Used Concentricity for sale (261)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

China

China

11,525 km

Bag forming, filling and sealing machine

Shanghai cat claw tradingFb001

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: Fb001, warranty duration: 12 months, total height: 1,000 mm, total width: 800 mm, total length: 1,100 mm, type of input current: three-phase, overall weight: 100 kg, power of the servo motor: 1 W, film width: 38 mm, compressed air connection: 0.25 bar, input voltage: 220 V, nominal power: 0.5 kW (0.68 HP), heating capacity: 0.8 kW (1.09 HP), Equipment: CE marking, Performance and features:

1). The machine is mainly made of quality stainless steel; the parts contact the material is made of 304# stainless steel and food grade plastic tubes and comply with hygienic standards for food;

2).It can fullfill accurate filling and capping at one operating position.

3). The machine uses flow meter for filling which is with high filling precise.

4). All its pneumatic and electric parts are from world famouse brand which are good quality.

5). can achieve vacuum pumping before they are filled, thereby helping extend the shelf life of the product.

6) Can add nitrogen function according to clients requirement.

Knodpfxoxmwkqj Agzjf

Application:

It can be widely used in bag-in-box filling applications for such liquid materials as wine, edible oil, fruit juice, additives, milk, syrup, alcoholic beverages and concentrated seasonings.suitable for all kinds of bags and caps.

Listing

Thalmässing

Thalmässing

8,051 km

Drilling and milling machine

OptimumMF 2-B

Call

Condition: as good as new (ex-display), Year of construction: 2018, functionality: fully functional, machine/vehicle number: 64011811002, feed length X-axis: 610 mm, feed length Y-axis: 230 mm, feed length Z-axis: 310 mm, travel distance X-axis: 690 mm, travel distance Y-axis: 310 mm, travel distance Z-axis: 390 mm, spindle speed (max.): 4,200 rpm, throat depth: 415 mm, quill stroke: 127 mm, type of input current: three-phase, total length: 2,000 mm, total height: 2,010 mm, table width: 230 mm, input voltage: 400 V, total width: 1,600 mm, table length: 1,246 mm, drilling capacity: 24 mm, stroke length: 127 mm, rotational speed (max.): 4,200 rpm, workpiece weight (max.): 200 kg, rotational speed (min.): 60 rpm, Equipment: rotational speed infinitely variable, Multifunctional drilling and milling machines with mechanically infinitely variable drive and digital 3-axis position display

- Solid design made from high-quality Meehanite cast iron

- High concentricity due to tapered roller bearings, ≤ 0.01 mm measured in the quill

- X- and Z-axis with adjustable 55° dovetail guide

- Y-axis with adjustable flat guide

- Coolant device

- Solid and generously dimensioned cross table, precisely surface-finished with adjustable end stops

- Drilling/milling head can be tilted ± 45

- Automatic quill feed, 3-stage 0.04 - 0.15 mm/rev

Kjdpfx Aet Sk E Esgzonf

- Precision micro feed

- Adjustable drilling depth stop with millimeter scale, readable from the front

- Right/left rotation

- Infinitely variable speed control

- Milling spindle with precision bearing

- Mechanical spindle brake

- Height-adjustable protective screen with microswitch, against flying chips and parts, for maximum protection of the user

user

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Various Equipment

Tetra Pak®Tetra Alcip 1

Call

Condition: used, Year of construction: 2010, Used CIP Tetra Pak year 2010 15T/h

Ksdpfjwga Iusx Agzjnf

The Used CIP Tetra Pak year 2010 15T/h, model Tetra Alcip 1, performs Cleaning in Place (CIP) to automate the cleaning process in bottling and food processing plants. Consequently, this system ensures an effective sanitation cycle without requiring production line disassembly, optimizing downtime and reducing water and detergent consumption.

Tetra Pak built the Used CIP Tetra Pak year 2010 15T/h in 2010. Specifically, its 15-ton-per-hour operational capacity makes it suitable for high-productivity plants while ensuring hygiene standards that comply with food and beverage industry regulations.

Technical Features of the Used CIP Tetra Pak year 2010 15T/h

The Tetra Alcip 1 applies a controlled washing cycle to remove organic and inorganic residues from production circuits. In particular, the system integrates separate tanks for water, alkaline detergent, and acid, and it automatically regulates temperature, chemical concentration, and washing time based on plant requirements. As a result, it enhances the efficiency of cleaning operations.

