Used Zerma Cutting Mill for sale (50)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Zerma

Listing

Zuzenhausen

Zuzenhausen

7,895 km

Side mills

ZERMAGSL 180

Call

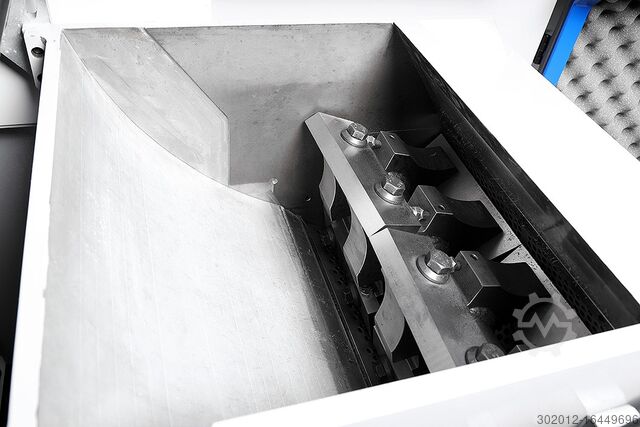

Condition: new, machine/vehicle number: Baureihe GSL 180 / Neumaschine, The ZERMA auxiliary mills of the GSL series 180/120 to 180/430 were developed as low-speed mills especially for applications in the injection moulding sector. They have a rotor diameter of 180 mm and working widths of 120 to 430 mm. The rotor is driven directly by a geared motor. The special rotor knives can be reground several times.

The material to be shredded is fed via a noise-reduced feed hopper of sandwich construction, which is available in different versions depending on the type of feed. Depending on the task, the side mills of this series are mounted on a low or high chassis and completed with a corresponding suction/outlet trough. Together with numerous options, the side mills are extremely variable in use.

In addition to the usual advantages of all low-speed mills, such as low noise emission and almost dust-free grinding material, the GSL 180/120 to GSL 180/430 beside-the-machine mills are characterized above all by their knife, rotor, quick-snap system and by their good accessibility.

Isdeghgbdspfx Ad Dsbd

Listing

Soerendonk

Soerendonk

7,581 km

Granulator / Shredder

Pallmann / ZermaPS 4 - 7,5 F

Call

Condition: like new (used), “Pallmann PS 4-7,5 F – Granulator / Roll Crusher” for Sale

Find our complete stock on our website.

Iedpfsglvv Ujx Ad Dobd

Manufacturer: Pallmann

Type: PS 4 – 7,5 F

Mach. No.: 2264036

Electrical Motor: 75 kW Included

Included frame.

Shredder will be overhauled, sandblasted and painted.

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

7,698 km

Single shaft shredder

ZermaGST 400/600

Call

Condition: new, Year of construction: 2025, functionality: fully functional, overall weight: 2,000 kg, rotor diameter: 400 mm, number of blades: 6, rotor length: 600 mm, rotor width: 400 mm, power: 22 kW (29.91 HP), filling opening width: 490 mm, filling opening length: 590 mm, warranty duration: 12 months, input voltage: 400 V, The compact inline granulators of the GST series are designed for use in injection molding and blow molding operations. They are suitable for recycling, for example, voluminous parts such as bottles, canisters, crates, sprues, and molded parts. Thanks to the low feed height, the machines can be easily loaded by hand or with a small conveyor belt. The low noise emissions and space requirements make the GST series the ideal solution for inline size reduction.

All GST series machines feature a compact, soundproofed housing and a noise-insulated feed hopper. The feed hopper can be tilted open and closed via a gas strut. The compact granulators are available with two rotor diameters (250 mm, 400 mm) and rotor widths from 300 to 1000 mm. The smaller models feature an open F-rotor, while the larger machines come equipped with the heavier S-rotor. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material blockages. Thanks to the modular design, the granulator can be easily upgraded with additional options such as replaceable wear plates. As with all ZERMA granulators, rotor and stator knives can be adjusted outside the machine to minimize downtime during maintenance. A setting gauge is included in the delivery. The control cabinet is mounted externally on the noise protection enclosure, with internal wiring throughout the system.

Technical specifications:

Rotor diameter (mm): 400

Rotor width (mm): 600

Drive (kW): 22

Rotor knives (rows): 3 x 2

Stator knives (rows): 2

Screen perforation (mm): > 6

Cutting chamber size (mm x mm): 400 x 600

Ijdpfsvgncujx Ad Debd

Weight (approx. kg): 2000

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Montbrison

Montbrison

7,834 km

Single-shaft shredder

ZERMAGSE 300/600

Call

Condition: as good as new (ex-display), Year of construction: 2021, operating hours: 10 h, functionality: fully functional, machine/vehicle number: GSE 30602103001, ZERMA shredder

Type: GSE 300/600

+ DUST CYCLONE

Includes spare parts, knives, counter-knives.

