Used Leake Detector for sale (925)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Bremen

Bremen

7,656 km

CNC Lathe

MAZAKQT 250MAL x 500

Call

Condition: used, turning diameter max. 360 mm

turning length 505 mm

control Mazatrol SmoothC

max. swing diameter over bed 660 mm

swing diameter over slide guides max 255 mm

bar material dia. max. 80 mm

turning speed range - spindle 35 - 4000 U/min

max. torque on the spindle 358 Nm

x-axis 225 mm

rapid traverse X-axis 30 m/min

z-axis 605 mm

rapid traverse Z-axis 33 m/min

spindle nose A2-8''

spindle bore 91 mm

spindle hollow 80 mm

Milling spindle speeds ( driven tools) 5000 1/min

torque on milling spindle max: 47 Nm

power capacity - milling spindle 5,5 (40%ED) kW

tailstock quill taper MT 5

Travel- tailstock 565 mm

Axial pressure max 5,0 Nm

Tool turret 1

Numbers of tools 12 (angetrieben)

turning tool - shaft cross cut 25 x 25 mm

tool taper BMT

Required air-pressure 5 / 160 bar / l/min

voltage 400 V

coolant tank 180 l

engine output 18,5 (30min Betrieb) kW

Rated power (100% continuous operation) 15 kW

weight of the machine ca. 6 t

dimensions of the machine ca. 3,6 x 2 x 1,8 m

Machine incl. the following special accessories:

Chip conveyor on the right side

Productivity package C - special according to storage machine

This package includes:

High-performance coolant system (1.1 kW) Flow rate max. 17.6 l/min

Preparation for chip conveyor (lateral)

Automatic tool eye

STANDARD ACCESSORIES

Transformer for the European market

Use of linear systems with guide carriage

SD MEMORY I/F(1P) + USB MEMORY I/F(1P)

1 x USB memory interface (1 slot)

Spindle bore 91 mm

Set of manuals in electronic form on CD

Mazak standard colour

CE marking, metric, 50 Hz

C-axis input accuracy 0.0001°

NC controlled tailstock

Tailstock pressure adjustment

Tailstock with fixed quill MK5

SAFETY DEVICES

Operator door with interlock switch

Double foot switch

Hydraulic pressure lock

Nedpfx Ajv Dxw Rjgzjdf

Fully enclosed work area

Work area lighting

Safety precautions according to global standard

COOLANT SUPPLY

Grundfos coolant pump type MTA (0.25kW / 7.6L/min)

Complete coolant system

Automatic switch-off via circuit breaker triggering

MESSSYSTEM

Absolute positioning system

NUMERICAL CONTROL

Synchronous tapping with milling spindle

Relocation Detector

Mazatrol SmoothC

10.4’ colour screen

User macro (600 variables)

EIA/ISO input function

Tool path check in the background

Thread cutting function (G33)

Polar coordinate input (EIA)

Drawing data direct input function

Interface for LAN

Various tool holders

- All dimensions, weights and performance data are non-binding

- Used machine without warranty -

Listing

Wellingborough

Wellingborough

7,151 km

Injection molding machine

Boy35M

Call

Condition: refurbished (used), Year of construction: 2006, functionality: fully functional, clamping force: 350 kN, screw diameter: 28 mm, injection pressure: 1,577 bar, Now fully refurbished by our team at STV Machinery in Wellingborough, Northamptonshire, is this high precision BOY 35M injection moulding machine. The 30 & 35 machines are a rare find on the used market as they offer a versatile four tie bar setup with good platen areas, from a footprint not much larger than that of a BOY 22. If you’re looking for the most versatile little machine, this has to be worthy of consideration. Fitted with the Procan MD controller and 28mm diameter screw, which gives a shot weight of 55.8 (PS)g.

Refurbished machines from STV Machinery undergo a comprehensive test procedure during which every function of the machine is tested and if necessary repaired. A production run of at least 5000 fault free cycles prior to sign off ensures trouble free operation once delivered. Machines are ultra clean and cosmetically as good as we can get them. We guarantee our refurbs are delivered fault free and leak free.

Prices shown are ex-works, but we can quickly provide DAP (Delivered at Place) Incoterm pricing on request. We can take out the hassle and additional costs of purchasing machinery within the UK and EU. Contact us with a potential delivery address and we’ll do the rest.

Nodexxlmdspfx Agzsdf

Listing

Friolzheim

Friolzheim

7,927 km

Crushing plant

MetsoLT 300 HP

Call

Condition: new, functionality: fully functional, power: 403 kW (547.93 HP), operation weight: 47,500 kg, Year of construction: 2022, operating hours: 41 h, Dear interested party, please find below the details of the investment on offer.

Stock number 1440-103

Additional options rental possible, ex demo

General rating (1:bad; 5:like new) condition icon iconcondition iconcondition iconcondition iconcondition icon 5/5

Service weight 47500 convert_weight

Crusher type Cone crusher

Emission class Emission class 5 / Tier V

Engine C15

Ndsdpfeq U Swysx Agzjf

Engine manufacturer CAT

Production capacity (t/h) 300

Feed size (mm) 0-700

Transport dimensions (L x W x H) 18000x3500x3800 mm

Country of production Finland

Delivery conditions EXW

Certificates EPA, CE

Additional equipment Feed hopper rigid, with separate feed chute and pre-screen

Capacity: approx. 5.00 m³

Width: approx. 2.90 m

Length: approx. 3.20 m

Loading height: approx. 2.90 m

Hydraulically folding and lockable bunker walls

Bjw7erffl90

Belt feeder H12-8

Width: 1,200 mm

Length: 8,000 mm

Belt: EP630/4 incl. metal detector

Crusher type: Nordberg HP300 cone crusher

Feed opening: max. 235 mm

Extended main conveyor H12-12

Belt width: 1,200 mm

Length: 12,000 mm

Discharge height: 3.70 m

Diesel unit for system operation

Engine: CAT C15 diesel engine, Stage V, with exhaust silencer and intake filter

Power: 225Kw

Control panel: Switches, measuring and display instruments

Diesel tank: approx. 375 l

Infinitely variable crusher speed adjustment

Refueling pump for diesel unit

71kVA generator

Radio remote control

Water spraying with pump

Feed material: Natural stone, concrete, asphalt, construction waste

Throughput rate: up to 300 t/h (depending on feed material)

Feed piece size: 0/700 mm (max. room diagonal)

If you have any further questions, please do not hesitate to contact us!

The offer is subject to change.

