Used Calibration System for sale (912)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Duxford

Duxford

7,214 km

Mettler Toledo Seven Excellence Multi parameter Metre

Mettler ToledoExcellence Metre

Call

Condition: used, This listing is for one of 2 Mettler Toledo Seven Excellence Multi parameter Metres

The unit is in full working condition and is ready for immediate use

The METTLER TOLEDO SevenExcellence series includes a line of advanced benchtop meters designed for high-precision electrochemical measurements. These meters are ideal for applications in pharmaceuticals, food and beverage quality control, and environmental testing.

Key Features Across the Series

Measurement Capabilities: Models support pH, conductivity, resistivity, redox/ORP, TDS, salinity, ISFET, ion selective electrodes (ISE), and dissolved oxygen (DO).

User Interface & Workflow Optimization:

Large touchscreen display for intuitive, efficient navigation.

Plain language menu structure eliminates confusion during setup.

One-click operation launches one of 17 predefined or 60 customizable methods, boosting throughput.

Choose from uFocus™ view, which displays only critical data, or standard view for detailed information including setup and measurements.

Data Management:

Export results to printers, Excel, or LIMS.

Compatible with LabX software for 21 CFR Part 11 compliance and advanced data control.

Gbodpfxsxv Adbj Ah Ejw

Time and date stamps from a radio-controlled clock ensure compliance with GLP standards.

Security & Compliance:

User management settings and PIN protection prevent unauthorized method changes.

Integrated Sensor Management (ISM®) pH electrodes are automatically recognized and retain their own calibration data—ensuring accuracy even when electrodes are swapped.

Modular and Ergonomic Design:

Electrode arm enables easy one-handed operation and precise vertical movement to reduce spills and save time.

Modular construction allows for easy upgrades and expansion as your lab's needs change.

Connectivity options include USB, Ethernet, and RS-232 ports for integration with PCs and peripheral devices.

Listing

Nördlingen

Nördlingen

8,026 km

Vertical machining center

Deckel MahoDMG DMF 360 linear

Call

Condition: good (used), Year of construction: 2012, operating hours: 52,789 h, functionality: fully functional, Travelling Column Milling Machine DMF 360 (Yll00)

New DMG Design

Travel paths: X = 3,600 mm, Y = 1,100 mm, Z = 900 mm

Rapid traverse: 40 m/min, acceleration: 4 m/s²

Spindle speed range: 20 to 8,000 rpm

Vertical motor spindle with 23.5 / 13.5 kW (25 / 100% duty cycle)

Tool holder: SK40 according to DIN 69871

Tool clamping according to DIN 69872

Magazine for 30 tools (chain-type with double gripper)

Chip-to-chip time: 9 s (SK40)

Fixed table: 4,200 x 1,100 mm

Full enclosure, coolant tank

Direct measuring systems

Dynamic package for DMF 360 linear (Yll00):

Linear drive X-axis with 80 m/min

Rapid traverse XYZ: 80 / 60 / 60 m/min, acceleration XYZ: 5 / 6 / 6 m/s²

Active cooling for main spindle and linear motor

Chip-to-chip time: 7.5 s (SK40)

Fixed table with integrated rotary table, Ø 1,050 mm, left-side arrangement

Max. load capacity: 1,200 kg

Hydraulic clamping

Swivel head, B-axis, 20 – 10,000 rpm, HSK-A100

for tool holder according to DIN 69893

Gbedpfx Ahsxuqk Te Ejw

with power 32 / 22 kW (40/100% duty cycle)

with torque 298/205 Nm (40/100% duty cycle)

Infrared probe

Make: Heidenhain TS 649 DMG

Laser tool measurement: Blum (not compatible with TT140; for pendulum machining, please order 2 units as needed)

Calibration arbor with tool holder

Production package includes:

- Chip conveyor

- Internal coolant supply 40 bar / 980 l

- 2 rotating viewing windows

- Purge air for linear measuring systems

- Rinsing gun

- Rotary union for spindle

Packaging floor/foil

Tool magazine with 60 / 120 positions SK50 / HSK-A100

The complete list of features is available in the uploaded PDF file.

NOTE:

We offer flexible financing solutions for all machines as well as a professional relocation service. Disassembly, transport, and professional assembly – everything from a single source. Billing according to individual terms and duration. Contact us for your personal offer.

Clickout

Auction ended

Plauen

Plauen

8,010 km

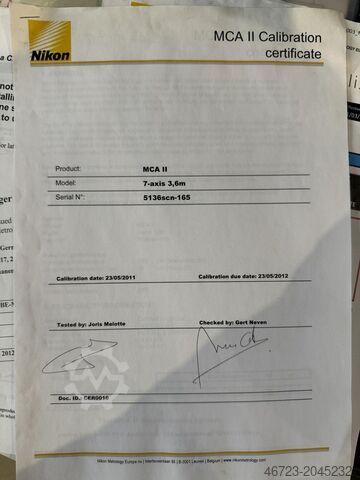

Coordinate measuring machine

Nikon MetrologyMCA II

Condition: used, Year of construction: 2011, Portable 7-axis measuring arm with a measuring range of 3.6 m, designed for tactile and non-contact 3D measurements.

