Used Crankshaft for sale (129)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Turkey

Turkey

9,663 km

C-type 150 ton eccentric press machine

CRONOSSTECHCECP 150

Call

Condition: new, Year of construction: 2025, throat depth: 320 mm, table width: 920 mm, table length: 660 mm, pressing force: 160 t, ram bore: 55 mm, power: 15 kW (20.39 HP), punching force: 160 t, warranty duration: 24 months, Equipment: safety light barrier, Eccentric presses are mechanical presses that operate with force generated via an eccentric mechanism and are used in cold forming operations such as punching, cutting, and forming with dies. Thanks to their high production speed and repeatability, they provide an efficient and reliable solution for mass production lines.

The CRONOSSTECH C-Type Eccentric Press 150 Ton is engineered for stable operation in cold forming applications. Its rigid steel construction, pneumatic clutch-brake system, and CE-compliant safety infrastructure ensure reliable performance for serial production.

Gtedpfx Abovtywdorju

Key Advantages

- Stable stroke performance and high repeatability in serial production

- Operator safety-oriented design (light curtain + safety systems)

- Reduced maintenance needs with centralized automatic lubrication

- PLC control + dual hand/foot control for production-ready operation

Application Areas

- Cold cutting and punching operations

- Cold forging applications

- Metal die forming

- High-volume production lines

✅ STANDARD FEATURES

• Steel construction frame

• Four-sided slide guidance

• Spheroidal cast iron connecting rod and gear bushings

• 4140 quenched and tempered steel crankshaft and transmission shafts

• Central fully automatic grease lubrication system

• Pneumatic clutch and brake combination

• CE safety compliant

• Dual-coil safety valve

• Manually adjustable stroke

• Finger and hand protection with light curtain safety system

• PLC control system

• Dual hand/foot control system

• Mechanical safety lock system

• Emergency reverse motor operation

• Compliant with occupational safety regulations

• Meets CE standards

✅ OPTIONAL FEATURES

• Anti-vibration mountings

• Touchscreen LCD display (standard for 150–300 ton)

• Hydraulic safety system (standard for 200–300 ton)

• Spare die plate

• Decoiler, feeder, and straightener

• One set of die to customer specifications

• 8-sided slide guidance

✅ TECHNICAL SPECIFICATIONS (150 TON)

Capacity: 150 Ton

Throat depth: 320 mm

Bed-to-ram distance: 500 mm

Slide-to-table distance: 540 mm

Distance between uprights: 500 mm

Ram adjustment (stroke): 120 mm

Approx. width: 1600 mm

Approx. depth: 2280 mm

Approx. height: 2750 mm

Front anchoring size: 840 mm

Side anchoring size: 1300 mm

Bed bore diameter: Ø220 mm

Table size: 660×920 mm

Die mounting hole diameter: Ø55 mm

Ram size: 600×290 mm

Floor-to-table height: 805 mm

Stroke adjustment: 10–125 mm

Strokes per minute: 42 spm

Motor power: 15 kW

Motor speed: 1450 rpm

Approximate weight: 7100 kg

Note: If you require changes in technical specifications, please let us know.

✅ PRODUCTION / SUPPLY NOTE

This machine is manufactured by CRONOSSTECH in Turkey. Sales, commissioning, and after-sales processes are managed by CRONOSSTECH.

Listing

Turkey

Turkey

9,663 km

C-type 125 ton eccentric press machine

CRONOSSTECHCECP 125

Call

Condition: new, Year of construction: 2025, drop-through hole in table: 220 mm, table width: 750 mm, table length: 1,000 mm, stroke adjustment: 140 mm, pressing force: 130 t, ram bore: 55 mm, punching force: 130 t, warranty duration: 24 months, Equipment: safety light barrier, Eccentric presses are a type of mechanical press powered by the force generated through an eccentric mechanism, commonly used for cold forming processes such as punching, cutting, and die forming. With high production speed and repeatability, they provide an efficient and reliable solution for mass production lines.

The CRONOSSTECH C-Type Eccentric Press 125 Ton is engineered for stable operation in cold forming applications. Its rigid steel welded body, pneumatic clutch-brake system, and CE-compliant safety infrastructure ensure reliable performance suitable for series production.

Key Advantages:

- Stable stroke performance and high repeatability in mass production

- Operator safety-oriented design (light barrier + safety systems)

- Low maintenance requirement thanks to central automatic lubrication

- Production-ready operation with PLC control + dual hand/foot controls

Fields of Application:

- Cold cutting and punching operations

- Cold forging applications

- Metal die forming

- High-volume production lines

✅ STANDARD FEATURES

• Steel welded frame

• 4-sided slide guidance

• Spheroidal cast iron connecting rod and gear bearings

• Crankshaft and transfer shafts made from 4140 hardened steel

• Central fully-automatic grease lubrication system

• Pneumatic clutch and brake combination

• CE safety directive compliant

• Dual-coil safety valve

• Manually adjustable stroke

• Light barrier finger/hand protection safety system

• PLC control system

• Dual hand/foot control system

• Mechanical safety lock system

• Emergency reverse motor movement

• Occupational safety regulation compliant

• CE-conformant

✅ OPTIONAL FEATURES

• Anti-vibration pads

• Touchscreen LCD panel (standard for 150–300 tons)

• Hydraulic safety system (standard for 200–300 tons)

• Spare table

• Decoiler, feeder, and straightener

• 1 die set tailored to specifications

• Eight-point slide guide

✅ TECHNICAL SPECIFICATIONS (125 TON)

Capacity: 125 Tons

Gtodpsvtyvgofx Abrju

Throat depth: 310 mm

Distance table–slide: 500 mm

Distance between slide and table: 510 mm

Distance between uprights: 450 mm

Slide adjustment (stroke adjustment): 100 mm

Press width: 1500 mm

Press depth: 2200 mm

Press height: 2700 mm

Front anchorage (footprint): 790 mm

Side anchorage (footprint): 1250 mm

Table hole diameter: Ø210 mm

Table size: 630×820 mm

Die clamping slot diameter: Ø55 mm

Slide size: 500×250 mm

Table height from floor: 785 mm

Stroke adjustment: 10–125 mm

Strokes per minute: 50 spm

Motor power: 11 kW

Motor speed: 1450 rpm

Weight: 6000 kg

Note: Please inform us if you require changes to the technical specifications.

✅ MANUFACTURING / SUPPLY NOTE

This machine is manufactured in Turkey by CRONOSSTECH. Sales, commissioning, and after-sales processes are managed directly by CRONOSSTECH.