The information provided is for descriptive purposes only.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Eberswalde

Eberswalde

7,941 km

Profesional compresor

Ingersoll-RandR160ne

Call

Year of construction: 2017, condition: as good as new (ex-display), DISPLAY COMPRESOR

more infoo - office at medilaabs.com

Efficient Design: Time-proven airends, a sequential cooling system and an option Energy recovery Stystem (ERS) significantly improves efficiency

Leak-free Design: V-Shield Technology provides a totally integrated, leak-free design featuring PTFE stainless steel braided oil hoses and O-ring face seals

Remote Intelligent Control: Xe-Series controller delivers increased control functionality through an intuitive user interface and remote access with any common, current web browser

Ndodsirz Thspfx Agzsf

Reduced Downtime: Progressive Adaptive Control (PAC™) monitors key operating parameters and continuously adapts to prevent unexpected downtime

Trouble-Free Operation: Features such as two-stage filtration, easy maintenance and extended life Ingersoll Rand premium grade coolant keep your operation running smoothly

Listing

Nordland

Nordland

6,954 km

Gemsa Gemrok 45 drilling rig. WATCH VIDEO.

GemsaGemrok 45 drilling rig. WATCH VIDEO.

Call

Year of construction: 2011, condition: used, Field of application: Construction

Serial number: 110245xxxx

Please contact ATS Norway for more information

Please provide reference number upon request: 20555

Specifications:

Nodpfx Aowph Egjgzedf

Model year: 2011

Engine hours: approx. 7,200 (may increase – machine is in daily use)

New chains on the mast

Undercarriage: see photos for condition

Boom rotor replaced about a year ago (cost: EUR 21,000)

Oil leakage under the rig

Tracks at the front of the mast are damaged and need replacement

Hammer not included

Video available

Delivery by arrangement

Description:2011 Gemsa Gemrok 45 SDKJM drill rig.Fitted with new chains on the mast and storage unit. The boom rotor was replaced approximately one year ago, with a total investment of EUR 21,000.There is an oil leak under the rig, and the front tracks on the mast are damaged and will need to be replaced.The machine is currently in daily use, so the hour count may increase.A video is available upon request. Delivery to be arranged.

Hours: 7200

Own weight: 11

Model: Gemrok 45 borevogn. SE VIDEO

Listing

London

London

7,228 km

Chiller

CarrierCarrier Chiller 30RBP-430-0095-PE

Call

Condition: excellent (used), Year of construction: 2019, machine/vehicle number: M2019011975, cooling capacity: 430 kW (584.64 HP), Carrier Chiller 30 RBP-430-0095-PE (AquaSnap Series)

Type: Air-Cooled Liquid Chiller

Model: 30RBP-430-0095-PE

Variant: 30RBM/RBP

Serial Number: M2019011975

Year of Manufacture & Test: 06/2019

Manufacturer: Carrier SCS, Montluel, France (United Technologies, Carrier Corporation, USA)

Technical Specifications:

Nominal Cooling Capacity: 430 kW

Refrigerant: R-410A

Circuit A: 23.50 kg / Circuit B: 26.70 kg

Total Charge: 50.2 kg

GWP: 2088

Compressors: Danfoss Scroll SH240A4ACE (thermally protected)

Power Supply: 400 V / 3 Ph / 50 Hz

Maximum Current Draw: 340 A

Maximum Starting Current: 210 A

Power Input: 210 kW

Operating Temperature Range: –20 °C to +52 °C

Net Weight: 2760 kg

Protection Rating: IP54

Ndsdpfx Aoxb D Raegzof

Pressure Data

Refrigerant: R-410A

Allowable Pressure (Min/Max):

High side (PS): –1.0 / 44.2 bar (–99.0 / 4420.0 kPa)

Low side (PS): –1.0 / 31.1 bar (–99.0 / 3110.0 kPa)

Safety Relief Valve Setting: 42 bar

Rupture Disc Setting: 45 bar

Test Pressure: 15.0 bar (unit leak test)

Additional Information:

Air-cooled design with axial fans and integrated condensers.

Electrical control panel with Carrier management system.

Hermetically sealed system, original Carrier service log included.

Serviced and maintained by official Carrier service centre.

Listing

Bremen

Bremen

7,656 km

CNC Lathe

MAZAKQT 200MSx500

Call

Condition: used, Year of construction: 2020, turning diameter 380 mm

turning length 511 mm

control Mazatrol SmoothG

turning diameter over slide 276 mm

max. swing diameter over bed 675 mm

Standard machining diameter 276 mm

bar material dia. 65 mm

x-axis 234 mm

rapid traverse X-axis 30 m/min

z-axis 625 mm

rapid traverse Z-axis 33 m/min

turning speeds 35 - 5000 U/min

spindle nose A2-6

spindle bore 76 mm

Motor output (40%ED) 26 KW

22 KW

Max. Torque 465 Nm

turning speeds 6000 U/min

Main drive power 11 KW

Max. Torque 90 Nm

Milling spindle speeds ( driven tools) 35-6000 1/min

torque on milling spindle max: 47 Nm

power capacity - milling spindle 5,5 (40% ED) kW

Milling spindle power 3,7 kW

Numbers of tools 12 (angetrieben)

Tool cross section (outside) 25 qmm

Boring bar- Ø 40 mm

Drill- Ø 20 mm

Mill- Ø 20 mm

Tap- Ø M20x2,5

Switching time one turret station ca. 0,20 sec

coolant tank 180 l

connected load 46,2 kW

weight of the machine ca. 5,9 t

dimensions of the machine ca. 2,7 x 1,9 x 1,9 m

incl. the following accessories:

- Signal light (3-colour LED), rectangular

- High-performance coolant system (1.1 kW)

Flow rate max. 17.6 l/min, pressure (at pump) 5 bar.

- Additional coolant nozzle main spindle

- Preparation for oil mist extraction electrical/mechanical flange 98mm

- Preparation for bar feed

- Robot interface (Advance/Profibus)

- Chip conveyor with low ejection height

- Overload monitoring system

Nedjtugggepfx Agzsdf

- Drilling cycle with torque-dependent chip breaking

- Preliminary use of a hollow clamping cylinder on counter spindle

- Hollow clamping device incl. draw tube + cylinder

- Clamping chuck Hainbuch Spanntop Nova Axfix mini size 52

- Chuck Hainbuch Spanntop Nova Axfix special mini size 52

- 2 x collets

- Changing device for collet chuck

STANDARD ACCESSORIES

Automatic on/off and warm-up function

Air blowing device on the chuck on the counter spindle

Use of linear systems with guide carriage

USB connection (1 connection)

Set of manuals in electronic form on CD

C-axis main spindle Input accuracy 0.0001°

Spindle positioning counter spindle without C-axis Input accuracy 0.001°

Tool turret with 12 stations VDI,

Operator door with locking switch

Double foot switch for both main and counter spindle

Hydraulic pressure interlock

Fully enclosed work area

Work area lighting

Safety precautions in accordance with global standards

High-performance coolant system (520W)

Flow rate max. 11.5 l/min.