Calibration certificate “MCA II Calibration Certificate” confirms the following specifications:

Maximum deviation: 100 µm (Range 1)

70 µm (Range 2)

Ambient temperature: 20 °C

Test type: Single Point Articulation Test (SPAT)

Accessories visible in the images:

Gjdpoxuf Ugefx Ah Eebw

- ROMER “Infinite™ Series Portable Measurement System” setup manual

- CMM-Manager Software License (Version 3.0)

- Probe stylus set

- USB dongle (license key)

- Calibration bar and connection cables

- Transport cases with protective foam inserts

Country of origin on the device: Made in the UK

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Miechucino

Miechucino

8,056 km

Wide belt sander CB type KRT1N 6

CBKRT1N 630

Call

Condition: used, functionality: fully functional, grinding width: 630 mm, grinding height: 150 mm, height adjustment type: electric, - Italian-made

Gbsdpfxsw Ip Ekj Ah Eew

- Used sander, in very good condition

TECHNICAL SPECIFICATIONS:

- Maximum working width: 630mm

- Maximum working height: 150mm

1 unit: +

- Grooved rubber calibrating roller + pad + 1 metal roller: +

*from above:

- Rubber feed-in slip roller: +

- Processing unit: +

- Rubber feed-out slip roller: +

*from below:

- Rubber slip roller: +

- Feed belt: +

- Pneumatic belt oscillation with photocells: +

- 2 feed speeds: 0.28kW

- Motor: 6kW

- Electric brake: +

- Electric table elevation: +

- Working pressure: 6-8 bar

- Extraction nozzle diameter: 150mm

- Overall dimensions (L/W/H): 1070x1320x1900mm

- Weight: 722kg

Listing

Nürtingen

Nürtingen

7,970 km

Jig

GF Machining SolutionsFORM 300

Call

Condition: refurbished (used), Year of construction: 2015, functionality: fully functional, travel distance X-axis: 600 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 450 mm, workpiece weight (max.): 1,600 kg, total height: 2,780 mm, total width: 2,265 mm, total length: 2,110 mm, quill stroke: 450 mm, workpiece length (max.): 1,220 mm, workpiece width (max.): 870 mm, workpiece height (max.): 470 mm, The GF AgieCharmilles FORM 300, built in 2015, is a powerful and precise used die-sinking EDM machine, specially designed for demanding machining tasks in tool and mold making. Thanks to its modern control system, excellent surface quality, and high efficiency, it offers an excellent investment opportunity for companies that value precision and cost-effectiveness.

Key Features & Benefits:

✅ Large work area & high load capacity:

Travel paths (X/Y/Z): 600 x 400 x 450 mm

Maximum workpiece size: 1220 x 870 x 470 mm

Maximum workpiece weight: 1600 kg

Maximum electrode weight: 50 kg

✅ High-precision machining with state-of-the-art technology:

Positioning accuracy thanks to linear glass scales (no recalibration required)

Innovative ISPG (Intelligent Speed Power Generator) for maximum efficiency

Adaptive control (ACC & ACO) for optimized spark discharge and reduced electrode wear

Surface quality up to Ra 0.08 µm

✅ Powerful control & automation:

AC FORM HMI with intuitive user interface & touchscreen

Automatic CAD/CAM linking for seamless data transfer

Job management with prioritization and Real-time monitoring

Remote monitoring via SMS notification

✅ Maximum productivity & flexibility:

Automatic 48-station electrode changer for unattended machining

Intelligent workpiece measurement & 3D correction

Reduced electrode wear thanks to iQ technology

Gbjdpfxew Ebtvj Ah Esw

✅ Reliability & low operating costs:

Robust C-construction with high stability

Efficient dielectric management with 6 filter cartridges

Energy-efficient operation with low maintenance requirements

Ideal for:

✔ High-precision mold and tool machining

✔ Series production with the highest quality requirements

✔ Complex geometries and fine surface structures

Experience maximum productivity with the GF AgieCharmilles FORM 300 – your solution for precise and economical die-sinking EDM!

📌 Our used machine, built in 2015, is cleaned, overhauled, and comprehensively tested before sale to ensure the highest quality and reliability.

Discover more used machines

Listing

United Kingdom

United Kingdom

6,838 km

Vertical Machining Centre

DMG DECKEL MAHOHSC 55 linear

Call

Condition: ready for operation (used), Year of construction: 2008, General Data

Measurements width 2930 mm

Gbsdoxn U A Hepfx Ah Eew

Measurements depth 3210 mm

Measurements height 2900 mm

Machine weight 9200 kg

Control Unit

Brand HEIDENHAIN

Model iTNC 530

Main Drive

Spindle speed range 28000 rpm

Spindle motor power 38/28 kW

Tool taper HSK-A63

Number of axis 5

Movement

X-Axis Movement 450

Y-Axis Movement 600

Z-Axis Movement 400

Table

Outer length 400 mm

Outer width 400 mm

Number of tslots 5

Distance between 63 mm

Media

Chip conveyor Yes

Internal cooling Yes

Additional Equipment

Tool Storage Capacity: 30 tools /Max Tool Weight: 6 kg / Max Tool Diameter: 80 mm / Max Tool Length: 250 mm

Graphite Dust Collector

Heidenhain Touch Probe TS 649

3D Quick Set for 5-Axis Calibration

This 5-axis DMG DECKEL MAHO HSC 55 linear vertical machining centre was manufactured in 2008. Consider the opportunity to buy this DMG DECKEL MAHO HSC 55 linear vertical machining centre if you are looking to get high quality milling capabilities. Contact us for more information about this machine.

Application Types

Milling

Listing

Duxford

Duxford

7,214 km

Pacific Scientific 3313LL Met One Particle Counter

Pacific Scientific3313LL Met One

Call

Condition: used, This listing is for a Pacific Scientific 3313LL Met One Particle Counter

The unit is in full working condition and is ready for immediate release.

