Used Turning And Milling for sale (22,174)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Oelde

Oelde

7,700 km

CNC Turning- and Milling Center

DMG MORINLX 2500 SY / 700

Call

Condition: used, Year of construction: 2018, turning diameter max. 356 mm

turning length 705 mm

control M730 UM Mapps CELOS

greates pass round over bed 920 mm

Swing dia. over traverse guideway 742 mm

turning speed range - main spindle 4.000 min/-1

power capacity - main spindel 18,5 / 15 kW

spindle nose JIS A2-8

spindle bore 80 (91) mm

C-Axis 0,001 °

Spindle speed range subspindle 6.000 min/-1

power capacity - Sub spindle 11 / 7,5 kW

spindle bore 43 mm

C-Axis 0,001 °

x-travel 260 mm

z-travel 795 mm

Y - Axis +/-50 mm

rapid traverse ( X / Y / Z ) 30 / 10 / 30 m/min

number of toolpositions 12 pos.

Schank height for square tool 25 mm

Drill shank diameter 50 mm

turret change time 0,27 sec.

Gbedpfx Aevy Ig Hjh Ejw

Spindle speed - driven tools max. 10.000 min -1

power capacity - driven tools 5,5 / 4,2 kW

total power requirement 41 kVA

weight of the machine ca. 6,4 t

dimensions of the machine ca. 5,0 x 3,0 x 2,3 m

CNC - Turning- and MillingCenter

DMG MORI - NLX 2500 SY / 700

- Subspindle

- Tool-Drive

- C, Y-Axis

Listing

Olching

Olching

8,116 km

CNC turning and milling centre

OkumaMultus U 3000

Call

Condition: used, _____

Description:

Year of manuf. : 2022

Control : Okuma OSP-P300 SA

Turning diam. : 650 mm

Turning length : 1000 mm

Main spindle:

Technology:Motor spindle

Speed:4,200 rpm

Power:22 kW

Torque:427 Nm

spindle bore:91 mm

Hollow clamping cylinder:86 mm

C-axis:High precision package

Chuck:SMW KNCS-N 275-86 K8

Sub spindle:

Technology:Motor spindle

Speed:5,000 rpm

Power:22 kW

Torque:420 Nm

spindle bore:80 mm

Hollow clamping cylinder:77 mm

C-axis:High precision package

Chuck:SMW BHD-FC 210-52-3

Tool carrier X/Y/Z/B:

Technology:Milling spindle

Speed:12.000 rpm

Power:22 kW

Torque:120 Nm

Tool holder:HSK 63

Y-axis:250 mm (+/- 125 mm)

B-axis:240°

Tool magazin:

Number of stations:80

Equipment:

Measuring systems:Direct in X/Y/Z axis (glass scales)

Chip disposal:Chip conveyor

Coolant supply:IKZ system, 70 bar

Coolant temperature control:Deltatherm E4

Chip rinsing:working area, manual gun

Accuracy package:C-axis high accuracy

Software package:5-axis auto-tuning

Gbsdpjwu I Irefx Ah Esw

Software option:Multifunction tool

Gear cutting software package:Gear hobbing, gear peeling

Control extension:Dialogue programming

Workpiece measurement:Renishaw measuring probe

Tool measurement:Tool setter

Tool breakage monitoring:Renishaw TRS2

B-axis:NC function and turning function

Bar loader:LNS Quickload Servo III+

Automation preparation:Robot interface

Work area door:Automatic

Set-up mode:Electronic handwheel

Listing

Halberstadt

Halberstadt

7,855 km

CNC Turning and milling machine - 4 Axes - C Axis (Sup-Spindle)

DOOSANDAEWOO PUMA 300 MSC

Call

Condition: good (used), Year of construction: 2003, Ref. -No.: 10454

Manufacturer: DOOSAN

Type: DAEWOO PUMA 300 MSC

Year of construction: 2003

Type of control: CNC

Control: FANUC 18i-TB

Storage location: Halberstadt

Country of origin: South Korea

Machine-No.: 0MS19XX

Turning Speeds: 4500 RPM

Bar passage: 62 mm

Turning Length: 595 mm

Turret places: 12 Pcs

Further information:

- 4 axes (X/Z/C/B)

- counter spindle

- driven tool station

- finished part removal system

- conveyor belt

- chip conveyor

Gbjdpfjxc Trpex Ah Esw

- Powercool coolant system

- LNS Quickload Servo 3 bar loader

- tool holder

- collet holder

- collets

Machines can be inspected under power by appointment.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Bydgoszcz

Bydgoszcz

8,150 km

Cnc turning and milling center

HWACHEONHi-TECH 230B

Condition: excellent (used), Year of construction: 2018, operating hours: 3,370 h, functionality: fully functional, HWACHEON CNC Lathe

Year of manufacture: 2018

Model: HI-TECH 230B YMC

Control: FANUC 0i-TF with Manual Guide

Max turning diameter: Ø400 mm

Max turning length: L-290 mm

Gbodpjxqhxgsfx Ah Eow

Machine weight: 4400 kg

Max spindle speed: 3500 rpm

Machining time: 2040 operating hours

Machine running time: 3370 operating hours

Machine dimensions: 2100x3100x2000 mm

Self-centering three-jaw chuck on main spindle Ø250 mm, through hole Ø80 mm

Through spindle, through hole Ø80 mm

Measuring probe

Cooling system

Chip conveyor

Technical documentation

Quoted net price negotiable

All further information and machine condition are available in the photos.

