading machine arm has been equipped with a touch control panel with an intuitive menu in Polish . This panel allows easy programming of threading parameters, such as rotational speed, threading direction and thread cutting depth.

The standard equipment of the threading machine includes a micro-spray system, which effectively cools the tool with minimal lubricant consumption. In addition, the device is equipped with a blower, which removes chips, providing good visibility of the drilled hole. The threading machine arm has a quick-clamping holder, allowing easy and quick clamping of taps in both through and blind holes. The threading head can be set both vertically and horizontally in the range of 90°, as well as to the right or left by 180°. Compared to traditional manual threading, the threading machine offers greater precision and reliability, while maintaining a right angle (90°).

The collets of the tap machine are equipped with adjustable overload clutches. The tap machine set includes DIN tap holders from M6 to M36, which provides a wide range of applications for different thread sizes. They are set to standard torque values for different tap sizes, but it is possible to adjust these settings using a special key, which is part of the set.

In addition, the machine is equipped with a manual mode that allows the user to control the threading process independently. It is also possible to program a cyclic change of the threading direction, which helps to break chips and maintain the efficiency of the process. Thanks to these functions, the threading machine provides even greater flexibility and precision in performing threading operations.

The electric threading machine is designed to create threads in various materials, such as steel, stainless steel, aluminum and non-ferrous metals. It is a reliable and efficient tool that speeds up the threading process, improving the precision and quality of the threads produced. Thanks to its versatility and ease of use, it is widely used in various industries, from the manufacturing industry to craft workshops.

Thanks to the use of modern technologies and a solid construction, the electric threading machine guarantees not only time savings, but also long-term efficiency and durability. It is an irreplaceable tool for professionals who require fast, precise and reliable threading in their daily work. The electric threading machine offers convenience, efficiency and excellent thread quality, significantly facilitating and streamlining the threading process.

DIN tap holders included:

M5-6, M8, M10, M12, M14, M16, M18, M20, M22-24, M27, M30, M33, M36

Cpedpfevugrqjx Afnsu

The machine is sold without a work table, vice and taps

Technical parameters

Power 1.2kW

Power supply 230V

Libra 56kg

Max arm reach 1700mm

Max. rotation speed 125 rpm

Listing

Siedlce

Siedlce

8,431 km

Threading machine

CORMAKRGE36PWx1200

Call

Condition: new, Year of construction: 2026, Characteristics of the RGE36PWx1200 threading machine

The electric threading machine is a versatile device for creating threads that is used in both large factories and small workshops. Its main advantage is that it shortens the time required for the threading operation, which makes the entire process more efficient.

The threading machine has a simple and compact design, equipped with a movable head, which increases its versatility. The device is driven by a strong servo drive, which guarantees strong and reliable operation. To enable operation, the threading machine arm has been equipped with a touch control panel with an intuitive menu in Polish . This panel allows easy programming of threading parameters, such as rotational speed, threading direction and thread cutting depth.

Csdpovugq Tsfx Afnopu

The standard equipment of the threading machine includes a micro-spray system, which effectively cools the tool with minimal lubricant consumption. In addition, the device is equipped with a blower, which removes chips, providing good visibility of the drilled hole. The threading machine arm has a quick-clamping holder, allowing easy and quick clamping of taps in both through and blind holes. The threading head can be set both vertically and horizontally in the range of 90°, as well as to the right or left by 180°. Compared to traditional manual threading, the threading machine offers greater precision and reliability, while maintaining a right angle (90°).

The collets of the tap machine are equipped with adjustable overload clutches. The tap machine set includes DIN tap holders from M6 to M36, which provides a wide range of applications for different thread sizes. They are set to standard torque values for different tap sizes, but it is possible to adjust these settings using a special key, which is part of the set.

In addition, the machine is equipped with a manual mode that allows the user to control the threading process independently. It is also possible to program a cyclic change of the threading direction, which helps to break chips and maintain the efficiency of the process. Thanks to these functions, the threading machine provides even greater flexibility and precision in performing threading operations.

The electric threading machine is designed to create threads in various materials, such as steel, stainless steel, aluminum and non-ferrous metals. It is a reliable and efficient tool that speeds up the threading process, improving the precision and quality of the threads produced. Thanks to its versatility and ease of use, it is widely used in various industries, from the manufacturing industry to craft workshops.