Operational & Practical Notes / Behavior

The 3313LL counts particles by passing a laser (or light source) through the sampled air stream; when particles pass through the beam, they scatter light, which is detected by a photodetector.

By having multiple size channels, the instrument can bin the counts into different particle-size ranges (for example: 0.3 µm, 0.5 µm, 1.0 µm, 3.0 µm, 5.0 µm, 10.0 µm).

Gbjdpfx Aoxv Ab Heh Eew

It likely offers programmable sampling intervals, hold times, alarm thresholds, etc. (common features in Met One/Met One‑type instruments).

Data export via serial is standard, allowing integration with control or data acquisition systems.

Because it’s a relatively high‑flow device (1 CFM), it can sample a substantial volume of air (improving statistical confidence in counts).

The stainless steel construction helps with durability, cleanliness, and possibly resistance to corrosion or harsh environments.

As a used / legacy device, calibration, maintenance, and replacement parts (filters, laser, pump, optics) may be important considerations.

Listing

Oberkochen

Oberkochen

8,006 km

Sanding machine

LÖWERDSM 2004 Video

Call

Condition: used, Number of sanding units 4 St.

sanding width 190 mm

Sanding height max. 180 mm

Control ja

weight 3300 kg

Dimensions (L/W/H) 2600x920x1890 mm

Dust suction hood 2x180, 2x120 mm

Löwer DSM 2004 Double-Sided Sanding Machine

-----

4-Belt Sander + Disc Unit (Top/Bottom)

Manufacturer's Description:

-----

Double-sided, four-belt, single-wood sander for sanding

solid wood such as window frames, etc.

Highly stable, top-quality design with innovative details. Suitable for high

continuous loads, even with high material removal rates.

- Sequentially arranged grinding units for roughing, fine grinding,

and finishing, each from above and below

1. Belt grinding unit with heavy steel roller

2. Belt grinding unit with rubberized roller and shoe

3. Finishing unit with fiber brush (see optional equipment below)

- Direct-drive grinding rollers for slip-free power transmission

- Maintenance-free and wear-free CERMET-coated grinding shoes with

very good thermal conductivity and absolute dimensional accuracy

- External cooling of the grinding zones for cooler grinding and longer

belt life

- Forced pneumatically controlled grinding belt oscillation

- Effective grinding dust extraction directly at the grinding rollers

- Airborne dust extraction at the tension rollers

- Integrated brushing and finishing unit with large grinding dust extraction

- Motorized grinding thickness adjustment via precision threaded spindles and

large linear ball bearing sets on hardened and

ground precision shafts with dust and Dirt protection

- Chip removal adjustment at the bottom via precision threaded spindle

with dimension display via scale ring (0.1 mm resolution)

- Sanding belt tension via pneumatic cylinder with constant tension pressure

- Sanding belt change with pneumatic belt release in seconds

- Sanding belt tracking adjustment during belt change

- Electropneumatic compressed air monitoring

- Infeed protection via contact roller for workpieces that are too thick

- Workpiece transport via calibrated, non-slip and adhesive conveyor belts

over heavy-duty cast iron tables with a finely planed surface and spring-loaded

pressure rollers with fine adjustment

- Cardan shaft drive for smooth and consistent workpiece transport

- Geared feed motor with infinitely variable speed 4-20 m/min

- All motors electrically protected

- Ergonomically arranged operating elements

- Digital thickness display (0.1 mm resolution) with modern magnetic tape system

Technical data:

-----

- Sanding belt speed 22 m/s

- Sanding belt length 1800 mm

- Sanding belt width 200 mm

- Working width 190 mm

- Sanding thickness 2-180 mm

- Four brake motors for drive 5.5 kW

- Feed motor 1.5 kW

- Feed speed 4-20 m/min

- Automatic height adjustment 0.37 kW

Gbjdpfx Ahjvu Hgbe Eow

- Two brush units with fiber brushes D 120 x 200 mm at 0.37 kW each

- Extraction ports 2 x 180 mm, 2 x 120 mm

- Extraction air velocity 20 m/s

- Pneumatic connection 6 bar

- Working height 870 mm

- Length (with soft disc 2740 mm) 2600 mm

- Length with control unit (with soft disc 3035 mm) 2985 mm

- Width 880 mm

- Height 1910 mm

- Weight approx. 3300 kg

- Operating voltage 400 volts, 50 Hz, 3P

- CE compliant

Equipped with the following special options:

-----...

Listing

Herning

Herning

7,476 km

Angular window machining center

SCM GROUPWINDOR 60

Call

Condition: good (used), Year of construction: 2007, Technical characteristics :

- Max machinable length 3200 mm

- Minimum machinable length 200 mm

- Maximum width 200 mm

- Minimum width 40 mm

- Maximum workpiece height 130 mm

- Depth with max Ø to tenon 320 mm: 105 mm

- Tenoning carriage speed min / max 0/100 m / min

- Min / max profiling speed: 3/15 m / min

Tenoning:

1- end cut saw

5.5 hp (4 kW)

Saw Ø 400 mm

2- tenoning router

Counter bearing 50 x 620 mm

15 hp (11.3 kW)

Max tool Ø 320 mm

Axle stroke 575 mm

Automatic splinter guard

3- tenoning router

Counter bearing 50 x 620 mm

15 hp (11.3 kW)

Max tool Ø 320 mm

Axle stroke 575 mm

Automatic splinter guard

Gsdst R T Hcspfx Ah Esbw

Vertical positioning with continuous axis

4- Digital angular adjustment clamp

Profiling:

5-: router to be profiled on the right

Shaft 50 x 320 mm

10 hp (7.5 kW)

Ø tools 130/240 mm

Axle stroke 280 mm

Time-delayed anti-shattering intervention during calibration

Double direction of rotation

Vertical and horizontal positioning with continuous axis

6-: router to be profiled on the right

Shaft 50 x 320 mm

10 hp (7.5 kW)

Ø tool 130/240 mm

Axle stroke 280 mm

Vertical and horizontal positioning with continuous axis

7-: router to be profiled on the right

Shaft 50 x 320 mm

10 hp (7.5 kW)

Ø tool 130/240 mm

Vertical and horizontal positioning with continuous axis

8-: close-out recovery group

Vertical and horizontal positioning with continuous axis

Device for extracting the shutter

9-: lower horizontal shaft for groove

Vertical and horizontal positioning with continuous axis

88.5 hp (66.4kW)

10-: digital guide

11-: Return of parts to the operator

NO TOOLS AVAILABLE

OBTAIN ADDITIONAL PHOTOS

NOTE: SUBJECT TO CHANGES IN TECHNICAL DATA

Listing

Borken

Borken

7,621 km

Instron 34TM-50 50kN Serie 3400

Instron 34TM-50 50kN Serie 340034TM-50 Zug und Druckmaschine

Call

Year of construction: 2022, condition: excellent (used), functionality: fully functional, We are selling an Instron tensile and compression testing machine in excellent condition.

Instron 34TM-50 benchtop model

Config: E1-F1-G1

50KN

Year of manufacture: 2022

Weight: 151Kg

Load transducer: 50KN 2530-50kN/165541

Load transducer: 5kN 2530-5kN/166885

Last service and calibration August 2024

Next service and calibration August 2026

The 3400 Series universal testing machines cover a test force range from 500 N to 300 kN. Featuring the patent-pending Instron operator protection architecture, the 3400 Series testing machines are easier to use, smarter, and safer than ever before. The testing systems are suitable for performing tensile, compression, bending, peeling, puncture, friction, shear, and numerous other tests and can be used with a wide range of clamping devices and testing fixtures from our extensive accessories catalog.

Total height: 1604mm

Maximum vertical test space (daylight test - from base to bottom of crosshead): 1198mm

Test type: Tension, compression, and zero-crossover operation

Basic control mode: Displacement control

Load capacity - kN (lbf): 50 (11240)

Maximum speed - mm/min (in/min): 508 (20)

Minimum speed - mm/min (in/min): 0.05 (0.002)

Maximum force at maximum speed - kN (lbf): 25 (5620)

Gjdpfswz Iktox Ah Esbw

Maximum speed at maximum force - mm/min (in/min): 254 (10)

Return speed - mm/min (in/min): 508 (20)

Crosshead speed accuracy: ± 0.2% of the set speed at a steady rate and without Load

Travel (Crosshead Position) Display Accuracy: In no-load condition, ±0.02 mm (0.0008 in) or ±0.10% of the displayed reading, whichever is greater.

Travel (Crosshead Position) Repeatability - mm (in): ±0.015 (0.0006)

Load measurement accuracy: ±0.5% of the reading up to 1/200 of the force transducer's rated force.

Strain measurement accuracy: ±0.5% of the displayed reading up to 2% of the full scale value, with an ASTM E83 Class B or ISO 9513 Class 0.5 strain transducer.

Listing

Lüdenscheid

Lüdenscheid

7,707 km

Multi-spindle automatic lathe

SCHUETTESF 32

Call

Condition: good (used), Year of construction: 1984, 6 spindles

Tapping with electronic limit stop

Gbjdpfx Ahsv R U D Ts Eow

Hexagonal punching

Calibration

Pick-up device

Many accessories

With IEMCA PRA 40/42 F bar loader

Includes STEIMEL chip removal, box conveyor, and 24/7 production

Listing

Germany

Germany

7,870 km

Twin Screw Extruder

KraussMaffeiKMD 75 XS/P

Call

Year of construction: 2013, condition: ready for operation (used), Additional Equipment

Extruder (Krauss Maffei)

Calibration table (Ide)

Godpfx Ahsxg Uidj Ejbw

Haul-off (Ide)

Separation unit (Ide)

Optionally a sawing unit (Battenfeld) can be purchased

the capacity is 180 kg / h

This twin screw extruder was manufactured in 2013. It features a robust 4m long base frame, galvanized and powder-coated for durability. The machine includes three liquid ring vacuum pumps and a motorized longitudinal adjustment of 400mm. It's equipped with a caterpillar haul-off capable of speeds from 0.7 to 14.0 m/min. Ideal for producing roller shutter profiles, the Krauss Maffei KMD 75 XS/P machine we have for sale represents a significant opportunity. Contact us for further details.

Application Types

Extrusion

Listing

Borken

Borken

7,623 km

Climate test chamber with humidity, 800 liters

EspecPSL-4KPH -70°C bis +150°C

Call

Condition: excellent (used), Espec

Model: PSL-4KPH

Espec Temperature and Climate Test Chamber, Air-Cooled

There is a minor dent at the upper edge of the door (see photo).

The door closes perfectly, the seal is intact, and the climate chamber operates without any technical issues.

The dent is purely cosmetic and does not affect function, sealing, or control accuracy.

Temperature range: -70°C to +150°C

Humidity range: 20 to 98% r.h.

