Used Line Bore for sale (20,065)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Italy

Italy

8,629 km

Squaring Lines

FERWOOD CUSTOMIZEDFW DET LINE

Call

Condition: used, machine/vehicle number: 007975, Position 1: Panel Feeding and Loading FERWOOD CUSTOMIZED-FW DET LINE

Position 2: introducer FERWOOD CUSTOMIZED-FW DET LINE

Position 3: Double Squaring Machines FERWOOD CUSTOMIZED-FW DET LINE

Position 4: Roller Conveyors FERWOOD CUSTOMIZED-FW DET LINE

Gedpewmw Edsfx Ag Tett

Position 5: Double Squaring Machines FERWOOD CUSTOMIZED-FW DET LINE

Position 6: Panel Stacking and Offloading FERWOOD CUSTOMIZED-FW DET LINE

Listing

Breda

Breda

7,520 km

Single-screw extruder line

KuhneK 60E - 33D

Call

Year of construction: 2008, condition: good (used), This extruder line from Kuhne is in machine storage at Plastima Used Machinery. The machine comes from 2008 and is in great condition.

Brand: Kuhne GmbH

Model: K 60E - 33D

Type Screw: single screw

Year of construction: 2008

Screw diameter Ø: 600mm

L/D ratio: 33

cylinder height: 425 mm

Cone height: 325 mm

Total height: 750 mm

Gsdpfx Aou Etygjg Tett

Listing

Klaipėda

Klaipėda

8,108 km

Cut-to-length and slitting line

ForstnerMST 1250

Call

Condition: used, Year of construction: 2010, functionality: fully functional, sheet thickness steel (max.): 1 mm, number of blades: 5, working width: 1,250 mm, number of feed rollers: 2, FORSTNER MST 1250 Longitudinal Slitting and Sheet Cutting Machine

The machine is in very good condition and fully operational. Designed for longitudinal slitting and cutting into sheets.

It is currently connected - can be tested on site.

Longitudinal slitting into 6 strips (5 pairs of knives), with the option to mount up to 7 pairs.

Control – Siemens SIMATIC touchscreen panel.

Full documentation (PDF) included.

Gtjdsx R Sk Nepfx Ag Tot

Specifications:

Model: FORSTNER MST 1250

Made in: Austria

Year: 2010

Working width: 1250 mm

Thickness: up to 1.0 mm

Slitting knives: 5 pairs

Shearing: circular shears

Controller: Siemens SIMATIC panel

If you have any further questions, we will be happy to answer.

Listing

Wiefelstede

Wiefelstede

7,607 km

Smart Line Module 10 kW

Siemens6SL3130-6AE21-0AAO

Call

Condition: good (used), Frequency converter, frequency inverter, drive inverter, controller, variable speed drive, single motor module, double motor module

Manufacturer: Siemens, Sinamics Smart Line Module

-Type: 6SL3130-6AE21-0AAO

Godjhzh Epspfx Ag Tott

-Input: DC 600 V

-Output: 3 AC 400 V 3 A/3 A

-Dimensions: 480/50/H270 mm

-Weight: 4.7 kg

Listing

Częstochowa

Częstochowa

8,372 km

Complete production line

Deutscher Hersteller

Call

Condition: excellent (used), Sale of 4 complete roll forming lines + 1 spare part. Production of spacers and glazing beads made of aluminum and stainless steel. Modernized lines: two equipped with servo motors, the remaining with cardan shaft drive. Lines feature automatic loading, cutting, high-frequency welding, as well as automatic collection and packaging. Individual lines can be purchased separately.

Freely selectable cardan shaft-driven lines at a price of €42,000 per unit / 2 units available.

Gjdjx Da A Rspfx Ag Tstt

Servo motor-driven lines at a price of €95,000 per unit

Quantity: 2 units

PRICES FOR A PACKAGE OF 4 LINES + ONE SPARE LINE

Price: €299,000 – catalogue price

Price: €199,000 – special offer valid until 31 December 2025

Patents valid until 2033 and the HELIMA brand can also be acquired.