Listing

Turkey

Turkey

9,663 km

C type 100 ton eccentric press machine

CRONOSSTECHCECP 100

Call

Condition: new, Year of construction: 2025, pressing force: 100 t, table width: 670 mm, table length: 950 mm, drop-through hole in table: 180 mm, power: 7.5 kW (10.20 HP), punching force: 100 t, ram bore: 45 mm, stroke adjustment: 120 mm, warranty duration: 24 months, Equipment: safety light barrier, An eccentric press is a type of mechanical press powered by an eccentric mechanism, designed for cold forming operations such as punching, cutting, and die forming. Thanks to its high production speed and repeatability, it provides an efficient and reliable solution for mass production lines.

The CRONOSSTECH C-Type Eccentric Press 100 Ton is engineered for stable operation in cold forming applications. Its rigid steel construction, pneumatic clutch-brake system, and CE-compliant safety infrastructure deliver dependable performance suitable for serial production.

Key Advantages

- Stable stroke performance and high repeatability in mass production

- Operator safety-focused design (light barrier + safety systems)

- Low maintenance requirement with centralized automatic lubrication

- Production-ready operation with PLC control + dual-hand/foot pedal control

Application Areas

- Cold cutting and punching operations

- Cold forging applications

- Metal die forming

- High-volume production lines

✅ STANDARD FEATURES

• Steel construction frame

• 4-sided slide guiding

• Spheroidal cast iron connecting rod and gear housings

• Crankshaft and transmission shafts made of 4140 tempered steel

• Centralized fully automatic grease lubrication

• Pneumatic clutch and brake combination

• CE safety compliant

• Dual-coil safety valve

• Manually adjustable stroke

• Light barrier hand and finger safety protection system

• PLC control system

• Dual-hand/foot pedal control system

• Mechanical safety system

• Emergency reverse motor operation

• Compliant with occupational safety regulations

• CE standards compliant

✅ OPTIONAL FEATURES

• Anti-vibration pads

• Touchscreen LCD panel (standard for 150–300 ton)

• Hydraulic safety system (standard for 200–300 ton)

• Spare table

• Uncoiler, feeder, and straightener

• One set of custom die as requested

• 8-sided slide guiding

✅ TECHNICAL SPECIFICATIONS (100 TON)

Capacity: 100 Ton

Throat depth: 300 mm

Bolster–ram distance: 400 mm

Slide–table distance: 465 mm

Distance between side frames: 420 mm

Ram adjustment (stroke setting): 85 mm

Approx. press width: 1400 mm

Approx. press depth: 1900 mm

Approx. press height: 2450 mm

Front anchoring dimension: 710 mm

Side anchoring dimension: 1135 mm

Bolster hole diameter: Ø200 mm

Bolster size: 600×780 mm

Die mounting slot diameter: Ø50 mm

Ram size: 405×240 mm

Table height from floor: 775 mm

Stroke adjustment: 10–110 mm

Strokes per minute: 50 spm

Gedpfx Absvtx Insrjtu

Motor power: 11 kW

Motor speed: 1450 rpm

Approximate weight: 4650 kg

Note: Please inform us if you require changes to the technical specifications.

✅ PRODUCTION / SUPPLY NOTE

This machine is manufactured by CRONOSSTECH in Turkey. Sales, commissioning, and after-sales processes are handled directly by CRONOSSTECH.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Turkey

Turkey

9,663 km

C Type 80 Ton Eccentric Press Machine

CRONOSSTECHCECP 80

Call

Condition: new, Year of construction: 2025, drop-through hole in table: 180 mm, table width: 660 mm, table length: 860 mm, stroke adjustment: 110 mm, pressing force: 80 t, power: 5.5 kW (7.48 HP), punching force: 80 t, warranty duration: 24 months, Equipment: safety light barrier, An eccentric press is a type of mechanical press that operates via a force generated by an eccentric mechanism and is used in cold forming operations such as punching, cutting, and die forming. Thanks to its high production speed and repeatability, it is an efficient and reliable solution for mass production lines.

The CRONOSSTECH C-Type Eccentric Press 80 Ton is engineered for stable operation in cold forming applications. Its rigid steel frame, pneumatic clutch-brake system, and CE-compliant safety infrastructure ensure reliable performance suitable for mass production.

Key Advantages:

- Stable stroke performance and high repeatability in serial production

- Operator safety-focused design (light curtain + safety systems)

- Low maintenance requirement with centralized automatic lubrication

- Production-ready operation with PLC control + dual-hand/foot control

Typical Applications:

- Cold shearing and punching operations

- Cold forging applications

- Metal die forming

- High-volume production lines

✅ STANDARD FEATURES

• Steel construction frame

• Four-sided guided slide

• Spheroidal graphite cast iron connecting rod and gear bushings

• Crankshaft and transmission shafts made of 4140 tempered steel

• Centralized, fully automatic grease lubrication system

• Pneumatic clutch and brake combination

• Compliant with CE safety directives

• Double-coil safety valve

• Manually adjustable stroke

• Finger–hand protection light curtain safety system

• PLC control system

• Dual-hand/foot control system

• Mechanical locking system

• Emergency reverse motor operation

• Occupational safety regulation compliant

• Conforms to CE standards

✅ OPTIONAL FEATURES

• Anti-vibration mounting pads

• Touchscreen LCD panel (standard between 150–300 tons)

• Hydraulic safety system (standard between 200–300 tons)

• Spare bolster plate

• Decoiler, feeder, and straightener

• One die set to requested specifications

• Eight-way slide guides

✅ TECHNICAL SPECIFICATIONS (80 TON)

Godpsvtx H Rofx Abrjtu

Capacity: 80 Ton

Throat depth: 280 mm

Bed–ram distance: 400 mm

Slide–table distance: 420 mm

Distance between side frames: 400 mm

Ram adjustment (slide adjustment): 85 mm

Approx. press width: 1400 mm

Approx. press depth: 1735 mm

Approx. press height: 2220 mm

Front anchor dimension: 670 mm

Side anchor dimension: 1040 mm

Table hole diameter: Ø190 mm

Table size: 540×740 mm

Die clamping hole diameter: Ø40 mm

Ram size: 370×230 mm

Bed height from floor: 755 mm

Stroke adjustment: 10–100 mm

Strokes per minute: 45–75 spm

Motor power: 7.5 kW

Motor speed: 1450 rpm

Approximate weight: 4000 kg

Note: Please inform us if you require modifications in the technical specifications.

✅ PRODUCTION / SUPPLY NOTE

This machine is manufactured by CRONOSSTECH in Turkey. All sales, commissioning, and after-sales processes are directly managed by CRONOSSTECH.