Temperature/humidity fluctuation: ± 0.3°C / ± 2.5% r.h.

Temperature/humidity stability: ± 0.5°C / ± 3% r.h.

Heating/cooling rates & times:

Heating rate: 5.0°C/min

Cooling rate: 3.0°C/min

Test chamber dimensions: Width 1000 mm x Height 1000 mm x Depth 800 mm

External dimensions: Width 1410 mm x Height 1983 mm x Depth 1593 mm

Feed-through with silicone stopper, 100 mm

With RS232 interface

Test chamber volume: 800 liters

Refrigerants: R-404A, R-508A

Stainless steel construction, AC 400 V 3φ, 50Hz, 31 A

Net weight approx. 720 kg

For your safety as a buyer, please note the following:

The following points are carried out in advance on all chambers we offer:

1. Functional inspection and replacement of necessary components

2. New refill with legally compliant refrigerants

Gbsdjwz Er Uepfx Ah Eow

3. After successful inspection, the chambers undergo a trial run monitored by calibrated devices.

Condition: used

Scope of delivery: (see picture)

(Specifications and technical data are subject to change and correction!)

We would be happy to answer any further questions you may have by phone.

Listing

Spatenhof

Spatenhof

8,439 km

Wide-belt sander

KündigENORM PRIMO - TOP

Call

Condition: used, Kündig ENORM PRIMO - TOP

FIXED TABLE MACHINE / automatic head positioning

Wide-belt calibrating and fine sanding machine

Combination unit with contact roller and sanding pad unit featuring electronically controlled segmented sanding shoe

Enormatic

Digital thickness display for workpiece height

Gbsdpfxsxu Dqmo Ah Ejw

Belt drive motor power approx. 9 kW

Contact roller level steplessly adjustable according to grit scale

Infeed and outfeed tables with roller support

Working width 1100 mm

Feed speed 2.5 – 15 m/min

Machine will be WORKSHOP-REFURBISHED

Available ex-stock Lieboch

Listing

Ystad

Ystad

7,770 km

Meat processing machine

Poly-ClipICA 8700

Call

Condition: excellent (used), Year of construction: 2009, functionality: fully functional, Poly-Clip ICA 8700 double clipper year of construction 2009. deal machine for large calibres and moulded products up to a calibre of 200 mm. Fibrous, collagen and plastic casings can be processed. The innovative iris separator makes the ICA ideal for the production of large volumes like slicer products, moulded ham, even those made of whole muscles.

Gbjdsxrnmyjpfx Ah Ejw

Listing

Barntrup

Barntrup

7,744 km

Wide-belt sander

HEESEMANNMFA 8

Call

Condition: ready for operation (used), Year of construction: 1996, functionality: fully functional, VERY WELL-MAINTAINED MULTIPURPOSE SURFACE SANDING AUTOMATON WITH CROSS AND LONGITUDINAL BELT; SUITABLE FOR WOOD CALIBRATION SANDING, WOOD SURFACE SANDING, AS WELL AS INTERMEDIATE COAT SANDING.

Maximum working width: 1,300 mm

Conveyor belt with vacuum system

Conveyor extraction unit with pressure regulator

Feed motor: 1.5 kW

Feed speed: 3 - 15 m/min

CSD – computer-controlled selective pressure regulation technology

with 2 mm tolerance compensation

Distance between control rollers: 16 mm

Pressure shoe spacing: 48 mm

Switch spacing: 82 mm

Unit configuration:

Gbsdpfxjxrdk Ue Ah Esw

1) Cross sanding unit

Belt dimensions

with lamella intermediate belt

Abrasive belt dimensions: 15 x 4,800 mm

Abrasive belt speed continuously variable,

therefore suitable for surface and lacquer sanding

2) Longitudinal sanding unit with combined sanding roller and sanding shoe,

hence suitable for both calibration sanding as well as

wood and veneer surface sanding

Abrasive belt speed continuously variable, therefore also

suitable for lacquer sanding

Abrasive belt dimensions: 1,350 x 2,620 mm

Control:

Machine operation control on the right-hand machine side

Up to 20 programs storable

Transport dimensions:

2.4 x 2.2 x 2.35 m

Weight approx. 5.4 t

Large selection of sanding belts included

Listing

Stolberg

Stolberg

7,649 km

Shark/Solutionix/assembly tables

Shark/Solutionix/Montagetische

Call

Condition: good (used), Year of construction: 2022, functionality: fully functional, Metal Band Saw MEP - SHARK 281 CCS

Year of manufacture: 2023

Max. vice opening: 285 mm

Saw blade dimensions: 2950 × 27 × 0.9 mm

Saw blade speed: 36 / 72 m/min (2 steps)

Motor power: 1.5 / 1.8 kW (three-phase)

Coolant tank capacity: 22 liters

Working height: 860 mm

Machine weight: approx. 370 kg

Gbsdpfxexvyius Ah Ejw

Dimensions (approx.): W: 1785 mm, D: 1000 mm, H: 1650 mm

3D Scanner Solutionix D500

Year of manufacture: 2022

Feature Specification

Camera technology: 2 × 2.0 MP cameras

Light source: Blue LED

Measurement accuracy: Up to 0.01 mm

Point-to-point distance: 0.056 mm

Scan area (FOV): 92 × 70 × 60 mm

Measurement range: Up to approx. 120 mm

Volumetric capture area: Up to 385 mm³

Turntable: Integrated, fully automatic

Calibration: Fully automatic

Texture capture: High-resolution, without additional color cameras

Interface: USB 3.0 Type B

Software: ezScan 2017, compatible with Geomagic DesignX & ControlX

Typical applications: Jewelry, precision engineering, reverse engineering, cultural heritage, 3D printing

