Used Monitoring for sale (4,810)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Used labeling machne PE Pack Lab 6000 bph

P.E. LabellersPack Lab

Call

Condition: used, Year of construction: 2008, machine/vehicle number: ET226, Machine Overview

Automatic inline pressure‑sensitive labelling machine equipped with two self‑adhesive application stations for front and back labels. The system conveys containers in a linear path and provides positive product control via an integrated spacing device, wrap/rolling unit and a top hold‑down counter‑belt. At the machine exit a dedicated smoothing system ensures optimal label adhesion and finish. The unit is suited for medium to large containers in the 1–10 L range and has been refurbished in 2022 to extend lifecycle and reliability. Designed and built by P.E., model PACK LAB, year of manufacture 2008.

Key Technical Data

Configuration: Linear labeller with 2 self‑adhesive stations

Labelling method: Pressure‑sensitive (adhesive) labels

Label placement: Front and Back (single or dual application)

Optical centering: Not equipped (mechanical guidance and product handling)

Container range: 1–10 L containers (typical rigid bottles/cans with stable base)

Product handling: Container spacing device, wrap/rolling unit, top hold‑down counter‑belt

Outfeed: Label smoothing system at machine exit

Protection class: IP54 (machine and electric motors)

Year: 2008 | General overhaul: 2022

Productivity: 6000 bph

Dodpfxeyhcgze Afnjkh

Automation & Control

Control architecture: Industrial PLC‑based control with 24 VDC auxiliaries for machine logic

Electrical distribution: 400 V ±5%, 50 Hz, 3P + N + PE (neutral and separate protective earth)

Instrumentation supply: 24 VAC / 230 VAC

Operator interface: HMI with recipe/format management and station status (typical for this series)

Sensors and interlocks: Safety‑interlocked guards, product presence and label application monitoring

Line Integration

Infeed control: Integrated spacing module stabilizes product pitch before labelling

Product stabilization: Top hold‑down counter‑belt and wrap/rolling unit for accurate label placement

Outfeed quality: Smoothing/pressure elements at discharge to ensure adhesion and finish

Mechanical interface: Linear conveyor path suitable for integration into existing bottling/packaging lines

Utilities interface: Standard industrial electrical connections as specified below; no optical centering required

Condition & Maintenance

Refurbishment: Comprehensive overhaul performed in 2022, including verification of application stations, drive components, belts/rollers, guarding and electrical sections

Preventive maintenance: Routine service recommended on label unwind/rewind groups, rollers, belts and sensors according to operating hours and label materials

Spare parts: Standard wear components readily serviceable for long‑term support

Performance & Versatility

Applications: Front and back labelling on a wide variety of rigid containers in the 1–10 L segment (e.g., food, beverages, household/industrial chemicals)

Materials: Compatible with common pressure‑sensitive label stocks (paper and film) and standard adhesives

Changeover: Recipe‑based adjustments with mechanical guides and positioning scales to reduce format setup time

Quality: Stable product handling and final smoothi...

Listing

Costa Rica

Costa Rica

8,269 km

Used pasteurizer Alfa Laval 1998 - 5000 L/h

ALFA LAVAL

Call

Condition: used, Year of construction: 1998, machine/vehicle number: PST26, Alfa Laval Pasteurizer – Overview

This pre-owned Alfa Laval pasteurizer is designed for continuous thermal treatment of dairy liquids, ensuring product safety and consistent quality for downstream processing and packaging. Built by Alfa Laval engineering, it offers reliable performance for beverage production and dairy operations seeking a dependable second hand unit to integrate into a used bottling line or industrial packaging environment. With a capacity range of 3,000 to 5,000 L/h, it is well suited for medium-scale production of milk destined for cheese, yogurt, sour cream, and goat’s milk applications.

Recognized for robust construction and sanitary design, this pasteurizer supports efficient heat exchange and stable process control. Its throughput and versatility make it a practical choice for processors looking to optimize line efficiency without compromising hygiene or product integrity.

Technical Specifications & Performance Data

Manufacturer: Alfa Laval

Year: 1998

Capacity: 3,000–5,000 L/h (maximum 5,000 L/h)

Application: Pasteurization of milk for cheese, yogurt, sour cream, and goat’s milk

Configuration: Continuous pasteurization system suitable for integration in beverage production and dairy lines

Advanced Automation & Control Systems

The unit is engineered to support precise thermal control and holding times typical of continuous pasteurization processes. Instrumentation and safeguards are designed to help maintain consistent product temperatures across varying flow rates. Control provisions support operational adjustments, recipe setpoints, and monitoring to align with production standards in industrial packaging and processing environments.

Production Line Integration Capabilities

This pasteurizer can be integrated inline with upstream storage and standardization processes and downstream filling and packaging equipment within a used bottling line or dairy production setup. Its capacity range fits a wide variety of operational scenarios, providing flexibility for multi-product dairy plants handling different milk types. It is compatible with typical CIP-centric plant layouts and can function as a standalone thermal treatment node or as part of a fully automated beverage production line.

Machine Condition & Maintenance History

Offered as a second hand unit and available for immediate use, this machine is presented as ready for operation based on the seller’s offering context. Detailed service logs, operating hours, and refurbishment records were not provided in the available documentation.

Dedsyhb Dfepfx Afnskh

Operational Performance & Versatility

Optimized for milk processing, including cow’s and goat’s milk, the system supports product preparation for diverse end uses such as cheese, yogurt, and sour cream manufacturing. Its continuous flow design is suitable for stable throughput within the 3,000–5,000 L/h range, supporting consistent quality control and dependable thermal performance.

Installation Requirements & Site Preparation

Typical installation involves connection to process utilities and alignment with existing production lines. Site preparation generally includes adequate floor space for the heat exchanger frame, piping access, and integration with plant uti...

Listing

Netherlands

Netherlands

8,269 km

Used complete CSD can bottling line – 14,000 cans/hour

Call

Condition: used, Year of construction: 2011, operating hours: 35,000 h, machine/vehicle number: LC581, Used Complete CSD Can Bottling Line – 14,000 cans/hour – Overview

This second hand, complete CSD can bottling line is engineered for carbonated soft drink (CSD) beverage production and industrial packaging at up to 14,000 cans per hour on 250 ml format. The core of the line is an Ortmann Herbst isobaric can filler with 45 valves, paired with a Ferrum 706 6-head can seamer (can ends size 200). The scope includes depalletizing, can washing, filling and seaming, tunnel pasteurization, in-line inspection, coding, secondary packaging, palletizing, and end-of-line handling, providing a turnkey used bottling line solution.

Technical Specifications & Performance Data

Core Monoblock: Can Filler–Seamer

Filler: Ortmann Herbst, isobaric, 45 valves (year: 1980)

Seamer: Ferrum 706, 6 heads (year: 1982)

Product type: Carbonated soft drinks (CSD)

Nominal capacity: 14,000 cans/hour on 250 ml

Can end: 200 end (industry size 200)

Monoblock configuration: filler–seamer integrated block for minimized DO pickup

Formats & Throughput

Primary can size: 250 ml

Line speed: up to 14,000 cph (format- and product-dependent)

Process Equipment Included

Kaeser compressor package with booster and two air receivers (p.y. 2010, start 2011)

CIP station, three tanks (p.y. 2011)

Syrup room with cooling system (p.y. 2011)

Nagema mixer (p.y. 1992)

Five ready-to-drink tanks, 100 hl each, steel with food-grade lining

Beverage filter (p.y. 2011)

Frezart can depalletizer (p.y. 2009, start 2011)

Two can washers adapted to 250 ml (p.y. 2011)

Hermis tunnel pasteurizer (p.y. 2015)

Stratec can fill level inspector (p.y. 2000)

Victor can printer / coder (p.y. 2020)

Kisters packaging machine (p.y. 1993)

Keber palletizer (p.y. 1997)

Sita pallet wrapper (p.y. 2011)

Complete conveyor system interconnecting all machines + two can accumulation turntables (p.y. 2011)

Thermo-shrink labeling line for blank cans (p.y. 2015)

Advanced Automation & Control Systems

In-line quality control: Stratec can fill-level inspection for continuous monitoring and reject of out-of-spec containers

Product identification: Victor industrial can printer for date/lot coding

CIP capability: three-tank CIP station supports hygienic cleaning cycles for filler and product pathways

Integrated conveying and accumulation: conveyors with two turntables provide smooth flow and buffer management to protect uptime

Detailed electrical and controls documentation is available on request.