Complete coolant system

Automatic opening/closing of the chuck jaws

Automatic tool eye

Absolute positioning system

Preparation for chip conveyor (lateral)

Synchronisation of main and counter spindle

Synchronised tapping with milling spindle

Relocation Detector

Mazatrol SmoothG control

19" LCD colour screen (touch screen)

User macro (600 variables)

EIA/ISO input function

Optional stop (optional stop)

Tool path check in the background

Thread cutting function (G33)

Polar coordinate input (EIA)

Drawing data direct input function

Interface for LAN

SD memory card I/F

- Second-hand machine without warranty

- All dimensions, weights and performance specifications are non-binding

Listing

Bydgoszcz

Bydgoszcz

8,145 km

PRESS BRAKE 80X2500 OT-41

OtinusPBO-2580-CNC OT-41

Call

Condition: new, Year of construction: 2024, Attention!! Special Offer!!

Warranty inspection free of charge—only for Customers who have taken part in the demonstration at the machine showroom in Bydgoszcz.

A part of our machines is available IMMEDIATELTY.

Hydraulic press brake PBO-2580-CNC OT-41

Specifications

- Maximum bending thickness (S235): up to 4.0 mm

- Nominal bending force: 800 kN

- Maximum bending length: 2500 mm

- Throat depth: 250 mm

- Maximum stroke: 120 mm

- Daylight: 385 mm

- Distance between side frames: 2000 mm

- Backgauge travel distance: 600 mm

- Motor power output: 5.5 kW

- Length: 2600 mm

- Width: 1450 mm

- Height: 2300 mm

- Weight: 4500.0 kg

Nsdoh Ranljpfx Agzodf

Tools

- Front supports: 2 pcs.

- Backgauge drive (travel along the X-axis): servo motor

- Ram drive (travel along the Y-axis): servo motor

- Backgauge fingers positioning (R-axis): manual

- Punch quick change tooling system form AMADA

Otinus CNC OT-41 control

The CNC controller Otinus is featured with convenient and intuitive menu. The software calculates the bending angle on its own. The large color touchscreen is readable from any angle.

The controller can store up to 2,000 programs of 30 steps each.

Top quality components

- Rexroth hydraulic valve

- Schneider electrical components

- Omron and Schneider safety circuit parts.

- Steel hydraulic line tubings

- Hydraulic lines made of steel instead of rubber reduce the risk of future leaks.

Safety

We attach great importance to the safety of our Clients and their employees; therefore our press brakes are equipped with visible safety labels, side guards, rear safety doors, easily accessible safety switches and light curtains that protect the operator against inserting their hands between the upper and lower dies.

The machines comes with carefully prepared instructions manual.

The machine has a CE marking and EU declaration of conformity.

Oil cooling system

The Oil Cooling System guarantees the stability of the machine's performance even after long, continuous operation.

Assistance by a specialist

We strive to maintain constant communication with our Customers. To support this, every machine purchase includes a specialist support package with hours of expert guidance.

Within the service, our technicians may:

- Specify the bending steps for intricate parts.

- Advise on material and gas selection

- Assist in the selection of operating parameters for different materials

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Haverhill

Haverhill

7,231 km

Single shaft shredder

WEIMAWLK 1500

Call

Condition: used, Year of construction: 2020, operating hours: 4,930 h, functionality: fully functional, machine/vehicle number: 510-3888, rotor diameter: 370 mm, number of blades: 82, power: 75 kW (101.97 HP), WEIMA WLK 1500 / 75 kW V-Rotor Industrial Shredder

Suitable for Paper, Wood, Plastic, Metal (Swarf), Textiles and General Waste Processing

Summary

Heavy-duty WEIMA WLK 1500 industrial shredder with a 75 kW V-Rotor, suitable for continuous processing across multiple waste streams including paper and cardboard, wood and biomass, plastics, metal swarf, textiles, and general waste reduction. The machine is supplied complete with its associated extraction unit.

Key Specifications

• Manufacturer: WEIMA

• Model: WLK 1500

• Rotor Type: V-Rotor

• Installed Power: 75 kW

• Cutting Chamber: 1500 mm working width

• Material Suitability: Paper, cardboard, wood, plastics, metal swarf, textiles, mixed waste

• Feed: Conveyor-compatible

• Running Hours: 4,930 hours

• Condition: Operational and available for inspection

Included with the Machine

• New, unused replacement blade set

• Dedicated extraction unit (multi-port extraction with collection bags, as shown in photos)

Inspection and Condition

This machine was originally purchased from Fercell. A recent inspection by Fercell identified several maintenance and condition items, which have been fully considered within the selling price.

Nodpjx Eklnofx Agzodf

Inspection Findings

• Hydraulic hose leaking

• Screen door switch damaged

• Screen door handle missing

• Screen doors modified for reverse Ram operation (recommended to return to factory specification)

• Control panel isolator switch damaged (replacement recommended – panel currently remains live/on)

• Hopper dog box damaged (replace if required)

• Rear hydraulic door – two damaged threads requiring repair

• Hydraulic oil low due to hydraulic hose leakage (full service and oil top-up recommended)

Full inspection notes can be provided to interested buyers.

Applications

• Paper and cardboard recycling

• Wood recycling and biomass preparation

• Plastic recycling and re-processing

• Metal swarf reduction

• Textile destruction and processing

• General waste management and volume reduction

Condition and Viewing

• Operational condition

• Available immediately

• Available for inspection by prior arrangement

Decommissioning and Removal

Buyer to arrange full decommissioning, disconnection, dismantling, lifting and removal of the equipment. Seller will provide reasonable site access for inspection and collection.

Additional Items Available (separate cost)

Outfeed Incline Conveyor (1.75 kW) – Heavy-Line PVC Belt “L-Type” Conveyor

Industrial conveyor transferring shredded material from the shredder to the extraction system.

Key Features:

• Durable PVC belt

• L-shaped elevation design

• Steel frame

• Adjustable discharge height

Price: £9,000

Screen Insert – WEIMA WLK 1500 (30 mm, t = 10 mm)

Spare classification screen for controlling shred size from the WLK1500 shredder.

Key Features:

• 30 mm hole pattern

• 10 mm heavy-gauge steel

• Improves consistency of final product

• Quick installation

Price: £1,000

Pricing

• WEIMA WLK 1500 Shredder with extraction unit: £55,000 (€62,960)

• Outfeed Incline Conveyor (optional): £9,000 (€10,300)

• Screen Insert (optional): £1,000 (€1,445)

Reason for Sale

Business closure.

Location

Haverhill, CB9 8QP, United Kingdom

Listing

Pfeffenhausen

Pfeffenhausen

8,119 km

Box van

MERCEDES-BENZSprinter ideal als Foodtruck Camper Wohnmobil E5

Call

Condition: used, mileage: 75,000 km, power: 70 kW (95.17 HP), first registration: 04/2012, fuel type: diesel, overall weight: 3,498 kg, color: yellow, gearing type: automatic, emission class: euro5, number of seats: 2, loading space volume: 17 m³, loading space length: 4,400 mm, loading space width: 2,000 mm, loading space height: 2,000 mm, Year of construction: 2012, Equipment: ABS, central locking, electronic stability program (ESP), soot filter, Net selling price: €9,950

Mercedes Benz Sprinter MAXI – Box Body (SAXAS)

Euro 5

Please no emails, as responses can only be handled sporadically due to time constraints! Thank you for your understanding!