Assembly Table MT-400

Year of manufacture: 2015

Feature Specification

Load capacity: up to 400 kg

Max. plate size: 1200 × 1900 mm

Height adjustment: Electric, stepless, 750–1150 mm (partially up to 400 mm stroke)

Tilt adjustment: Electric, 0–90°

Support frame: With variable extension up to 300 mm

Plate fixation: By vertical or quick clamps

Mobility: 4 swivel castors with total lock

Installation aid: Roller bar for sliding the plate into the control cabinet

Material: Powder-coated steel base frame, MiniTec standard profiles

Listing

Kleve

Kleve

7,583 km

Flame cutting system

MicroStepMasterCut Eco (A) Plus 30001.15

Call

Condition: used, Year of construction: 2017, operating hours: 159 h, functionality: fully functional, machine/vehicle number: 2259, MicroStep CNC Plasma Cutting System MasterCut Eco (A) Plus 3001.15 with the following features:

- Kjellberg HiFocus 161i neo with automatic gas console and Contour Cut Speed technology

- High-performance TEKA Eco75 filtration system with 7.5 kW and spark pre-separator

- Prepared for future retrofitting with an oxy-fuel torch

Complete scope of the system:

* MicroStep CNC guiding machine MasterCut Eco (A) Plus 3001.15 (3,000 x 1,500 mm)

* MicroStep CNC control iMSNC with integrated network card

* LCD operator panel mounted on the gantry

* Laser pointer with automatic offset transfer

* iMSNC Module I Expert System

Gbedpjw H R Uzsfx Ah Ejw

* iMSNC Module I Assistant for loading CNC programs

* iMSNC Module I Automatic Calibration of mechanical sensing

* iMSNC Module I Assistant for service and maintenance operations

* "AsperWin Basic" programming system for direct programming at the machine control

* "AsperWin Select" macro library module

* "AsperWin NC-Sim" NC simulator module

* "Plasma Marking" module (for centering punch) via plasma source

* "THC" Module I Automatic height control via arc voltage

* CNC cutting table with sectional extraction I 3,000 x 1,500 mm

* USB 3.0 interface for storage device

* MicroStep RemoteDiagnostics remote maintenance module

* HiFocus 161i neo plasma source from Kjellberg with automatic gas control and Contour Cut Speed technology

* Module for controlling the HiFocus 161i neo automatic gas console

* CNC interface for HiFocus 161i neo I connection to CNC control

* TEKA filter unit ECO75 – 7.5 kW with control unit

* TEKA spark pre-separator TK-FVS 7000 – 12000

* Remote control for the filtration system

* KAESER Aircenter 8 compressed air compressor

* System prepared for future retrofitting with an oxy-fuel torch

The system can be inspected on site by prior arrangement.

Disassembly and transport are the responsibility of the buyer.

Listing

Nattheim

Nattheim

8,019 km

Wide-belt sander

OTTRS-0 110

Call

Condition: used, Year of construction: 1978, Number of belts: 2-belt

Max. working width: 1100 mm

Min. working height: 3 mm

Max. working height: 160 mm

1st belt: calibration roller

Diameter of 1st roller: 260 mm

Type of 1st roller: grooved rubber roller

Abrasive belt length 1st unit: 1900 mm

Abrasive belt width 1st unit: 1100 mm

Abrasive belt speed 1st unit: 25 m/sec

Drive unit 1: 20 kW

2nd belt: pad unit

Sanding shoe 2nd unit: pneumatic

Abrasive belt length 2nd unit: 1900 mm

Abrasive belt width 2nd unit: 1100 mm

Abrasive belt speed 2nd unit: 25 m/sec

Drive unit 2: 13.5 kW

Gbodpfxoxta H Ie Ah Esw

Cleaning brushes: Yes

Feed speed: 7 m/min / 14 m/min (selectable)

Control: manual control panel

Electric/pneumatic belt oscillation: Yes

Table lift: electro-motorized

Table display: mechanical numerical indicator

Operating pressure: 6 bar

Machine number: 185

Weight approx.: 2500 kg

Dimensions: 1800 x 2000 x 1900 mm

Extraction diameter: 2 x 200 mm

Location: Nattheim

Listing

Sheffield

Sheffield

7,050 km

CNC horizontal boring & milling machine

Giddings and LewisMC50 Twin Pallet HBM

Call

Condition: like new (used), Year of construction: 1987, Used Giddings and Lewis Model MC 50 Twin Pallet Horizontal Machining Centre with Live Spindle, 60 ATC and G&L 8000A Control System. Serial # 445-1052.Year of Manufacture: 1987

Machine Formerly Installed at Rolls Royce Plc In Derby UK. Immediately for Sale and now Located in Belgium where it can be Inspected.