Thanks to the use of modern technologies and a solid construction, the electric threading machine guarantees not only time savings, but also long-term efficiency and durability. It is an irreplaceable tool for professionals who require fast, precise and reliable threading in their daily work. The electric threading machine offers convenience, efficiency and excellent thread quality, significantly facilitating and streamlining the threading process.

DIN tap holders included:

M5-6, M8, M10, M12, M14, M16, M18, M20, M22-24, M27, M30, M33, M36

The machine is sold without a work table, vice and taps

Technical parameters

Power 1.2kW

Power supply 230V

Libra 56kg

Max arm reach 1200mm

Max. rotation speed 125 rpm

Listing

Siedlce

Siedlce

8,431 km

Work table for threading machines

CORMAK900x600

Call

Condition: new, Year of construction: 2025, functionality: fully functional, A marking work table dedicated to threading machines is a solid and functional solution for professionals. It has holes for mounting the threading arm and a polished top with T-slots with a spacing of 152 mm. This high-quality table with dimensions of 900 m x 600 mm 780 mm ensures stability, precision and mobility when machining threads. Additionally, the table is equipped with tool cabinets that provide easy and practical storage of necessary items.

Description

It has dedicated holes for mounting the threading arm

Grinded top equipped with T-slots - 3x 14 mm, spacing 152 mm - ideal for marking work

The table has 2 tool cabinets.

Table top dimensions 900x600 mm

Table height 760 mm

Tabletop thickness 50 mm

Groove width 3x14 mm

Cpsdevugwgepfx Afnsu

Groove spacing 152 mm

Weight 99 kg

Listing

Iserlohn

Iserlohn

7,695 km

External threading machine

SONE2000

Call

Condition: good (used), Year of construction: 1990, Thread cutting machines with accessories

Manufacturer SONE Type: 2000 .

230V .

Cpjdsvk D Rpjpfx Afnsu

Listing

Iserlohn

Iserlohn

7,695 km

Thread cutting machine

ROTHENBERGER3S-G

Call

Year of construction: 2000, condition: excellent (used), Thread cutting machine make ROTHENBERGER

TYPE:3S-G year of construction ca.2000

Without cutting head

with pipe cutter and end burr device.

Runs with V230 current.

Cjdjmn Thhopfx Afnspu

In top condition, like new.

Listing

Germany

Germany

7,963 km

Honing Machine - Internal - Vertical

Werkzeugmaschinenfabrik Frunse2A78

Call

Condition: used, Year of construction: 1977, Technical details:

Cpjdpfx Afsw Rv Taonou

honing diameter: 125 mm

stroke: 500 mm

throat: - mm

grinding spindle speed: 26-1200 (12Steps) U/min

honing diameter: 30 (min.) mm

honing diameter: 165 (max.) mm

table adjustment:: 800/150 (max.) mm

table surface area: 500 x 1000 cm

total power requirement: 4,22 kW

Weight approx.: 0,15 t

dimension machine xH: 1,30 x 1,20 x 2,70 m

There is a movable table that moves lengthwise and crosswise.

·There is a movable table that travels in both longitudinal and transverse directions.

·Manual lubrication with cooling.

·The machine is capable of honing.

·Pendulum movement in rapid traverse between two adjustable end positions is possible.

*

Listing

Switzerland

Switzerland

8,020 km

Internal Grinding Machine

HAUSERKELLENBERGER H55-400

Call

Condition: ready for operation (used), Year of construction: 2019, Control Unit

Brand FANUC

Model §==I

Main Drive

Number of axis 5

Table

Number of tslots 7

Inner width 14 mm

Table load 800 kg

This 5-axis HAUSER KELLENBERGER H55-400 was manufactured in 2019, designed for precision internal grinding. Ideal for complex geometries, it offers advanced control for high accuracy. Consider the opportunity to buy this HAUSER KELLENBERGER H55-400 internal grinding machine. Contact us for more information.