Listing

Geel

Geel

7,553 km

Box van

Ford TruckF-Line 2633 6x2 - Garantie 1+1 jaar

Call

Condition: new, functionality: fully functional, machine/vehicle number: NM0LKXTP6LRC90705, mileage: 1,000 km, power: 242.71 kW (329.99 HP), fuel type: diesel, empty load weight: 12,428 kg, maximum load weight: 12,572 kg, overall weight: 25,000 kg, tire size: 315/80 R 22.5, tire condition: 100 %, axle configuration: 4x2, wheelbase: 4,250 mm, axle spacing: 1,350 mm, fuel: diesel, fuel tank capacity: 400 l, brakes: engine braking, color: white, driver cabin: day cab, gearing type: automatic, number of gears: 9, emission class: euro6, suspension: steel-air, number of seats: 2, total length: 9,397 mm, total width: 2,550 mm, total height: 3,815 mm, permissible axle load (axle 1): 8,000 kg, permissible axle load (axle 2): 11,500 kg, permissible axle load (axle 3): 7,500 kg, loading space length: 6,906 mm, loading space width: 2,460 mm, loading space height: 2,400 mm, Equipment: ABS, AdBlue, Android Auto, Apple CarPlay, Bluetooth, EBS, USB port, air conditioning, central locking, cruise control, differential lock, electric window regulation, electronic stability program (ESP), fog lights, full service history, hill-start assist, navigation system, non-smoking vehicle, onboard computer, power mirror, seat heater, soot filter, spoiler, tachograph, tail-lift, tire pressure monitoring, traction control, NM0LKXTP6LRC90705 – Reference 78819 – Warranty 1+1 year

STANDARD EQUIPMENT:

Air conditioning ▪ Multimedia system with 9" touchscreen & navigation (Radio, Bluetooth, USB (A type - C type), Apple CarPlay, Android Auto, remote control) ▪ Cruise control ▪ Differential lock ▪ Disc brakes ▪ Engine brake ▪ Electronic Braking System (EBS) and Anti-lock Braking System (ABS) ▪ Electronic Stability Control (ESP) ▪ Hill Launch Assist ▪ Electrically operated windows ▪ Electrically adjustable and heated side mirrors ▪ Height and tilt adjustable steering column ▪ Electrically operated headlamp leveling ▪ Heated and air-suspended driver's seat ▪ Lumbar support ▪ Brake pad wear sensor ▪ Immobilizer ▪ Automatic light sensor ▪ Home safe light ▪ Approach light ▪ Front fog lights ▪ Digital tachograph ▪ Spare wheel ▪ Liftable rear axle (Auto drop function) ▪ DAB radio ▪ Advanced driver assistance systems (enhanced cybersecurity, rear view camera, departure information system, blind spot information system, tire pressure monitoring system, emergency stop signal, alcohol interlock facilitation, traffic sign recognition, driver alert system, lane keeping alert, pre-collision assist) ▪ Manually operated sunroof ▪ Single key with remote control and central locking ▪ Automated transmission (with various operating modes) ▪ Convertible air compressor (for improved fuel efficiency) ▪ Axle load indicator ▪ Rear fog lights ▪ 4-point independent cab suspension

OPTIONAL EQUIPMENT:

Technology Package 3: Automatic high beam headlights, Pre-collision assist with pedestrian detection ▪ Steerable rear axle ▪ Driver's seat armrest ▪ Front towing eye ▪ 8T front axle ▪ Electrically tiltable cab ▪ Window in rear cab wall ▪ PTO - NH4C ▪ LED headlights ▪ 4.375 FDR ▪ 315/80 Pirelli tires ▪ Distribution truck with tail lift up to top and side loading door – distribution version with tie rails – internal load bed length 6800 mm – internal load bed height 2.40 m – internal width 2.46 m – D'hollandia 2.40 m tail lift with 2,000 kg capacity – roll stops on the tail lift – tie rails in sidewalls – 1 side door – side underrun protection

Discover our dealers on the website fordtrucksbelux.be

Interested? Please feel free to contact your nearest Ford Trucks dealer.