Opening hours and further information:

Inspection/purchase without appointment possible:

No appointment necessary!!!!

MON - THU: 9:00 am to 4:00 pm

FRI: 9:00 am to 1:00 pm

SAT: 9:00 am to 12:00 pm

Address:

Tabakried 11

84076 Pfeffenhausen

If you have any questions, please contact Christian Hirsch or our friendly staff.

Ndjdowcv Dwjpfx Agzjf

TÜV: A new inspection (TÜV) will be performed upon request at the time of purchase

-Service book maintained/service history available

-1 owner

-LED interior lighting

-Motion detector in cargo area

-Sliding door between cab and box

-Reversing camera (see photos)

-Various ventilation openings

-Folding shelves

-Electronically locked doors

-Rear step

Load compartment length: 4.40 m

Load compartment height: 2.00 m

Load compartment width: 2.00 m

Special equipment:

- Hill start assist

- Generator 220 A

- Steering wheel (mechanically adjustable steering column)

- Radio pre-installation

- Front mud flaps

- Rear stabilizer

- Reinforced front stabilizer

- AGM battery 95 Ah

Additional features:

- Adaptive brake lights

- Driver's airbag

- Washer fluid level indicator

- Electrically adjustable and heated exterior mirrors, both sides

- Exterior mirrors with integrated indicators

- 74 Ah battery

- Brake assist

- Brake system with ABS+ASR

- Roof lining in cab

- Lockable glovebox

- Body/build type: Box body

- Fuel tank: Main tank 75 liters

- Headlight range adjustment

- Registered as truck

- Engine: 2.1 liter – 70 kW CDI

- Wheelbase: 4,325 mm

- Smoker’s package

- Tire repair kit with compressor

- Low emissions according to Euro 5 standard

- Seat covers/upholstery: Fabric Lima

- Service interval indicator Assyst

- Heat-insulating glazing

- Permissible gross weight: 3.5 t

If you have questions:

Christian Hirsch

Please try calling several times as we are often busy with customers.

Further offers available at /

Equipment details obtained via VIN query—technical errors may occur.

Information provided online is non-binding and for descriptive purposes only. They do not represent guaranteed features. The seller is not liable for mistakes in typing or data transmission / changes / input errors. Errors and prior sale excepted.

Listing

Tirschenreuth

Tirschenreuth

8,062 km

Jig

IngersollGantry 500

Call

Condition: repair required (used), Year of construction: 2002, Year of manufacture 2002

20-fold changer

C02 extinguishing system

Please note: Dielectric cables leaking, axle module defective.

Ndjdpfou St A Iex Agzof

Loading free.

ex warehouse 95643 Tirschenreuth

Shipping possible, transportation costs borne by the buyer

Listing

Koprki

Koprki

8,349 km

1200 mm Stainless Steel Vibrating Screen Allgaier Process Technology

ALLGAIER WERKED1200

Call

Condition: used, Used stainless steel round vibrating screen by Allgaier Process Technology GmbH (Germany) model D1200. Screen has working diameter 1200 mm. Single deck and cleaning deck with rubber balls. Central feeding inlet has diameter 200 mm. Side wall outlet has connection 145 mm. Central discharge of final product has diameter 200 mm. Screen is driven by two vibrating motors, each: 0,75 kW, 1000 rpm, 220-240/380-415 V, 50 Hz, kN 11,1 Ex design. Machine is mounted on stainless supporting frame.

Additional equipment:

- gravity feed metal detector by Cassel (D) model Shark 2, on stainless steel supporting frame

Ndodpex Db Rpsfx Agzof

- carbon steel construction frame with discharge stainless steel pipe and butterfly valve.

Listing

Frankfurt am Main

Frankfurt am Main

7,838 km

Refrigerated truck

MERCEDES-BENZ1833 L ACTROS Tiefkühlkoffer LBW ATP Pharma

Call

Condition: used, mileage: 115,300 km, power: 240 kW (326.31 HP), first registration: 05/2023, fuel type: diesel, overall weight: 18,000 kg, axle configuration: 2 axles, gearing type: automatic, emission class: euro6, loading space volume: 48 m³, loading space length: 7,520 mm, loading space width: 2,480 mm, loading space height: 2,600 mm, Equipment: ABS, air conditioning, navigation system, tail-lift, Bär tail lift 1,500 kg, 1,700 mm, accessible from underneath.

* Thermo King T-1200R cooling unit, diesel + 380 V, cold recorder.

* Service history

----Schmitz freezer box with Cool Slide partition and cold retention system (can be moved lengthways and folded up). ATP/FRC. Pharmaceutical transport possible.

----* 12-speed automatic transmission

Ndsdpowt Hi Eefx Agzjf

* Tail lift can be driven under

* Box with rear doors and tail lift

* Electronic braking system (EBS) with ABS and ASR

* Disc brakes on front and rear axles

* Electronic parking brake

* Wheelbase 5,200 mm

* Smoke detector in driver's cab

* Driver's suspension seat, comfort

* Air conditioning

* Use of residual heat

* Additional thermal insulation in driver's cab

* High storage compartment on engine tunnel

* Storage net on rear wall

* Roof hatch/roof ventilation flap

* Interface, Fleet Management System FMS

* ADR type class EX/II, including AT

* Trailer socket 24 V, 15-pin

* Reversing alarm

* ClassicSpace M driver's cab, 2.30 m wide, engine tunnel 320 mm high

* M driver's cab (medium length)

* Sun visor outside, transparent

* Air horn

* Locking system, with central locking

* Comfort locking system

* Light sensor

* Rain sensor

* Predictive Powertrain Control (PPC)

* Mercedes PowerShift 3

* Heating for driver's seat

* Tires 315/70 R 22.5

* Tires 315/70 R 22.5 HA

* Air suspension, rear axle

* Navigation system

* Rear view camera with monitor in the driver's cab

* Tank 390 liters

* AdBlue tank 60 liters

* Automatic high/low beam and cornering lights

* Fog lights, LED daytime running lights

* Engine OM470, R6, 10.7 l, 240 kW (326 hp), 1700 Nm

* Engine version Euro 6, E

* 2nd generation engine OM470

* High Performance Engine Brake

* Comfort Package

* ADR Package

* Aluminum loading floor

* Stability Control Assistant (ESP)

* Lane Keeping Assistant

* Attention Assistant

* Traffic sign assistant

* Active Brake Assist 5

* Active Sideguard Assist

* Airbag, driver

* Cruise control

* Actros S/M driver's cab, model generation 5

* Load securing rails

* Mercedes-Benz OnRoadService

* MB ATS warranty in accordance with general terms and conditions from first registration 3 years/450,000 km

* EBS

----Sale to commercial customers only! No guarantee for the information! Subject to prior sale! Our general terms and conditions apply exclusively! We would be happy to make you a leasing or financing offer.