Spindle Diameter - 130 MM

Spindle Taper - 50 ISO

Spindle Travel (Z Axis) - 915 MM

Spindle Speeds (4 Ranges) - 5 to 1500 RPM

Main Motor - 30 HP

Pallet Size - 1219 x 1245 MM

Pallet Rotation Increments - 0.001 DEG (360,000 POSITIONS)

Pallet Changer Max Load - 5000KGS

Pallet Max Load Without APC - 9000 KGS

Gbsdou Dahnjpfx Ah Ejw

Longitudinal Travel (W) - 1700 MM

Vertical Travel Of Head (Y) - 1500 MM

Cross Travel (X) - 1800 MM

Feed Rates Per Minute - 1.00MM/MIN TO RAPID RATE

Rapid Traverse Rate Per Minute (X And Y) - 4500 MM / MIN

Rapid Traverse Rate Per Minute (Z And W) - 3000 MM / MIN

Auto Tool Changer - 60 POSITIONS

Electrical Supply - 415V, 3PH, 50HZ

FEATURES AND EQUIPMENT

High Pressure (25 Bar) Through Spindle Coolant, High Tolerance Machine. Accurate Machine which was well Maintained and Regularly Calibrated by Manufacturer. Renishaw Probing.

Length - 11679 MM

Width - 6502 MM

Height - 4423 MM

Weight - 40329 KGS

Listing

Ystad

Ystad

7,770 km

Meat processing machine

Schröderhamax 800

Call

Condition: excellent (used), Year of construction: 2006, functionality: fully functional, Schröder Hamax 800 year of construction 2006. HAMAX 800 whole muscle stuffer is automatic filling of fresh (for example, as restructured meat) or cured meat parts/pieces of meat (for example, as raw and cooked cured meat) in artificial casings. The fundamental principle of the machine is based on a hydraulically driven piston that presses the meat into the casings. The HAMAX 800 whole muscle stuffer forms the technical requirement for increasing the efficiency in the production of sliced goods which are calibrated in length and thickness. In combination with an automated double clipping-machine, swift and efficient processing can be reached, which was previously very time-consuming for these products. The combination of the whole muscle stuffer and the integrated cutting system is the innovative factor. This affects the exact portioning of pork loins with tendon.

2x filling pipes including 95 mm & 125 mm.

Capacity up to 1200 kg / hour.

Gbedpfoxrnkfjx Ah Esw

Trust Seal

Dealers certified through Machineseeker

Listing

Duxford

Duxford

7,214 km

Sartorius

Sartorius MSA4202S 8.2g-2500g Precision BalanceMSA4202S 8.2g-2500g

Call

Condition: used, This listing is for a Sartorius MSA4202S 8.2g-2500g Precision Balance

The unit is in full working condition and is ready for immediate release.

Modular design (part of the Cubis® series) – the system is built of a weighing module + display/control unit + interface modules, designed for flexible configuration.

High-resolution colour TFT display + touchscreen interface, offering an intuitive user interface.

Multiple interfaces standard: USB, Ethernet, RS-232, SD card reader for data transfer and traceability.

Functions typically include: weighing, density determination, averaging, formulation, percentage-weighing, check-weighing, totalising.

Assisted (and optionally motorised) levelling; the system detects inclination and assists the user in levelling the instrument.

Gsdpfx Asxuu Hljh Esbw

Automatic internal calibration (isoCAL) for improved stability and lower drift.

GLP/GMP/traceability ready: audit trail functions, user profiles, etc

Listing

Borken

Borken

7,623 km

Climatic chamber

VötschVCS 7034-5

Call

Condition: used, Vötsch

Model: VCS 7034-5

Climatic Test Chamber, Water-Cooled

Test chamber volume: 335 liters

Specifications for temperature testing:

Temperature range: -70 to +180°C

Temporal temperature deviation: K ±0.1 to ±0.5

Spatial temperature deviation: K ±0.5 to ±2.0

Temperature gradient: 1 to 4 K

Rate of change:

Cooling: 6.7 K/min

Heating: 6.8 K/min

Heat compensation at +20°C: 3000 W / at -20°C: 3000 W

Temperature calibration values: +23°C and +80°C

Specifications for climate testing:

Temperature range: +10 to +95°C

Temporal temperature deviation: ±0.1 to ±0.3 K

Spatial temperature deviation: ±0.5 to ±1.0 K

Temperature gradient: 1 to 2 K

Humidity range: 10 to 98%

Temporal humidity deviation: ±1 to ±3%

Dew point range: -3 to +94°C

Heat compensation: 400W

Climate calibration values: +23°C / 50% RH and +95°C / 50% RH

Test chamber dimensions: Width 580mm, Depth 765mm, Height 750mm

External dimensions: Width 870mm, Depth 1595mm, Height 1775mm

Gbjdpfx Aexqzbbeh Eow

Electrical connection: 3/N/PE AC, 400 V ±10%, 50 Hz

Rated power: 10 kW

Rated current: 21 A

Sound pressure level: 64 dB(A)

Cooling water consumption: 1.4 m³/h

Refrigerants: R404A / R-23

For your safety as a buyer, please take note of the following information!

The following procedures are carried out in advance on all chambers we offer:

1. Functional check and replacement of necessary components

2. If required, refilling with legally compliant refrigerant

3. Leak test with certificate

4. Upon successful inspection, the chambers undergo a documented test run

Condition: used

Scope of delivery: (see picture)

(Technical specifications subject to change and error)

If you have further questions, we would be happy to answer them by phone.

Listing

Saarbrücken

Saarbrücken

7,784 km

Optical multi-sensor measuring machine

HEXAGONOPTIV CLASSIC 321 GL tp

Call

Condition: good (used), functionality: fully functional, measuring range X-axis: 300 mm, measuring range Y-axis: 200 mm, measuring range Z-axis: 150 mm, workpiece weight (max.): 20 kg, Optical Multisensor Measuring Machine HEXAGON OPTIV CLASSIC 321 GL tp

Excellent condition, available for inspection at a specialist company for industrial metrology – commissioning, calibration etc. can be arranged upon request!