Gedpfx Aex Uqz Usg Tott

- ACB Motors BV

- AD Services Srl

- CTSL BV

- Eeckhout Cardoen BV

- Garage De La Vierre Srl

- Garage O.C.M. Srl

- GTTS Jourdan SA

- Herman Noyens Trucks NV

- Marc Vansteenland BV

Listing

Germany

Germany

7,870 km

Assembly Lines

PRIESSPRIESS ASSEMBLY LINE

Call

Condition: used, machine/vehicle number: 007948, Position 1: Horizontal Storage Systems PRIESS-PRIESS ASSEMBLY LINE

Position 2: Horizontal Storage Systems PRIESS-PRIESS ASSEMBLY LINE

Gtedpfx Agjwk Uygo Tst

Position 3: CNC for Flexible Drilling PRIESS-PRIESS ASSEMBLY LINE

Position 4: Clamping Press PRIESS-PRIESS ASSEMBLY LINE

Position 5: Automatic Dowelling Machine PRIESS-PRIESS ASSEMBLY LINE

Listing

Breda

Breda

7,520 km

Complete tube belling line

Thyssen NothelferKM-D 400 A

Call

Year of construction: 1996, condition: ready for operation (used), This belling machine from Thyssen Nothelfer is a very complete line. The line is disassembled and has a throughput of up to 10m pipe length. See attached PDF for all accessoires.

– Brand: Thyssen Nothelfer

– Year built: 1996

Gtodpfeibatgjx Ag Tet

– Max. tube Ø: 500mm

Listing

Poland

Poland

8,289 km

Double Sided Edgebander

IMACOMBIMA line with loading station

Call

Condition: ready for operation (used), Year of construction: 2002, This IMA Combima complete edge banding line with loading station was manufactured in 2002. A robust double-sided edgebander, it features a working width of 235 to 2600 mm and a length range of 200 to 2600 mm. Capable of speeds from 10 to 40 m/min, it includes jointing milling, a semi-automatic gluing unit with a 6-piece edge magazine, and both straight and profile trimming units. Consider the opportunity to buy this IMA Combima double sided edgebander. Contact us for more information about this machine.

Application Types

Edge Banding

Godsx D Iq Nspfx Ag Tott

Listing

Wiefelstede

Wiefelstede

7,607 km

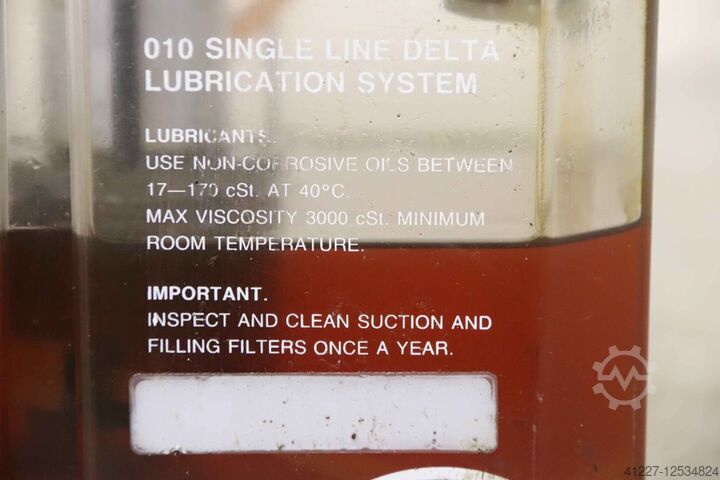

Central lubrication

Kopa DMT010 Single Line Delta

Call

Condition: good (used), Central lubrication, oil circulation system, single-line pump, central lubrication unit, grease lubrication pump, piston pump, lubrication pump, oil central lubrication pump, oil in-line pump

-Manufacturer: Kopa, OIL central lubrication pump oil inlet pump from lathe DMT CD320

-Type: 010 Single Line Delta

-Container contents: l

-Flow rate: l/min / bar

Gtedpfen Tvbkox Ag Tst

-Dimensions: 210/135/H275 mm

-Weight: 6 kg

Listing

Częstochowa

Częstochowa

8,372 km

Roll forming line

Walzenprofilieranlage

Call

Condition: excellent (used), A roll forming line with rollers for cold rolling office and storage cabinet fronts made of cold-rolled sheet metal. Roller center distance: 140 mm, Roller diameter: 45 mm, Keyway: 12 mm. The system features an electric mechanism for moving the roller sets apart by up to 1500 mm. The system is electrically operated.