Listing

Bydgoszcz

Bydgoszcz

8,145 km

PRESS BRAKE 63X2500 OT-41

OtinusPBO-2563-CNC OT-41

Call

Condition: new, Year of construction: 2024, Attention!! Special Offer!!

Warranty inspection free of charge—only for Customers who have taken part in the demonstration at the machine showroom in Bydgoszcz.

Hydraulic press brake PBO-2563-CNC OT-41

Specifications

- Maximum bending thickness (S235): up to 4.0 mm

- Nominal bending force: 630 kN

- Maximum bending length: 2500 mm

- Throat depth: 250 mm

- Maximum stroke: 120 mm

- Daylight: 370 mm

- Distance between side frames: 2000 mm

- Backgauge travel distance: 600 mm

- Motor power output: 5.5 kW

- Length: 2600 mm

- Width: 1400 mm

- Height: 2200 mm

- Weight: 3700.0 kg

Tools

- Front supports: 2 pcs.

- Backgauge drive (travel along the X-axis): servo motor

Ndsdpfxsgi Dpho Agzef

- Ram drive (travel along the Y-axis): servo motor

- Backgauge fingers positioning (R-axis): manual

- Punch quick change tooling system form AMADA

Otinus CNC OT-41 control

The CNC controller Otinus is featured with convenient and intuitive menu. The software calculates the bending angle on its own. The large color touchscreen is readable from any angle.

The controller can store up to 2,000 programs of 30 steps each.

Top quality components

- Rexroth hydraulic valve

- Schneider electrical components

- Omron and Schneider safety circuit parts.

- Steel hydraulic line tubings

- Hydraulic lines made of steel instead of rubber reduce the risk of future leaks.

Safety

We attach great importance to the safety of our Clients and their employees; therefore our press brakes are equipped with visible safety labels, side guards, rear safety doors, easily accessible safety switches and light curtains that protect the operator against inserting their hands between the upper and lower dies.

The machines comes with carefully prepared instructions manual.

The machine has a CE marking and EU declaration of conformity.

Oil cooling system

The Oil Cooling System guarantees the stability of the machine's performance even after long, continuous operation.

Assistance by a specialist

We strive to maintain constant communication with our Customers. To support this, every machine purchase includes a specialist support package with hours of expert guidance.

Within the service, our technicians may:

- Specify the bending steps for intricate parts.

- Advise on material and gas selection

- Assist in the selection of operating parameters for different materials

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Norway

Norway

7,151 km

Forklift

Toyota02-3FD33 forklift WATCH VIDEO

Call

Condition: used, machine/vehicle number: 3FD35-1xxxx, Year of construction: 2002, Please contact ATS Norway for more information

Please provide reference number upon request: 19534

Specifications:

2002 model

Service done by owner

Lifting height: 5,200 mm

Weight: 5,740 kg

Lifting capacity: 2,600 kg

Fuel: Diesel

Forks: 120 cm

Ready for delivery

Description:Toyota forklift with a lifting capacity of 2,600 kg.Lifting height is 5,200 mm.There is a minor oil leak from the engine.Video available.Delivery by agreement.

Own weight: 5740

Nsdpfx Agswphwcezsdf

Total Weight: 5740

Model: 02-3FD33 gaffel truck SE VIDEO

Listing

Karsin

Karsin

8,083 km

Grundfos pump CRN 10-12 A-FGJ-G-E-HQQE

GrundfosCRN 10-12 A-FGJ-G-E-HQQE

Call

Condition: new, Year of construction: 2022, functionality: fully functional, NEW Grundfos Pump CRN 10-12 A-FGJ-G-E-HQQE | Stainless Steel AISI 316 | 4 kW

Condition: Brand new, never used.

Model: CRN 10-12 A-FGJ-G-E-HQQE

Manufacturer: Grundfos (Leading pump solutions provider)

DEVICE DESCRIPTION

The item for sale is a high-performance, vertical multistage centrifugal pump from the CRN series. This is a version made entirely from acid-resistant stainless steel (AISI 316), setting it apart from the standard cast iron models (CR). It is designed for operation in the most demanding industrial conditions, ensuring reliability when handling aggressive and demanding liquids.

The pump is an ideal solution for businesses seeking a high-efficiency device, ready for immediate installation in water treatment systems, technological processes, or high-pressure setups.

_____

KEY TECHNICAL DATA

• Rated flow: 10 m3/h

• Rated head: approx. 96.7 m (max up to 122 m)

• Motor power: 4 kW

• Power supply: 3-phase

• Rotational speed: 2900 rpm

• Maximum operating pressure: 25 bar

• Liquid temperature range: -20°C to +120°C

• Number of impellers: 12

• Year of manufacture: 2022

CONSTRUCTION AND MATERIALS

• Material configuration (G): All liquid-contacting parts are made from stainless steel EN 1.4401 / AISI 316 (providing maximum corrosion resistance).

• Shaft seal (HQQE): Durable cartridge mechanical seal made from silicon carbide (SiC/SiC) with EPDM elastomers. Guarantees longevity and leak-tight operation even with hot water.

• Connection (FGJ): Universal flanged system (DIN/ANSI/JIS), allowing easy adaptation in existing installations.

_____

APPLICATIONS

Ndsdpfx Aox Im Ahegzsf

Thanks to its acid-resistant construction, the CRN pump is suitable for:

1. Chemical and pharmaceutical industries (pumping acids, alkalis, aggressive media).

2. Filtration and water treatment systems (reverse osmosis, ultrafiltration).

3. Industrial washing systems and CIP/SIP cleaning setups.

4. Process water installations in brewing, dairy, and food industry.

_____

WHY BUY THIS PUMP?

• Premium product: The CRN series is the “Mercedes” among vertical pumps.

• Time-saving: Device is available immediately (no long lead times from the manufacturer).

• No usage marks: The pump is brand new, properly stored, and ready to operate at full capacity.

Important: Please verify that the electrical and hydraulic parameters match your project requirements before purchase.

Listing

Roosendaal

Roosendaal

7,499 km

Tanker truck

DiversenFluid, 50.100L, P28BH, Propane, Butan, GAZ, ADR...

Call

Condition: excellent (used), axle configuration: 3 axles, first registration: 03/2003, loading space length: 13,250 mm, loading space width: 2,550 mm, loading space height: 3,200 mm, loading space volume: 50 m³, total length: 13,250 mm, total width: 2,550 mm, total height: 3,200 mm, suspension: air, tire size: 385/65-R22.5, color: white, Year of construction: 2008, Equipment: ABS, = Additional Options and Equipment =

- ADR

- BPW axles

- EBS

- Lift axle

- Alloy wheels

- Air suspension

- Disc brakes

= Notes =

Fluid chassis, year of manufacture 2008, with GOFA tank body, year of manufacture 1991, single-compartment tank semi-trailer with a capacity of 50,000 litres for butane/propane/gas, ADR (FL, AT), tank inspection valid until 03/2028; leak test valid until 02/2031, ABS/EBS, BPW axles with disc brakes, 1st axle = lift axle, Alcoa rims, 28 bar test pressure, tyres 385/65-R22.5 (L: 10/10/9 mm; R: 16/10/14 mm), unladen weight: 12,000 kg, permissible total weight: 35,000 kg, German registration with valid technical inspection until 31.05.2026.