The lathe is regularly serviced and has been properly maintained.

Please contact us for further information or to arrange an inspection.

Listing

Borgo San Dalmazzo

Borgo San Dalmazzo

8,135 km

CNC turning and milling center

DOOSANPUMA 2000 SY

Call

Condition: used, Year of construction: 2007, functionality: fully functional, turning length: 510 mm, turning diameter: 330 mm, spindle speed (max.): 4,500 rpm, rapid traverse X-axis: 20 m/min, rapid traverse Y-axis: 24 m/min, rapid traverse Z-axis: 20 m/min, CNC Fanuc 18i - TB

Max turning diameter x length: mm 330 x 510

Chuck size: mm 210

Spindle speed: rpm 4.500

Gsdpfx Aoxqgl Eoh Eobw

Spindle motor power (Cont. / Short term): kW 11/15

Sub spindle motor power (Cont. / Short term): kW 5,5/7,5

Rapid traverse (X/Z/Y/B): m/min 20/24/7,5/20

Tool holder type: BMT 55P

No. of tool stations: 12

Machine equipped with:

• Nr. 2 self centering chucks

• Nr. 1 radial live tool holder

• Nr. 1 axial live tool holder

• Nr. 2 external fixed tool holders

• Nr. 2 boring tool holders

• Dichiarazione di conformità CE

Listing

Germany

Germany

10,526 km

CNC Turning- and Milling Center

MORI SEIKINZ 2000 T3Y2 Lehmann-Robot

Call

Condition: used, Year of construction: 2011, Technical details:

standard turning dia.: 200

turning length: max. 810 mm

control: MSX-701 MAPPS IV

greates pass round over bed: 800 mm

Max. distance between centres: 1130 mm

max. turning diameter: 320 mm

max. workpiecediameter: 300 mm

bar material dia.: 65 mm

Traverse X-Axis 1: 210

Traverse X-Axis 2: 210 mm

Traverse X-Axis 3: 210 mm

Traverse Y-Axis 1: 110 (+65/-45) mm

Traverse Y-Axis 2: 110 (+45,/-65) mm

Traverse Z-Axis 1: 300 mm

Gbedpfx Ajxq E Eweh Esw

Traverse Z-Axis 3: 300 mm

Traverse Z-Axis 2: 810 mm

Traverse B-Axis: 870 mm

turning speed range - spindle: 5.000 1/min

Number of spindle speed ranges: 2 .

spindle nose: JIS A2-6

spindle bore: 73 mm

spindle bearing diameter: 120 mm

C-Axis: 0,001 °

turning speed range - spindle: 5.000 1/min

spindle nose: JIS A2-6

spindle bore: 73 mm

bar material dia. max: 65/52 mm

spindle bearing diameter: 120 mm

C-Axis: 0,001 °

Number of Turrets: 3 .

Number of tool stations: 16 x 3=48 pos

Schank height for square tool: 20 mm

Diameter of boring bar: 32 mm

turret changing time (4-stations): 0,18 sec

Number of driven tools: 16 x 3=48 pos

max. spindle speed driven tools: 6.000 U/min.

Rotary tool machining ability: M16 / Ø16 .

rapid traverse X-axis: 30 m/min

rapid traverse Y-axis: 20 m/min

rapid traverse Z-axis: 50 m/min

drive capacity - spindle motor: 25 / 22 kW

power capacity - driven tools: 7,5 / 5,5 kW

total power requirement: 92,7 kVA

weight of the machine ca.: 9,4 t

dimensions of the machine ca.: 4,0 x 2,8 x 2,4 m

Accerories

Chip conveyor

Coolantsystem

C-axis in main and sub spindle

Y-axis 2 x

part counter

total counter

tool setting

Overhead partsgripper with conveyor belt.

Spindle 1 Chuck SMW KNCS-N 210 / 52 mm

Spindle 2 Collet Chuck Hainbuch Spanntop nova Kombi Axfix 65

Robot interface

Lehmann Robot with parts belt for feeding and disposal

CNC Turning- and Milling Center

MORI SEIKI NZ 2000 T3Y2

The NZ2000 T3Y has 2 spindles and 3 turrets, and 2 turrets have the Y-axis function and built-in milling motors. This not only allows synchronized machining using 3 turrets, but also achieves heavy-duty cutting and high-speed machining using rotary tools thanks to the built-in motor turrets.

For shaft parts loading and unloading there is a Lehmann Robot conveyor belts for loading and unloading .