Gsdpfx Agewxv H De Tott

Listing

Hardinxveld-Giessendam

Hardinxveld-Giessendam

7,508 km

Finger jointing line

GreconCombipact 4

Call

Condition: good (used), Year of construction: 2014, functionality: fully functional, pressing force: 20 t, GRECON finger jointing line Combipact 4

Godpex Tnt Esfx Ag Tett

Manufacture year 2012

Pos. 107 Compartments packaging BF 4-600 / 1500

Pos. 115 Plug-in station ESTA-600 / 1000

Pos. 120 GreCon Combipact cutter CP-205 / 600 / 1000

Pos. 121 Graco glue pump (year 2022)

Pos. 130 Conveyor belt FB-600 / 1500

Pos. 140 Cross thrust transfer / turning station ÜKS 240 / 600 / 1000

Pos. 150 Chain threading station EKK 240 / 4000 RE-K

Pos. 160 Feeding station VE 205

Pos. 170 GreCon forehead press Conti A-20 / 6500

Pos. 190 Electric cabinet and control unit

See PDF for full technical details

Listing

Isselburg

Isselburg

7,600 km

Box trailer

BlyssFR1326 /150HL BASE LINE SANDWICH | SEITENTÜR 262X150X150CM 1300KG KOFFERANHÄNGER

Call

Condition: new, * AVAILABLE IMMEDIATELY *

Includes side door / internal lashing rails / 100 km/h approval / rear supports / double-wing rear doors

TECHNICAL DATA

• Brand: Blyss

• Model: FR1326/150HL

• Vehicle type: box trailer

• Vehicle condition: new vehicle

• First registration: not yet registered

• General inspection (TÜV): 2 years from first registration

• Internal dimensions (LxWxH): 262 x 150 x 150 cm

• External dimensions (LxWxH): 380 x 196 x 240 cm

• Loading height (from ground): 50 cm

• Gross vehicle weight: 1,300 kg

• Unladen weight: 475 kg

• Payload: 825 kg

• Chassis: low-loader (wheels mounted beside superstructure)

• Tyres: 165R13C

• Suspension: ALKO rubber spring axle

• Jockey wheel: yes

• 100 km/h approval: yes

DESCRIPTION

• Reinforced continuous V-drawbar

• Hot-dip galvanized frame

• 15mm multiplex floor panel

• Body made from 23mm sandwich panels

• Double-wing rear doors, lockable with rotary bar lock

• Right-front side door, hinged and lockable from outside with rotary bar lock

• 2x manoeuvring handles at the front

• 4x recessed lashing rings in the floor

• Internal lashing rails mounted on both sides at two heights, h = xx cm

• Forced ventilation on the sidewalls: 2x interior ventilators

• Maintenance-free ALKO rubber suspension axle

• Shock absorbers incl. 100 km/h type approval

• 2x rear support legs for safe loading when uncoupled

• Reverse automatic system

• KNOTT overrun brake and parking brake

• Plastic mudguards

• 13-pin plug

• Reversing lights

• Large-format safety lighting

• Integrated rear fog light

• Recessed rear-frame lighting

• Jockey wheel fitted

Retrofittable accessories available on request:

• Motorcycle wheel chocks

• Motorcycle tie-down straps

• Lashing straps

Gtedex Tvgtopfx Ag Tot

• Additional lashing eyes

• Additional lashing rails on walls and floor for tension belts & load bars

• Load bars

• Internal lighting

• Reversing lights

• and much more

New vehicle with warranty and TÜV.

- Financing or leasing available

- Nationwide delivery possible

- All prices include VAT

- Vehicle registration document can be dispatched in advance or temporary registration plates (Germany) can be supplied

- Export plates incl. customs clearance available

Descriptions and images are copyright protected!

Anhänger Zentrum BAUMANN GmbH

Dekkers Waide 17

46419 Isselburg

More than 1,200 trailers available immediately from stock!

We have been specialist dealers & repair workshop for over 30 years for Brian James / Blyss / Debon / Humbaur / Hapert / Unsinn / Cheval Liberte / Koch / Lorries / Martz / Stedele / TPV / Tohaco / Vezeko / Variant / Vlemmix

- Subject to error, alteration and prior sale -

Listing

Germany

Germany

7,963 km

Shotblasting Line - Drum Blasting Machine

Schlickrotojet-Wheelabrator USF BergerPT 1 - WW312/380/15

Call

Year of construction: 2001, condition: used, Technical details:

Numbers of turbines: 1 Stck.

drum length: 580 mm

operating hours: 30.810 h

compressed air: 5 - 7 bar

filling volume: 100 dm³

total power requirement: 24,2 kW

total wight: ca. 5,8 t

DRUM - Shotblasting Plant

in a closed drum

Manual and automatic operation

technical specifications:

-spinning wheel Ø = 380mm

-drum Ø = 1150 mm x length 580 mm

-max. filling weight = 220 kg, filling volume 100dm³

-piece size (max. edge length) = 100mm

-Turbines 380mm; 15.0 kW

-blast media discharge speed approx. 80.0 m/s

-Ablast media throughput/turbine approx. 240.0 kg/min.

