Used Compensation System for sale (37,145)

Eisenberg (Pfalz)

Eisenberg (Pfalz) Vibratory finishing system

PERSTurbo-Line140 S

Europa

Europa STEAM SYSTEM

JUMAGDG 260

Tauberbischofsheim

Tauberbischofsheim Impregnate system

Wichmann

Europa

Europa INJECTION MOLDING M. WITH DOSING SYSTEM

NETSTALSYNERGY S 3000-900

Marl

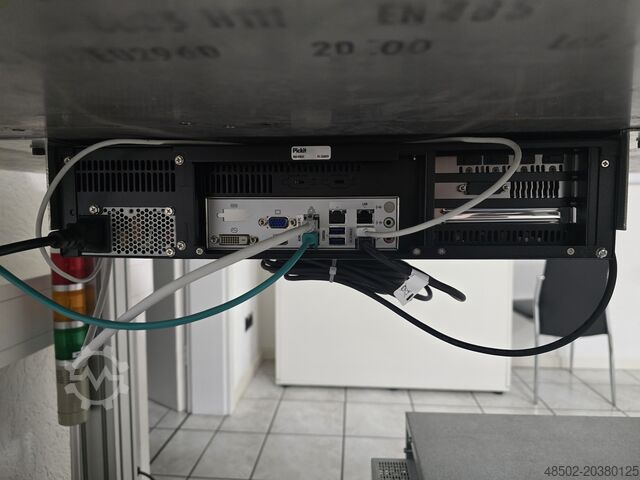

Marl Pickit 3D

ABBPickit 3D system Complete Package

Discover more used machines

Tönisvorst

Tönisvorst Control system

HeidenhainND 281 B

Tauberbischofsheim

Tauberbischofsheim Transport system

Unbekannter Hersteller

Tauberbischofsheim

Tauberbischofsheim Transport system

Weinig

Tauberbischofsheim

Tauberbischofsheim Transport system

Haneu

Kuchl

Kuchl Mobile exhaust system

FelderRL 160

Lambsborn

Lambsborn Mobile exhaust system

AL-KOMobilJet 100

Lambsborn

Lambsborn Mobile exhaust system

SpänexMobil

Tönisvorst

Tönisvorst Control system

ABBTZIDC 18345-2011160001

Sierakowska Huta

Sierakowska Huta Multispindle Drill

MAGGIBoring System 23

Germany

Germany 3D Camera Measuring System

ARAMIS GOM300 / 2.3M

Buseck

Buseck Drying and disinfection system

PHTHYGIfeet MINI SBSFM05

Janville

Janville Suction lifting system

Manut LM-

Gleisdorf

Gleisdorf Compact system promptly delivery

CloosOrbit 4 DP-2200 N

Juszczyn

Juszczyn Stationary exhaust system

F.lli ferrari

Great Britain

Great Britain Bulk packing line

Gainsborough Engineering Co.GV4 Complete Packing System

Babenhausen

Babenhausen Grease recovery system

ReimeltEL 6/1000S

Neukamperfehn

Neukamperfehn High-bay warehouse pallet racking system

SSI Schäfer PR600Regallänge: 17,04 lfm.

Drachten

Drachten Outlet conveyor system behind Weinig

RGBTMC-3500

Vuren

Vuren BDF system

MERCEDES-BENZACTROS 2542 LS

Vuren

Vuren BDF system

VOLVOFH 500 WB460 I-PARK-COOL

Used Compensation System (37,145)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you