*

Listing

Oelde

Oelde

7,700 km

CNC Turning- and Milling Center

MORI SEIKINZ 2000 T2Y

Call

Condition: used, Year of construction: 2011, turning diameter max. 320 mm

turning length max. 810 mm

control MSX-701 IV

greates pass round over bed 800 mm

Swing dia. over traverse guideway 800 mm

distance between spindles 1.130 mm

Number of revolutions max. 5.000 rpm

power capacity - main spindel 25 / 22 kW

max. Torque 358 Nm

spindle diameter in front bearing 120 mm

spindle bore 73 mm

max. usable bar diameter 65 mm

C-Axis 0,001 °

spindle nose JIS A2-6

collet chuck 160 mm

Number of revolutions max. 5.000 rpm

Godpev E R E Nofx Ah Esbw

power capacity - Sub spindle 25 / 22 kW

max. Torque 358 Nm

spindle diameter in front bearing 120 mm

spindle bore 73 mm

max. usable bar diameter 65 mm

C-Axis 0,001 °

spindle nose JIS A2-6

collet chuck 160 mm

number of toolpositions 16 pos.

Number of driven toolspositions 16 pos.

Spindle speed - driven tools max. 6.000 min -1

power capacity - driven tools 7,5 / 5,5 kW

Y - Axis 110 mm

Shank diameter 20 x 20 mm

Drill shank diameter 32 mm

turret change time 0,18 sec.

number of toolpositions 16 pos.

Number of driven toolspositions 16 pos.

Spindle speed - driven tools max. 6.000 min -1

power capacity - driven tools 7,5 / 5,5 kW

Shank diameter 20 x 20 mm

Drill shank diameter 32 mm

turret change time 0,18 sec.

x-travel 1/2: 210 mm

y-travel 110 mm

z-travel 1/2: 810 mm

Traverses Subspindle B: 870 mm

rapid traverse ( X / Y / Z ) 1: 30 / 20 / 50 m/min

rapid traverse ( X / Y / Z ) 2: 30 / - / 50 m/min

Tipp feed 0 - 5.000 mm/min

total power requirement 94 kVA

weight of the machine ca. 8,3 t

dimensions of the machine ca. 10,0 x 3,0 x 2,5 m

CNC - Turning- and MillingCenter

MORI SEIKI - NZ 2000 T2Y

- Main- and Subspindle

- 2 turrets, up and below

- Y-Axis

- 2x 16 driven tool positions

Listing

Burgoberbach

Burgoberbach

8,004 km

CNC turning-milling center 6 AGW

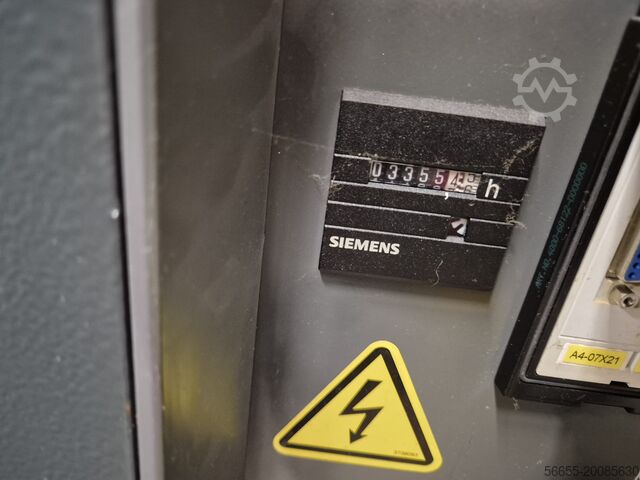

GildemeisterCTX 310 Eco (nur 3.350 h)

Call

Condition: excellent (used), Year of construction: 2012, operating hours: 3,355 h, functionality: fully functional, turning length: 450 mm, turning diameter: 200 mm, spindle speed (max.): 5,000 rpm, spindle bore: 51 mm, travel distance X-axis: 160 mm, travel distance Z-axis: 450 mm, overall weight: 3,800 kg, For sale is a CNC lathe from the brand Gildemeister, model CTX 310 Eco.

The machine is in excellent condition and ready for immediate use.

Godpfx Ahexf T N Te Esbw

Technical specifications:

Year of manufacture: 2012

Operating hours: 3,355 h (see picture)

Control: SIEMENS SINUMERIK 810D Powerline

Max. turning diameter: 200 mm

Max. swing diameter over bed: 330 mm

Max. turning length: 450 mm

X-axis travel: 160 mm

Main spindle speed: 5,000 rpm

Spindle bore: 51 mm

Turret: 12-station turret (VDI 30)

Live tooling: 6 driven tool stations

Live tool speed: approx. 4,500 rpm

Rapid traverse X/Z: 30/30 m/min

Dimensions: approx. 4200 mm x 1700 mm x 2300 mm

Machine weight: approx. 3,800 kg

Chip conveyor included in the offer.

Tool holders not included in the offer (can be offered additionally).

Transport and loading can be organized across Europe upon request, at extra cost.

Prices are exclusive of VAT.

Inspection by appointment possible. Contact us — our team is happy to assist you!

Trade-in or exchange possible!

Machinery trading

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MORE.

Are you looking for a high-quality yet affordable metalworking machine for your production? Or do you wish to sell yours?

For more information or contact options, please visit our website.