Iodpovdkw Njfx Ad Dsbd

Like new, only used for a few hours

Listing

Anderstorp

Anderstorp

7,638 km

Kvarn

ZermaGSL 180/300

Call

Year of construction: 2023, condition: new, functionality: fully functional, Zerma cutting mill type GSL 180/300

IE motor 4.0 KW, 400V, 50 Hz

Rotor diameter: 180mm, rotor width: 300mm

Rotor knives: 30 pieces, stationary knives: 2 pieces

low version, on wheels

Standard - hopper

Ioder E Aqvepfx Ad Djbd

Screen insert: Ø >5mm round

Discover more used machines

Listing

Kunda

Kunda

8,051 km

Shredder for tires and plastics

ZermaZXS 2000T

Call

Condition: used, functionality: fully functional, Year of construction: 2010, operating hours: 5,000 h, machine/vehicle number: ZXS20001004001, For Sale: ZERMA ZXS 2000T Heavy-Duty Shredder used for tires. In a very good shape. Max. 5000 working hours.

Industrial-grade single-shaft shredder designed for heavy-duty size reduction of tires and plastics such as PE, PP, and PVC. Built with a massive 1900 mm wide rotor (750 mm diameter) featuring 96 rotor knives and 25 stator knives, driven by two powerful 132 kW motors plus an 11 kW hydraulic unit.

✅ Large feed opening: 2020 x 2540 mm

✅ Hydraulic pusher system for controlled material feed

✅ Replaceable screen system for flexible output sizing

✅ Rotor water cooling option for demanding applications

✅ Robust steel frame – approx. machine weight 18,000 kg

✅ Noise level approx. 95 dB(A) (without soundproofing)

✅ Advanced control panel with automatic load management

✅ Safety features: emergency stop system, interlocked access panels, and more

Ibsdpfxjwri U Ue Ad Djd

Ideal for recycling plants, tires and plastics processing, and high-volume material reduction. Supplied with full technical documentation and user manual.

Listing

Zuzenhausen

Zuzenhausen

7,895 km

Shredder

ZERMAZWS

Call

Condition: new, With the cost-effective single-shaft shredders of the ZWS series, a wide range of shredding tasks can be realized, e.g. as a preliminary stage for subsequent briquetting, for the production of wood chips for firing or return to the particleboard industry. Depending on throughput and material, the machines can still be individually adapted to the task.

Typical feed materials for shredding are:

Large panel and board sections

Wooden pallets

Waste from carpentry workshops

Packaging wood

Iodpfx Adsghgdgj Debd

Construction and demolition wood

Veneers, MDF and chipboard

Listing

Wien

Wien

8,408 km

Side grinders GSL -180/ 180

ZERMAGSL-180/180

Call

Condition: excellent (used), Side mills

Ibodelvt Eqopfx Ad Ded

Zerma

Year of manufacture 2005

Type: GSL -18AMIS)

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

7,697 km

Shredding machine

ZermaGST 250/450

Call

Condition: new, Year of construction: 2024, Optimization of an established concept.

Shredding of large-volume blow-molded parts as well as start and end pieces

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

98T8Mrx

Optional rear panel with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection-molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Ibjdpfet Aagaox Ad Dod

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Opening feed option of the M version (mm) 295 x 450

Listing

București

București

9,232 km

Zerma granulator

ZermaGSH 700/1000-7-2(3)-WET

Call

Condition: like new (used), Year of construction: 2022, operating hours: 150 h, functionality: fully functional, machine/vehicle number: #12350, Plastic granulator GSH 700/1000 with production 800 kg/h

Iedovdkpxepfx Ad Dsbd

Listing

Zuzenhausen

Zuzenhausen

7,895 km

Shredder

ZERMAZHS 1100

Call

Condition: used, machine/vehicle number: 13187, Rotor diameter: 400 mm

Rotor width: 1100 mm

Rotor blades: 54

Isdpswbwvlofx Ad Dsbd

Stator blade rows: 1

Inlet cross-section approx. 1100 x 1500 mm

Drive motor: 37 kW

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

7,698 km

ZERMA GST250/450 granulator hollow body

ZERMAGST 250/450

Call

Year of construction: 2025, operating hours: 1 h, condition: new, functionality: fully functional, Optimization of an established concept.