Production Line Integration Capabilities

Upstream

Depalletizing of empty cans (Frezart) and transfer to washing

Dksdpoyhbpzsfx Afnjh

Dual can washers adapted for 250 ml format

Syrup room with cooling, beverage filtration, and mixing (Nagema) for consistent syrup preparation

Compressed air supply package (Kaeser) with booster and storage

Filling & Seaming

Isobaric filling with 45-valve Ortmann Herbst filler ensures stable carbonation retention

Ferrum 706 can seamer with 6 heads for reliable double seam integrity on 200 ends

Downstream

Hermis tunnel pa...

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Switzerland

Switzerland

8,269 km

Used Tetra Cap Applicator TCA45

Tetra Pak®TCA 45 TETRA PACK

Call

Condition: used, Year of construction: 2004, operating hours: 28,000 h, machine/vehicle number: TP117, Technical Specifications & Performance Data

The Used Tetra Cap Applicator TCA45 is a robust, single-head cap application unit from Tetra Pak®, engineered for reliable operation in beverage production environments and seamless integration within a used bottling line. Purpose-built for continuous industrial packaging, it offers steady output with precise cap application after filling and before packing.

Manufacturer: Tetra Pak®

Model: TCA 45 TETRA PACK

Year of manufacture: 2004

Nominal speed: up to 7,500 bricks/hour

No. of heads: 1

Cap type: OEM code 4 (per manufacturer specification)

Rotation direction: OEM code 0 (per manufacturer specification)

Category: Capping Machine / Cap Applicator

Placement: downstream Tetra Pak filling, upstream final packaging

Container compatibility: Tetra Pack bricks with appropriate change parts

Typical products: water, juice, beer, wine, and other still beverages

Documentation: manuals available

Safety: integrated safety features included

Advanced Automation & Control Systems

Designed around an industrial PLC with a user-friendly HMI, the TCA45 facilitates stable, repeatable cap application. Recipe-based settings support format recall, and process alarms help operators maintain consistent performance. Torque control, cap presence verification, and fault diagnostics contribute to cap quality and minimize rework in high-speed beverage production.

PLC/HMI control for straightforward operation and monitoring

Automatic fault detection with guided troubleshooting

Integration-ready I/O for upstream filling and downstream packing synchronization

Electrical: built for standard industrial power supplies (details per manual)

Machine guarding with interlocked access doors and emergency stop circuits

Production Line Integration Capabilities

This cap applicator is well-suited to second hand or newly engineered used bottling line projects. It interfaces efficiently with infeed/outfeed conveyors, bottle orienters, fillers, and labelers, ensuring balanced line flow and minimal downtime.

Compatible with Tetra pak fillers.

Communication-ready for line control and buffer management

Djdpjyhblvofx Afnekh

Machine Condition & Maintenance History

The unit is currently under maintenance, undergoing inspection and service to verify core functions and safety systems. Wear components are being checked and adjusted as needed to align with expected performance at up to 7,500 bricks/hour. OEM manuals are available to support commissioning, operation, and preventive maintenance schedules.

Operational Performance & Versatility

Optimized for consistent, high-quality capping, the TCA45 supports a broad mix of beverage formats common in industrial packaging. With suitable change parts, it can handle PET and glass bottles as well as aluminum containers, making it versatile for diversified production runs.

Suitable applications: water, juice, beer, wine, functional drinks, and similar beverages

Stable cap application to support product integrity and shelf-life

Gentle handling...

Listing

Georgia

Georgia

8,269 km

Used SIPA blow molding machine 2017 - 18.000 bph

SipaSFR EVO3

Call

Condition: used, Year of construction: 2017, machine/vehicle number: SO133, Technical Specifications & Performance Data

This SIPA SFR EVO3 is a rotary stretch blow molding machine designed for high-efficiency PET bottle production in modern beverage operations. As a robust second hand asset for industrial packaging, it delivers reliable output for beverage production lines seeking consistent quality and throughput. The machine features an 8-cavity configuration and supports a broad range of bottle sizes commonly used across water and soft drink applications.

Manufacturer: SIPA

Model: SFR EVO3

Year of manufacture: 2017

Production speed: up to 18,000 bottles per hour

No. of cavities: 8

Neck finish: PCO 28-1810

Bottle formats: Compatible with 0.5L, 1.0L, 1.5L bottle formats

Container type: Designed for PET bottle handling

Bottle diameter (min–max, diagonal): 50–125 mm

Bottle height (min–max, without neck): 80–349 mm

Dkjdpfxjyhbihe Afnoh

Advanced Automation & Control Systems

Engineered for consistent performance, the SFR EVO3 integrates advanced automation with precise preform heating and controlled blowing sequences. Operator-friendly HMI and PLC-based control help streamline recipe management, process monitoring, and format changes. The machine architecture prioritizes repeatability of pre-blow and blow phases, promoting stable bottle quality across high-speed runs.

Automated process control with user-oriented HMI

Efficient preform heating for uniform material distribution

Quick-change features to support format adjustments

Safety-interlocked guards and emergency stop circuitry for operator protection

Production Line Integration Capabilities

This blow molder integrates seamlessly into used bottling line configurations for PET, whether operated as a standalone unit upstream of a filler or synchronized within a complete beverage production line. The included preform feeding and preform cooling systems facilitate smooth infeed and stable production conditions, enhancing overall line efficiency.

Inline or standalone operation with standard conveyor interfaces

Compatible with downstream filling, capping, and labeling equipment

Flexible handling across 0.5L, 1.0L, and 1.5L bottle formats

Suitable for modernization or capacity upgrades in second hand packaging machinery setups

Machine Condition & Maintenance History

The machine is currently working, indicating operational readiness within an active environment. Built in 2017, it offers a modern platform for operators seeking dependable performance and repeatable quality in PET bottle production. Its status as a functional, second hand unit makes it a strong candidate for rapid deployment in industrial packaging lines.

Operational Performance & Versatility

With 8 cavities and up to 18,000 bph output, the SFR EVO3 balances speed and quality for high-demand beverage production. The PCO 28-1810 neck standard supports widespread closure compatibility, simplifying cap sourcing and line interoperability. The preform feeding system and preform cooling system help stabilize process conditions, enabling uniform bottle perform...

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Used Nissei blow molding machine ASB 50MB 2010

NISSEIASB-50MB

Call

Condition: used, Year of construction: 2010, operating hours: 39,000 h, machine/vehicle number: SO134, Technical Specifications & Performance Data

This Nissei ASB ASB-50MB is a one-stage biaxial orientation stretch blow molding machine designed for precision PET bottle production. As a compact rotary indexing platform, it integrates injection and blow molding in a single cycle, ensuring excellent neck finish accuracy and consistent wall distribution. This second hand machine offers reliable output for beverage production and industrial packaging projects seeking a proven, cost-effective solution.