Listing

Italy

Italy

8,629 km

CNC Turning & milling center

DMG MORICTX Gamma 3000

Call

Condition: excellent (used), With C-axis

With Y-axis

With driven tools

SIEMENS 840D SL ShopTurn control

Turning diameter max 700 mm

Turning length -3065 mm

Swing Diameter -900 mm

Spindle speeds -2'500 rpm

C-axis Dividing 0.001°

Gsdsw S Iq Hspfx Ah Ejbw

Bar diameter 105mm

Top turret tool holders 12 driven positions

Y-axis travel 160 mm

Tool breakage control system

Misc. accessories

MARCELS MASCHINEN CH

Listing

Germany

Germany

7,870 km

CNC Turning- and Milling Center

Niles-SimmonsN30/2500 MC

Call

Year of construction: 2002, condition: ready for operation (used), With two machining modules, X-axis: -50 to 725mm, Y-axis: -200 to 300 / -250 to 250mm, rapid traverse X-, Y-, Z-axis: 18/12/30m/min, control: Siemens Sinumerik, temperature range: 5–40°C, power type/frequency: 3 PEN / 50Hz, rated voltage: AC 400V, control voltage: DC 24V, auxiliary voltage: AC 230V, connected load: 102kVA, rated current: 148A, rated current (fast): 148A, fuse (slow): 160A, length: 8000mm, width: 3000mm, height: 4000mm, weight: approx. 17t, operating hours: approx. 80,000h. The machine is fully functional, the ball screw drive (recirculating spindle) of the Z-axis was renewed in 2024 and it has been regularly maintained. Comes with documentation, control cabinet, hydraulic unit, filter elements, and chip conveyor. An on-site inspection is possible.

Gjdpfx Aowbuyzoh Ejbw

Auction

Auction ended

Bayern

Bayern

8,019 km

CNC turning and milling center

GILDEMEISTERGMX 250 linear

Condition: ready for operation (used), Year of construction: 2005, functionality: fully functional, turning length: 1,185 mm, turning diameter: 640 mm, spindle speed (max.): 4,000 rpm, turning diameter over bed slide: 640 mm, counter spindle torque (max.): 5,000 Nm, Turning and Milling Center with Main and Counter Spindle and Comprehensive Equipment!

TECHNICAL DETAILS

Turning diameter: 640 mm

Turning length: 1,185 mm

Swing diameter: 640 mm

Distance between headstocks: 1,500 mm

SLIDE I

X-Axis travel: 550 mm

Y-Axis travel: 180 mm

Z-Axis travel: 1,185 mm

B-Axis: 240°

Feed rate X-axis: 0 – 40,000 mm/min

Feed rate Y-axis: 1 – 24,000 mm/min

Feed rate Z-axis: 1 – 70,000 mm/min

Feed rate B-axis: 1 – 20 rpm

Rapid traverse X/Y/Z: 40 / 24 / 70 m/min

Feed force X/Y/Z S6: 7.00 / 11.00 / 7.50 kN

Tool interface: HSK 63

Milling spindle speed: 10 – 12,000 rpm

Drive power 100% duty cycle: 13.20 kW

Drive power 40% duty cycle: 22.00 kW

Milling spindle torque: 60 / 100 Nm

Max. tool length: 350 / 200 mm

Tool diameter: 80 mm

Tool diameter with 2 free pockets: 120 mm

Max. tool weight: 6 / 10 kg

SLIDE II

X-Axis travel: 180 mm

Z-Axis travel: 1,050 mm

Feed rate X-axis: 1 – 24,000 mm/min

Feed rate Z-axis: 1 – 36,000 mm/min

Rapid traverse X + Z axes: 24 / 36 m/min

Feed force Z / X S6: 11.00 / 9.00 kN

Turret (positions): 12

Tool holder: DIN 69880 Ø40

Driven tool positions: 12

Speed: 1 – 4,000 rpm

Drive power 100% duty cycle: 10.70 kW

Torque S1: 32 Nm

SLIDE III

Z-Axis travel: 1,150 mm

Feed rate Z-axis: 1 – 36,000 mm/min

Rapid traverse Z-axis: 36 m/min

Feed force Z-axis S6: 13.00 Nm

MAIN SPINDLE

Model: ISM90

Speed: 10 – 4,000 rpm

Drive power 100% duty cycle: 36.00 kW

Drive power 40% duty cycle: 45.00 kW

Torque at 40% / 100% duty cycle: 800 / 630 Nm

Spindle bore: 80 mm

COUNTER SPINDLE

Speed: 10 – 5,000 rpm

Godexf A Edspfx Ah Eebw

Drive power 100% duty cycle: 21.00 kW

Drive power 40% duty cycle: 28.00 kW

Torque at 40% / 100% duty cycle: 320 / 240 Nm

Spindle bore: 80 mm

MACHINE DETAILS

Electrical Data

Total power requirement: 70.00 kW

Dimensions & Weight

Machine weight: approx. 20.00 t

Footprint: approx. 8.50 x 4.50 x H3.10 m

Control

Control manufacturer: Siemens

Control model: SINUMERIK 840D

EQUIPMENT

Chip conveyor

Oil mist separator

DMG Automation WH10top

Main spindle ISM90: Hollow chuck, C-axis, 3-jaw power chuck SMW-AUTOBLOK KNCS-NB-315-91

Counter spindle ISM76: Partial hollow chuck, C-axis, 3-jaw power chuck SMW-AUTOBLOK KNCS-NB-315-91