Ibjdpfjum Rnvex Ad Dod

Shredding of large-volume blow-molded parts as well as start and end pieces

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

98T8Mrx

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

Optional rear wall with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection-molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Opening feed option of the M version (mm) 295 x 450

Listing

Zuzenhausen

Zuzenhausen

7,895 km

Shredder

ZERMAZWS 600 SMART

Call

Condition: new, machine/vehicle number: ZWS 600 SMART, The ZWS 600 SMART serves as a supplement to the ZWS series. The series was designed as a cost-effective solution specifically for shredding wood residues in small and medium-sized wood processing companies.

AT A GLANCE:

Compact design

Stable welded steel construction

Large-volume hopper for material feeding

Rotor made of solid steel with screwed knife holders

PLC control for fully automatic operation

Technical data SMART 600:

Iedsghgdcjpfx Ad Dsbd

Inlet 600 x 840 mm

Motor 11 / 15 kW

Rotor diameter 250 mm

Rotor speed 80 - 120

13 rotor knives

Technical data SMART 600 S:

Inlet 600 x 840 mm

Motor 18.5 / 22 / 30 kW

Rotor diameter 250 mm

Rotor speed 80 - 120

26 rotor knives

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

7,698 km

High speed granulator

ZERMAGST 250/300

Call

Year of construction: 2025, condition: new, Size reduction of large-volume blow molded parts as well as start and end pieces

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

Ibodpop Sr Ansfx Ad Djd

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 300

Drive (kW) 7.5

Number of rotor blades 3 x 1

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 950

Feed opening (mm) 380 x 300

Feed opening option of M version (mm) 295 x 300

Listing

Zuzenhausen

Zuzenhausen

7,895 km

Shredder

ZERMAZHS

Call

Condition: new, ZHS 600 - 18.5/22 kW

Rotor diameter: 400 mm

Working cross-section: 520 x 470 mm

ZHS 850 - 30 kW

Rotor diameter: 400 mm

Working cross-section: 800 x 820 mm

ZHS 1100 - 37 kW

Rotor diameter: 400 mm

Working cross-section: 1,080 x 1,040 mm

ZHS 1400 - 55 kW

Rotor diameter: 400 mm

Working cross-section: 1,400 x 1,380 mm

ZHS 1500 - 90/110 kW

Rotor diameter: 600 mm

Working cross-section: 1,360 x 1,430 mm

ZHS 1700 - 75 kW

Rotor diameter: 400 mm

Working cross-section: 1,640 x 1,550 mm

ZHS 2000 - 2 x 90 kW

Rotor diameter: 400/600 mm

Working cross-section: 1,920 x 1,550 mm

ZHS 2600 - 2 x 90 kW

Rotor diameter: 400/600 mm

Working cross-section: 2,480 x 1,550 mm

Iedpfxeghgdkj Ad Debd

ZHS - economical all-rounders

The ZHS series has a load-dependent hydraulic slide that feeds the material to the rotor in a slightly inclined position in a horizontal movement. The material is cut between the rotor and stator blades until it falls through the sieve installed and screwed under the rotor. The replaceable sieve defines the final grain size. The shredded material can be discharged via a conveyor belt, a discharge screw or pneumatically using a suction system.

The single-shaft shredders of the ZHS series are designed for light to medium-heavy loads in the plastics industry.

Technical details:

Roller-bearing hydraulic slide with horizontal movement

Screwed knives and knife holders

Optionally with segment base for particularly thin parts and materials

Aggressiveness of the rotor can be reduced or increased by screwing on filler pieces

Can be combined in a 2-stage system with a cutting mill as a pre-shredder

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

7,698 km

High speed granulator

ZERMAGST 250/600

Call

Year of construction: 2025, condition: new, Size reduction of large-volume blow molded parts as well as start and end pieces

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 600

Drive (kW) 11

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 1450

Iedpfjp Sr Iajx Ad Dobd

Feed opening (mm) 380 x 600

Feed opening option of M version (mm) 295 x 600

Listing

Zuzenhausen

Zuzenhausen

7,895 km

Shredder

ZERMAZRS

Call

Condition: new, The solution for shredding large, long pipes and profiles. The ZRS series has been specially developed for shredding pipes with diameters of up to 1,300 mm and made of different materials such as PE, PP, PVC.