= Further Information =

Axle configuration

Tyre size: 385/65-R22.5

Axle make: BPW

Brakes: Disc brakes

Suspension: Air suspension

Rear axle 1: Alloy wheels; lift axle; max. axle load: 9,000 kg; tyre tread left: 65%; tyre tread right: 95%

Rear axle 2: Alloy wheels; max. axle load: 9,000 kg; tyre tread left: 65%; tyre tread right: 65%

Rear axle 3: Alloy wheels; max. axle load: 9,000 kg; tyre tread left: 55%; tyre tread right: 90%

Weights

Unladen weight: 12,000 kg

Payload: 23,000 kg

GVW: 35,000 kg

Functional

Body manufacturer: GOFA Gocher Fahrzeugbau GmbH GAZTANK 50,080L

Number of compartments: 1

Ndjdox El Rxjpfx Agzef

Maintenance, History and Condition

APK (Main technical inspection): valid until 05/2026

Technical condition: very good

Visual condition: very good

Listing

Töltéstava

Töltéstava

8,528 km

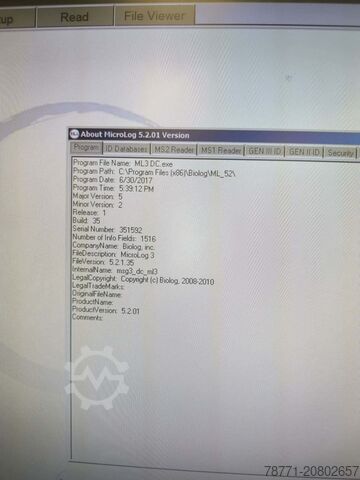

Microplate Reader

Bio- Tek BiologELx808 BLG

Call

Condition: used, Specifications:

Detection modes Absorbance

Read methods End point, kinetic, linear scanning

Microplate types 96-well plates

Temperature control 4-Zone incubation to 50 °C; ±0.2 °C at 37 °C

Shaking Linear

Software Gen5 Reader Control Software; Gen5 Secure for 21 CFR Part 11 compliance (option)

Absorbance

Parameter Specification

Light source Tungsten halogen

Detector Photodiode

Wavelength selection Filters

Wavelength range 380–900 nm; 340–900 nm (ELx808IU)

Dynamic range 0 to 4.0 OD

Resolution 0.001 OD

Pathlength correction No

Filter wheel capacity 6 positions

Filters supplied 4 filters (5 with UV option)

OD accuracy < 1% at 2.5 OD; < 2% at 3.5 OD

OD linearity < 1% at 2.5 OD

OD repeatability < 0.5% at 2.5 OD; < 1.5% at 3.5 OD

Reading speed (kinetic) 96 wells: 8 seconds

General

Parameter Specification

Power 100–240 V AC, 50/60 Hz

Dimensions 15.5" W × 16" D × 8.75" H

Nsdox I Ndbopfx Agzsdf

Weight 30 lbs (13.6 kg)

Listing

Luckenwalde

Luckenwalde

7,959 km

⭐Powder Coating Booths With Filter⭐

ELBOYBOOTHLINE-1200

Call

Condition: new, ⭐⭐⭐⭐⭐ (5.0) 42 ratings

✈️ 25 day delivery ✈️

✅✅✅Energy class A+++✅✅✅

⚡️ Top service ⚡️ Fast delivery ⚡️ Great support!

PLUS VAT. & SHIPPING

►►Buy It Now◄◄

✳️Keep your liquidity! We offer a variety of financing models to ensure your investment has the best chance of success. Contact us today to learn more about our hire-purchase, warranty or lease programs. ✳️

➖➖➖➖➖

►►►⌛⏰ FASTEST delivery time❗ ⌛⏰►►►

✨✨Buy directly from the manufacturer and secure the price and quality advantage!✨✨

Benefit from Proton's 40 years of experience in surface coating technologies.

➖➖➖➖➖

☘️Eco-Friendly☘️⚡️Green Energy⚡️☘️

⭐ Powder booth – BOOTHLINE1200 - FL

✔️ Internal dimensions: 1130 mm L * 1250 mm W * 1450 mm H

✔️ 2 Flanged polyester filter

✔️ Ø325*1000mm filter dimensions.

✔️ Automatic filter cleaning system (adjustable cleaning time)

✔️ Powder coating collection drawer

✔️ 360 degree rotatable and movable hanging device.

✔️ 1 PC 2.2 KW suction fan - 4500 m3/h

✔️Cab construction

The powder booth is designed for manual application of the powder coating in an electrostatic field. The spray booth is made of powder-coated galvanized sheet iron.

The interior and exterior of the cabin construction is coated with electrostatic powder paint [RAL 7024 MX - RAL 7047].

All parts of the powder booth are easily assembled with bolted connections and, if desired, easily disassembled.

✔️Suction system

It is a system that prevents powder paint from leaking out of the booth and causing pollution when painting in the booth.

The extraction system has been specially designed for each booth to ensure excellent extraction.

Thanks to the suction system, the personnel applying powder coating are not affected by the paint.

✔️Filtration system

The dust particles in the air extracted by the suction fans are held in the cab by fleece filters for long-lasting filtration, and filtered air is discharged from the exhaust stack.

The filters separate the powder from the air by passing the powder/air mixture through the outside of the filter through a filter layer that keeps the dust and permeates the air.

As filtration continues, dust accumulates outside the filter, increasing dust holding efficiency. The filter size is 330x1000, the surface is 9-10 m2.

✔️Powder recovery

The powder paint applied in the booth is collected in the paint powder compartment at the bottom of the booth and can be reused manually.

As an option, an automatic paint screen can be installed instead of the booth compartment. This screen collects the paint with the vibration motor from the booth and transfers it directly to the spray gun.

Ndsdpfedhi Aaox Agzof

✔️Conveyor or suspension

It can be integrated with bar transfer conveyor systems. In the models with eyelets, the product can be guided into the cabin with a suspension. Standard models feature a 360 degree rotating and articulating hanger.

The price shown is for the smallest standard version. All devices/machines are new, not used.

Do you want a special configuration ❗ Call us now❗

Listing

Hüllhorst

Hüllhorst

7,700 km

Edge banding machine

LangeB 90 KFE Plus mit Fügen + Eckenkopieren

Call

Condition: as good as new (ex-display), Year of construction: 2025, One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces (EVA-PUR Glue pot with run-out function/optional), HF-cut-off saw station with 2xMotors , HF-top and bottom milling unit, corner rounding unit, chain feed, double roller top pressure, extendable work piece support, signal lamp for work piece sequence and synchronisation of working units by encoder. For ABS, PVC, melamine and

strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0/6.0 mm and of 8 – 60 mm work piece thickness.