Pick-off unit with integrated conveyor belt

Automatic safety cover

Differential pressure clamping

With pump stand for coolant: Pump 1: 17 l/min at 80 bar / Pump 2: 20 l/min at 8 bar / Pump 3: 40 l/min at 20 bar

Hainbuch collet chuck including collets Ø30, 45, 50, 55, 60, 65, 72, 82, 85, 90

1 workpiece pick-off for turret

Listing

Vieira de Leiria

Vieira de Leiria

7,247 km

Mori Seiki MT1500SX milling & turning

Mori SeikiMT 1500 SZ

Call

Condition: used, Year of construction: 2006, functionality: fully functional, turning length: 1,000 mm, turning diameter: 400 mm, spindle bore: 56 mm, travel distance X-axis: 800 mm, travel distance Y-axis: 600 mm, travel distance Z-axis: 460 mm, rapid traverse Z-axis: 80 m/min, rotational speed (max.): 12,000 rpm, overall weight: 10,500 kg, fuel: electricity, number of slots in tool magazine: 40, Mori Seiki MT 1500 SX 9-axis milling and turning center, manufactured in 2006, with Fanuc Series 18iB (MSX-501) control, maximum chuck length of 920mm, maximum diameter of 400mm, bore size of 56mm, 4000 and 6000 rpm spindle rotation, and 12,000 rpm milling spindle. 12-position turret with live tools, Y axis, B axis +/- 120, C axis 0.001, ATC 40 tools, and chip extractor. In excellent working condition and can be seen working in Portugal.

Gedpeh Elp Esfx Ah Eobw

Listing

Oelde

Oelde

7,700 km

CNC Turning- and Milling Center

MORI SEIKINZ 1500 T3Y3

Call

Condition: used, Year of construction: 2008, turning diameter max. 320 mm

turning length 810 mm

control MSX 701 MAPPS III

standard turning dia. 200 mm

Main spindle:

Number of revolutions max. 6.000 min/-1

power capacity - main spindel 22 / 18,5 kW

Bar feed max. 52 mm

spindle bore 61 mm

C-Axis 0,001 °

Subspindel:

Number of revolutions max. 6.000 min/-1

power capacity - Sub spindle 22 / 18,5 kW

Bar feed max. 52 mm

spindle bore 61 mm

C-Axis 0,001 °

Turret 1 + 3:

number of toolpositions je 16 pos.

Number of driven toolspositions je 16 pos.

Spindle speed - driven tools max. 6.000 min -1

power capacity - driven tools 7,5 / 5,5 kW

Y - Axis 110 (+65 / -45) mm

Turret 2:

number of toolpositions 16 pos.

Number of driven toolspositions 16 pos.

Gedpfx Astqmqweh Esbw

Spindle speed - driven tools max. 6.000 min -1

power capacity - driven tools 7,5 / 5,5 kW

Y - Axis 110 (+45 / -65) mm

axis stroke:

x-travel 1-3: 210 mm

y-travel 1-3: 110 mm

z-travel 1+3: 300 / 2: 810 mm

total power requirement 90 kVA

weight of the machine ca. 9,3 t

dimensions of the machine ca. 4,5 x 3,0 x 2,5 m

CNC - Turning- and MillingCenter

MORI SEIKI - NZ 1500 T3Y3

- Main- and Subspindle

- 3 turrets, 2x upper / 1x below

- 3x Y-Axis

- 3x 16-pos. tool-drive

- incl. 28x collets

- incl. Hainbuch changing device

Listing

Root

Root

8,011 km

CNC turning and milling center

EMCOE65, 95mm

Call

Condition: good (used), Year of construction: 2009, Machine used only for plastic. thry spindle 95.mm

Gbodpfju Ibnqox Ah Eew

Technical data shown on picture.

27.03.2025. With machine will come another spannpfutter with possibility 80 mm.

Parts shown by hand not come.

Listing

Đakovo

Đakovo

8,738 km

CNC turning and milling center

ASAHI OKUMAAF 2020-5

Call

Condition: used, Year of construction: 1990, Used 20 mm Cold Forming Machine

Manufacturer: Asahi-Okuma (Japan)

Year of manufacture: 1990

Model: AF-2020-5

Station No.: 5

Cutting diameter: Max. 20 mm (tensile strength below 70 kg/mm²)

Cutting length: 210-15 mm

Projection length:

Punch side projection: Max. 52 mm

Main die x depth: 115 mm diameter x 250 mm

Punch die x depth: 85 mm diameter x 150 mm

Cutting die x depth: 80 mm diameter x 80 mm

Gjdsxlac Hopfx Ah Esbw

Ejector die diameter: 30 mm diameter

Cutting die diameter x thickness: 80 mm x 40 mm

Die center distance: 140 mm

Crank stroke: 380 mm

Transfer stage length: 210 mm

Head piece net diameter: 45 mm diameter.

Punch net diameter: 100 mm diameter.

Force: 250 tons

Production capacity: 100 units/min (max.)