Listing

Turkey

Turkey

9,663 km

C TYPE 60 TONS ECCENTRIC PRESS MACHINE

CRONOSSTECHCECP 60

Call

Condition: new, Year of construction: 2025, drop-through hole in table: 140 mm, table width: 590 mm, table length: 800 mm, stroke adjustment: 100 mm, pressing force: 60 t, ram bore: 40 mm, power: 5.5 kW (7.48 HP), punching force: 60 t, warranty duration: 24 months, Equipment: safety light barrier, An eccentric press is a type of mechanical press powered by force generated through an eccentric mechanism, used for cold forming operations such as punching, cutting, and die forming. Thanks to its high production speed and repeatability, it offers an efficient and reliable solution for mass production lines.

The CRONOSSTECH C-Type Eccentric Press 60 Ton is engineered for stable operation in cold forming applications. Its rigid steel frame, pneumatic clutch-brake system, and CE-compliant safety infrastructure deliver reliable performance suitable for serial production.

Key advantages:

- Stable stroke performance and high repeatability in mass production

- Operator safety-focused design (light curtain + safety systems)

- Low maintenance requirement through centralized automatic lubrication

- Production-ready operation with PLC control + dual hand/foot control

Areas of application:

- Cold cutting and punching operations

- Cold blanking applications

- Metal die forming

- High volume production lines

✅ STANDARD FEATURES

• Steel frame construction

• Four-way guided slide

• Spheroidal cast connecting rod and gear housings

• Crankshaft and drive shafts in 4140 tempered steel

• Centralized fully automatic grease lubrication system

Gedpfx Abjvtx D Nsrotu

• Pneumatic clutch and brake combination

• CE safety directive compliant

• Dual coil safety valve

• Manually adjustable stroke

• Finger/hand protection safety system with light curtain

• PLC control system

• Dual hand/foot control system

• Mechanical locking system

• Emergency reverse motor function

• Conforms to occupational safety regulations

• Compatible with CE standards

✅ OPTIONAL FEATURES

• Anti-vibration pads

• Touch screen LCD display (standard for 150–300 tons)

• Hydraulic locking system (standard for 200–300 tons)

• Spare bolster plate

• Decoiler, feeder and straightener

• One custom die set as requested

• 8-point slide guide

✅ TECHNICAL SPECIFICATIONS (60 TON)

Capacity: 60 Ton

Throat depth: 260 mm

Table-to-ram distance: 360 mm

Slide-to-table distance: 395 mm

Distance between uprights: 380 mm

Ram adjustment (stroke adjustment): 70 mm

Approx. press width: 1340 mm

Approx. press depth: 1450 mm

Approx. press height: 2200 mm

Front anchor dimension: 630 mm

Side anchor dimension: 875 mm

Table hole diameter: Ø150 mm

Table size: 520×720 mm

Die mounting slot diameter: Ø40 mm

Ram size: 340×220 mm

Table height from floor: 730 mm

Stroke adjustment: 0–95 mm

Strokes per minute: 50 spm

Motor power: 4 kW

Motor speed: 1450 rpm

Approx. weight: 2750 kg

Note: Please contact us if you need modifications to the technical specifications.

✅ PRODUCTION / SUPPLY NOTE

This machine is manufactured by CRONOSSTECH in Turkey. Sales, commissioning, and after-sales processes are managed directly by CRONOSSTECH.

Listing

Turkey

Turkey

9,663 km

C-type 25 ton eccentric press machine

CRONOSSTECHCECP 25

Call

Condition: new, Year of construction: 2025, throat depth: 175 mm, table width: 375 mm, table length: 570 mm, stroke adjustment: 60 mm, pressing force: 25 t, An eccentric press is a type of mechanical press driven by a force generated through an eccentric mechanism, used in cold forming operations such as punching, shearing, and die forming. Thanks to its high production speed and repeatability, it provides an efficient and reliable solution for mass production lines.

CRONOSSTECH C-Type Eccentric Press 25 Ton is designed for stable operation in cold forming applications. Its rigid steel frame, pneumatic clutch-brake system, and CE-compliant safety infrastructure deliver reliable performance suited for mass production.

Key advantages:

- Stable stroke performance and high repeatability in series production

- Operator safety-focused design (light curtain + safety systems)

- Low maintenance requirement with centralized automatic lubrication

- Production-ready usage with PLC control + dual hand/foot operation

Areas of use:

- Cold shearing and punching operations

- Cold blanking applications

- Metal die forming

- High-volume production lines

Gtsdpfxexg R Ucj Abrou

STANDARD FEATURES

• Steel fabricated body

• Four-sided guided ram

• Spheroidal cast iron connecting rod and gearboxes

• Crankshaft and transmission shafts made of 4140 normalized steel

• Centralized fully automatic grease lubrication system

• Pneumatic clutch and brake combination

• Compliant with CE safety directives

• Dual coil safety valve

• Manually adjustable stroke

• Light curtain finger–hand protection safety system

• PLC control system

• Dual hand/foot operation system

• Mechanical safety system

• Emergency reverse motor function

• Conforms to occupational safety regulations

• Meets CE standards

OPTIONAL FEATURES

• Anti-vibration pads

• Touchscreen LCD panel (standard for 150–300 tons)

• Hydraulic safety system (standard for 200–300 tons)

• Spare bolster plate

• Decoiler, feeder, and straightener

• One die set customized to requirements

• Eight-sided slide guidance

TECHNICAL SPECIFICATIONS (25 TON)

Capacity: 25 Ton

Throat depth: 175 mm

Bed-to-ram distance: 300 mm

Slide-to-table distance: 310 mm

Distance between uprights: 290 mm

Ram adjustment (stroke regulation): 50 mm

Approx. press width: 870 mm

Approx. press depth: 1380 mm

Approx. press height: 1870 mm

Front anchorage dimension: 490 mm

Side anchorage dimension: 670 mm

Table hole diameter: Ø145 mm

Table size: 375×570 mm

Die mounting slot diameter: Ø35 mm

Ram size: 260×170 mm

Floor to table height: 710 mm

Stroke adjustment: 10–60 mm

Strokes per minute: 120 spm

Motor power: 3 kW

Motor speed: 1000 rpm

Approx. weight: 1300 kg

Note: Please inform us if you require any modifications to the technical specifications.

PRODUCTION / SUPPLY NOTE

This machine is manufactured by CRONOSSTECH in Turkey. Sales, commissioning, and after-sales processes are managed by CRONOSSTECH.

Listing

Turkey

Turkey

9,663 km

C TYPE 40 TON ECCENTRIC PRESS MACHINE

CRONOSSTECHCECP 40

Call

Condition: new, Year of construction: 2025, drop-through hole in table: 140 mm, table width: 440 mm, table length: 700 mm, stroke adjustment: 80 mm, pressing force: 40 t, ram bore: 35 mm, power: 4 kW (5.44 HP), punching force: 40 t, warranty duration: 24 months, Equipment: safety light barrier, An eccentric press is a type of mechanical press driven by force generated through an eccentric mechanism, used in cold forming operations such as punching, cutting, and die forming. With its high production speed and repeatability, it offers an efficient and reliable solution for mass production lines.