Manufacturer: Nissei ASB engineering

Model: ASB-50MB

Manufacturing year: 2010

Process: One-stage ISBM (injection-stretch-blow)

Production speed: approx. 1000 bph with 4 cavities

Cavities: current setup 4 (machine supports 1–6 cavities depending on article)

Bottle formats: 40 ml to 750 ml

Container type: PET bottles

Electrical data (plate): 400 V AC heater, 6.1 kW; motor 380 V AC 18.5 kW and 200 V AC 0.75 kW; 50 Hz

Installed power (approx.): 25.35 kW

Advanced Automation & Control Systems

The ASB-50MB platform offers stable, repeatable operation with synchronized control of injection, conditioning, stretching, and blowing stations. Its rotary indexing table ensures precise timing between stages, supporting high-quality bottle formation in a compact footprint. Operator interfaces facilitate routine adjustments and process monitoring, while integrated heating controls deliver accurate temperature profiles for consistent preform conditioning.

Dedpfx Asyhbf Aofnekh

Rotary indexing one-stage machine with coordinated station control

Dedicated heater power section for precise thermal management

Structured electrical supply at 50 Hz for stable operation

Designed for quick mold and format changeovers within the compatible size range

Integrated protections and interlocks for safe machine access

Production Line Integration Capabilities

This blow molding machine integrates seamlessly within a used bottling line or as a standalone PET container production unit. Its output can feed conveyors to downstream rinsing, filling, capping, and labeling equipment in beverage production and other industrial packaging applications.

Standalone or inline configuration with downstream bottling equipment

Compatible with standard conveyor interfaces

Format flexibility for 0.04L to 0.75L PET bottles

Suitable for water, juice, CSD, and other PET applications when paired with appropriate downstream systems

Machine Condition & Maintenance History

This second hand ASB-50MB is in good working condition and ready for operation. The machine shows approximately 39,000 operating hours, consistent with typical industrial usage while retaining solid performance potential for new production environments.

Operational status: ready for operation

Operating hours: approx. 39,000

Well-maintained example from a proven ISBM series

Operational Performance & Versatility

Known for robust build quality, the ASB-50MB delivers precise neck geometry and excellent clarity through controlled stretch ratios. The one-stage pr...

Listing

South Korea

South Korea

8,269 km

Used injection molding machine HyPET 120 - 2009

HuskyHyPET120 P85/95 E85

Call

Condition: used, Year of construction: 2009, machine/vehicle number: PR21, Technical Specifications & Performance Data

This Husky injection molding machine is engineered for high-volume PET preform manufacturing and is well suited for integration into a used bottling line or as a second hand addition to industrial packaging operations. The 120-ton clamping platform is paired with a 32-cavity hot runner system, enabling consistent output of PET preforms across multiple bottle formats. Manufactured by Husky in 2009, the unit is configured for rapid mold changeovers and stable cycle times, supporting beverage production with precise neck finishes and preform weights.

Manufacturer: Husky

Model: HyPET120 P85/95 E85

Year of manufacture: 2009

Clamping force: 120 tons

Cavities: 32

Dkodpsyhbd Ssfx Afnsh

Hot runner system: Husky 32-cavity hot runner, common across supplied molds

Neck finishes: 29/25 mm primary; additional parts for 30/25 mm

Preform weights (29/25 mm sets): 9.02 g, 12.46 g, 18.70 g

Additional 30/25 mm parts: 10.5 g, 14.0 g, 22.0 g, 25.0 g (one complete assembled set at 22.0 g)

Cycle times (typical): 7 s, 8 s, 9 s

Electrical supply: 400 V, 50 Hz, 3PH+N+PE

Main supply current: 191 A (auxiliary supply: 40 A)

Short-circuit rating (panel): 10 kA

Included peripherals: Plastic Systems resin dryer with material hopper, mold dehumidifier, and available spares

Bottle formats supported via preforms: 0.2L, 0.5L, 1.0L

Container material: PET

Advanced Automation & Control Systems

The machine features Husky engineering for precise temperature control, shot stability, and efficient thermal management across the 32-cavity hot runner. The molding system supports fast setup with plug-and-play cold half plates, simplifying changeovers between formats and weights. Operator interaction is streamlined through an integrated control interface for recipe management, alarm diagnostics, and process monitoring. The control panel is designed for industrial duty with a 10 kA short-circuit rating and clear segregation of main and auxiliary supplies.

Integrated HMI for process control and monitoring

Hot runner temperature control across all 32 cavities

Quick-change cold half plates, tooling plate, and cooling pick set

Electrical: 400 V, 50 Hz, three-phase with neutral and protective earth

Production Line Integration Capabilities

Optimized for PET preform manufacturing, this system integrates cleanly with upstream resin handling and downstream conveyance to stretch blow molding, quality inspection, and packing stations in beverage production. The included Plastic Systems resin dryer and mold dehumidifier stabilize material and mold conditions, enhancing repeatability and line throughput in broader bottling equipment ecosystems.

Inline or standalone operation for preform supply

Compatible with industrial packaging and beverage production lines

Rapid format changes across 0.2L, 0.5L, and 1.0L bottle formats

Designed for PET preforms used in water, juice, and other beverage applications

Ma...

Listing

Germany

Germany

8,087 km

CNC machining center

Holz-HerDynestic 7507 10.7 push

Call

Condition: used, Year of construction: 2022, Used machine

Year of manufacture: 2022

Equipment and technical data:

BASE MACHINE DYNESTIC 7507 10.7_Push

Processing length: 3,100 mm (without tools)

Processing dimension in Y-direction: 2,200 mm

CAMPUS V7 CAD/CAM Software, 1 x license incl. CabinetControl Base and material removal simulation

Upgrade "CAMPUS "Better Nest" freeform nesting software"

Uninterruptible power supply (UPS)

Milling unit 7830, power: 10.3 kW (S6/40)

Sensor package Chipcontrol for 3-axis spindle incl. receiver

7884 Drilling unit, complete, 14 spindles, drive power 3 kW

Integrated saw unit for cutting/grooving in X-direction,

n(max.) 1,000–7,330 rpm, infinitely variable

1 rear stop rail for the machining field (Field D) at the rear with 1 lateral stop

(replaces lateral stops at the rear)

Stop monitoring for 5 standard stops at the rear and right

Tool changer 7873, 6-position linear pick-up, pneumatically liftable with cover for HSK holders integrated

2 additional mounts for HSK holders for tool changer 7873.

Tool changer 7872, single aggregate magazine swiveling in X and Y directions

2 x vacuum pump 140 m³/h, dry-running

Vacuum unit complete, (VP8) 250 m³/h, 400V additional (upgrade)

Dsdpfx Afjygn Ibjnokh

Vacuum connection complete, 16-circuit vacuum VF16

LASER, alignment complete, dot laser complete, option ZB8

Lubrication complete, central lubrication on encoder side

2 x vacuum suction pads for smooth table surfaces, complete 140 x 115 mm, height 30 mm with connection hose

2 x vacuum suction pads for smooth table surfaces, complete 120 x 50 mm, height 30 mm with connection hose

Conveyor belt complete, push-off conveyor belt AUT 5 10.7 push-off table

Additional extraction via push-off conveyor belt

Push-off device on gantry, controlled,

incl. simultaneous extraction of the wear plate

Label printer Direct Label 7507 and complete touch label light Option ZB74

TouchTool tool length measurement

Availability: by arrangement

Location: Bavaria

Listing

Germany

Germany

7,824 km

Mazak CV5-500

MazakCV5-500

Call

Condition: ready for operation (used), Year of construction: 2023, travel distance X-axis: 730 mm, travel distance Y-axis: 450 mm, travel distance Z-axis: 470 mm, total height: 2,933 mm, overall weight: 6,500 kg, spindle speed (max.): 12,000 rpm, spindle motor power: 18,500 W, tool weight: 8,000 g, product length (max.): 2,570 mm, number of axes: 5, This 5-axis Mazak CV5-500 vertical machining center was manufactured in 2023. It features a maximum spindle speed of 12,000 rpm, a dual-stage electric gear, and a rapid traverse rate of 36 m/min in X, Y, and Z axes. The machine supports a table load of 200 kg and includes a 30-position automatic tool changer. Ideal for complex, multi-axis precision machining. Contact us for more information about this machine.