Application Types

Cpodpfjx D Ny Sox Afnsu

Grinding

Listing

Русе

Русе

9,280 km

Thread milling and hobbing machine

STANKOIMPORT5А352ПФ

Call

Condition: ready for operation (used), Year of construction: 1989, operating hours: 2,100 h, functionality: fully functional, workpiece weight (max.): 200 kg, thread length: 880 mm, feed length X-axis: 1,060 mm, feed length Y-axis: 500 mm, feed length Z-axis: 400 mm, feed rate X-axis: 1 m/min, feed rate Y-axis: 5 m/min, position of the milling head: Horizontal, swivelling, center height in crank: 250 mm, center height: 250 mm, type of input current: AC, power of feed motor: 1,500 W, milling spindle length: 200 mm, spindle bore: 90 mm, spindle speed (max.): 400 rpm, spindle speed (min.): 25 rpm, mandrel length: 200 mm, collet bore: 90 mm, clamping length: 880 mm, workpiece diameter (max.): 500 mm, Thread Milling and Gear Hobbing Machine MSZ 5A352ПФ

The MSZ model 5A352ПФ is a universal thread milling and gear hobbing machine, designed for machining threads, worms, and spur gears by milling and hobbing processes. Manufactured in 1989, the machine is intended for industrial applications requiring reliable performance, versatility, and repeatable accuracy.

The machine is suitable for workpieces with a maximum length of 1060 mm and a maximum diameter of 500 mm. The maximum thread length is 880 mm, and the machine supports gear cutting up to module 8, covering a wide range of thread and gear machining tasks. Helix and thread angles up to 30° can be machined, allowing flexible use in mechanical engineering and transmission manufacturing.

The milling and hobbing spindle features a 90 mm spindle bore and supports cutting tools with a maximum hob diameter of 160 mm and a maximum hob length of 200 mm. The spindle operates in a speed range of 25 to 400 rpm, providing suitable cutting conditions for different materials and tool diameters. The main drive motor offers multiple power and speed stages (5 / 6.3 / 10 kW at 750 / 1000 / 1500 rpm).

The machine is equipped with stepless longitudinal and radial feeds, with longitudinal feed rates from 2 to 100 mm/min and radial feed rates from 2 to 50 mm/min, enabling precise control during machining operations. A complete set of change gears allows accurate synchronization for thread milling and gear hobbing.

With overall dimensions of approximately 3100 × 2270 × 2100 mm and a total weight of about 7890 kg, the 5A352ПФ features a rigid, heavy-duty construction that ensures excellent stability and vibration damping. The machine operates on three-phase AC power and is supplied with original factory documentation.

Condition:

*Used machine

*Ready for operation

*Fully functional

*Operating hours: approx. 2,100 h

Scope of delivery:

Cpjdpfox Unpvsx Afnou

*Complete set of change gears

*Technical passport (Russian)

*Operating manual (Russian)

Typical applications:

*Thread milling

*Gear hobbing (spur gears, worms)

*Machining of transmission components

*General mechanical engineering

*Repair and small- to medium-series production

Listing

Korschenbroich

Korschenbroich

7,642 km

Thread rolling machine

LeistritzRT 400-CCA

Call

Condition: excellent (used), Year of construction: 2004, functionality: fully functional, machine/vehicle number: 1028, Thread Rolling Machine LEISTRITZ RT 400-CCA

Year of manufacture: 2004 / Control system retrofit in 2019

Connection voltage: 3x400 V

Frequency: 50 Hz

Rated power: 65 kW

Main fuse: 125 A

Operating pressure: Air: 6 bar, Oil: 270 bar

Control voltage: 24 VDC

Maximum shaft length: 275 mm

Minimum shaft length: 125 mm

Maximum roll set diameter: Tool Ø69.85: 215 mm, Tool Ø80: 210 mm

Minimum roll set diameter: Tool Ø69.85: 176-178 mm, Tool Ø80: 176 mm

Maximum rolling force: 40 t

Space requirement: 3.4 m x 2.9 m x 2.2 m

Weight: 4900 kg

Accessories:

- Coolant filtration system

- Second spindle pair (1x for tools Ø69.85 mm, 1x for tools Ø80 mm)

Cpodpjxytmhefx Afneu

Listing

Schwieberdingen

Schwieberdingen

7,939 km

Internal and face grinding machine

WMW VEBS164 ASX500

Call

Condition: excellent (used), grinding length: 500 mm, The machine is in good condition.