-Steel abrasive grade, nothing else possible! (recommended is: StD-Z 0,6 DIN 8201 HV 700)

-Compressed air with cartridge filter system approx. 12 m³/h

Gjdsu Nu Nkjpfx Ag Tstt

The plant is not electrically connected.

Sale as currently is at the warehouse Leipzig (see last photos).

Machine has been functional before dismantling.

*

Listing

Woolverton

Woolverton

7,106 km

Dough line

RondoStarline

Call

Condition: excellent (used), Rondo starline is a high-performance bakery make-up line. Approx 13m long. The line consists of a calibrator. strip cutters. spray unit. Horizontal guillotine unit. Can be used for processing various dough types, including puff pastry, Danish pastry, yeast dough, shortcrust, and thin doughs for products like pizza or donuts

Gsdsx Squcepfx Ag Tstt

Listing

Hilzingen

Hilzingen

7,994 km

Wall line complete system for house construction

Call

Year of construction: 2011, condition: excellent (used), This is a complete plant for house construction. Prices are listed with each item.

Consisting of the following individual elements (see attached document as well):

Photos will follow, they are already included in the attached document.

Table 1 (Positioning and clamping of the frame structure) €34,500

- Elevating longitudinal conveyor with 3 hinge conveyors and sheathing

- Pneumatic cross clamping

- Connections for compressed air and electricity

Table 2 (Applying the first sheathing and fastening) €25,300

- Longitudinal conveyor with 3 hinge conveyors and sheathing

- Pneumatic cross clamping

- Connections for compressed air and electricity

Intermediate conveyor 3 m long €4,600

(Parking station for multifunctional bridge)

- Longitudinal conveyor with 3 hinge conveyors

Table 3 (Applying the second sheathing, fastening and turning the element onto the next table) €35,650

- Longitudinal conveyor with 3 hinge conveyors and sheathing

- Pneumatic cross clamping

- Connections for compressed air and electricity

- Hydraulic turning device

Table 4 (Electrical installation and insulation) €34,500

- Cross conveyor with rollers and sheathing

- Table traverse drive

- Connections for compressed air and electricity

- Hydraulic turning device

Table 5 (Applying the first sheathing and fastening the second side) €32,775

- Longitudinal conveyor with 3 hinge conveyors

- Cross conveyor with rollers

Gtedpfx Ageu D Amge Tet

- Pneumatic cross clamping

- Connections for compressed air and electricity

Intermediate conveyor 3 m long €4,600

(Parking station for multifunctional bridge)

- Longitudinal conveyor with 3 hinge conveyors

Table 6 (Applying the second sheathing and fastening) €28,750

- Longitudinal conveyor with 3 hinge conveyors

- Pneumatic cross clamping

- Connections for compressed air and electricity

Table 7 (Erection and distribution table) €29,900

- Longitudinal conveyor with 3 hinge conveyors

- Hydraulic tilting unit

- Table traverse mechanism

- Upper guide for holding the walls vertically

Manual surface gantry with vacuum lifter on Table 2 €13,800

(Applying the first layer of sheathing)

- Load capacity 85 kg with Schmalz vacuum unit

- Steel substructure with low-friction rails

- Travel range 12 x 5 m

Manual surface gantry with vacuum lifter on Table 3 €13,800

(Applying the second layer of sheathing)

- Load capacity 85 kg with Schmalz vacuum unit

- Steel substructure with low-friction rails

- Travel range 12 x 5 m

Manual surface gantry with vacuum lifter on Table 5 €13,800

(Applying the first layer of sheathing on the second side)

- Load capacity 85 kg with Schmalz vacuum unit

- Steel substructure with low-friction rails

- Travel range 12 x 5 m

Manual surface gantry with vacuum lifter on Table 6 €13,800

(Applying the second layer of sheathing on the second side)