These machines can directly shred plastic pipes up to a length of 9 meters without prior cutting or sawing. At the heart of the machines are rotors with diameters of up to 1,500 mm, which can be equipped with up to 206 cutting crowns and gently shred the material at low speed.

The pipe is fed into a closed feed trough in which the pipe is pressed against the rotor by means of a hydraulic ram. The pre-shredded material is then fed from the shredder to a granulator via a conveyor belt. The granulator grinds the material into a directly processable regrind.

Iedpoghgd Iefx Ad Djbd

The entire plant is operated automatically via a central control unit. Another advantage of the plant is the low energy requirement, the avoidance of power peaks, and the minimization of accident risks during pre-shredding.

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

7,698 km

Slow speed granulator

ZERMAGSL 300/800

Call

Year of construction: 2025, condition: new, Direct driven staggered rotor

Special knife design makes adjustment unnecessary

Easy access for maintenance and cleaning

Slow rotor speed creates less noise and dust

Easily customizable to suit different applications

Rotor diameter (mm) 300

Rotor width (mm) 800

Rotor speed (rpm) 150

Drive capacity (kW) 18.5

Rotor knives (pcs) 66

Stator blades (rows) 2

Screen size (mm) > 6

Weight approx. (kg) 1100

Ibjden Hqv Dopfx Ad Dod

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

7,698 km

Granulator

ZERMAGSL 300/600

Call

Year of construction: 2025, condition: new, GSL - Slow speed granulator GSL 300

Rotor diameter (mm) 300

Rotor width (mm) 600

Rotor speed (rpm) 150

Drive capacity (kW) 11

Rotor knives (pcs) 48

Stator blades (rows) 2

Screen size (mm) > 6

Weight approx. (kg) 950

The slow speed granulators in the GSL range are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues. The machines can be used for rejected products in the inline recycling process as well. Different hopper and base frame designs make it possible to integrate the machine with most types of injection molding machines and robots.

Driven by gear motor

Unique knife design eliminates adjustment after resharpening.

Simple tool less access for maintenance and cleaning

Iodpfxei Hpf Nj Ad Dsbd

Customizable hopper and base frame

The slow speed granulators in the GSL 300 range feature a staggered 300 mm diameter rotor with widths ranging from 400 to 800 mm.

The rotor is directly driven by a geared motor. The low rotor speed reduces the noise level of the machine and creates less dust while grinding.

The special design knives of the GSL series can be sharpened easily and do not need adjustment afterwards. The material is fed via a sound absorbing feed hopper that can be tailored to fit various applications and feeding ways.

Depending on the requirements the machines can be fitted with a wide variety of hoppers, they are mounted on either low or high level base frames with matching suction bins or bag filling adapters.

Quick snap fasteners and hand screws make access to the machine for cleaning and maintenance fast and easy.

Applications

The GSL slow speed granulators of the 300 series are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues.

But they can be used as low noise central granulators for small throughput requirements as well.

The stronger design of the 300 series GSLs allow them to be used for stronger and thicker materials while offering the same advantages regarding low noise and dust as the smaller GSL machines.

All GSL models can be equipped with a built in blower system in case a vacuum loading system is not available, or to transport the ground material to bags for storage.

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

7,698 km

Shredding machine

ZERMAGSL 180/300

Call

Condition: new, Year of construction: 2025, Slow-running mill for storage

Rotor diameter (mm) 180

Rotor width (mm) 300

Rotor speed (rpm) 150

Ibsdpfx Aet Aam Hed Dsd

Drive (kW) 4

Number of rotor blades 30

Number of stator blades 2

Screen perforation (mm) >5

Approx. weight (kg) 180

The slow-running mills of the GSL 180 series have a rotor diameter of 180 mm and working widths from 120 to 430 mm.

The rotor is driven directly by a gear motor. The low rotor speed ensures a pleasant noise level and a high-quality product.

The special rotor blades can be resharpened several times, eliminating the need for complex adjustment work. The mills are fed via a noise-reducing sandwich-type hopper. Depending on the task, the machines can be equipped with various hopper variants.

Low and high base frames are available as options. The ground material is either vacuumed or filled into bags or a plastic container.

Good accessibility for simple and quick maintenance work is ensured by the Quick Snap locking system.

Listing

Brahlstorf

Brahlstorf

7,755 km

High speed granulator

ZERMAGST 250/450

Call

Year of construction: 2024, condition: new, Optimization of an established concept.