Moreover, the Used CIP Tetra Pak year 2010 15T/h automates the cleaning process, reducing cross-contamination risks and improving production efficiency. Additionally, the system allows operators to configure different washing parameters, which enables adaptation to specific production needs and ensures thorough cleaning of filling lines, pipelines, and heat exchangers.

Safety and Process Control

The system includes advanced safety features, such as:

Sensors that continuously monitor detergent concentration.

Temperature and pressure controls throughout the cleaning cycle, ensuring optimal performance.

Alarm systems that detect and manage sanitation process anomalies, thereby preventing potential failures.

As a result, these features ensure this Used CIP operates reliably, minimizing operational errors and optimizing water and chemical consumption. Furthermore, the system’s automated monitoring enhances safety while reducing maintenance requirements.

Operational Advantages

Using this Used CIP Tetra Pak enhances plant productivity in multiple ways. First and foremost, it reduces downtime: the continuous washing system completes fast cleaning cycles without requiring component disassembly. Moreover, it optimizes resource usage: the automatic detergent dosing system prevents chemical waste. Additionally, it ensures regulatory compliance: the system meets high hygiene standards and complies with industry regulations.

At the same time, the automated nature of this system helps manufacturers streamline their cleaning procedures. Consequently, businesses benefit from both improved production continuity and reduced operational costs. Likewise, the ability to customize cleaning parameters provides greater control over sanitization processes.

Conclusion

In summary, this Used CIP Tetra Pak provides an efficient and reliable solution for sanitizing bottling and food production plants.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Peuerbach

Peuerbach

8,250 km

Milling machine

Emco FamupMC 75 - 50

Call

Condition: repair required (used), Year of construction: 2010, functionality: not functional, machine/vehicle number: M-075.068.10, feed length X-axis: 750 mm, feed length Y-axis: 500 mm, feed length Z-axis: 640 mm, spindle speed (max.): 12,000 rpm, spindle speed (min.): 50 rpm, table width: 520 mm, table length: 900 mm, CNC milling machine Emco MC 75/50

Machine no.: M-075.068.10

Year of manufacture: 2010

includes 30 SK40 tool holders with pull studs

includes 4th rotary axis

includes various tools and holders

includes coolant concentrate

ATTENTION: Machine is being sold as needing repair.

The machine control is defective: Heidenhain MC420

Kedoxn Hy Ropfx Agzonf

includes documentation and operating manual

sold without guarantee or warranty

Listing

Berlin

Berlin

7,952 km

Fire engine with water tank TLF 3000

RenaultD14 4x4 Allrad Single-Bereifung Staffel

Call

Condition: new, functionality: fully functional, power: 209.62 kW (285.00 HP), fuel type: diesel, axle configuration: 4x4, Year of construction: 2025, Equipment: additional headlights, air conditioning, all wheel drive, differential lock, parking heater, trailer coupling, Are you looking for a reliable and affordable emergency vehicle for your fire department? Then you’ve come to the right place!

From our immediately available new vehicle stock, we offer:

Knjdpfx Agoxiwb Iszjf

TLF 3000 AWD on off-road capable Renault D14 chassis

Outstanding for small and medium-sized fire departments in rural areas that want to handle a wide variety of tasks with a compact vehicle while still requiring a large water supply. Ample weight and space reserves are available for custom additional equipment.

Also ideal due to its off-road capability and comprehensive firefighting equipment for vegetation and forest fire operations.

Chassis:

• Renault D14 4x4 EURO 6 with 286 hp (210 kW) and manual transmission

• Single tires with matching track for high off-road mobility

Cab:

• Standard crew cabin (1:5) in RAL 3000 (fire red)

• Air conditioning and auxiliary heater included

• 4 standard SCBA holders in the crew compartment

Body:

• High-quality body in frame construction using rust- and corrosion-free materials

• Folding steps for each side compartment

• Stainless steel storage systems individually tailored to your requirements

• Walkable, anti-slip roof with large, LED-illuminated roof box

Fire pump / extinguisher tank:

• Maintenance-free combined normal/high-pressure pump FPN 2000-10, pump & roll capable