Codpfx Afsx N A Agenjpu

Listing

Korschenbroich

Korschenbroich

7,642 km

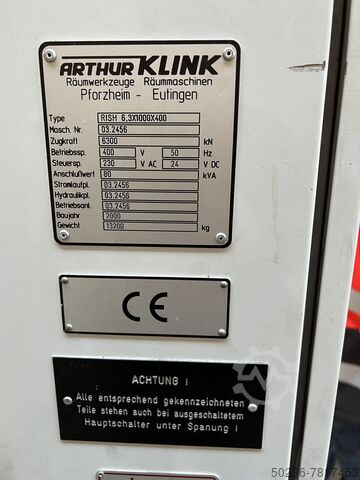

CNC internal broching machine

Arthur KlinkRISH 6.3X1000X400

Call

Condition: excellent (used), Year of construction: 2000, machine/vehicle number: 03.2456, CNC Ibroching machine

Arthur Klink

Cpjdpfx Afsirwiqeneu

RISH 6.3X1000X400

Renewed in 2016

Listing

Tönisvorst

Tönisvorst

7,631 km

External threading machine

Rems3/8 - 2 Zoll

Call

Condition: excellent (used), Manual thread cutting stock (28682)

Manufacturer: Rems

Model: EVA

7 thread cutting dies from 3/8 to 2 inches

Csdpfxoxw U Nle Afnepu

Listing

Brügg

Brügg

7,941 km

Internal grinding machine

STUDERCT 960

Call

Condition: used, STUDER CT 960 is an Internal grinding machine delivering precision, high accuracy and reliable performance. Working capacities: centre height 150 mm, grinding length 150 mm, X/Z travels 400 mm, wheel diameter 250 mm, spindle hole 35 mm; B-axis +61/-91°, rotatable head -5/+275°, turret with 4 spindles. Main specs: spindle speeds 6000 / 45000 / 60000 / 90000 rpm; X/Z feeds 12 m/min; air 6–10 bar; 3x 400 V 50 Hz; total power 34 kVA; weight ~4050 kg; dimensions L 3218 × W 2256 × H 2300 mm. Equipment: coolant system, measuring probe, diamond redresser, spindle cooling, flanges for internal grinding, tool holders, 3-jaw chucks Ø100/125/160, magnetic chuck Ø125/300, tool cabinet, lamp, fire system, electronic handwheel, external grinding spindle 6000 rpm, calibration accessories. Enables tight tolerances; suited to automotive, watchmaking, machine tools, aerospace and medical sectors.

Cedpfx Asxx U Auofnspu

Listing

Αθήνα

Αθήνα

9,621 km

Male thread cutting machine

HMVOK-5

Call

Condition: excellent (used), functionality: fully functional, overall weight: 785 kg, total width: 1,015 mm, total length: 1,570 mm, total height: 1,270 mm, type of input current: three-phase, input voltage: 380 V, metric thread diameter (max.): 80 mm, metric thread diameter (min.): 16 mm, thread length: 450 mm, rotational speed (min.): 14 rpm, rotational speed (max.): 94 rpm, metric thread pitch (max.): 6 mm, metric thread pitch (min.): 2 mm, HMV thread cutting machine, type OK-5

Specifications

Thread cutting range (Whitworth/UNC) 5/8"- 3"

Thread cutting range (BSP) 1/2"- 4"

Thread cutting range (Metric) M16-M80

Number of speeds 8

Speeds, rpm 14,20,28, 32, 40, 48, 64, 94

Motor output, hp 2.7 - 4.5

Motor output, kW 2.3 - 3.0

Motor speed, rpm 700 / 1400

Spindle bore, mm 118

Spindle bore, in 4 21/32"

Max cutting length

without relocation, mm 450

Csdpfx Afexz R Huonepu

without relocation, in 17 3/4"

with relocation infinite

Dimensions and weight

Overall length, mm 1570

Overall width, mm 1015

Overall height, mm 1270

Height from floor to bed, mm 830

Width of bed, mm 370

Required floor space, mm 1570 x 1015

Bed size (L x W), mm 815 x 580

Net weight, kg 785

Listing

Trittau

Trittau

7,709 km

Honing Machine - Internal - Vertical

NAGEL3VS8-50T

Call

Condition: used, Year of construction: 2005, Type Honanlage

Control Nagel

In our opinion, the machine is in good used condition

and can be inspected under power by appointment.