Main motor: 75 kW (6/8/12 poles)

Machine weight: 75 tons

Machine dimensions: 9.1 x 3.45 m

Listing

Cascina Faustina

Cascina Faustina

8,156 km

CNC turning and milling center Y

Mori SeikiSL 2500 Y

Call

Condition: used, Year of construction: 2001, functionality: fully functional, Japanese-built 4-axis CNC lathe for secondary machining, featuring C axis, Y axis, and driven tools. Installed in 2002 and compliant with CE standards, with the following main specifications:

Turning diameter: 755 mm

Workable diameter: 390 mm

Workable length: 655 mm

12-position driven turret

Y axis travel: +/- 60 mm

Godpfsxf Iygjx Ah Eobw

C axis

Spindle nose: A2-8

Kitagawa B-210, 250 mm

Spindle speed: 3,500 rpm

Spindle motor: 18.5 kW

Driven tool motors: 5.5 kW

Driven tool speed: 4,000 rpm

Bar capacity: 73 mm

Tailstock: MT5

Rapid traverse speed: 18 and 24 m/min on X and Z axes

Weight: 5,800 kg

Complete with:

- Hydraulic programmable tailstock

- Box ways

- Chip conveyor

- Headstock oil cooling

- Dual foot pedal for main chuck and tailstock open/close

- Set of fixed tool holders

- Set of driven tool holders

- Complete manual set

- CE certificate

Listing

Germany

Germany

10,526 km

CNC Turning- and Milling Center

EMAGVLC 800 MT

Call

Condition: used, Year of construction: 2008, Technical details:

x-travel: 2665 mm

y-travel: 2440-2890 mm

z-travel: 750 mm

max. torque on the spindle: 4400 Nm

Gsdpfx Ahsw S Htao Ejbw

control: Siemens 840D

workpiece diameter - max.: 800 mm

workpiece length - max.: 750 mm

tool changer with: Scheiben-Revolver 12-fach places

spindle speed:: 750 U/min

tool taper: 50

voltage: 400 V

Total power requirement: 92 kW

Weight approx.: 30 t

dimension machine xH: 7,0 x 3,1 x 4,5 m

The machine has a turret with 12 tool stations (VDI 50) and a milling spindle with a tool changer for up to 96 tools.

The tool magazine can be loaded during machining, which reduces setup time and allows the use of “sister” tools. The proven EMAG turret is available for turning operations on the machine.

The VLC 800 MT multifunctional machining center can completely machine parts up to 800 mm in diameter in a single clamping.

If necessary, a new (unused) spindle unit can be purchased as an option. (#1100673)

*

Listing

Minareliçavuş

Minareliçavuş

9,741 km

CNC turning and milling center

YCMDCV4030B-5AF

Call

Condition: used, Year of construction: 2017, functionality: unexamined, 🏭 YCM DCV4030B-5AF (Double Column Type)

Technical Specifications

Specification Description

Model DCV4030B-5AF

X-Axis Travel (mm) 4065

Y-Axis Travel (mm) 3500

Z-Axis Travel (mm) 1016

Spindle Speed (rpm) 10,000

Tool Magazine Capacity (optional) 40T (optional 60T / 120T)

Table Load Capacity (kg) 20,000

Machine Weight (kg) 60,000

⚙️ Standard Accessories and Features

YCM-designed High-Performance / High-Speed 5-Axis Indexing Head

HSK-A100 Spindle Taper – 10,000 rpm

Spindle and Gearbox Cooling System (air conditioner + oil cooler)

Spindle Motor Power: 43 kW (58 HP)

High Torque: 188 Nm

Head Indexing Angle: 5° (optional 1°)

Head Swing / Rotation Range: Tilt ±110°, Rotation ±180°

Spindle Air Curtain – prevents moisture and dust ingress

Automatic Tool Changer (ATC): 40-tool arm type (optional 60T / 120T)

Foot Pedal for Tool Unclamping

Rapid Traverse Rates (X/Y/Z): 20 / 20 / 15 m/min

Cutting Feedrate: 10,000 mm/min

High-rigidity Meehanite Cast-Iron Structure, designed for heavy-duty and high-speed cutting

X-Axis: 3 sets of IKO Roller Linear Guideways (each with 5 blocks)

Y-Axis: 3 sets of angularly adjusted IKO Roller Guideways

Gbodpfx Asxcnk Tsh Eew

Z-Axis: Built-in Box-Type Guideway

Hydraulic Counterbalance System for Z-axis

Bridge and Column: One-piece casting design

Table: Heavy-duty design for deep-cut machining

🧠 Control System

Control: FANUC 200FB (Option 1 & Option 2 included)

Display: 15.1” TFT LCD color screen

High-speed machining block processing time: 0.5 ms

Look-ahead function: 5000 blocks

Option 1: 4-axis simultaneous machining + tool plane setting

Option 2: 5-axis simultaneous machining + tool plane setting

TCPM (Tool Center Point Management)

DCM (Collision Detection / Prevention System)

Kinematic Compensation: Automatic via Cycle 451

Kinematic Calibration Ball: Ø 20 mm

Hard Disk: 32 GB + Ethernet connectivity

Mouse Pad Function

Mold Package (for die & mold applications)

Smart NC: 3D graphic display and full graphical conversational programming

Rigid Tapping (Tapping without Floating Holder)