The CRONOSSTECH C-Type Eccentric Press 40 Ton is designed for stable operation in cold forming applications. Its rigid steel construction frame, pneumatic clutch-brake system, and CE-compliant safety infrastructure provide reliable performance suitable for series production.

Key Advantages:

- Stable stroke performance and high repeatability in mass production

- Operator safety-focused design (light curtain + safety systems)

- Low maintenance requirement with central automatic lubrication

- Ready-to-use operation with PLC control + dual-hand/pedal control

Areas of Use:

- Cold cutting and punching operations

- Cold shearing applications

- Metal die forming

- High-volume production lines

✅ STANDARD FEATURES

• Steel construction body

• Four-sided slideway guide

• Spheroidal cast iron connecting rod and gear housings

• Crankshaft and transmission shafts made from 4140 alloyed steel

• Central system fully automatic grease lubrication

• Pneumatic clutch and brake combination

• Compliant with CE safety directives

Gtedpevtx Axjfx Abrju

• Double solenoid safety valve

• Manually adjustable stroke

• Finger-hand protection safety system with light curtain

• PLC control system

• Dual-hand/pedal operation system

• Mechanical lock system

• Emergency reverse motor function

• Compliant with occupational safety regulations

• CE standards compliant

✅ OPTIONAL FEATURES

• Anti-vibration pads

• Touchscreen LCD display (standard for 150–300 tons)

• Hydraulic protection system (standard for 200–300 tons)

• Spare bolster plate

• Decoiler, feeder, and straightener

• One set of die made to required specifications

• Eight-sided slide guidance

✅ TECHNICAL SPECIFICATIONS (40 TON)

Capacity: 40 Ton

Throat depth: 220 mm

Table–ram distance: 340 mm

Distance between uprights: 330 mm

Ram adjustment: 60 mm

Approx. press width: 1050 mm

Approx. press depth: 1280 mm

Approx. press height: 2100 mm

Front anchorage size: 575 mm

Side anchorage size: 740 mm

Table hole diameter: Ø150 mm

Table size: 440×630 mm

Die clamp slot diameter: Ø40 mm

Ram size: 290×180 mm

Floor-to-table height: 720 mm

Stroke adjustment: 10-70 mm

Strokes per minute: 55 spm

Motor power: 4 kW

Motor speed: 1450 rpm

Approx. weight: 2100 kg

Note: Please notify us if you require any modifications to the technical specifications.

✅ PRODUCTION / SUPPLY NOTE

This machine is manufactured in Turkey by CRONOSSTECH. Sale, commissioning, and aftersales processes are handled by CRONOSSTECH.

Listing

Nordhausen

Nordhausen

7,870 km

Machining center

HellerRFK20-2-800 und DRZ20-2-800

Call

Condition: good (used), BJ. 1999+2001

Combined Crankshaft Machining

Combination of centric turning and eccentric milling operations on two machines connected via a shared chip conveyor with a single chip discharge.

Siemens 840D control system

Tool holder - Heller

Nominal tool diameter Ø700 - tools are not included but can be purchased or newly acquired for an additional charge.

NC-controlled steady rest for milling operations

3-jaw chucks on both sides from Blessing with integrated alignment arms

Both machines with automatic loading hatch from above with a loading interface or for manual loading.

The machines are currently still in series production and can be inspected under power.

Installation of components is possible upon request for an additional charge, with documentation of the interchangeable parts and tools.

Safety lock for the control system and drives included - free location.

Availability upon request, warranty excluded.

Year of Production: 1999+2001

Combination of concentric turning. and eccentric Milling Operations in 2 separate machines, which are linked through a common chip conveyor with high drop-off

Machine control: Siemens 840D

Gedpov I Ab Ujfx Abretu

Tool Adapter - Brighter

Tooling diameter Ø700 nominal - Tooling is not subject might be subject for separate purchase or new from supplier

NC controlled support with pads

both sides 3-jaw-chucks from Company Blessing with integrated equalizing device

automatic Gantry door for overhead loading and corresponding interface or manual loading also possible

Machines are actually in serial production and can be inspected upon request

set-up of individual parts possible for separate oncost including documentation of change-over parts and tooling

safeguarding of control and drives included - free location

availability on agreement, no warranty possible

Listing

Velen

Velen

7,625 km

Center Lathe

MEUSERM1 L

Call

Condition: used, Year of construction: 1959, turning diameter over bed 460 mm

Godsxpi A Dspfx Abrotu

turning diameter over slide rest 280 mm

turning length 1000 mm

centre height 230 mm

720 mm

spindle bore 53 mm

spindle turning speed range 28 - 1250 U/min

total power requirement 4,0 kW

weight of the machine ca. 1,8 t

dimensions of the machine ca. 2,4 x 1,4 x 1,75 mm

Lathes with:

- Digital display

- Quick-release tool post

- 3-jaw chucks (200 mm and 160 mm)

- Chip tray

- Centering center

Listing

Brzesko

Brzesko

8,511 km

Presssure Washer Den-Sin Merlion E500

DEN-SINMerlion PLUS E500 - NEW PUMP - 500bar

Call

Condition: reconditioned (used), functionality: fully functional, operating pressure: 500 bar, empty load weight: 220 kg, input voltage: 400 V, fuel: electricity, warranty duration: 6 months, DEN-SIN MERLION PLUS E500 COLD WATER PRESSURE WASHER NEW COMET PUMP

NEW COMET TW4573 PUMP - MADE IN ITALY

Gjdox Exwrepfx Abrotu

Manufactured in 2017

The device features new accessories, including a pressure gun, stainless steel lance, steel braided hose, and a 15° power nozzle.

A durable brass head with new ceramic pistons and seals guarantees long and trouble-free operation.

A highly efficient three-phase motor ensures stable operation even during prolonged use.

With operating parameters of 500 bar and 960 l/h, the machine can be effectively used for heavy-duty work in construction, logistics, and agriculture.

Each device we offer has individually taken photos; you are buying exactly what you see.