• 2,000 l/min at 10 bar and 400 l/min at 40 bar

• Integrated, infinitely variable foam proportioning system

• 3,000 l water tank with integrated 300 l foam concentrate tank

Firefighting Equipment:

• High-pressure rapid attack system with 50 m form-stable hose

• Foam/water monitor 2,000 l/min on the vehicle roof

• Self-protection system with 4 spray nozzles in front of the wheels

Safety and Lighting:

• LED mini lightbar on the vehicle roof / 2 LED front flashers

• Pneumatic special signalling system

• 100 W speaker system with announcement unit

• Rear view camera

• Comprehensive LED lighting in crew and all equipment compartments

• LED perimeter lighting on the body and auxiliary spotlights

• Pneumatic LED light mast with remote control

We would be happy to provide you with a detailed offer and to present the vehicle to you at our Berlin location.

All information provided to the best of our knowledge, without guarantee for completeness or accuracy. This advertisement does not constitute a binding offer, but is for information purposes only. Subject to prior sale!

Discover more used machines

Listing

Butzbach

Butzbach

7,816 km

Oil spill remover / road cleaner

Mercedes-Benz1424 Ölspurenbeseitiger

Call

Year of construction: 1997, condition: excellent (used), functionality: fully functional, - Manufacturer: Mercedes-Benz

- Type: 1424

- First registration: 07/1997

- Kilometers: 153185km

- Unladen weight: 12.200kg

- Payload: 3.800kg

- Gross vehicle weight: 16,000kg

- Power: 180kw / 244PS

- Gearbox 7 speed manual

- Wheel formula 4x2

- 2 auxiliary drives

- Power take-off 1: NMV 4/12

- Power take-off 2: NA 4/120-10c

- Travel drive in work mode

- Make ZF Type HZA Duodrive

- Vmax: 15/min, best cleaning speed 11/min

- Body/tank

- Decontamination chamber: 500 liters

- Water pockets: 3200 liters (reduced from 5000 to 3200 due to weight problem)

- Dirty water tank: 6000 liters (A1 tank)

- Cyclone separator x2

- Cleaning concentrate

- Hot water treatment

- 2 vacuum pumps (capacity 1650cmb/h at 460 mbar)

- 2 high pressure pumps (capacity 15 l/min-280bar)

- Manual suction through suction device at the rear

- High-pressure lance with adjustable dosage

- High-pressure front bumper pre-treatment

Knsdeu Tuzljpfx Agzsf

- Next HU: 11/2025

- German vehicle

- German papers

- Ready for immediate use

You also can have the description in another language by Email

- Our service

-

- Export declaration-customs registration-yellow short-term license plates-red customs license plates.

- Purchase of your used construction machine or commercial vehicle

- we help you with financing

- we offer you transportation solutions

- Inspection and demonstration of the machines from Mon-Fri 9.00-17.00 (Saturday by appointment only).

-

- Our pool of machines is constantly changing and is always up to date on our website

-

-

- We are also at your disposal by telephone

-

- Sanisa GmbH

- Otto Hahn Street 13

- 35510 Butzbach

-

- This offer is non-binding and subject to change.

- Subject to prior sale,

- Errors and/or typing errors not excluded.

- Sale to our AGB`s.

Listing

Freising

Freising

8,128 km

Water treatment plant

ProMinent

Call

Condition: used, Year of construction: 2007, Prominent water treatment plant, consisting of: 1. Softening: The raw water is fed into the double softener. Only one bottle is ever in operation and the other is in regeneration or stand-by. In the softener, calcium and magnesium are replaced by sodium. The system has a volume counter that switches to the other bottle when the preset quantity is reached. Regeneration takes place with saline solution from the brine tank. The value at the outlet is 0°dH. 2. reverse osmosis: Reverse osmosis fills the permeate tank with demineralised water, so-called permeate. Depending on the raw water quality, water temperature, condition of the membrane and correct setting, different conductance values and operating pressures result. The following flow rates are set during commissioning: Permeate 600 l/h, concentrate 200 l/h, corresponding to a yield of 75%. 3. permeate tank and ozonisation: The unpressurised 500 l permeate tank has an adjustable level control. For treatment with ozone, the water in the permeate tank is circulated via an adjustable ozone feed point. The ozone is generated from air in the ozone generation system by means of a silent electrical discharge and is available as an ozone-air mixture. The air and the undissolved ozone rise upwards in the permeate tank and are discharged via the residual ozone destroyer. A redox potential and ozone measurement is carried out after the centrifugal pump for monitoring purposes. The ozone dosage is set via the touch panel. You can choose between regulation via the redox potential or the ozone concentration.

