Used Pastry Filling for sale (5,177)

Łódź

Łódź Roll line

Linia Rondo Doge - Bread & Pastry LineLaminazione

Heerhugowaard

Heerhugowaard Filling machine and sealing machine

Lubeca can filling and can seaming lineLW792 and LW303

Przemyśl

Przemyśl Beverage production machine

ELOPAK SHIKOKU ASEPTIC FILLING LINES-PS80HA

+44 20 806 810 84

Suffolk

Suffolk 6 head jar filler and inline steam capper.

Filling SystemsJar filler and steam capper

Bristol

Bristol Bottle filling, carbonating and capping

ic filling systems5.5.1 MICROBLOCK

Discover more used machines

Freising

Freising Glass bottle rinser, filler and capper

IC Filling Systems

Freising

Freising Labeling machine

IC Filling Systems

Heerhugowaard

Heerhugowaard Filling machine and sealing machine

Can filling and seamingmonobloc

Heerhugowaard

Heerhugowaard Filling technology

Glass jar filling and closingline

Escanaba

Escanaba Keg filling technology

KHSTILL COMBIKEG

Bury St Edmunds

Bury St Edmunds Doy pouch filling and packing machine -

Toyo JidokiTVP-E3

Reykjavík

Reykjavík Pastry line

RondoZGP665.C

Zwevegem

Zwevegem Automatic filling flow divider, 6 exits

BarssoProduct stroomverdeler, 6 uitgangen

Menslage

Menslage Krones Checkmat 731 Fill Level Inspector (2014)

KronesFüllhöhenkontrolle

Thisted

Thisted Filling technology

GrunwaldGRUNWALD HITTPAC AKH-019R/1

Thisted

Thisted FILLING MACHINE GALDI RG270 UCS

GaldiRG270 UCS (NEW PRICE)

Misterton

Misterton Rotary filling machine

Technogel4000E

Ireland

Ireland Bag forming, filling and sealing machine

Thom Spout Inserting Machine for Pre-MadSI-900

Freising

Freising Fill level control

miho

Freising

Freising Rinsing, filling and sealing machine

KHS

Janville

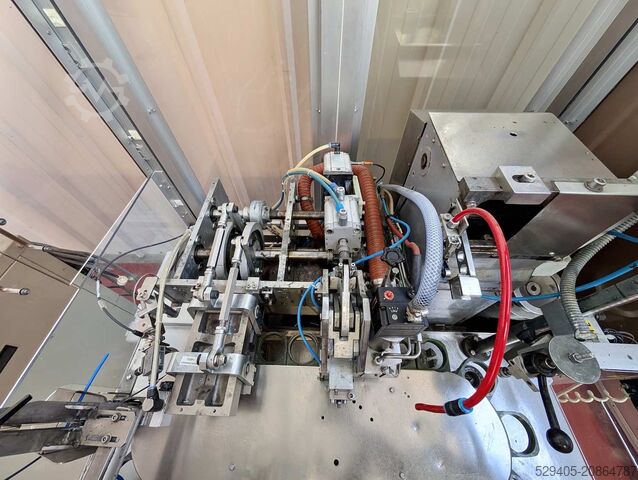

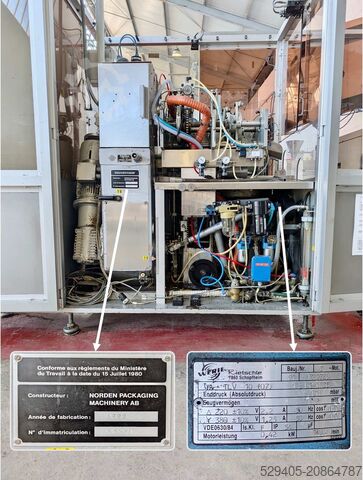

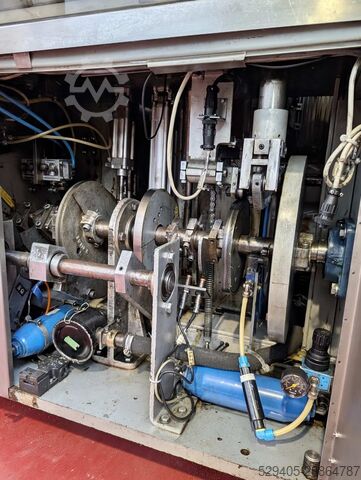

Janville Automatic tube filling machine

NordenNordenmatic 700

Janville

Janville Tube filling line

MarchesiniMillenium 200 + MA 250

Janville

Janville Hot filling line

TirelliCHICO 2P

Janville

Janville Filling and capping

GroningerKFVG251 + DTE 1000

Janville

Janville 6-head filling machine

StoppilEC6050

Used Pastry Filling (5,177)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84