TECHNICAL DATA:

Voltage [Ph / V / Hz]: 3 / 400 / 50

Working pressure (bar): 500

Maximum pressure (bar): 520

Flow rate (l/h): 900

Inlet water temperature (°C): max. 60

Nominal power (kW): 18.65

Pump type: crankshaft

Weight without accessories (kg): 220

EQUIPMENT:

NEW COMET TW4573 PUMP - MADE IN ITALY

NEW durable P.A RL84 500bar pressure gun

NEW 800mm stainless steel pressure lance

NEW 15m reinforced steel braided pressure hose - 600bar

NEW 15° power nozzle

Water filter and GEKa claw couplings - FREE

KEY FEATURES:

Open system Oil-cooled - no operating time limits

Highly readable and intuitive control panel

Simple design and easy access to individual components under the housing make the machine user-friendly and easy to service

Large wheels facilitate transport over uneven terrain

Listing

Monheim am Rhein

Monheim am Rhein

7,670 km

Balancing machine

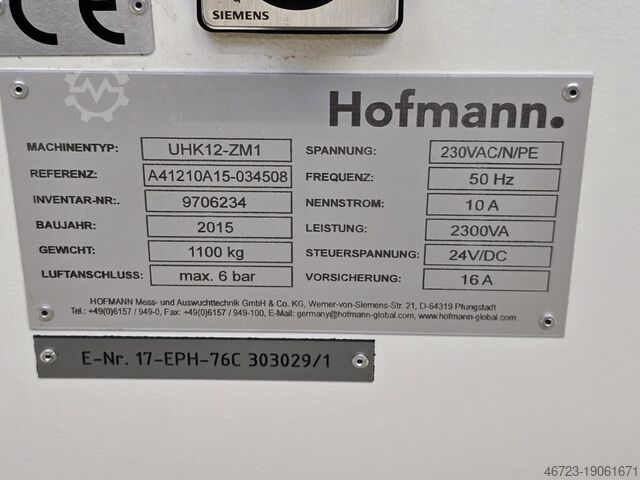

HofmannUHK 12 - ZM1

Call

Condition: good (used), Year of construction: 2015, Lot consists of:

(1) CNC Crankshaft Control Balancing Machine

Position consists of:

(1) CNC crankshaft control balancing machine

Technical Details/Technical Details:

English:

max crankshaft length 800mm, max dia 300/200mm, max weight 50kg, bearing dia 30 - 80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH,:1.3x1x1.5m

Parts Gantry System and/or Cranes are not included in the scope.

German:

Maximum crankshaft length 800mm, maximum diameter 300/200mm, maximum weight 50kg, bearing diameter 30-80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH: 1.3x1x1.5m

Gtjdpfx Aowg A Sisbreu

Parts gantry system and/or cranes are not included in delivery.

Listing

Kraków

Kraków

8,463 km

High-pressure cleaner

KarcherHD 9/25 G Classic NOWY

Call

Condition: new, Year of construction: 2024, operating pressure: 250 bar, total length: 878 mm, high-pressure hose length: 10,000 mm, total height: 702 mm, total width: 538 mm, empty load weight: 57 kg, fuel: super 95, warranty duration: 24 months, We offer for sale the HD 9/25 G Classic petrol-powered high-pressure washer.

Condition: New

Year of manufacture: 2024

Technical specifications:

- Pump performance (l/h): 900

- Working pressure (bar): 250

- Maximum pressure (bar): 300

- Water connection: R 3/4″

- Drive type: petrol

- Engine type: G390FA

- High mobility

- Colour: anthracite

- Weight with accessories (kg): 56.8

- Dimensions (L x W x H) (mm): 878 x 538 x 702

Scope of delivery:

- Standard spray gun

- 10 m high-pressure hose

- Crankshaft pump with ceramic pistons

- Power nozzle

- Protection frame

- Water filter

Features:

Independence

- No reliance on external power sources.

- Compliant with EU STAGE V emission standards.

- Convenient manual start.

High mobility

- Puncture-proof wheels.

- Compact and easy to manoeuvre in confined areas.

- Fits inside a vehicle.

Robust and durable design

- Sturdy tubular frame protects the pump from damage.

- High-pressure pump equipped with a safety valve and water filter.

- Crankshaft pump with ceramic pistons.

Accessory storage

- Holder for power leads and accessory compartment for easy storage and transport.

Godpfx Abox At R Ejrstu

- Ergonomic handle and convenient hose storage.

The HD 9/25 G Classic cold-water high-pressure cleaner, with a working pressure of up to 250 bar, a delivery rate of 900 litres per hour, and a durable crankshaft pump, is designed to handle even the most demanding cleaning tasks. Its high-performance EU STAGE V petrol engine eliminates the need for external power sources. Sturdy tubular steel frame and puncture-proof tyres make it ideal for challenging tasks on construction sites, in industry, municipal areas, or service companies in the construction sector. The ergonomic handle, very compact dimensions, and dedicated accessory holders (e.g., for high-pressure hose and lance) simplify operation and allow for easy transport by vehicle. All major components are easily accessible for servicing and are effectively protected by thermal and safety valves. Please note: The machine does not support suction from alternative water sources.

Listing

Velen

Velen

7,625 km

Center Lathe

STANKO1A625

Call

Condition: used, Year of construction: 1967, turning diameter over bed 500 mm

turning diameter over slide rest 320 mm

turning length 2100 mm

centre height 250 mm

spindle bore 60 mm

spindle turning speed range 11 - 2000 U/min

total power requirement 7,0 kW

Gtedpfx Abexwzdcsrju

weight of the machine ca. 2,9 t

dimensions of the machine ca. 4,3 x 1,2 x 1,3 mm

Lathes with:

- 4-position tool post

- 3-jaw chuck 315mm

- Centering point

Listing

Küçükbalıklı

Küçükbalıklı

9,752 km

Eccentric press

FresanFP 60P Eccentric Press

Call

Condition: new, Year of construction: 2025, machine/vehicle number: 25.12.15, Fresan FP 60P - C Frame Eccentric Press - 60 Tons (600kN)

TECHNICAL DATA:

* Power: 60 tons (600kN)

* Strokes Per minute: 65

* Ram-Table Distance: 365 mm

* Stroke Adjustment: 0 - 100 mm

* Ram Adjustment: 70 mm

* Table Dimensions: 500 x 700 mm

STANDARD SPECIFICATIONS:

* Conformity to CE safety regulations

* Welded steel frame

Gtodpfx Abjnwpc Ioreu

* Crankshaft made of AISI 4140 (42CrMo4) alloy steel. Highly durable and ductile. CNC ground for minimum surface friction.

* SnBz-12 quality bronze bearings

* Pneumatic clutch-brake combination

* Fully closed gearbox with helical gears working in oil

* Double body press safety valve

* Safety PLC control (Pilz)

* Covers with safety switches

* Light curtains around work table

* Ram with 4 sliding surfaces (6-slide version available, optional)

* Mechanical fuse for overload protection

* Pneumatic counterbalance cylinders

* Automatic central lubrication & used oil collectors (Thin oil / slideways oil)

OPTIONAL EQUIPMENT:

* Additional work table

* Speed control with AC inverter

* HMI / Touchscreen operator panel

* Part ejector mechanisms(upper and/or lower ejectors)

* Material feeding, loading & unloading systems (Decoilers, straighteners, pneumatic & servo feeders...)