Additional title: Water softening, reverse osmosis system, ozone sterilisation

Permeate output: 600 l/h

Ksdpfx Agsw Uvdgezenf

Concentrate output: 200 l/h

Ozone output: 5 g/h

Max. working pressure: 16 bar

Current: 2 A

Voltage: 230 V

Frequency: 50 Hz

Water: < 5 bar (cooling water)

Compressed air: 5,5 - 6,5 bar (max. 10 bar); max. 0,37 Nm³/h

Operation / Control: Simatic S7-300, Touch Panel

Position: free standing

Base construction: Fully mounted on tubular frame with spherical feet

Features: Reverse osmosis unit, reaction tank complete with residual ozone destroyer, ozone generator, ozone gas warning device, ozone and redox sensor, switch cabinets with control unit

Listing

Karczmiska Pierwsze

Karczmiska Pierwsze

8,486 km

Evaporation station for apple concentrate

Call

Condition: used, Evaporation station for apple concentrate with a capacity of 12,000 liters juice inflow. In 2014, it was completely modernized by B&P Przeworsk, which is now Bucher Unipektyn.

Knjdpfjxn Uq Dox Agzjf

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Syrup Room

FischerE18DFP

Call

Condition: used, Year of construction: 2006, Used Syrup Room up to 6000 L/h

Components of the Syrup room:

1. Electrical control cabinet.

2. Sugar receive tank 200 l

3. Sugar dissolving tank 8000l

4. Sugar filtration

5. Sugar syrup pump

6. Heat exchanger (syrup cooling)

7. Sugar syrup tank I 6000 l

8. Sugar syrup tank II 6000 l

9. Tank for emulsions, concentrates, aroma adding 200l

10. FISCHER pasteurizer for syrup and juices 6000 l/h

11. All pumps, pipes

Introduction to the Used Syrup Room up to 6000 L/h

Initially, the “Used Syrup Room up to 6000 L/h” emerges as a pivotal asset in liquid processing. Since its inception in 2006, this powerful machinery has led the forefront of syrup production. Boasting a notable capacity of 6000 liters per hour, it serves as an epitome of high-efficiency operation. Currently, it rests in storage, eagerly awaiting integration into its next productive chapter.

Core Machinery Components

Central to the syrup room’s functionality, the electrical control cabinet stands out. This crucial unit guarantees precise automation of the entire syrup-making process. Subsequently, the journey begins with a 200-liter sugar receive tank. Following closely, an 8000-liter sugar dissolving tank plays an indispensable role, ensuring each batch meets the highest quality standards.

Filtration and Cooling

Moreover, sugar filtration acts as a critical juncture, aiming to eradicate impurities and guarantee a pristine syrup output. Concurrently, a dedicated pump aids in the efficient transfer of syrup between stages. Furthermore, a sophisticated heat exchanger steps in, crucial for maintaining the syrup at ideal processing temperatures.

Storage and Flavoring

Additionally, the setup includes two voluminous 6000-liter tanks for syrup storage, designed with both capacity and easy access in mind. Also, a versatile 200-liter tank accommodates emulsions, concentrates, and flavor additions, providing essential flexibility in production. Notably, the FISCHER pasteurizer, with its 6000 L/h capacity, plays a pivotal role in ensuring both syrup and juice safety, solidifying product quality before the final bottling stage.

Integrated System Readiness

Moreover, the inclusion of all necessary pumps, pipes, and valves—as showcased in the accompanying visuals—underscores the system’s operational readiness. This comprehensive assembly ensures a seamless transition to active production, fostering a smooth and efficient workflow throughout the syrup preparation process.

Conclusion of the Used Syrup Room up to 6000 L/h

Knsdpfx Aevgvxdegzsf

In summary, the “Used Syrup Room up to 6000 L/h” represents a holistic approach to syrup production. Featuring advanced technological components, it underscores a commitment to efficiency and product quality. Therefore, its adoption into a manufacturing environment promises to significantly elevate operational capabilities, positioning it as a valuable investment for any forward-thinking beverage production enterprise.