Two machines are available.

Accessories, tools, and clamping devices shown are only included in the

scope of delivery

if noted in the additional information.

Csdpexwdxijfx Afnspu

Subject to changes and errors in the technical data and information, as well

as

subject to prior sale!

Listing

Iași

Iași

9,095 km

Threading machine

SENYD 75 B

Call

Condition: used, Year of construction: 2000, functionality: fully functional, machine/vehicle number: 308, Technical characteristics:

⚙️ Core Specifications

Attribute Value

Thread Diameter Range: 3 mm to 75 mm

Rolling Pressure: 0.5 to 20 tons

Max Thread Length (Plunge): 160 mm

Max Thread Length (Through): 2000 mm

Speed Range: 24 to 114 rpm (8-step gearbox)

Cedpfsxx Nuxsx Afnopu

Tool Diameter: 145 mm to 200 mm

Roll Spindle Diameter: 54 mm

Shaft Distance: 130 mm to 200 mm

Machine Dimensions (L×W×H): 1880 (INCLUDING HYDRAULIC UNIT) × 991 × 1270 mm

Weight: ~1.6 tons

🧰 Features & Capabilities

Variable Rolling Pressure: Adjustable to suit different materials and thread profiles.

Heavy-Duty Construction: Built for long-term industrial use with high repeatability.

Manual or Semi-Automatic Operation: Depending on configuration and accessories.

Machine status:

WORKING

Listing

Germany

Germany

7,870 km

Thread Cutting Machine

Microtapmegatap 90-G12

Call

Year of construction: 1992, condition: ready for operation (used), Application range: large threads, breakage protection: from M3.0, capacity in stainless steel: up to M10, capacity in 9SMn28: up to M10, connected load: 2000W, with automatic Z-axis feed for automation. The machine is fault-free and operational, showing signs of use. With documentation and five holders. An on-site inspection is possible.

Csdpfx Aox Hfgpsfnopu

Listing

Korschenbroich

Korschenbroich

7,642 km

CNC internal broaching machine

FORSTRISH 6.3X1000X320

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 1999, machine/vehicle number: 20, Used CNC internal broaching machine

Make: FORST

Csdpfx Aev Htluofnspu

Type: RISH 63X1000X320

Year of manufacture: 1999/ Reconditioned

Mach. No.: 20

Listing

Ebenweiler

Ebenweiler

8,029 km

Cylindrical grinding machine with internal grinding attachment.

SchaudtAR500

Call

Condition: good (used), Internal item no.: 25087

Cylindrical grinding machine

Cpodpsxtpbbefx Afnsu

Schaudt

AR 500

+ Magnetic chuck D160mm

+ Internal grinding attachment!

Grinding length: max. 500mm

Grinding diameter: max. 300mm

Centre height: 150mm

Centre distance: 500mm

Tailstock taper: MK4

Machine dimensions (LxWxH): 2700 x 2000 x 1800mm

Weight: approx. 2000kg

Trust Seal

Dealers certified through Machineseeker

Listing

Ebenweiler

Ebenweiler

8,029 km

5-axis CNC machining center + internal coolant supply (IKZ)

PosmillH500U

Call

Condition: good (used), Year of construction: 2018, Internal item no.: 25043

5-Axis CNC Machining Center

POSmill H 500 U

Year: 2018

Just approx. 1,000 spindle hours since spindle replacement

Machine total approx. 20,500 hours

Spindle replaced in 2024 (18,000 rpm)

Geometry realigned in 2024.