* Special design / customized machine

Listing

Küçükbalıklı

Küçükbalıklı

9,752 km

Eccentric press

FresanFP 100P Eccentric Press

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 25.12.15, Fresan FP 100P - C Frame Eccentric Press - 100 Tons (1000kN)

TECHNICAL DATA:

* Power: 100 tons (1000kN)

* Strokes Per minute: 60 (variable)

* Ram-Table Distance: 445 mm

* Stroke Adjustment: 0 - 132 mm

* Ram Adjustment: 95 mm (motorized)

* Table Dimensions: 700 x 1000 mm

STANDARD SPECIFICATIONS:

* Conformity to CE safety regulations

* Welded steel frame

* Crankshaft made of AISI 4140 (42CrMo4) alloy steel. Highly durable and ductile. CNC ground for minimum surface friction.

* SnBz-12 quality bronze bearings

* Pneumatic clutch-brake combination

* Fully closed gearbox with helical gears working in oil

* Double body press safety valve

* Safety PLC & light curtains & safety switches (Pilz)

* Ram with 6 slides & waste oil collector

* 7-inch HMI touchscreen operator panel

* Speed control with AC inverter

* Motorized ram adjustment

* Mechanical fuse for overload protection (Hydraulic fuse can be installed on standard a machine after purchase)

* Pneumatic counterbalance cylinders (ISO, 4 pcs)

* Automatic central lubrication & used oil collectors (Thin oil / slideways oil)

OPTIONAL EQUIPMENT:

* Additional work table

* Part ejector mechanisms(upper and/or lower ejectors)

* Material feeding, loading & unloading systems (Decoilers, straighteners, pneumatic & servo feeders...)

* Special design / customized machine

Gjdpfx Asnxh T Rsbretu

Listing

Küçükbalıklı

Küçükbalıklı

9,752 km

Eccentric press

FresanFP 80P Eccentric Press

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 25.12.15, Fresan FP 80P - C Frame Eccentric Press - 80 Tons (800kN)

TECHNICAL DATA:

* Power: 80 tons (800kN)

* Strokes Per minute: 60 (variable)

* Ram-Table Distance: 400 mm

* Stroke Adjustment: 0 - 112 mm

* Ram Adjustment: 80 mm (motorized)

* Table Dimensions: 600 x 900 mm

STANDARD SPECIFICATIONS:

* Conformity to CE safety regulations

* Welded steel frame

* Crankshaft made of AISI 4140 (42CrMo4) alloy steel. Highly durable and ductile. CNC ground for minimum surface friction.

* SnBz-12 quality bronze bearings

* Pneumatic clutch-brake combination

Gjdpfx Aenxh Hrebrotu

* Fully closed gearbox with helical gears working in oil

* Double body press safety valve

* Safety PLC & light curtains & safety switches (Pilz)

* Ram with 6 slides & waste oil collector

* 7-inch HMI touchscreen operator panel

* Speed control with AC inverter

* Motorized ram adjustment

* Mechanical fuse for overload protection (Hydraulic fuse can be installed on standard a machine after purchase)

* Pneumatic counterbalance cylinders (ISO, 4 pcs)

* Automatic central lubrication & used oil collectors (Thin oil / slideways oil)

OPTIONAL EQUIPMENT:

* Additional work table

* Part ejector mechanisms(upper and/or lower ejectors)

* Material feeding, loading & unloading systems (Decoilers, straighteners, pneumatic & servo feeders...)

* Special design / customized machine

Listing

Küçükbalıklı

Küçükbalıklı

9,752 km

Eccentric press

FresanFP 40P Eccentric Press

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 25.12.15, Fresan FP 40P - C Frame Eccentric Press - 40 Tons (400kN)

TECHNICAL DATA:

* Power: 40 tons (400kN)

Gtodonwmh Sopfx Abrou

* Strokes Per minute: 125

* Ram-Table Distance: 320 mm

* Stroke Adjustment: 0 - 84 mm

* Ram Adjustment: 70 mm

* Table Dimensions: 450 x 650 mm

STANDARD SPECIFICATIONS:

* Conformity to CE safety regulations

* Welded steel frame

* Crankshaft made of AISI 4140 (42CrMo4) alloy steel. Highly durable and ductile. CNC ground for minimum surface friction.

* SnBz-12 quality bronze bearings

* Pneumatic clutch-brake combination

* Double body press safety valve

* Safety PLC control (Pilz)

* Covers with safety switches

* Light curtains around work table

* Ram with 4 sliding surfaces

* Mechanical fuse for overload protection (Starting from 20 tons)

* Pneumatic counterbalance cylinders (Starting from 40 tons)

* Central lubrication & used oil collectors (Thin oil / slideways oil)

OPTIONAL EQUIPMENT:

* Additional work table

* Automatic central lubrication

* Speed control with AC inverter

* HMI / Touchscreen operator panel

* Part ejector mechanisms(upper and/or lower ejectors)

* Material feeding, loading & unloading systems (Decoilers, straighteners, pneumatic & servo feeders...)

* Special design / customized machine

Listing

Küçükbalıklı

Küçükbalıklı

9,752 km

Eccentric press

FresanFP 15P Eccentric Press

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 25.12.15, Fresan FP 15P - C Frame Eccentric Press - 15 Tons (150kN)

TECHNICAL DATA:

* Power: 15 tons (150kN)

* Strokes Per minute: 200

* Ram-Table Distance: 215 mm

* Stroke Adjustment: 0 - 40 mm

* Ram Adjustment: 40 mm

* Table Dimensions: 320 x 490 mm

STANDARD SPECIFICATIONS:

* Conformity to CE safety regulations

* Welded steel frame

* Crankshaft made of AISI 4140 (42CrMo4) alloy steel. Highly durable and ductile. CNC ground for minimum surface friction.

* SnBz-12 quality bronze bearings

* Pneumatic clutch-brake combination

* Double body press safety valve

* Safety PLC control (Pilz)

* Covers with safety switches

Gtsdpfxonvfv Ns Abrju

* Light curtains around work table

* Ram with 4 sliding surfaces

* Mechanical fuse for overload protection (Starting from 20 tons)

* Pneumatic counterbalance cylinders (Starting from 40 tons)

* Central lubrication & used oil collectors (Thin oil / slideways oil)

OPTIONAL EQUIPMENT:

* Additional work table

* Automatic central lubrication

* Speed control with AC inverter

* HMI / Touchscreen operator panel

* Part ejector mechanisms(upper and/or lower ejectors)

* Material feeding, loading & unloading systems (Decoilers, straighteners, pneumatic & servo feeders...)