Speed: 10,0 m/min.; 8,0 m/min. with corner rounding • 3 spaces for finishing units • 10“ Colour Touch screen

→Automatic edge feeding for roller material over turntable D = 800 mm

→Longer infeed lineal (650 mm)

Ndedpel Rix Njfx Agzjf

→Two reverse, operating-controlled pre-milling units with diamond charged helical joining millers provide a neat and tear-free premilling of the work pieces before the gluing of the edge material

→Glue application directly to workpieces: Teflon-coated glue pot with a capacity of 1,5 kg, leak proof with glue supply from below (excess glue automatically flows back into the glue pot). Glue roller allows exact dosage of glue. Separate glue roller temperature adjustment. Electronic temperature control with automatic stand-by function (reduces probability that the glue burns if the machine is not used for a longer periods and is still turned on).

Optional: EVA/PUR gluepot with run out / cleaning function for quick change of glue

→Pneumatically operated cut-off knife from roll material up to 3mm edge thickness

→Automatic feeding magazin (70mm magazin capacity) with spiked roller for solid wood

→Pressure unit consisting of one driven pressure roller synchronized with glue spreading roller and two of smaller diameter, conical, one positive and one negative pressure roller with spring tension for a nearly invisible joint of the edge material with the work piece , adjustment of the pressure unit with digital readout.

→High-frequency cut-off saw equipped with 2xHF motor 0.55 kW, 12,000 rpm, 2 saw blades and high-precision linear guides ensure a clean and precise saw cut, with extraction hood.

→High-frequency top and buttom milling station, 2 powerful 0.55 kW high-frequency motors with HM-WPL special millers; suitable for radius, bevel and flush milling, horizontal and vertical scanning of the work piece; aggregate adjustment equipped with digital readouts for setting to various edge types; 2 extraction hoods for shavings with central extraction nozzle 2 x Ø 100 mm; height adjustment of the upper aggregate with the top roll pressure

→Corner rounding unit : Automatic processing of corner edges up to 2 mm edge thickness. Equipped with one high frequency motor 0, 27 kW, selectable on operating panel.

One side (front or back edge) or both side corner rounding unit.

→Rotatable control panel with 10“ color touch screen controls glue temperature settings, automatic temperature reduction for stand-by function of the machine, switching on and off of aggregates and error diagnosis, incl. digital Meter counter

Additional finish aggregates :

→Radius scraper unit : With a slight draw cut eventual radius milling traces are removed to provide a perfect finish. The fine adjustment is made by digital readouts.

→Glue scraper unit : Removes eventual glue rests with a slight draw cut from the glue joint of th

Listing

Norway

Norway

7,196 km

Wheel loader

VolvoL90E wheel loader. WATCH VIDEO.

Call

Condition: used, Year of construction: 2006, operating hours: 15,400 h, CE mark: yes

Serial number: L90EV2xxxx

Please contact ATS Norway for more information

Please provide reference number upon request: 21381

Specifications:

- 2006 model

- Hours: approx. 15,400

- Weight: 17,000 kg

- 121 kw

- HP attachment

- Tires (see pictures)

- New batteries last winter

- Front hydraulic couplings

- Left front wheel and right rear wheel are leaking air

- Rearview camera

- AC/climate

- CD player

Ndodpfx Agjxfgcmozjf

- Ready to ship

Description:

2006 Volvo L90E wheel loader.

Air is leaking from left front wheel and right rear wheel. Owner must fill air once a month.

Hydraulic pallet fork, regular pallet fork, leveling bucket can be sold at extra cost.

Ready for delivery.

Hours: 15400

Own weight: 17000

Kw: 121

CE: Yes

Model: L90E hjullaster. SE VIDEO

Trust Seal

Dealers certified through Machineseeker

Listing

Florange

Florange

7,733 km

Standard tractor unit

RenaultC-Series

Call

Condition: new, mileage: 100 km, power: 520 kW (707.00 HP), maximum load weight: 19,000 kg, axle configuration: 1 axle, wheelbase: 3 mm, fuel: diesel, driver cabin: day cab, gearing type: automatic, emission class: euro6, Equipment: Bluetooth, air conditioning, central locking, cruise control, fridge, onboard computer, rear view camera, retarder, VOITH

REVERSING CAMERA

CARPLAY & ANDROID AUTO

BLUETOOTH

AIR CONDITIONING

LOAD INDICATORS

ECO ROLL

TRAFFIC SIGN RECOGNITION

ECO MODE

BLIND SPOT DETECTORS

LANE CHANGE ASSIST

DISTANCE WARNING

TOUCHSCREEN

KEYLESS START

LED REAR LIGHTS

LEATHER STEERING WHEEL

WEBASTO (AUXILIARY HEATER)

FRIDGE

HEATED SEAT

Njdpfxjx E Sg Hj Agzedf

CRUISE CONTROL & SPEED LIMITER

AUTOMATIC LIGHTS & WIPERS

4-POINT AIR SUSPENSION CAB

POWER TAKE-OFF (PTO)

...

WHEELBASE 3800 mm

Listing

Hüllhorst

Hüllhorst

7,700 km

Edge banding machine

LangeB 80 KF-VR mit Fügen+VR Funktion

Call

Condition: as good as new (ex-display), Year of construction: 2025, One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces, end trimming station with VR function , HF-top and bottom milling unit, chain feed, double roller top pressure and extendable work piece support. For ABS and PVC roll material as well as fixed lengths from 0.4 – 2.0 mm and of 8 – 50 mm work piece thickness.

• Speed: 5,5 m/min. • 2 spaces for finishing unit • 5,6“ Colour Touch screen

→Automatic edge feeding for roller material over turntable D = 600 mm

→Two reverse, operating-controlled pre-milling units with diamond charged helical joining millers provide a neat and tear-free premilling of the work pieces before the gluing of the edge material

Nodoip Uzpspfx Agzjdf

→Glue application directly to workpieces: Teflon-coated glue pot with a capacity of 1,5 kg, leak-proof with glue supply from below (excess glue automatically flows back into the glue pot). Glue roller allows exact dosage of glue. Electronic temperature control with automatic stand-by function (reduces probability that the glue burns if the machine is not used for a longer period and is still turned on)

→Pneumatically operated cut-off knife from roll material up to 2 mm edge thickness

→Pressure unit consisting of one driven pressure roller synchronized with glue spreading roller and one adjustable pressure roller with spring tension for a nearly invisible joint of the edge material with the work piece

→End trimming station for front-and back egde with HF-Motor 0,27 KW /12000 U/min ,milling head with interchangeable knives and VR Function for vertical rounding . Automatic setting from workpiece, with dust collector system