• Electrical load

• Apparent power (40% duty): 45.5 kVA

• Permanent apparent power: 43.4 kVA

• Electrical connection: 3-phase AC 380/400/415/440/460/480 V ±10%; 50/60 Hz ±1 Hz

• Pneumatics

• Pressure: 5–9 bar

• Flow rate: 26 l/min

• Air blow-off through spindle: 345 l/min

• Spindle

• Spindle nose: Steep taper 40°

• Gear stages: 2-stage (electric)

• Rated power (AC inverter motor): 18.5 kW (10% duty), 15.0 kW (25%), 11.0 kW (40% and continuous)

• Max torque: 119.4 Nm (10%), 95.5 Nm (25%), 70.0 Nm (40%); continuous 57.3 Nm

• Axes, feeds, rapids

• Number of simultaneously operating axes: 5

• Rapid traverse X/Y/Z: 36 m/min

• Rapid traverse B/C: 30 min⁻¹

• Feed rates X/Y/Z: 36,000 mm/min

• Table

• Diameter: 500 mm

• Tapped holes: M16 × 2

• Reference bore: Ø50 mm H6 (+0.016 / −0.000 mm)

• Workpiece capacity

• Max diameter: 500 mm

• Max height: 320 mm

• Travels / Working area

• B-axis swivel/indexing: 220° (±110°), 0.0001°

• C-axis swivel: 360°

• Distance spindle nose – table top (horizontal): 50–520 mm

• Distance spindle nose – table center (vertical): 95–565 mm

• Automatic tool changer

• Tool positions: 30 (optional magazine: 48)

• Selection: Random, shortest path

• Tool holder: MAS BT 40 or SK 40

• Pull bolt: Yamagaxi ANSI type

• Max tool diameter: 80 mm (adjacent occupied) / 125 mm (adjacent free)

• Max tool length: 300 mm

• Tool change time (chip-to-chip): 4.60 s

• Tank capacities

• Guideway/ballscrew lube: 1.80 l

• Hydraulic oil: 5.0 l

• Spindle coolant: 26.0 l

• Option: 18,000 min⁻¹ spindle coolant (oil tank): 60 l

• Total tank capacity: 320.0 l

Additional equipment

• Monitoring/sensing package

• Analog inputs: 4 × 0–10 V

• Digital inputs: 8

• ACC-SENSOR.1AXIS.10M: 1‑axis accelerometer with 10 m cable

• Active power sensor (Dimensions: 8105 × H85 mm)

• Toolscope IP for DIN rail Rev.4

• Industrial PC functionality in the control cabinet

• Communication and control via HMI

• PM: Tool and process monitoring

• Tool breakage detection

• Self-learning wear limit

• Fixed and dynamic tolerance bands

Dsdpfx Ajyf H Tyofnskh

• Process performance monitoring strategy

• Collision monitoring with all Goliog

• DIN rail mounting in the control cabinet

• Dimensions: 812 × H90 × D62 mm

• Documentation including Toolscope

• Chip conveyor (dimension reference provided: machine width 3,365 mm including chip conveyor)

Listing

Buseck

Buseck

7,812 km

Combi steamer + US III + UltraVent hood

RationalSCC 61

Call

Year of construction: 2010, condition: refurbished (used), functionality: fully functional, machine/vehicle number: E61SG10042213272+660610910-02608, This combi steamer from the manufacturer Rational is a used SelfCooking Center® with 6 x 1/1 Gastronorm trays in electric version from a highly matured series. Our offer, as shown, includes the UltraVent condensation hood + combi steamer + US III at a package price as offered. This unit is easy to operate, even for unskilled staff. Without the need for constant monitoring or control, you can achieve outstanding food quality. You can prepare different dishes at the same time, and the combi steamer also features automatic cleaning with Care Control®. The combi steamer has undergone extensive overhaul in our in-house workshop and is fully functional.

This device is sold as a complete package, including the US III + UltraVent condensation hood.

Total tower height: 2125 mm

You will receive an invoice with stated VAT.

The SelfCooking Center® from RATIONAL is much more than just a professional combi steamer that handles heat and steam. Thanks to four innovative assistants, dishes are prepared faster and more precisely. Cooking becomes an experience and cleaning the appliance is effortless.

Technical data – UltraVent condensation hood:

• W x D x H: approx. 854 x 1226 x 470 mm

• Minimum door opening for transport (W x H): 845 x 1050 mm

• Power supply: V: 230 / Hz: 50-60

• Weight: approx. 55 kg

• Serial number: 660610910-02608

Technical data – combi steamer:

• Serial number: E61SG10042213272

• Year of manufacture: 2010

• Trays for: 1/1, 1/2, 2/3, 1/3, 2/8 GN

• Capacity: 6 x 1/1 GN

• Meals per day: 30-80

• Width: 850 mm

• Depth: 780 mm

• Height: 810 mm

• Minimum door opening for transport (W x H): 845 x 850 mm

• Weight: 110 kg

• Connection values: 3 NAC 400 V / 10.0 kW / Hz: 50/60

Condition: used, overhauled, fully functional

Further features:

• 100% hygienic fresh steam from the steam generator

• Intelligent cooking: the SelfCookingCenter 101 covers 95% of all common cooking applications

• Easy to use for everyone, including unskilled staff

• SelfCooking Control® – with 9 applications: large roasts, grilled items, poultry, fish, side dishes, potato products, egg dishes/desserts, baking, Finishing®

• Cockpit – graphically assisted overview of current cooking chamber climate, forecast cooking progress, review and preview functions, and options at the end of the cooking process

• Combi steamer mode with operating modes: steam 30–130 °C, hot air 30–300 °C, combination of steam and hot air 30–300 °C, Finishing®

• ClimaPlus Control® – precise humidity measurement, 5-stage adjustment and regulation

• Care Control – self-cleaning program

• Manual steam injection

• Low-temperature and overnight cooking

• Delta-T cooking for gentle cooking of large cuts of meat

• TFT color display and touchscreen for easy selection

• Central control dial with "push" function

• Hand shower with automatic retract function

• Core temperature probe

• Cool-down for quick and safe cooling of the cooking chamber

• Halogen cooking chamber lighting

• Longitudinal tray insertion suitable for 1/1, 1/2, 1/3, 2/3, and 2/8 GN containers

Dkjdpfx Afoyf Eaxjnsh

• Interchangeable, easy-to-replace door gasket

• Double glazing, pivoting for easy cleaning

• Operating and warning indications, for example in case of water shortage

Sale is subject exclusively to our general terms and conditions (GTC).

Listing

Germany

Germany

7,824 km

Engel ES650H/200W-200HL-2F

EngelES650H/200W-200HL-2F

Call

Condition: ready for operation (used), Year of construction: 2001, operating hours: 98,780 h, clamping force: 2,000 kN, overall weight: 12,200 kg, controller manufacturer: ENGEL, controller model: CC100, This 3-axis Engel ES650H/200W-200HL-2F was manufactured in 2001. It features a clamping force of 2000 kN, a mold opening stroke of 700 mm, and a tie-bar distance of 920 x 750 mm. Equipped with dual injection units, screw diameters of 40 mm and 25 mm, and a rotary table control. Consider the opportunity to buy this Engel ES650H/200W-200HL-2F hydraulic injection moulding machine. Contact us for more information about this machine.