Helical Interpolation

🧰 Lubrication, Cooling & Safety Systems

Piston-Type Automatic Centralized Lubrication System

Anti-Crash Protection during Power Failure

Wash-down Gun for cleaning chips and interior

Air-Blow System for Cutting Tool Cooling

MPG (Manual Pulse Generator) Handwheel

Screw-Type Chip Conveyor

Electrical Cabinet Cooling System

Automatic Separation System for slideway oil and coolant

Listing

Oelde

Oelde

7,700 km

CNC Turning- and Milling Center

MORI SEIKISL 204 MC

Call

Condition: used, Year of construction: 2002, turning diameter 390 mm

turning length 507 mm

control MSG 805 MAPPS

max. turning diameter 390 mm

greates pass round over bed 680 mm

Swing dia. over traverse guideway 510 mm

centre distance 618 mm

turning speed range - main spindle 45 - 4.500 min/-1

power capacity - main spindel 11 / 7,5 kW

spindle bearing diameter 110 mm

spindle bore 73 mm

max. bar capacity 51 mm

spindle nose JIS A2-6

chucking diameter 210 mm

C-Axis 0,001 °

x-axis 235 (195+40) mm

z-axis 520 mm

number of toolpositions 12 pos.

Number of driven toolspositions 12 pos.

Spindle speed - driven tool stations max. 3.000 min -1

power capacity driven tool-stations 5,9 / 4,5 kW

Shank height for square tool 25 mm

Drill shank diameter max. 50 mm

turret change time 0,2 sec.

tailstock adjustment 490 mm

dia. of quill 85 mm

taper of center MT 4

quill stroke 120 mm

Gsdpovzhiqofx Ah Esbw

rapid traverse X: 18 / Z: 24 m/min

Tipp feed 0 - 1.260 mm/min

total power requirement 30,1 kW

weight of the machine ca. 4,5 t

dimensions of the machine ca. 5,0 x 2,5 x 2,5 m

CNC - Turning- and Millingcenter

MORI SEIKI - SL 204 MC

Listing

Hattingen

Hattingen

7,668 km

CNC Turning- and Milling Center

HEYLIGENSTAEDTHEYNUMAT 5 UK / 1500

Call

Condition: used, Year of construction: 2007, greates pass round over bed 670 mm

swing diameter over bed slide 490 mm

Gedpfexcbktjx Ah Eobw

max. turning diameter 490 mm

control SIEMENS - 840 D

main spindle bore 115 mm

external spindle dia. in forward position 160 mm

CNC Turning- and Milling Center | HEYLIGENSTAEDT - HEYNUMAT 5 UK / 1500 equipped with a turret for driven tools as well as travelling lynette and tailstock.

Additional equipment:

- Centering points,

- Jaw sets,

- Clamping jaws,

- 3 jaw chuck,

A machine video from the production plant will be shared on request.

The machine is in a well-maintained condition and can be inspected at any time under power.

Please refer to further technical details in the attachement of the offer.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

#Tags: Heynumat 5 U | Heynumat 5-U | Heynumat 5 U 1500

Listing

Warszawa

Warszawa

8,361 km

CNC turning and milling center

DMG MORISPRINT 20-8

Call

Condition: used, Year of construction: 2010, functionality: fully functional, turning length: 300 mm, turning diameter over cross slide: 20 mm, turning diameter: 20 mm, spindle speed (min.): 10,000 rpm, spindle speed (max.): 10,000 rpm, spindle bore: 20 mm, rotational speed (max.): 10,000 rpm, power: 30 kW (40.79 HP), Turning and milling center complete with bar feeder LNS HYDROBAR MINI SPRINT bar loader(Maximum bar length 3,000mm)

DMG MORI SPRINT 20-8

Control: Fanuc 310i

Main spindle

speed: 10.000 rpm

Power: 5,5 kW

torque: 14 Nm

bar passage: max. 20 mm

C1 axis: 0.001

travel Z1 axis: 80 mm

Counter spindle

speed: 10.000 rpm

power: 5,5 kW

torque: 14 Nm

C2 axis: 0.001

Travel X2 / Z2 axis: 240 / 300 mm

rapid traverse in X2 / Z2 axis: 40 m/min

Gjdpfxeq Nmm Eo Ah Eebw

Tool carrier I (X/Y)

Technology: Linear slide

Internal machining: 6 stations

tool holder: 20 mm

External machining: 6 stations

Tool holder: 12 x 12 mm

Driven tool stations: 5

Tool drive: 3,450 / 6,000 rpm

Tool holder: collet chuck, ESX 16

Travel in X/Y axis: 50/350 mm

Rapid traverse in X/Y axis: 40/30 m/min

Tool carrier II (Y)

Technology: Linear slide

internal machining: 4 stations

tool holder: 20 mm

External machining: 4 stations

Tool holder: 12 x 12 mm

Driven tool stations: 5

Tool drive: 3,450 / 6,000 rpm

Tool holder: collet chuck , ESX 16

Travel in Y2 axis: 120 mm

rapid traverse in Y2 axis: 40 m/min

MACHINE DETAILS

weight: 4200 kg

Connected load: 30 kVA

Operating voltage: 400 V / 50 Hz

EQUIPMENT

Chip management: chip conveyor

Coolant management: Coolant pump

Fire extinguishing system: Kraft + Bauer

Oil mist extraction: Interface prepared

Further equipment: Signal lamp

Trust Seal

Dealers certified through Machineseeker

Listing

Oelde

Oelde

7,700 km

CNC Turning- and Milling Center

GILDEMEISTERCTX beta 1250 V4

Call

Condition: used, Year of construction: 2010, turning diameter max. 410 mm

turning length 1.235 mm

control IT / Turn Plus Heidenhain

greates pass round over bed 700 mm

turning speed range - main spindle max. 4.000 min/-1

power capacity - main spindel 35 / 45 kW

max. Torque 770 Nm

spindle head 220 h5

spindle diameter in front bearing 160 mm

max. usable bar diameter 95 / 104 mm

C-Axis 0,001 °

number of toolpositions 12 pos.