→High-frequency top and buttom milling station, 2 powerful 0.27 kW high-frequency motors with HM-WPL special millers; suitable for radius and bevel milling, horizontal and vertical scanning of the work piece; aggregate adjustment equipped with digital readouts for setting to various edge types; 2 extraction hoods, height adjustment of the upper aggregate with the top roll pressure

→OMRON 5,6“ colour touchscreen controls glue temperature settings, automatic temperature reduction for stand-by function of the machine, switching on and off of aggregates and error diagnosis

Additional finish aggregates (1 free space):

→Glue scraper unit : Removes eventual glue rests with a slight draw cut from the glue joint of the work piece surface

→Buffing unit : 2 motors 0,09 kW, 1,500 rpm provide a super-finish for ABS and PVC edge material

67641340ec347

Listing

Hüllhorst

Hüllhorst

7,700 km

Edge banding machine

LangeB 85 KF mit Fügen

Call

Condition: as good as new (ex-display), Year of construction: 2025, One-sided automatic edge banding machine with pre-milling

unit, direct glue application to straight workpieces (EVA-PUR

Glue pot with run-out function/optional), HF-cut-off saw station,

Nedpsd R U Acefx Agzodf

HF-top and bottom milling unit, chain feed, double roller

top pressure, extendable work piece support and signal lamp

for work piece sequence. For ABS, PVC, melamine and strong

wood veneer roll material as well as fixed lengths from 0.4 –

3.0 mm and of 8 – 50 mm work piece thickness.

Speed: 7,0 m/min.

• 2 spaces for finishing units • 7,0“ Colour Touch screen

→Automatic edge feeding for material over turntable D=600 mm

→Infeed lineal (400mm)

→Two reverse, operating-controlled pre-milling units with diamond charged helical joining millers provide a neat and tear-free premilling of the work pieces before the gluing of the edge material

→Glue application directly to workpieces: Teflon-coated glue pot with a capacity of 1,5 kg, leak proof with glue supply from below (excess glue automatically flows back into the glue pot). Glue roller allows exact dosage of glue. Separate glue roller temperature adjustment.

Electronic temperature control with automatic stand-by function (reduces probability that the glue burns if the machine is not used for a longer periods and is still turned on).

Optional: EVA/PUR glue pot with run out / cleaning function for quick change of glue.

→Pneumatically operated cut-off knife from roll material up to 3 mm edge thickness

→A group of two rollers exerting pressure on the edge band mechanically in order to achieve its adhesion onto the panel edge. The first roller is driven and the smaller second one is idle. Adjustment of the pressure rollers with mechanical SIKO display

→High-frequency cut-off saw equipped with HF motor 0.21 kW, 12,000 rpm , 2 saw blades and high-precision linear guides ensure a clean and precise saw cut, with extraction hood.

→High-frequency top and buttom milling station, 2 powerful 0.27 kW high-frequency motors with HM-WPL special millers; suitable for radius and bevel milling, horizontal and vertical scanning of the work piece; aggregate adjustment equipped with digital readouts for setting to various edge types; 2 extraction hoods for shavings with central extraction nozzle 2 x Ø 100 mm; height adjustment of the upper aggregate with the top roll pressure

→Rotatable control panel with 7,0“ color touch screen controls glue temperature settings, automatic temperature reduction for stand-by function of the machine, switching on and off of aggregates and error diagnosis

→LED lights

→Optional : Riepe non-stick spray station and Riepe cleaning spray station

Additional finish aggregates :

→Radius scraper unit : With a slight draw cut eventual radius milling traces are removed to provide a perfect finish. The fine adjustment is made by digital readouts

→Glue scraper unit : Removes eventual glue rests with a slight draw cut from the glue joint of the work piece surface

→Buffing unit : 2 motors 0.05 kW, 1,500 rpm provide a super-finish for ABS and PVC edge material

67641340eaae3

Listing

Hüllhorst

Hüllhorst

7,700 km

Edge banding machine

LangeB 85 KFE mit Fügen + Eckenkopieren

Call

Condition: as good as new (ex-display), Year of construction: 2025, One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces (EVA-PUR Glue pot with run-out function/optional), HF-cut-off saw station, HF-top and bottom milling unit, Corner rounding unit, chain feed, double roller top pressure, extendable work piece support and signal lamp

for work piece sequence. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from 0.4 –3.0 mm and of 8 – 50 mm work piece thickness. Speed: 7,0 m/min. • 2 spaces for finishing units • 10,0“ Colour Touch screen

→Automatic edge feeding for material over turntable D=600 mm

→Infeed lineal (400mm)

→Two reverse, operating-controlled pre-milling units with diamond charged helical joining millers provide a neat and tear-free premilling of the work pieces before the gluing of the edge material

→Glue application directly to workpieces: Teflon-coated glue pot with a capacity of 1,5 kg, leak proof with glue supply from below (excess glue automatically flows back into the glue pot). Glue roller allows exact dosage of glue. Separate glue roller temperature adjustment.

Electronic temperature control with automatic stand-by function (reduces probability that the glue burns if the machine is not used for a longer periods and is still turned on).

Optional: EVA/PUR glue pot with run out / cleaning function for quick change of glue.

→Pneumatically operated cut-off knife from roll material up to 3 mm edge thickness

→A group of two rollers exerting pressure on the edge band mechanically in order to achieve its adhesion onto the panel edge. The first roller is driven and the smaller second one is idle. Adjustment of the pressure rollers with mechanical SIKO display

→High-frequency cut-off saw equipped with HF motor 0.21 kW, 12,000 rpm , 2 saw blades and high-precision linear guides ensure a clean and precise saw cut, with extraction hood.

→High-frequency top and buttom milling station, 2 powerful 0.27 kW high-frequency motors with HM-WPL special millers; suitable for radius and bevel milling, horizontal and vertical scanning of the work piece; aggregate adjustment equipped with digital readouts for setting to various edge types; 2 extraction hoods for shavings with central extraction nozzle 2 x Ø 100 mm; height adjustment of the upper aggregate with the top roll pressure

→Corner rounding unit : automatic processing of corner edges up to 2 mm edge thickness. Equipped with one high frequency motor 0, 27 kW, selectable on operating panel

→Rotatable control panel with 10,0“ color touch screen controls glue temperature settings, automatic temperature reduction for stand-by function of the machine, switching on and off of aggregates and error diagnosis

→LED lights

→Optional : Riepe non-stick spray station and Riepe cleaning spray station

Additional finish aggregates :

→Radius scraper unit : With a slight draw cut eventual radius milling traces are removed to provide a perfect finish. The fine adjustment is made by digital readouts

Ndjdpfx Asd R U Adogzef

→Glue scraper unit : Removes eventual glue rests with a slight draw cut from the glue joint of the work piece surface

→Buffing unit : 2 motors 0.05 kW, 1,500 rpm provide a super-finish for ABS and PVC ed

67641340e9686

We make it easier for you to find: "leake detector"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Leake Detector (925)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month