- Load capacity 85 kg with Schmalz vacuum unit

- Steel substructure with low-friction rails

- Travel range 12 x 5 m

Wall storage 1: 12 m long x 24 tracks €11,500

Wall storage 2: 12 m long x 20 tracks

Vacuum lifter with column slewing crane €9,200

1 cross beam 2 t Abus €20,125

1 cross beam 2 t

Listing

Vilniaus miesto savivaldybė

Vilniaus miesto savivaldybė

8,370 km

Cut-to-length and slitting line

ForstnerSlit Cut 1250

Call

Condition: used, Year of construction: 2022, sheet thickness steel (max.): 1 mm, blade shaft diameter: 100 mm, number of blades: 5, working width: 1,250 mm, FORSTNER SLIT CUT Longitudinal Cutting and Sheet Shearing Line, Year 2022

The machine is in excellent condition and fully operational. It has undergone comprehensive maintenance, and the longitudinal slitting knives have been sharpened. The line is designed for longitudinal slitting and cutting sheets to size. The machine is connected and can be demonstrated.

Longitudinal slitting into 6 strips (5 pairs of knives), with the possibility to install up to 7 pairs.

Equipped with a modern S1 control system with touchscreen, allowing for easy programming of different lengths and quantities. The controller communicates with an electronic eye, automatically sets the zero point, and performs a perpendicular, clean cut.

Integrated material-saving function: the machine stops, raises the cutting knives, and the sheet is automatically fed to the shears.

Complete technical documentation included.

Specification:

Model: FORSTNER SLIT CUT 1250

Made in: Austria

Year: 2022

Gjdpfex R Tt Ssx Ag Tstt

Working width: 1250 mm

Max. thickness: up to 1.0 mm

Longitudinal slitting knives: 5 pairs

Shearing: rotary shears

Controller: S1

If you have any further questions, we will be happy to answer them.

Listing

Babenhausen

Babenhausen

7,862 km

Dishwasher

MilbrandtR-Line NEU

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 2025, warranty duration: 12 months, input voltage: 400 V, DGUV certified until: 12/2026, total length: 700 mm, total width: 600 mm, total height: 850 mm, input frequency: 50 Hz, type of input current: three-phase, power: 6.7 kW (9.11 HP), electrical fuse: 16 A, Dishwasher

Model: R-Line 1500

Quick-ready system

Euronorm 500

2.4 liters of fresh water consumption

7 washing programs with 3 easy

Rinse aid and detergent dosing pump

extra deep interior for sheets / tubs 600 x 400 mm

DGUV V3 checked

Sequence / drain pump

Connection: 400 V, 6.7 kW, 16A-CEE plug

Dimensions: 600 x 700 x 850 mm, WxDxH

with warranty

Included accessories:

1 plate basket

1 universal basket

1 cutlery basket

Godpsfffhwsfx Ag Tjtt

Inlet and outlet hoses

Listing

Sievi

Sievi

7,636 km

Feeding, straightening line + decoiler

LARADEMAE-300/86/600

Call

Condition: good (used), Year of construction: 2019, functionality: fully functional, EMAE-85/600 Servo feeding and straightening line with LARA D-3000/1600-MH decoiler:

Hydraulic coil loading table for Lara D-3000/1600MH decoiler

Max. width: 600mm

Max-Min thickness: 0.8 – 4mm

Godpfx Asvmmucsg Tott

Positioning accuracy: +/-0.05mm

Max. Diameter: 1600mm

Max. Weight: 3000kg

Connection to press CamPositioner_HBPS

DieTronic coil lubricator width 500 mm

Renewed safety logic and mesh fences 8/2020

CE approved

Listing

Pollenzo

Pollenzo

8,138 km

Drilling Line

PRIESSBMA DLS-CNC

Call

Condition: used, machine/vehicle number: 006500, Position 1: Vertical Storage Systems PRIESS-BMA DLS-CNC

Position 2: CNC for Flexible Drilling PRIESS-BMA DLS-CNC

Gtjdpfx Aowucmvog Tjt

Position 3: CNC Flexible Drilling & Inserting PRIESS-BMA DLS-CNC

Position 4: CNC Flexible Drilling & Inserting PRIESS-BMA DLS-CNC

Position 5: Brushing Machines PRIESS-BMA DLS-CNC

Position 6: Roller Conveyors PRIESS-BMA DLS-CNC

Listing

Falkenberg

Falkenberg

7,607 km

Wall line

Randek

Call

Condition: used, Year of construction: 2015, Wall line, manufactured to produce walls for modular manufacturing.

Used by a Swedish producer between 2015 and 2021.

NOTE: Sold in its current condition.