• Clamping unit

• Mold weight (WZ): 1500 kg

• Total moving weight: 3000 kg

• Minimum mold height: 550 mm

• Mold opening stroke: 700 mm

• Tie-bar distance (H × V): 920 × 750 mm

• Platen size: 1250 mm

• Ejector stroke: 150 mm

Dsdpjyf H Nnofx Afnjkh

• Ejector force: 61 kN

• Centering ring diameter A-side: 110 mm

• Centering ring diameter B-side: 90 mm

• Mold locking system: Hydraulic / Pneumatic

• Core pull control: Yes

• Number of cores: 4 (A-side)

• Rotary table control: Yes

• Index plate control: Yes

• Injection unit 1 (Main) – Type 650H

• Max. shot volume: 200 cm³

• Stroke volume: 251 cm³

• Screw diameter: 40 mm

• L/D ratio: 20

• Screw speed: 290 rpm

• Injection pressure: 1930 bar

• Injection rate: 142 g/s

• Shot weight (PS): 216 g

• Plasticizing rate: 26 g/s

• Nozzle orifice: 15 mm

• Pump motor: 30 / 12.3 kW

• Injection unit 2 (Secondary) – Type 200W

• Max. shot volume: 140 cm³

• Stroke volume: 69 cm³

• Screw diameter: 25 mm

• L/D ratio: 24

• Screw speed: 480 rpm

• Injection pressure: 2000 bar

• Injection rate: 104 g/s

• Shot weight (PS): 60 g

• Plasticizing rate: 12 g/s

• Nozzle orifice: 15 mm

• Pump motor: ~6.8 kW

• Machine axes travel

• X-axis (injection unit): 500 mm

• Y-axis (rotary table / mold carrier): 1000 mm

• Z-axis (clamping unit): 1400 mm

• Equipment and options (machine-integrated)

• SPC / Process control: Yes

• Pressure interface: Yes

• Second injection barrel: Yes

• Mold monitoring: No

• Cavity pressure sensor: p-θ-t-θ (Priam)

• Hot runner control: 16 zones

• Filter dryer: No

• Special programs: Yes

• Special option: GealanXcomp

• Automation: No

• Condition

• Well-maintained and serviced

Additional equipment

• Engel Linear Take-out Robot ERC 23/1-E (included)

Listing

Germany

Germany

7,824 km

Engel Engel ES650H/200W-200HL-2F (2000)

EngelEngel ES650H/200W-200HL-2F (2000)

Call

Condition: ready for operation (used), Year of construction: 2000, operating hours: 63,929 h, clamping force: 2,000 kN, controller manufacturer: ENGEL, controller model: CC 200 (CC200), This 3-axis Engel ES650H/200W-200HL-2F was manufactured in 2000. It features a clamping force of 2000 kN, a tie-bar distance of 920 × 750 mm, and a screw diameter of 50 mm. Equipped with dual injection units, hydraulic locking system, and a rotary table control, it ensures precise and efficient operation. If you are looking to get high-quality injection molding capabilities, consider the Engel ES650H/200W-200HL-2F machine we have for sale. Contact us for more information.

• Condition: Well-maintained and serviced

• Clamping unit:

• Mold weight: 1500 kg

• Total weight: 3000 kg

• Tie-bar distance (H × V): 920 × 750 mm

• Platen size: 1150 mm

• Opening stroke: 700 mm

• Daylight (opening): 700 mm

• Min. mold height: 450 mm

• Max. mold height: not specified

• Ejector stroke: 150 mm

• Ejector force: 61 kN

• Return force: not specified

• Centering diameter (A side): 110 mm

• Centering diameter (B side): 90 mm

• Locking system: Hydraulic / Pneumatic

• No. of cores: 4

• Rotary table control: Yes

• Core pull control: Yes

• Index plate control: Yes

• Injection unit 1 (650H):

• Max. shot volume: 200 cm³

• Stroke volume: 392 cm³

• Screw diameter: 50 mm

Dedpfsyf Htyjx Afnjkh

• L/D ratio: 20

• Screw speed: 290 rpm

• Injection pressure: 1240 bar

• Injection speed: 120 g/s

• Plasticizing rate: 41 g/s

• Nozzle orifice: 15 mm

• Pump installed: 30 / 12.3 kW

• Injection unit 2 (200W):

• Max. shot volume: 140 cm³

• Stroke volume: 69 cm³

• Screw diameter: 25 mm

• L/D ratio: 24

• Screw speed: 480 rpm

• Injection pressure: 2000 bar

• Injection speed: 60 g/s

• Plasticizing rate: 12 g/s

• Nozzle orifice: 15 mm

• Pump installed: ~6.8 kW

• Controls and functions:

• SPC (Statistical Process Control): Yes

• Pressure interface: Yes

• 2nd injection barrel: Yes

• Mold monitoring: No

• Special programs: Yes

Additional equipment

• Take-out device (robot): ERC 23/1-E

• Travels: X = 500 mm, Z = 1400 mm

• Max. mold dimensions (Y-axis): 1000 mm

• Hot runner control: 18 zones

• WZ sensor system: p–z–t–σ (Kistler)

• Additional equipment: GealanXcomp

• Automation cell: No

• Filter dryer: No

Listing

Trittau

Trittau

7,709 km

Press brake

BystronicXpert 40/1030

Call

Condition: used, functionality: fully functional, Year of construction: 2017, control type: CNC control, working width: 1,030 mm, stroke length: 200 mm, overall weight: 4,000 kg, Hydraulic Press Brake

Make: BYSTRONIC Model: Xpert 40

Year of Manufacture: 2017

Technical Specifications

Manufacturer: BYSTRONIC

Operating hours: approx. 9,500 h

Model: Xpert 40

Year: 2017

Press capacity: 40 t

Bending length: 1,030 mm

Stroke: 200 mm

Distance between frames: 1,060 mm

Motor power: 7.5 kW

Weight: 4 t

Dimensions: L 1.52 x W 1.60 x H 2.45 m

Equipment

• 6-axis backgauge

• Hydraulic clamping top & bottom

• RF-A tool holder, top

• Height-adjustable ByVision Bending display with 22-inch Full HD touchscreen

• Support table

• Ergo LED work area lighting

Dksdpfx Ajyficdefneh

• Low-noise Dynamic Drive System (DDS) with integrated EnergySaver

• OPC Interface Bending

• Bend curve generator

• Automatic tooling overload protection

• Oil cooler

• Ergo foot switch

• Rear sliding door with electrical monitoring

All details without obligation.

A powered demonstration is possible at any time in our showroom.

Listing

Schijndel

Schijndel

7,556 km

Kolbus case maker DA 370 (2023)

KolbusDA 370

Call

Year of construction: 2023, condition: used, Case maker

Kolbus DA 370

Year: 2023

New generation of casemaker for faster production and shorter make-ready times.

Automatic production of book cases, files, display cards, calendar backs or game boards, at rates of up to 65 cycles/min.

Maximum production and process reliability in the manufacture of book cases. The DA 370 casemaker is a versatile machine for a wide range of applications. The machine with its non-stop case feeder is engineered to be ergonomic and extremely operator-friendly so that it can be easily operated by one person.