Number of driven toolspositions 12 pos.

Gjdpovzhiwofx Ah Esbw

Spindle speed - driven tool stations max. 4.000 min -1

power capacity driven tool-stations 12 kW

max. Torque 36 Nm

tool taper VDI 40 DIN 69880

turret change time 30°: 0,4 sec.

Y - Axis 120 (+/- 60) mm

x-axis 300 mm

z-axis 1.300 mm

y-axis +/- 60 mm

tailstock 1.200 mm

taper of center MK 5

clamping capacity 1.400 daN

rapid traverse ( X / Y / Z ) 30 / 22,5 / 30 m/min

total power requirement 60 kVA

weight of the machine ca. 7,7 t

dimensions of the machine ca. 6,0 x 3,5 x 2,5 m

CNC - Turning- and Millingcenter

GILDEMEISTER - CTX beta 1250 V4

- Tailstock

- Y-axis

- Tool drive

- Direct measuring system

- Bar machining package

- Connection for bar feed / bar loading magazine

Listing

Hattingen

Hattingen

7,668 km

CNC Turning- and Milling Center

HEYLIGENSTAEDTHEYNUMAT 24 UK-2 / 2000

Call

Condition: used, Year of construction: 2006, greates pass round over bed 960 mm

swing diameter over bed slide o: 860 / u: 730 mm

turning diameter over bed slide o: 860 / u: 400

control SIEMENS - 840 D

forward bearing diameter 200 mm

CNC Turning- and Milling Center | HEYLIGENSTAEDT - HEYNUMAT 24 UK-2 / 2000

equipped with a turret for driven tools

as well as tailstock.

The machine is in a well-maintained condition and

can be inspected at any time under power.

Please refer to further technical details in the attachement of the offer.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Gjdjxcbkmspfx Ah Eebw

#Tags: HEYNUMAT 24 UK | HEYNUMAT 24-UK | HEYNUMAT 24 UK 2 2000

Listing

Oelde

Oelde

7,700 km

CNC Turning- and Milling Center

MORI SEIKINZ 1500 T2Y

Call

Condition: used, Year of construction: 2010, turning diameter max. 320 mm

turning length 810 mm

control MSX 701

Number of revolutions max. 6.000 U/min

power capacity - main spindel 22 / 18 kW

max. usable bar diameter 52 mm

C-Axis 0,001 °

spindle nose JIS A2-5

collet chuck 140 mm

Number of revolutions max. 6.000 U/min

power capacity - Sub spindle 22 / 18 kW

Gsdpfx Aev E R E Aoh Eobw

max. usable bar diameter 52 mm

C-Axis 0,001 °

spindle nose JIS A2-5

collet chuck 140 mm

number of toolpositions 16 pos.

Number of driven toolspositions 16 pos.

Spindle speed - driven tools max. 6.000 min -1

power capacity - driven tools 7,5 / 5,5 kW

Y - Axis 110 mm

number of toolpositions 16 pos.

Number of driven toolspositions 16 pos.

Spindle speed - driven tools max. 6.000 min -1

power capacity - driven tools 7,5 / 5,5 kW

x-travel 1/2: 210 mm

y-travel 110 mm

z-travel 1/2: 810 mm

b-axis 900 mm

total power requirement 86 kVA

weight of the machine ca. 8,1 t

dimensions of the machine ca. 8,0 x 3,5 x 2,8 m

CNC - Turning- and MillingCenter

MORI SEIKI - NZ 1500 T2Y

- Main- and Subspindle

- 2 turrets, up and below

- Y-Axis

- 2x 16 driven tool positions

Listing

Hattingen

Hattingen

7,668 km

CNC Turning- and Milling Center

NILES-SIMMONSN40 MC / 3000

Call

Condition: used, Year of construction: 1998, turning length 3.000 mm

greates pass round over bed 810 - 760 mm

swing diameter over slide rest 740 mm

control SIEMENS - 840 C

max. turning diameter 800 mm

turning diameter over slide 740 mm

travel -x2 axis 875 mm

travel -z2 axis 3.700 mm

CNC Turning- and Milling Center | NILES-SIMMONS - N40 MC / 3000

equipped with a well as travelling lynette and tailstock.

Additional equipment:

- Centering points,

- Jaw sets,

- Clamping jaws,

The machine is in a well-maintained condition and

can be inspected at any time under power.

Please refer to further technical details in the attachement of the offer.

Gbjdpfxexb Efrs Ah Ejw

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

#Tags: N-40 | N 40 | N40MC3000 | N40MC

We make it easier for you to find: "turning and milling"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Turning And Milling (22,174)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month