Station lengths: 7000 mm

Gtodpfx Agoxv Arxe Tot

Station width: 2700 mm

Station nr1: Framing station CAD/CAM (includes two nail tools)

Station nr2: Working table

Station nr3: Semi automatic nailing bridge (includes two nail tools)

Station nr4: Working table - Upraiser table

Station nr5: Multifunction portal CAD/CAM (includes four screw tools and milling unit)

Station nr6: Working station - Receiver table - Moveable sideways

Station nr7: Working station - Angle transmission

Station nr8: Working station - Upraiser table

Station nr9: Working station - Angle transmission

Station nr10: Working station - Upraiser table

Trust Seal

Dealers certified through Machineseeker

Listing

Hauzenberg

Hauzenberg

8,224 km

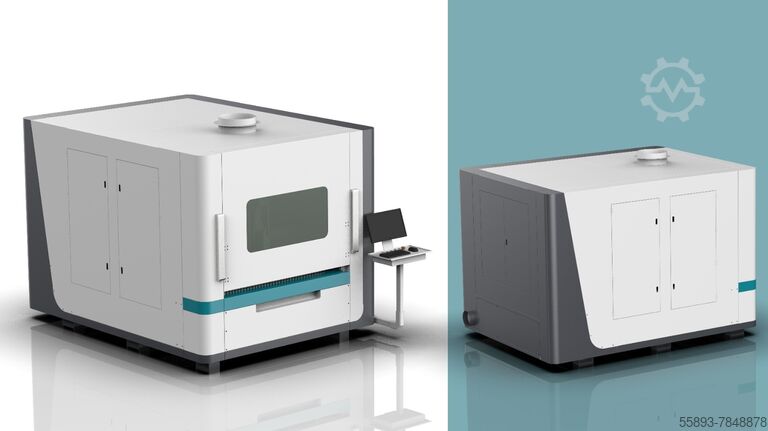

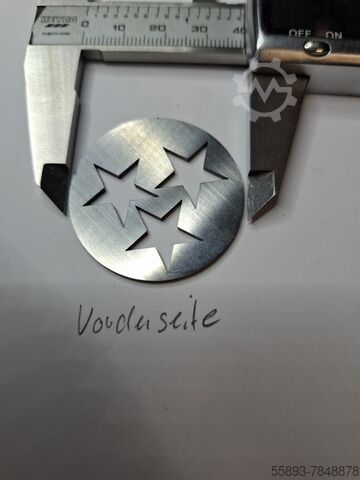

Laser cutting machine

Ledi LaserLG-1530 6kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 6,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 30 mm, sheet thickness stainless steel (max.): 15 mm, sheet thickness aluminum (max.): 12 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 3,000 mm, door opening height: 600 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 6kW fiber laser

Delivery time approx. 6-8 weeks

Our goal is to offer highly precise, long-term stable, and yet cost-effective laser machines. Our machines are ideal for workshops and repair businesses. A perfectly developed cutting parameter library is included in the delivery, as well as first-class service.

- Machine without automatic shuttle table!

Loading is performed on the long side of the machine

- Very space-saving design

- Extremely energy-efficient cutting system

- Requires only approx. 4 x 4.5 meters of floor space

- 6kW laser source from MaxPhotonics (G5/German specification)

- Laser generator with socket efficiency better than 30%

- Suitable for aluminum

- Top quality, book a viewing now!

Maximum cutting capacities:

- Steel sheet up to 30mm

- Stainless steel up to 15mm

- Aluminum sheet up to 12mm

- Brass sheet up to 8mm

Gsdsxw T Nkopfx Ag Tjtt

- Travel range: 1500 x 3000mm (for large formats)

- Machine control system in German

- Safety light curtain for maximum operator protection

- Extensive collision protection for the cutting head

- Large laser safety windows to monitor the cutting process

- Comprehensive cutting parameter files included

- Including nesting module

- Very easy to operate

- High-performance laser chiller

- German service and spare parts supply

- Filter extraction system is optionally available (5.5kW with frequency converter for pleasantly quiet operation)

Leasing or hire purchase is possible through our financing partner

Sale only to commercial customers.

Shipping / advice / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Length: 4.0m

Height: 2.3m

Width: 4.5m

Total weight: approx. 4500kg

Need a different laser power, table design, or table size?

No problem. I am happy to prepare a suitable offer.

E.g. 2kW machine from 29,990 Euro

Not sure which laser power is suitable for your application?

I will of course perform cutting tests according to your requirements.

There are many possibilities.