Configuration:

- Copilot system with touchscreen

- sectional touch panel for direct operation

- large display for showing the speed and malfunction messages

- board prestacking conveyor to automatically reload the magazines (stream cover and stack feeder)

- counter-stacker delivery with roller conveyor delivery incl. table

- cloth feeder for non-stop operation with stack magazine

- missing product check during separation of cloth and cardboard

- cloth cylinder with grippers and interchangeable plates for rubber pads (5 plates 500 mm wide and 5 plates 720 mm wide, incl. 10 rubber pads)

- cardboard centre strip magazine

- device used to prepare centre strip roll

- centre strip waste chopper

- centre strip rub-down unit (head and foot)

- rub-down unit used to bond the covering material to cardboards and spine strip without creases

- extendable gluing station for processing hot glue with glue preparation in the premelter, heated glue roller and scraper roller

- viscosity control unit for an automatic supply of water via a water container with a pump

- device for padded cases

- function used to request individual cases for monitoring purposes on the operating side

- servo-controlled drive technology based on Siemens technology

Special equipment:

- device for producing quarter-bound cases in two operating steps

- device for small format

- device for large format

- Remote Service Gateway

Technical specifications:

Dkjdpfx Afeydc A Iensh

- Mechanical speed: up to 65 cycles/min

- Open cover size max.: 205 x 670 mm

- Joint width: 4 - 15 mm

- Spine width: 14 - 120 mm

- Turn in width open: up to 19 mm

- Cloth width: 223 - 708 mm

- Cloth height: 158 - 428 mm

- Board thickness: 1 - 4 mm

- Board width: 95 - 328 mm

- Board height: 140 - 390 mm

- Board centre strip thickness: 1 - 4 mm

- Board centre strip width: 6 - 90 mm

- Centre strip roll thickness: 0,3 - 0,6 mm

- Centre strip roll width: 6 - 90 mm

- Lining width: 195 - 670 mm

- Lining height: 130 - 390 mm

Listing

Iserlohn

Iserlohn

7,695 km

Control BOSCH CC200 Spare Parts

Call

Condition: used, Year of construction: 1990, Bosch CNC control CC200 spare parts

Monitors, cards, controllers etc.

Dkedevk D R Njpfx Afnjh

Listing

Iserlohn

Iserlohn

7,695 km

Spare parts for CNC lathes

HITACHI SEIKI ErsatzteileHT 23R III

Call

Condition: used, Year of construction: 2000, Spare parts for the HITACHI SEIKI CNC lathe, type HT 23 RIII, built in 2000.

Dsdpfswf Aftsx Afnokh

1. Headstock with chuck.

1. X and Z axis motors.

1. Control panel with monitor.

1. X-Z axis controller.

1. VDI 40 tool turret with 12 positions.

Listing

Niederlangen

Niederlangen

7,585 km

Laser Cutting Machine

TRUMPFTrumatic L 3040

Call

Condition: used, Year of construction: 2006, table length 3000 mm

table width 1500 mm

laser capacity in Watt 4000

Equipment:

- Closed machine frame with integrated laser unit

- Laser unit: CO2 laser TFL 3200 high-frequency unit, maintenance-free turbo radial blower

Dkedpoydfngefx Afnjh

radial turbo blower, mirror telescope

- Automatic pallet changer

- Longitudinal conveyor belt for small parts / waste

- Drives: Maintenance-free three-phase servomotors

- Additional highly dynamic Xp-axis

- Cutting head quick-change device

- Laser cutting head with 5" lens and laser cutting head with 7.5" lens

- Programmable cutting gas pressure setting

- APC capacitive height adjustment and process control

- Automatic focus position adjustment AutoLas Plus

- Laser power control

- Position laser diode

- HI-LAS high-pressure cutting

- Fast processing with SprintLAS

- ContourLAS for the production of smaller holes

- PMS plasma sensor technology

- Automatic sheet outer edge detection

- Programmable power cycles

- Compressed air cutting

- PCS Process Control System

- Microweld

- Spraying device for safe thick sheet metal processing

- Automatic switch-off

- Work area lighting

- Sinumerik 840D control system: Open control system on PC basis, simple operation,

online help, integrated e-shop, diagnostic function, maintenance logbook,

technology data, teleservice

- Workshop programming ToPs 100 lite

- Safety: Multi-rigid light barriers, beam guidance

fully encapsulated and ventilated, monitoring system, multi-chamber extraction system

and compact dust extractor, safety cabin

Listing

Obertraubling

Obertraubling

8,114 km

Minibus

Mercedes-BenzV 300 EDITION 4MATIC Kompakt 7Sitzer 2xK

Call

Condition: excellent (used), functionality: fully functional, mileage: 53,770 km, power: 174 kW (236.57 HP), fuel type: diesel, gearing type: automatic, overall weight: 3,200 kg, first registration: 12/2021, next inspection (TÜV): 12/2026, emission class: euro6, color: grey, number of seats: 7, number of previous owners: 1, machine/vehicle number: COCK60, Equipment: ABS, air conditioning, airbag, all wheel drive, car registration, central locking, cruise control, electronic stability program (ESP), fog lights, immobilizer system, navigation system, onboard computer, parking sensors, power assisted steering, seat heater, sliding door, soot filter, trailer coupling, winter tires, 7992 PAINT COLOR SELENITE GREY METALLIC MB7992

BH1 HOLD function

C70 Pedestrian protection

C74 Mercedes-Benz illuminated door sill lettering

CA1 AGILITY CONTROL suspension

CL1 Steering wheel adjustable for tilt and height

CL3 Leather steering wheel

CL4 Multifunction steering wheel with trip computer

CM2 Bumpers and add-on parts painted in vehicle color

CU4 Aerodynamics package

D14 Anodized roof rails

E07 Hill start assist

E1D Digital radio (DAB)

E1E Navigation system

E1T Touchpad

E6M MBUX multimedia system Mid

EL9 2-way speakers front and rear

EZ5 Parking package

EZ8 PARKTRONIC

F65 Exterior mirrors, electrically folding

F72 Exterior and interior mirrors auto-dimming

FG0 Center console with roller cover

FH0 Trim elements in piano black finish

FLK LUXURY WAGON

FP3 Mirror package

FP5 Sport package exterior

FR8 Reversing camera

FS5 Illuminated mirrors for sun visors

G43 9G-TRONIC

HO0 Warm air duct to passenger compartment

H15 Seat heating for front passenger

H16 Seat heating for driver

H20 All-round heat-insulating glass

HH9 SEMI-AUTOMATICALLY CONTROLLED AIR CONDITIONING TEMPMATIC

HI1 Climate zone 1 (cold/comfort)