* Special design / customized machine

Listing

Küçükbalıklı

Küçükbalıklı

9,752 km

Eccentric press

FresanFP 10P Eccentric Press

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 25.12.15, Fresan FP 10P - C Frame Eccentric Press - 10 Tons (100kN)

TECHNICAL DATA:

* Power: 10 tons (100kN)

* Strokes Per minute: 200

* Ram-Table Distance: 190 mm

* Stroke Adjustment: 0 - 40 mm

* Ram Adjustment: 35mm

* Table Dimensions: 265 x 370 mm

STANDARD SPECIFICATIONS:

* Conformity to CE safety regulations

* Welded steel frame

* Crankshaft made of AISI 4140 (42CrMo4) alloy steel. Highly durable and ductile. CNC ground for minimum surface friction.

* SnBz-12 quality bronze bearings

* Pneumatic clutch-brake combination

* Double body press safety valve

* Safety PLC control (Pilz)

* Covers with safety switches

* Light curtains around work table

* Ram with 4 sliding surfaces

* Mechanical fuse for overload protection (Starting from 20 tons)

* Pneumatic counterbalance cylinders (Starting from 40 tons)

* Central lubrication & used oil collectors (Thin oil / slideways oil)

OPTIONAL EQUIPMENT:

* Additional work table

* Automatic central lubrication

Gtjdpfenvfmyjx Abreu

* Speed control with AC inverter

* HMI / Touchscreen operator panel

* Part ejector mechanisms(upper and/or lower ejectors)

* Material feeding, loading & unloading systems (Decoilers, straighteners, pneumatic & servo feeders...)

* Special design / customized machine

Listing

Wittlich-Wengerohr

Wittlich-Wengerohr

7,743 km

Swap body truck

MERCEDES-BENZACTROS 2545 / RETARDER / NAVI

Call

Condition: used, mileage: 277,000 km, power: 330 kW (448.67 HP), first registration: 08/2022, overall weight: 26,000 kg, axle configuration: 3 axles, brakes: retarder, color: white, gearing type: automatic, emission class: euro6, loading space length: 7,450 mm, Equipment: ABS, air conditioning, navigation system, HIGHLIGHTS & PACKAGES

* O3J Climate Package, with noise and thermal insulation

Gtsdpfx Abjxf Swpsrju

* U0Q Control Code, HDEP Fuel Efficiency Package - FE1

* O3D Safety Package, without anti-roll control

* 1256 Equipment Package: Powertrain 2

* O7L Cab: Chrome Interior Package

* O8I Equipment Package: Economy

ASSISTANCE SYSTEMS

* S5Z Cruise Control

* S1X Active Sideguard Assist

* Z1H EBS, manufacturer: Wabco

* S1O Traffic Sign Assist

* B1B Electronic Brake System (EPB) with ABS and ASR

* S1L Driver Assistance System: Attention Assist (Drowsiness Detection Sensor)

* S1W Driver Assistance System: Autonomous Emergency Braking Assist (Active Brake Assist 5)

* G0T Driver Assistance System: Predictive Powertrain Control (cruise control with satellite-aided transmission program)

* S1H Driver Assistance System: Lane Keeping Assist

* S1D Driver Assistance System: Stability Control Assist

* FA28 Driver Assistance System: Traffic Sign Recognition

* B5D Trailer Stabilization Program (TSA)

* S1I Driver Assistance System: Adaptive Cruise Control

* L1D Driver Assistance System: High Beam Assist and Cornering Light

* F8W Rain Sensor

ENGINE, TRANSMISSION & CHASSIS

* E7F Remote control for air suspension

* G5A Single-disc clutch

* O2N Starter Melco 95P65

* U2V Control Code, Catalytic Converter Kit 2

* Z5G Fan position, on crankshaft

* I6X Air suspension, rear axle

* C6I Power steering pump, controlled

* 64203 Differential lock, rear axle

* M0E Torque increase, 12th gear

* 90220 Air intake behind cab

* F3B Cab: steel-sprung, comfort

* E1T Alternator 100 A, controlled

* A3D Rear axle with active lubrication, non-controlled

* A2E Rear axle ring gear 440

* M6M Twin-stage air compressor

* M3B Engine 12.8 L – 330 kW inline 6-cylinder diesel (OM 471)

* G5G Mercedes-Benz PowerShift gearbox

* C6U Additional stabilizer, rear axle / trailing axle

* G2E 12-speed gearbox – Type: G 281-12

* M8D Integrated air intake

* M5V Enhanced engine brake

* 95020 Engine 12.8 L – 330 kW inline 6-cylinder diesel (OM 471)

* A5C Axle ratio i = 2.733

* Z6I Special permit, mandatory for axle transport

* M4X Emissions standard EURO 6

* STAB Front axle stabilizer

AUDIO & COMMUNICATION

* J2U Navigation system

* GPS navigation system

* J2K Speakers, 2-way system

* U3N Control Code, navigation map region EU

* 42690 Remote query function Remote Online

INTERIOR

* D6G Automatic climate control

* D8X Low seat box, lowered by 40 mm

* F5Y A-pillar trim

* O1S Interior color: almond beige

* O1Z Steering, indirect

* F2A Floor variant, flat floor

* J8Y Preparation for Truck Data Center 7

* J6C Multimedia cockpit, interactive

* D5Z Carpet covering, engine tunnel

* D7R Storage compartment above windscreen with lid

* F7X Cab: fixed cab entry

* 17671 Flat cab floor

* 33108 Electric sunroof

* 44311 Interactive multimedia cockpit

* 47305 Carpet on engine tunnel

* 47700 Sunblind, side window, driver's door

* F1I Cab: L StreamSpace, 2.50 m, flat floor

* 51000 Electric windows

* D3B Lower comfort bunk

* LEN5 Multifunction steering wheel

* 53707 Seats in cab: Dual armrests, driver's seat

* D1N Seats in cab: Co-driver functional seat

* D2N Seats in cab: Folding driver's seatback

* D7G Storage compartments with lids behind driver and co-driver seats

* 49584 12V socket in co-driver footwell

* J1O Tachograph / EC control unit

* D3A Upper comfort bunk, wide

* D3T Seat cover / upholstery: co-driver seat velour

* D3Q Seat cover / upholstery: driver’s seat velour

* D1C Seats in cab: Comfort suspension seat, driver

Listing

Babberich

Babberich

7,577 km

MillTurn 910 x 5000 mm with C + Y Axis

WFLM 100

Call

Year of construction: 2006, condition: good (used), Make: WFL Austria

Type: M 100 / 5000

Control: Siemen 840C

Year: 2006

MillTurn M100: Complete & Complex machining Turning & Milling

Equipped:

ATC 108 double chain for milling tool holders

ATC 10 positions boring bar holders up to 1000 mm

SCHUNK 3 chuck THW 630 - 160R

SMW Steady rest SLU-Z-5 50 - 310 mm

Field off application:

Aerospace

Gedpfekvndtox Abretu

Oil and Gas

Energy

Engineering

Crankshaft

Hydraulic and Pneumtaics

Specifications

Metric US Standard

Max. turning Ø

910 mm

X-Axis

900 (+850 to -40) mm

Y-Axis

500 (+300 to -200) mm

Z-Axis

5370 mm

B Axis

200 °

Spindle bore

165 mm

Speedrange

1600 Rpm

Spindle power

60 kW

ATC / revolver

108

B-Axis Toolsystem

Capto C8

B-Axis Speedranges

4000 Rpm

B-Axis power

25 kW

Chip conveyor

Yes

Pinole taper

6 Mk

Stroke pinole

200 mm

Quill Ø

180 mm

Dimensions (Estimate)

Length

14500 mm

Width

4500 mm

Height

3800 mm

Weight

40000 kg

Please Note: The information on this page has been obtained to the best of our ability and belief, and from the manufacturers where possible. It is given in good faith, but its accuracy can not be guaranteed. Accordingly, it will not form a representation or constitute contractual terms. We advise you to check any vital details!

Trust Seal

Dealers certified through Machineseeker

Listing

Tatabánya

Tatabánya

8,570 km

Eccentric Press Machine,Ruhrmann

RuhrmannE100R

Call

Condition: ready for operation (used), Eccentric Press Machine, AUG. RUHRMANN E100R, Used Machine

Manufacturer: AUG. RUHRMANN Maschinenfabrik GmbH & Co. KG

Type: E100R

Serial Number: 14339

Year of Manufacture: 1997

Gjdoxnqrdepfx Abrstu

Technical Data

Nominal pressing force: 1000 kN (100 tons)

Stroke length: 20 – 130 mm

Max. installation height (at bottom dead center): 580 mm

Stroke adjustment: max. 100 mm

Max. flywheel speed: 230 1/min

Number of strokes in continuous operation: 60 1/min

Max. clutch engagements: 16 1/min

Standard crankshaft stop point: 15° after B.D.C.

Max. tool size: 580 × 380 mm

Max. tool part weight: 70 kg

Operating pressure of clutch system: 6 bar

Compressed air connection: 6 – 8 bar

Total drive power: 7.5 kW

Safety distance: 345 mm

Overrun time: 215 ms

Table size: 1100 × 660 mm

Operating hours: 70,797

Overall dimensions

Width: 2000 mm

Depth: 1700 mm

Height: 3020 mm

Weight (without tools and accessories): 7000 kg

Listing

Hessisch Lichtenau

Hessisch Lichtenau

7,826 km

Single-column eccentric press, eccentric stamping press, mechanical press

WEINGARTENER 63

Call

Condition: used, Single-column eccentric press WEINGARTEN type ER 63

Machine. No. 52A / 63 Year of construction 1963

Pressure capacity 63 ton.

throat 280 mm

Table surface 630 x 530 mm

ram stroke adjustable 8-100 mm

ram adjustment 63 mm

Stroke rate 65 strokes / min.

Motor power 4 kW

Mains connection 380 Volt, 50 Hz

- Clutch/brake combination with WEINGARTEN friction threaded clutch

Gtjdjlb I Dzspfx Abrsu

- Electric lift release via foot switch

- Wheel reduction gear

- Overload protection by breaker plate

- Front crankshaft support bearing

Space requirement L x W x H 1500 x 1100 x 2500 mm

Weight 4.5 tons

good condition

Listing

Hessisch Lichtenau

Hessisch Lichtenau

7,826 km

Single-column eccentric press, eccentric stamping press, insertion press, production press, producti

WEINGARTENARP 100

Call

Condition: used, Single-column eccentric press WEINGARTEN type ARP 100

Machine no. No. 122481 Year of construction 1984

Pressure capacity 100 ton.

throat 400 mm

Table size 920 x 660 mm

ram surface 700 x 450 mm

Rear upright width 735 mm

Stroke adjustment 20 - 160 mm

Plunger adjustment 80 mm

Installation height with 160 mm stroke max. 355 mm (without intermediate table top)

Installation height with 20 mm stroke max. 425 mm (without intermediate table plate)

Stroke rate 60 strokes/min.

Table surface intermediate table top 920 x 610 mm

Thickness of intermediate table top 90 mm

Hole in intermediate table top Ø 210 / 180 mm

Through-hole in machine table Ø 210 / 180 mm

Table height above floor 800 mm (without intermediate table top)

T-slot width in table and ram 22 mm

Clamping pin bore 50 mm

Motor power 11 kW

Mains connection 400 Volt, 50 Hz

- Hydraulic overload protection in ram

- ORTLINGHAUS pneumatic clutch/brake combination

- Electromotive ram adjustment with counter

- Clamping pin bore with clamping piece

- Front crankshaft support bearing

- Gear reduction gears in closed oil bath gearbox

- Two pneumatic tappet compensation cylinders

- WOERNER automatic central grease lubrication

- Lift release via electric foot switch or two-hand control panel

- Electrical control cabinet permanently attached to the machine

Godpfx Aju Rwa Ijbrstu

- Operating instructions and circuit diagram

- UVV for manual insertion work

Space requirement L x W x H 2200 x 1600 x 3250 mm

Weight 8.3 tons

Good condition

Listing

Hessisch Lichtenau

Hessisch Lichtenau

7,826 km

Single-column - eccentric press, eccentric stamping press, inserting press

WEINGARTENE 40

Call

Condition: used, Single-column eccentric press WEINGARTEN type E 40

Machine. No. 643/62 Year of construction 1963

Pressure capacity 40 ton.

throat depth 250 mm

Table opening 150 x 80 and Ø 200 mm

Table surface 560 x 460 mm

ram surface 250 x 200 mm

Plunger stroke adjustable 8-88 mm

Plunger adjustment 63 mm

Installation height 320 mm

Clamping pin bore Ø 40 mm

Stroke rate 100/130 strokes / min.

Motor power 2.2 / 3 kW

Mains connection 400 Volt, 50 Hz

Godpetx E Rqsfx Abrjtu

Table height above floor 840 mm

- Clutch/brake combination with WEINGARTEN friction threaded clutch with TDC run-through protection

- Electric lift release via two-hand control

- Overload protection by breaker plate

- Manual central grease lubrication

- Front crankshaft support bearing

- Control cabinet adjacent

- UVV for manual insertion work

Space requirement L x W x H 1800 x 1500 x 2200 mm

Weight 3.1 tons

We make it easier for you to find: "crankshaft"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Crankshaft (129)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month