Listing

Sievi

Sievi

7,636 km

Feeding, straightening line + decoiler

CAMURSC 500/7

Call

Condition: good (used), functionality: fully functional, CAMU Pneumatic feeding and straightening line with decoiler:

- CAMU SCI 530 F decoiler

- CAMU RSC 500/7 straightener line

- Max. diameter: 1500mm

- Max. weight: 3000kg

- DieTronic coil lubricator width 500 mm

Godpfevmn H Tsx Ag Tstt

Mape ANP 510 gripper feeder

- width: 510mm

- Feed length: 500mm

- Thickness: 0.7 – 3.7mm

- Positioning accuracy: +/-0.05m

Listing

Hauzenberg

Hauzenberg

8,224 km

Laser cutting machine

Ledi LaserLG-1313 3kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser hours: 10 h, laser power: 3,000 W, laser wavelength: 1,070 nm, sheet thickness steel (max.): 22 mm, sheet thickness stainless steel (max.): 12 mm, sheet thickness aluminum (max.): 12 mm, sheet thickness brass (max.): 5 mm, warranty duration: 12 months, Equipment: CE marking, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, Offered here is a high-precision laser cutting machine with 3000-watt laser power

Type: LG-1313/3kW HaiCut Premium Line

- Maximum equipment level

- Innovative 3-gas switching system (pressure and gas type controllable via software)

Cutting with N2, O2, or mixed gas (compressed air)

- Automatic front door

- Machine bed lined with fireclay

- Machine bed and axes measured and aligned with Renishaw interferometer

Our goal is to offer the best, most stable, and cost-effective laser machines currently available on the market. Our machines are ideal for workshops and repair facilities. A perfectly crafted cutting parameter library is included, as well as first-class on-site service.

New machine, delivery time approx. 6-8 weeks

We are happy to demonstrate the machine for you at our facility.

Travel range: approx. 1300 x 1300 mm

Table size: approx. 2500 x 1300 mm (i.e., the machine accommodates a medium-format sheet)

Pull-out cutting table

For high-precision metal cutting

All systems fully installed and calibrated

Cutting software in German

Including nesting module

Very easy to operate

Switch on and start cutting

Laser source by Max Photonics (G5/German specification) with 3000 watts of power

Comprehensive electronic and mechanical collision protection for the cutting head

Large laser safety window on the front door

Automatic front door

Safety light curtain for maximum operator protection

Cutting capacity:

Gtsdpfx Asi Igauog Tot

- Stainless steel up to 12mm

- Steel up to 22mm

- Aluminum up to 12mm

- Brass up to 5mm

Heavy-duty industrial quality

Complete system / ready for immediate operation

LED workspace lighting

200mm duct connection for fume extraction

Including exhaust fan

Leasing or hire-purchase available through our financing partner

Need a different power rating or table size? No problem – we have numerous machines in stock or available at short notice.

Sales exclusively to commercial customers. Delivery / consulting / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 3.5 m, Height: 2.1 m, Depth: 3.5 m

Weight: approx. 2.5 tonnes

Listing

Hauzenberg

Hauzenberg

8,224 km

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser ecoline

Our goal is to offer highly precise, long-term stable, yet affordable laser machines.

Our machines are ideal for workshops and repair businesses.

A perfectly developed library of cutting parameters is included in delivery, as is first-class service.

The cost-effective entry into laser cutting technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approx. 3.0 x 3.0 meters of installation space

- Top quality, schedule a viewing now!

Gtsdpfx Agsitu Srj Tjt

Cutting capacity:

- Steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

- Travel distance approx. 1300 x 1300mm

- Table size: approx. 1300 x 2500mm

(suitable for a full mid-format sheet)

- Machine control system in German

- Manual front door

- Extensive collision protection measures

- Large front window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

- Comprehensive cutting parameter files

- Including nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy operation

- High-performance laser chiller

Sales exclusively to commercial customers.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 3.2m

Height: 2.3m

Length: 3.3m

Total weight: approx. 2800kg

Leasing or hire-purchase available through our financing partner.

Need different laser power, table type or table size?

No problem.

I will be happy to prepare a customized offer.

Not sure which laser power is suitable for your application?

Of course, I can carry out cutting trials tailored to your requirements.

A wide range is possible. From 0.5 kW up to 20 kW laser power.

We make it easier for you to find: "line bore"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Line Bore (20,065)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you