- Year of manufacture: According to Hexagon, likely 2015

- Machine number: 7F001-7

- Condition: Good

- Delivery terms: Loaded free on truck (unpacked)

- Location: 66127 Saarbrücken

- Availability: Immediately (subject to agreement)

- Payment terms: Advance payment by bank transfer

Godpfx Ahsxfagro Eobw

- Internal No.: OCU

Available for inspection under power: YES

Technical data:

- Metrology software: PC-DMIS Vision

- Vision sensor for non-contact measurement of very small and precise components

- CCD camera with 6.5x motorized CNC zoom

- DC servo motors

- Modular probe changer: TESASTAR

- Linear guides on all axes

- Coaxial LED top light (white LED)

- LED backlight (green LED + diffuser disc)

- Multi-segment LED ring light

- Maximum feed rate in X, Y, Z axes: 160 mm/s

- Maximum workpiece weight: 20 kg

- Measuring resolution: 0.05 µm

- Measuring accuracy in X, Y axis (optical sensor): Ex, Ey = (1.6 + L/250) µm

- Measuring accuracy in XY axis (optical sensor): Exy = (2.0 + L/250) µm

- Measuring accuracy in Z axis (optical sensor): Exy = (3.9 + L/200) µm

- Measuring accuracy in X, Y axis (tactile probe system): Ex, Ey = (2.0 + L/250) µm

- Measuring accuracy in XY axis (tactile probe system): Exy = (2.5 + L/250) µm

- Measuring accuracy in Z axis (tactile probe system): Ez = (2.9 + L/200) µm

- Measuring range (optical sensor) X 300mm Y 200mm Z 150mm

- Measuring range (tactile sensor) X 230mm Y 200mm Z 150mm

Scope of delivery:

- PC including measurement software PC-DMIS Vision

- Documentation / manuals

- Clamping devices / stops for workpieces to be measured

Probes:

- 3 x stylus holder HP-TM-SF

- 1 x stylus holder HP-TM LF

- 2 x stylus Ø1 x 10

- 2 x stylus Ø2 x 12

- 1 x stylus Ø3 x 20

- 2 x stylus Ø1.5 x 20

- 1 x stylus Ø2 x 20

- 1 x stylus Ø2 x 10

- 1 x stylus Ø3 x 10

- 1 x disc stylus Ø6 x 1.2 x 10

- 3 x extension Ø3 x 10

- 1 x extension Ø3 x 20

- 1 x angle piece (individually adjustable)

- 1 x stylus rack for holding 4 styli

Dimensions & weight:

- Installation dimensions (L x W x H) approx.: 705 x 986 x 890 mm

- Weight approx.: 170 kg

ℹ️ If you have any questions or wish to arrange an inspection, please contact us.

⚠️ Additional notes:

► The goods are sold under exclusion of any warranty

► Technical data subject to change

► Prior sale reserved

❗ Sale to businesses only ❗

Listing

Sankt Leon-Rot

Sankt Leon-Rot

7,889 km

Tool presetter

HAIMERUNO 20/40

Call

Condition: good (used), Year of construction: 2024, functionality: fully functional, Haimer Microset UNO smart

Machine purchased brand new; no commissioning will be carried out due to internal restructuring.

Basic unit

M-G1110*

Tool presetting device UNO 20|40 smart

Measuring range:

Length Z = 400 mm / 15.75 in

Diameter X = 400 mm / 15.75 in

Manual adjustment of X and Z axes

Glass scales on X and Z axes

Manual ISO50 precision spindle

Software and controls

MV SMART

99 zero points

5.7-inch touchscreen

Equipment package

M-A2020

Smart X pro package

Diameter 100 mm / 3.94 in, measured according to the snap fit principle at X position 50 mm set back (equals 1.97 in)

ISO50 high-precision spindle

Runout accuracy 0.002 mm / 0.00008 in

Vacuum tool clamping

Pneumatic spindle brake

Tool inspection lamp

Adjustable tool inspection lamp

Edge finder

For rapid detection of cutting edges

Triggered by tapping

Intelligent sensor control for axis movement

Sigma function

Measurement of all cutting edges in X and Z directions with subsequent detection of maximum values. Focusing individual cutting edges becomes unnecessary, simplifying the measurement of multi-edged tools.

Base cabinet including adapter storage for 3 tools or holders

Storage provided without inserts. Please select the appropriate inserts from article M Z2041 to M Z2046. Different inserts can be selected. Maximum number is limited to 3.

Spindle

M I1014

Indexing 4 x 90 degrees and spindle brake

Machine options

M Z1810

Manual fine adjustment

Manual and stepless micrometric fine adjustment of the X and Z axes

M Z1005

Thermal printer for label printing

Including 800 labels

M Z1910

Dust protection cover UNO

M Z1040

Alignment and calibration kit

Case with reference adapter and 300 mm / 11.81 in setting mandrel

M Z2043

Insert for adapter storage, size IV, 50 mm / 1.97 in

Suitable for ISO40, BBT40, HSK 63, Capto C6, KM 63

3 pieces

Adapters and reducing sleeves

M R1000

ISO50 to ISO BT / BBT / ANSI CAT 40

Note: Reduces setting length by 20 mm / 0.79 in

Measurement software language MV C III

M X1001

English

Gbsdpfx Ahexrf U Io Eow

Electrical

M L1000

230 volts

Only connect to a socket with protective earth

Packaging

M V5002

EU packaging

We make it easier for you to find: "calibration"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Calibration System (912)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month