HX1 Refrigerant R-1234yf

HZO Electric auxiliary heater

HZ7 Semi-automatic air conditioning, TEMPMATIC in rear

IG4 Standard

IH6 Headunit ECE/RoW

IKO Complete vehicle

IK3 Luxury wagon

IL4 Region EU/EFTA

Dkjdpjygkytjfx Afneh

IL5 Left-hand drive

IL6 Metallic paint

IN1 Wheelbase 3200 mm, short overhang

J55 Seat belt warning system for front passenger seat

JA1 Warning lamp for windshield washer fluid level

JA7 Blind Spot Assist

JF1 Rain sensor

JH3 Communication module (LTE) for digital services

JK5 Instrument cluster with color display

JP4 Lane package

JW5 Lane Keeping Assist

JW8 ATTENTION ASSIST

JX2 Maintenance interval 40,000 km

KB5 Main tank 70 liters

KP7 Emissions control SCR generation 4

LA2 Light Assist

LB9 Exit lights

LC4 Comfort roof control unit

LC5 Surround lighting in exterior mirrors

LC8 Surround lighting tailgate

LE1 Adaptive brake light

LG2 LED Intelligent Light System

LG4 Rear, brake and indicator lights in LED technology

LG8 High beam assist PLUS

LP3 Interior lighting package

M50 174 kW (237 hp) 4200 rpm

MG9 Generator management

MJ8 ECO start/stop function

M06 Emissions standard Euro 6d M/N1 GR II

MS1 CRUISE CONTROL

MU8 OM654 DE 20 LA Performance level 5 Top Type

MX0 BlueEFFICIENCY package

Q50 Towbar with removable ball head

QA4 Towing capacity 2500 kg

RY2 Tire pressure monitoring for front and rear axles, wireless

S37 Outer armrests for individual seats, 2nd row

SA6 Passenger airbag

SB1 Comfort driver's seat

SB2 Comfort front passenger seat

SH2 Thorax-pelvis side airbag, front passenger

SH9 Windowbags for driver and front passenger

T14 Active catch for sliding door

T19 Sliding door left

T70 Child safety locks on passenger compartment doors

U73 Armrests for passenger compartment seating

UR1 Seat track system with quick release

US4 3-seater comfort bench, 1st row, outer seat folding

US8 Single seat, 2nd row left

US9 Single seat, 2nd row right

V33 Carpet flooring in rear

V36 Roof lining

V44 Carpet flooring in front cabin

V4Y Fabric "Santos" black

VD5 Interior roof lining crystal grey

W16 Fixed window front left, in side wall/sliding door

W17 Fixed window front right, in side wall/sliding door

W32 Electrically operated vent window, rear passenger compartment

W64 Separately opening rear window

W68 EASY-PACK tailgate

W70 Privacy glass for rear compartment, black glass

X30 Registration certificate, part II

XA5 Weight variant 3,200 kg

XMO Model upd

Listing

Hauzenberg

Hauzenberg

8,224 km

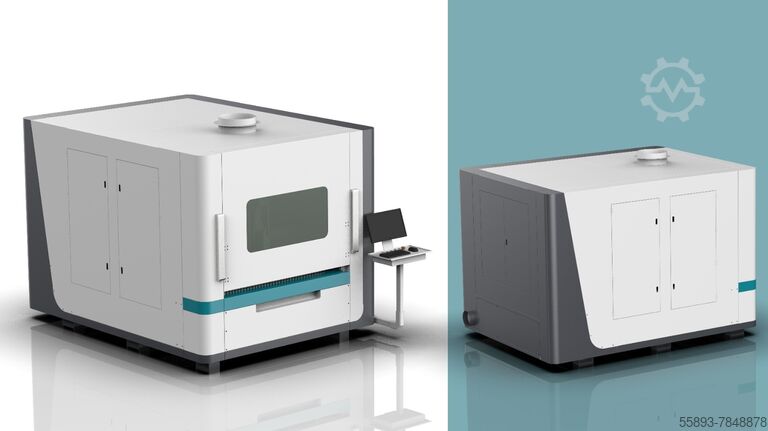

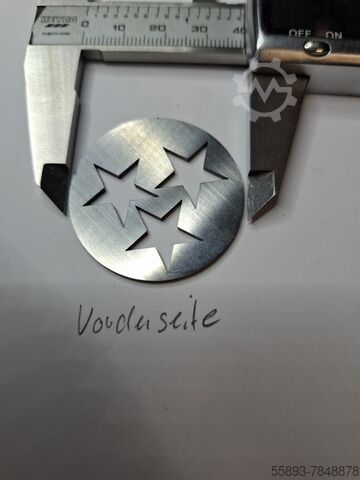

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser Ecoline

Our commitment is to offer highly precise, long-term stable, yet affordable laser machines.

Our machines are ideal for workshops and repair businesses. Included in delivery is a perfectly optimized cutting parameter library as well as first-class service support.

Please also take note of our attractive leasing and hire-purchase offers.

Cost-effective Entry Into Laser Cutting Technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approximately 3.0 x 3.0 meters of installation space

- Top quality – schedule a viewing now!

Cutting capacity:

- Mild steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

- Travel range: approx. 1300 x 1300mm

- Support table size: approx. 1300 x 2500mm (allows for full mid-format sheet loading)

- Machine control in German

- Manual front door

- Comprehensive collision protection measures

- Large front viewing window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

Dkjdpfeitu Srox Afnjh

- Extensive cutting parameter database

- Incl. nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy to operate

- Powerful laser chiller

Sale exclusively to commercial customers.

Delivery / consulting / sales only within Germany / Austria / Switzerland.

Machine dimensions (approx.):

Width: 3.2 m

Height: 2.3 m

Length: 3.3 m

Total weight: approx. 2,800 kg

Need a different laser power, table design, or table size?

No problem. I am happy to provide a customized quotation.

Not sure which laser power is suitable for your application?

We are happy to conduct test cuts based on your requirements. Wide range available – from 0.5 kW up to 20 kW laser power.

Listing

Hauzenberg

Hauzenberg

8,224 km

CO2 Laser Engraving Machine 30Watt

LD-LaserLD-RF-30

Call

Condition: new, Year of construction: 2025, functionality: fully functional, shaft length: 10,700 mm, laser power: 30 W, Laser Engraving Machine with 30 Watt Laser Power

- 30 Watt CO2 Metal Tube Laser Source

Demonstration unit, with minimal operating hours

- includes Windows 10 Pro 64-bit PC system

- includes 22" monitor

- fully installed and calibrated

- Engraving software in German

- Very easy to operate

Dkodpfx Ajirmgmjfnsh

- Switch on and start immediately

- 30 Watt CO2 laser source for high-contrast and fast marking with extremely high resolution

- Capable of deep engraving

- Wobble function

- Suitable for engraving on, e. g., wood, plastic, anodized surfaces, etc.

- Heavy-duty industrial quality

- Complete system / ready for immediate use

- Working area approx. 500 x 600 x 600 mm (W x D x H)

- Clamping table with mounting threads in 50 mm grid

- LED work area lighting

- 50 mm connection for fume extraction

- Engraving area approx. 180 x 180 mm

- Expandable up to approx. 300 x 300 mm

- Includes foot switch to start the engraving process

Please also check our attractive leasing/financing offers.

Sale exclusively to commercial customers.

Delivery / consulting / sales only within Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 800 mm

Height: 1800 mm

Depth: 1000 mm

Weight: approx. 150 kg

Listing

Hauzenberg

Hauzenberg

8,224 km

Laser cutting machine

LD-LaserLG-3015 6kW

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 6,000 W, laser wavelength: 1,080 nm, sheet thickness (max.): 30 mm, sheet thickness steel (max.): 30 mm, sheet thickness stainless steel (max.): 15 mm, sheet thickness aluminum (max.): 15 mm, table width: 1,500 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 2,500 kg, door opening width: 1,000 mm, door opening height: 1,000 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 6kW fiber laser

Our aim is to offer highly precise, long-term stable, and yet attractively priced laser machines. Our machines are ideal for workshops and repair businesses. A fully developed cutting parameter library is included with every machine, as well as first-class service.

We also offer attractive leasing and hire purchase options.

- Machine with automatic shuttle table

- Very space-saving design

- Extremely energy-efficient cutting system

- Only approx. 9 x 3.5 meters installation footprint

- 6kW laser source from MaxPhotonics (G5 / German version)

- Top quality – schedule a viewing now!

Cutting capability:

- Steel sheet up to 25mm (max. 30mm)

- Stainless steel sheet up to 15mm

- Aluminum sheet up to 15mm

- Brass sheet up to 12mm

Dedpfx Afohncfcenjkh

- Travel range: 1500 x 3000mm

- Machine control system in German

- Safety light curtain for maximum operator protection

- Comprehensive collision protection measures for the cutting head

- Large laser-protection windows on three sides for monitoring the cutting process

- Automatic, programmable 3-gas switching (compressed air, nitrogen, oxygen)

- Extensive cutting parameter file included

- Includes nesting module

- Very user-friendly operation

- High-performance laser chiller

- Machine control system in German

- German service and spare parts support

- High-performance laser chiller

- Optional fume extraction system

Leasing or hire purchase is available through our financing partner.

Sale to commercial customers only.

