Used Plasma Tubes for sale (2,434)

Balaguer

Balaguer Tube bending machine

BLMTUBE-FORM

Babberich

Babberich End machining Offshore tubes

AXAHFB Z600

Wasbek

Wasbek Tube End Finishing Machine - RGM 3

KnuthRGM 3

+44 20 806 810 84

Nürnberg

Nürnberg ESAB plasma cutter A60i

ESABA60i

Janville

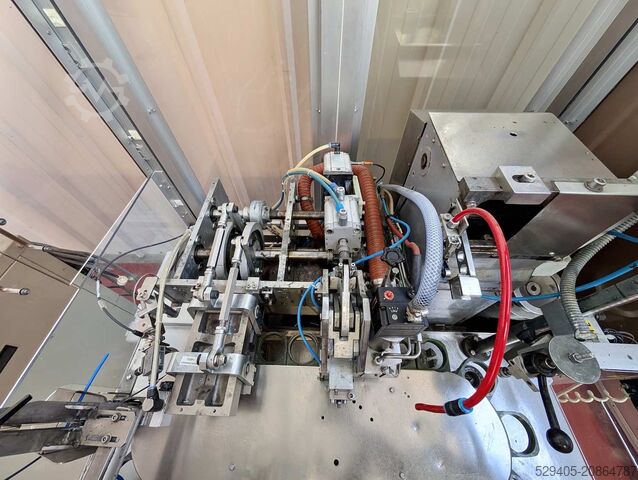

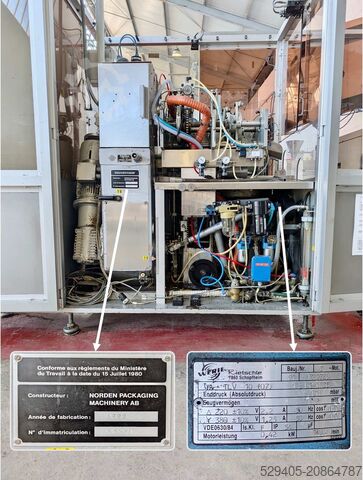

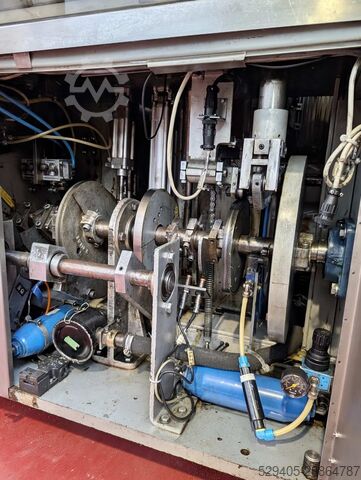

Janville Automatic tube filling machine

NordenNordenmatic 700

Discover more used machines

Janville

Janville Tube filling line

MarchesiniMillenium 200 + MA 250

Janville

Janville Manipulateurs à tube de levage par le vide

Manut LMMAN

Janville

Janville UV liquid treatment tube

Hanovia UVPMS150G4/4

Janville

Janville Soudeuse manuelle de tubes plastiques

CotuplasS4

Janville

Janville Remplisseuse tube plastique

Axomatic srlOptima 900 Matic

Wasbek

Wasbek Tube End Finishing Machine - EM 250

KnuthEM 250

Germany

Germany Plasma Cutting Machine

KOIKEPNC 12 Extreme

Wijchen

Wijchen Plasma cutters CR-Electronic OXY-4000x2000 2000

CR-ElectronicOXY-4000x2000

Wijchen

Wijchen Plasma cutters Messer MultiTherm eco 2600 2011

MesserMultiTherm eco 2600

Balaguer

Balaguer Plasma Cutting Table

OxiplasmaKompak EKO

Germany

Germany Plasma cutting system

Lind GmbHGemini 3000 DDS-Plasma 7 HiFocus 360i

Niederlangen

Niederlangen Plasma cutting machine

REHMBARRACUDA RTC 150

Königswinter

Königswinter Winder for filament/tubes

PMHW-250+

Austria

Austria CNC Plasma Cutter

PlasmaCut3015 - PMX 125

Austria

Austria CNC Plasma Cutter

PlasmaCut2512

Austria

Austria CNC Plasma Cutter

PlasmaCut2010

Wiefelstede

Wiefelstede Plasma cutting machine

HyperthermHT2000

Wiefelstede

Wiefelstede Plasma nozzle 4 pieces

Hypertherm020448 HT2000

Wiefelstede

Wiefelstede Servo drive for plasma cutters

CR Electronic S.R.L 7 Power AutomationOXY 5.1 - 25 PAT3-0190

Wiefelstede

Wiefelstede Plasma hose package

unbekannt10,5 m

Used Plasma Tubes (2,434)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84