Travel axes: X 650 / Y 850 / Z 500 mm

Rotary table: 360° infinite

Control: Heidenhain iTNC 530

Spindle: 18,000 rpm

Spindle interface: HSK-A63

The machine is equipped as follows:

60-position tool changer

Through-spindle coolant (20 bar) with belt filter system

Compressed air through the spindle

Kessler rotary table, diameter 500 mm

Infrared 3D part measurement probe

Tool measurement via BLUM laser

Rotating inspection window

POS DCM collision module

Mobile electronic handwheel

Oil mist extraction system

Heidenhain linear measurement system X, Y, Z

Purge air for all linear measurement systems

Active control cabinet air-to-air cooler

Active cooling for 4th + 5th axis, controlled

Network connection + USB port

Controlled spindle cooler

Heidenhain rotary measuring system

Contour protection POSkontur

External hinge belt chip conveyor

Coolant pump at the head, operated via M-functions

Pump for chip flushing device

Chip flushing device

Machine status indicator light

Spindle air purge

Electromechanical oil/coolant separator

Automatic coolant level monitoring

3-fold media interface in the center of the table

Hydraulic unit incl. control via M-function

Connected load: 60 kVA

Installation dimensions:

W 4800 / D 4600 / H 3000 mm

+ Through-spindle coolant unit (LxWxH): 2200 x 1300 x 1400 mm

Weight: approx. 13,000 kg

The machine is in very well-maintained condition and comes from a small, family-run business.

Cpodpfx Aewz I Acefnju

In 2024, the spindle was replaced and the geometry was set (guides repaired and adjusted). Since then, the machine has seen only minimal use.

Listing

Hessisch Lichtenau

Hessisch Lichtenau

7,826 km

Bench drilling and thread cutting machine, bench drill, drill, column drill

IXIONBT 15 GL

Call

Condition: used, Table Drilling and Thread Cutting Machine IXION Type BT 15 GL

Machine no.: Year of manufacture approx. 1975

Drilling capacity: 15 mm

Spindle mount: Taper B 16

Thread cutting range: M 2.5 to M10

Throat depth: 200 mm

Quill stroke: 90 mm

Table size: 285 x 220 mm

Column diameter: Ø 75 mm

Cedpfowk Nxqex Afnspu

Spindle speed: 320–1600 rpm, 4 steps

Motor power: 0.55 kW

Power connection: 380 Volt, 50 Hz

- Spindle speed adjustable in 4 belt stages

- Equipped with FAHRION GH 10 tapping attachment

- With thread pitch guide bush, operation without guide bush also possible

- Drill head height adjustment via hand crank

- Column lowers from table plate for drill head height adjustment

Required space (L x W x H): 650 x 420 x 900 mm

Weight: 86 kg

Good condition

Listing

Offenbach an der Queich

Offenbach an der Queich

7,866 km

Thread Boring Machine - Vertical

HAGEN & GOEBELHG 22 E

Call

Condition: good (used), Year of construction: 1981, Dimensions (L/W/H) 660x1050x1600 mm

metric thread M 33 Messing

Csdjul Eg Djpfx Afnspu

metric thread M 16 Gußeisen

metric thread M 14 Stahl

no. of flutes 25x10mm 2x T-Nuten

throat 220 mm

weight 730 kg

Listing

Contamine-sur-Arve

Contamine-sur-Arve

7,946 km

Cnc thread cutting machine

GLEASON PFAUTERP90WM

Call

Condition: used, TECHNICAL DETAILS

- Part diameter : 100 [mm]

- Nominal module

* gear hobbing : approx. 3.0 [mm]

Cpjdpfx Ajx Ed A Refnju

* endless screw milling : approx. 5.0 [mm]

- Max. axial movement : 320 [mm]

- Cutting head orientation : -45 / + 115 [°]

- Main mill max. diameter : 118 [mm]

- Max. cut out length of the mail mill : 180 [mm]

- Max. mill movement (Shifting) : 160 [mm]

- Max. part-holder spindle speed : 3000 [t/mm]

- Min./max. distance between axes : 10/100 [mm]

- Cutting head motor power : 14 [kW]

- Main mill speed : 50-12000 [t/mm]

- Weight : 5000 [kg]

EQUIPMENT

- CNC Siemens 840D

- Cooling tank

- Chip conveyor

We make it easier for you to find: "internal threading machine"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Internal Threading Machine (69,531)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- Automatic Welding Machine

- Cnc Internal Grinding Machine

- Construction Machine

- External Cylindrical Grinding Machine

- External Grinding Machine

- External Thread

- External Thread Cutting Machine

- External Threading Machine

- Internal Circular Grinding Machine

This may be of interest to you