Delivery / Consultation / Sale only within Germany / Austria / Switzerland

Machine dimensions approx.:

Length: 9.0m

Height: 2.3m

Width: 3.5m

Total weight: approx. 6500kg

Need a different laser power, different table style, or table size?

No problem.

I would be happy to create a suitable quote for you.

For example: 1kW machine from €29,990 or 3kW machine from €32,900

Not sure which laser power suits your application?

Naturally, I can carry out cutting trials based on your requirements. Many options are available.

Trust Seal

Dealers certified through Machineseeker

Listing

Hauzenberg

Hauzenberg

8,224 km

Engraving machine

LD-LaserLG-UV-Q15

Call

Condition: as good as new (ex-display), Year of construction: 2025, functionality: fully functional, shaft length: 355 mm, input voltage: 230 V, laser power: 20 W, UV Laser Engraving Machine with 20 Watt Laser Power

- Laser source with 355nm wavelength / 20 Watts

Demonstration machine, with minimal operating hours (approx. 15 hours)

- incl. Windows 64-bit PC system

- incl. 22" monitor

- everything fully installed and calibrated

- Engraving software in German

- 3D software (MM3D)

- very easy to operate

- switch on and start working

- UV laser source with 20 Watts for high-contrast and fast marking with extremely high resolution

Dsdpfx Aoflrnasfnekh

- suitable for engraving almost all metals (stainless steel, brass, aluminium, etc.)

- suitable for engraving almost all plastics (including PVC, silicone, etc.)

- suitable for engraving real glass (including crystal glass)

- capable of cutting real glass

- heavy-duty industrial quality

- complete system / ready for immediate use

- working area approx. 500 x 600 x 600 mm (W x D x H)

- clamping surface with threaded inserts on a 50 mm grid

- LED workspace lighting

- 50 mm duct connection for fume extraction

- Engraving area approx. 150x150 / 200x200 / 300x300 mm (switchable)

- 3D scanner for marking surfaces of any shape

- incl. foot pedal to start the engraving process

Sale to businesses only.

Delivery / consulting / sales only within Germany / Austria / Switzerland.

Please also ask about our attractive leasing/financing options.

Machine dimensions approx.:

Width: 800 mm

Height: 1800 mm

Depth: 1000 mm

Weight: approx. 150 kg

Listing

Hauzenberg

Hauzenberg

8,224 km

Engraving laser, engraving machine, 4th axis

LD-LaserLG50Q 60Watt Faserlaser

Call

Condition: new, Year of construction: 2025, shaft length: 1,070 mm, laser power: 60 W, type of cooling: air, Laser Engraving Machine with 60 Watt Laser Power

New demonstration unit

- 60 Watt MOPA laser (enables color laser engraving on stainless steel)

- Incl. 4th axis (rotary unit)

- Incl. Windows 10 Pro 64-bit PC system

- Incl. 22" monitor

- All software and hardware pre-installed and calibrated

- Engraving software in German

- Very user-friendly operation

- Plug and play – ready to use immediately

- 60 Watt fiber laser source for high-contrast, fast marking with extremely high resolution (see photos)

- Deep engraving up to 4mm possible (even in hardened steel)

- Wobble function, e.g., for cleaning metal components

- Suitable for engraving on many metals (stainless steel, brass, aluminium, etc.) and a wide range of plastics

- Heavy-duty industrial quality

- Complete system / immediately operational

- Working area approx. 500 x 600 x 600mm (WxDxH)

- Clamping surface with mounting threads in 50mm grid

- LED work area lighting

- 50mm port connection for fume extraction

- Engraving area approx. 180 x 180mm (expandable up to approx. 300 x 300mm)

- Incl. foot switch for starting the engraving process

Please also ask about our attractive leasing/financing offers.

Sale is exclusively to commercial customers.

Delivery / advice / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 800mm

Height: 1800mm

Depth: 1000mm

Djdpfxjfkgq Ne Afnjkh

Weight: approx. 150kg

Listing

Hauzenberg

Hauzenberg

8,224 km

Engraving laser engraving machine

LD-LaserlQ30G 30Watt Faserlaser

Call

Condition: as good as new (ex-display), Year of construction: 2024, operating hours: 10 h, functionality: fully functional, shaft length: 1,070 mm, input voltage: 230 V, type of input current: AC, laser power: 30 W, type of cooling: air, warranty duration: 12 months, laser wavelength: 1,070 nm, Equipment: cabin, Laser Engraving Machine with 30 Watt Laser Power

- Demonstration unit (approx. 10 hours of use)

- Worth a look

- Incl. Windows PC 64bit (incl. monitor/keyboard/mouse)

- Fully installed and calibrated

- Engraving software in German

- Very easy to operate

- Switch on and start immediately

- Fiber laser source with 30 watts for high-contrast and fast markings with extremely high resolution (see photos)

Dksdped Ha I Sefx Afneh

- Wobble function, e.g. for cleaning metal components

- Deep engraving up to 3mm possible

- Suitable for engraving on many metals (stainless steel, brass, aluminum, etc.) and a wide range of plastics

- Heavy-duty industrial quality

- Complete system / ready for immediate use

- Working area approx. 390 x 270 x 350mm (L x W x H)

- Clamping table with mounting threads in a 50mm grid

- LED work area lighting

- 50mm port for fume extraction

- Engraving area up to 170 x 170mm

- Motorized focus adjustment

- Incl. foot switch to start the engraving process

Please also take note of our attractive leasing/financing offers.

Sale exclusively to commercial customers.

Delivery / consulting / sales only within Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 450mm

Height: 800mm

Depth: 750mm

Weight: approx. 80kg

Listing

Hauzenberg

Hauzenberg

8,224 km

CO2 Laser Cutting Machine 150Watt

LD-LaserLD-1390

Call

Condition: as good as new (ex-display), Year of construction: 2025, functionality: fully functional, shaft length: 10,700 mm, input voltage: 230 V, laser power: 150 W, type of cooling: water, warranty duration: 12 months, Equipment: cabin, Laser cutting machine from our showroom

with 150-watt laser power

Delivery time: immediately available

----- Switch on and start working -----

----- Machine with only approx. 10 operating hours -----

----- Year of manufacture: 2025 -----

----- Professional-grade machine -----

- incl. Windows 11 PC system / monitor / keyboard / mouse

- Pre-installed cutting and engraving software in German

- Fully integrated and ready for immediate use

- Capable of extremely fine engraving as well as precise cutting of thick wood or acrylic (PMMA)

- Machine was only used for demonstration purposes

- Highly versatile cutting system

- Cuts wood up to 20 mm thick

- Cuts acrylic and various other plastics

- Cuts fabrics, nonwoven materials, etc.

- Cuts rubber sheets

- Engravings on wood, concrete, stone, many plastics

- Production of stamps

- Heavy-duty industrial quality

- Travel range: 1300 x 900 mm

- Drives with hybrid servos

- Linear guides on all axes

- reci laser tube with 150 watts peak output

- incl. honeycomb worktable (removable / extendable)

Dkjdpfx Aofkgq Aefnoh

- incl. knife blade table (removable / extendable)

- Sheets up to approx. 20 mm thick can be fed through the machine

- Continuous processing possible

- incl. generously dimensioned laser chiller

- incl. high-capacity extraction system

- Very easy to operate

- Machine control in German

- Machine controller in German with large color display

- Highly reliable data transfer via USB and network cable

- No hassle with occupational safety authorities

- All spare and wear parts are in stock

Please also see our attractive leasing/financing offers.

Sale exclusively to commercial customers.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 200 cm

Height: 125 cm

Depth: 150 cm

Shipping weight: approx. 600 kg

We make it easier for you to find: "monitoring"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Monitoring (4,810)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month