Used Filling Line for sale (18,284)

Winkelhaid

Winkelhaid Brochure production line

Duplo/FKSSystem 5000

Eislingen/Fils

Eislingen/Fils Coil line

DIMECO1676 EV / 2382 FFPS / Microfee

Freising

Freising Rinsing, filling and sealing machine

KHS

+44 20 806 810 84

Netherlands

Netherlands Complete baling line 140 t press force with conveyor system and wire stations

BollegraafBaler HBC 140 with conveyor Typ HBT 1216/1800 * 23

Bruckmühl

Bruckmühl Edging line EWD Combimes

Discover more used machines

Janville

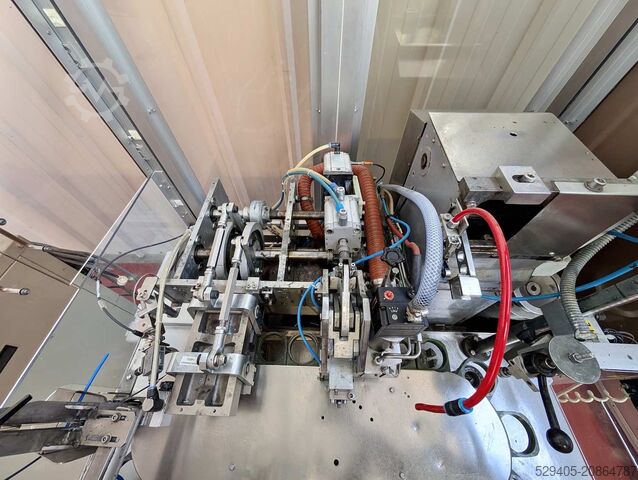

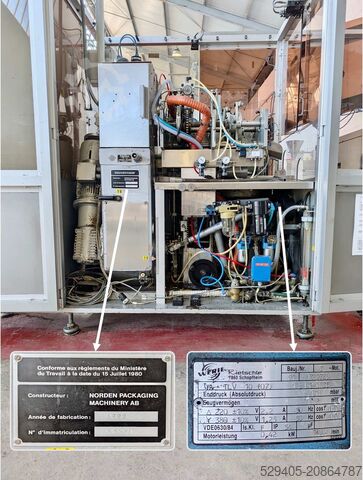

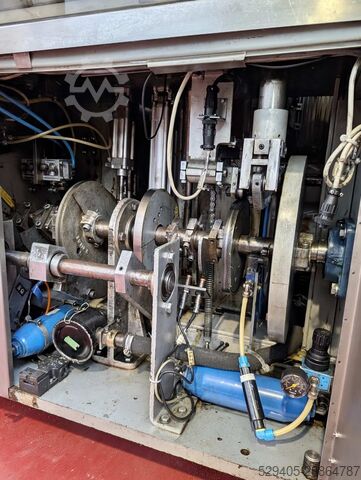

Janville Automatic tube filling machine

NordenNordenmatic 700

Corse Lawn

Corse Lawn Extruder

ReifenhäuserPET Extrusion Line

Eislingen/Fils

Eislingen/Fils Coil line

DREHER1676 E/RDS / 2380 FM-FPS

Freising

Freising Palletising line

Schäfer

Hennef (Sieg)

Hennef (Sieg) Extrusion line for weldingwire or profil

PMH GmbHEX 30

Wiefelstede

Wiefelstede Hydraulic line

Hansa-FlexHD240T 1 1/2"

Janville

Janville Filling and capping

GroningerKFVG251 + DTE 1000

Corse Lawn

Corse Lawn Extrusion Line

Reifenhäuser

Juszczyn

Juszczyn Hole line boring machine

TriadeFR-3 V-V

Shrewsbury

Shrewsbury Finger jointing line

FurnimateFSL-62H-FJ-420A

Koprki

Koprki Line For Packaging Liquid Products Into Plastic Bottles With Dose Up To 750 ml

Tang OG Weiss ASASK 450

Wiefelstede

Wiefelstede Spring balance

PesolaMacro-Line 80196 200 N

Janville

Janville 6-head filling machine

StoppilEC6050

Brno-město

Brno-město Line for trapezoidal sheet metal

Rollsett Machine Oy FinlandT18

Juszczyn

Juszczyn Hole line boring machine

TRIADEFR3

Wiefelstede

Wiefelstede Active Line Module

Siemens6SL3130-7TE21-6AA3

Janville

Janville Powder sachet line

MarchesiniMS 235 / AS 237 / BA 50

Wiefelstede

Wiefelstede Basic Line Filter

SiemensSinamics 36KW SLM/ALM / 40 KW BLM

Wiefelstede

Wiefelstede Granule conveyor filling nozzle

Digicolor260/250/H830 mm

Wiefelstede

Wiefelstede Active Line Module

Siemens6SL3130-7TE23-6AA3

Used Filling Line (18,284)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84