Shredding of large-volume blow-molded parts as well as start and end pieces

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

Optional rear wall with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Number of rotor blades 3 x 2

Ibsdpfxop Sr H De Ad Djd

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Opening feed option of the M version (mm) 295 x 450

Trust Seal

Dealers certified through Machineseeker

Listing

Brahlstorf

Brahlstorf

7,755 km

Granulator

ZERMAGSL 180/180

Call

Year of construction: 2024, condition: new, Beside the press granulator

Iodpsiy D Szefx Ad Dobd

Rotor diameter (mm) 180

Rotor width (mm) 180

Rotor speed (rpm) 150

Drive capacity (kW) 3

Rotor knives (pcs) 18

Stator blades (rows) 2

Screen size (mm) >5

Weight approx. (kg) 140

The slow speed granulators in the GSL range are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues. The machines can be used for rejected products in the inline recycling process as well. Different hopper and base frame designs make it possible to integrate the machine with most types of injection molding machines and robots.

Driven by gear motor or V-belt

Unique knife design eliminates adjustment after resharpening.

Simple tool less access for maintenance and cleaning

Customizable hopper and base frame

Listing

Brahlstorf

Brahlstorf

7,755 km

Slow speed granulator

ZERMAGSL 300/400

Call

Year of construction: 2024, condition: new, Direct driven staggered rotor

Special knife design makes adjustment unnecessary

Easy access for maintenance and cleaning

Gegqxgljx

Slow rotor speed creates less noise and dust

Easily customizable to suit different applications

Rotor diameter (mm) 300

Rotor width (mm) 400

Ibsdpfx Adon Hqxfe Dod

Rotor speed (rpm) 150

Drive capacity (kW) 7.5

Rotor knives (pcs) 33

Stator blades (rows) 2

Screen size (mm) > 6

Weight approx. (kg) 550

Listing

Brahlstorf

Brahlstorf

7,755 km

Size reduction mill

ZERMAGSL 180/180

Call

Year of construction: 2024, condition: new, Slow-speed, side-by-side granulator

Rotor diameter (mm) 180

Rotor width (mm) 180

Rotor speed (rpm) 150

Drive (kW) 3

Number of rotor blades 18

Number of stator blades 2

Screen perforation (mm) >5

Approx. weight (kg) 140

The slow-speed side-by-side granulators of the GSL series are primarily used in injection molding and blow molding for the inline reduction of sprues and defective parts. Various hopper and extraction systems allow the machines to be flexibly integrated into existing installations.

Iodpfx Aeqmik Ied Dobd

GSL 180 For the comminution of sprues from injection molding and blow molding

Highlights of the GSL series:

Low noise thanks to the low rotor speed, angled cut, and soundproof hopper in a multi-layer sandwich design.

Powerful and efficient drive thanks to a brand-name gearbox.

Easy maintenance, cleaning, and knife replacement.

The slow-running, stand-alone granulators of the GSL 180 series feature a closed rotor with a diameter of 180 mm. The machines are available in working widths from 120 mm to 430 mm.

The rotor consists of individual discs directly connected to the spur gear unit via an oversized drive shaft. This enables efficient and low-maintenance power transmission.

The material to be crushed can be fed by hand, by conveyor belt, or by robot via a generously dimensioned, soundproof hopper in a sandwich design. The granulator is mounted on a low base frame on casters as standard. The mill is emptied via an extraction tray inserted beneath the screen with a pipe connection for a suction conveyor.

Applications

The slow-running, stand-alone mills of the GSL 180 series were

specifically developed for the size reduction of sprues from injection molding and blow molding. Easy accessibility allows for quick color and material changes. The low rotor speed also allows for the processing of both soft and hard materials, ensuring good material quality with low dust content.

Listing

Brahlstorf

Brahlstorf

7,755 km

Granulator

ZERMAGSL 180/430

Call

Year of construction: 2025, condition: new, Beside the press granulator

Rotor diameter (mm) 180

Rotor width (mm) 430

Rotor speed (rpm) 150

Drive capacity (kW) 4

Rotor knives (pcs) 45

Stator blades (rows) 2

Screen size (mm) >5

Weight approx. (kg) 250

The slow speed granulators in the GSL range are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues. The machines can be used for rejected products in the inline recycling process as well. Different hopper and base frame designs make it possible to integrate the machine with most types of injection molding machines and robots.

Ibodpfxsi Hpfde Ad Ded

Driven by gear motor

Unique knife design eliminates adjustment after resharpening.

Simple tool less access for maintenance and cleaning

Customizable hopper and base frame

We make it easier for you to find: "zerma cutting"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Zerma Cutting Mill (50)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month