Listing

Gondelsheim

Gondelsheim

7,901 km

Low-pressure cleaner with hose reel

System Cleaners S2 Sateliten StationReinigungsstation + 20m Schlauchhaspel

Call

Condition: excellent (used), Year of construction: 2020, Complete cleaning station package :

1x System Cleaners - Manual Satellite TYPE S2 Low Pressure Cleaner

1x stainless steel hose reel approx. 20m with various nozzles and lance

2x stainless steel canister wall bracket

S2 is a solid satellite station with high operational reliability

The S2 satellite can be used in decentralized and centralized cleaning systems and manages a detergent with the option of adding a separate outlet for another product.

It can be used in a pressure range of 3-8 bar for connection to the water mains or 15-40 bar for connection to a boosted water supply from a System Cleaners main station, pump station or booster station.

It performs rinsing, foaming and disinfection*.

The S2 satellite is protected by a stainless steel cabinet and can either be wall-mounted or mounted on a trolley for mobile cleaning.

Features

Rinsing, foaming and disinfecting

Pressure range: 3-8 or 15-40 bar

Up to two chemical inlets for either premixed or concentrated detergents

System Cleaners stainless steel needle dosing valve as standard - alternatively click dosing valve or fixed dosing for decentralized chemical supply

Ksdpferk D E Iex Agzenf

Hygienic design

High-quality materials with high chemical resistance

Intuitive operation with mechanical function selector

Available for wall mounting or mounted on a trolley

Further devices are available, please enquire

Very good condition, see pictures

Location is 75053 Gondelsheim

Collection or shipping by forwarding agent possible.

Listing

Son

Son

7,563 km

Offset printing press

FAG (nowadays under Bobst)speedproof 4C

Call

Condition: excellent (used), Year of construction: 1988, functionality: limited functionality, machine/vehicle number: 25.05.004, total length: 9,500 mm, total width: 2,250 mm, total height: 2,300 mm, input voltage: 380 V, power: 50 kW (67.98 HP), overall weight: 21,000 kg, empty load weight: 18,000 kg, compressed air connection: 7 bar, Equipment: documentation/manual, Paper size: 730 x 1060 mm, printing area: 710 x 1040 mm

Paper thickness: 0.05 mm – 0.5 mm

Preset maximum speed (due to simulation of the throw-off time for high-speed presses) is 4,000 sheets per hour, but the machine can operate much faster for commercial jobs.

Four-fold central impression cylinder that prints all 4 colors in one gripper closure.

1988 FAG Speedproof with operator console for ink duct and cylinder adjustments, enabling extremely accurate register printing. Attached is the original factory brochure. The machine has been fully dry ice cleaned, and the cylinders are in excellent condition.

Offered strictly on an 'as is, where is' basis.

Maximum width is 225 cm, maximum height is 230 cm; shipping in a High Cube container is possible.

Price is absolutely fixed, based on the removal of easily separated parts which we could sell separately, such as the Mabeg feeder with vacuum belt delivery, and the four-fold Baldwin stainless steel unit—with each color having its own bath, a mixer, and adjustable temperature control, so all four baths can be set to different temperatures and alcohol concentrations.

The machine was dry ice cleaned, and it was intended for prominent use in printing electronic paper. However, due to too many initial losses, the project was discontinued.

The machine has been with us for 3 years and, due to its size, I want to sell it as quickly as possible. Hence this very low price. It is an excellent machine.

If the machine needs to be set up for testing and sampling, this is possible at an additional cost of €10,000, of which €5,000 must be paid in advance as a deposit under agreed conditions.

Knsdeuf Sy Aopfx Agzjf

All relevant information can be found in the original FAG folder for the machine, available via this advertisement as a PDF.

Technical Data

- Printing size max.: 710 × 1040 mm (27.95 × 40.94 in.)

- Paper size max.: 730 × 1060 mm (28.74 × 41.73 in.)

- Paper size min.: 500 × 700 mm (19.68 × 27.56 in.)

- Stock thickness: 0.05 – 0.5 mm (0.002 – 0.020 in.)

- Plate size max.: 800 × 1080 mm (31.50 × 42.50 in.)

- Plate thickness: 0.25 – 0.5 mm (0.010 – 0.020 in.)

- Speed max.: 4,000 sheets/h

- Floor space requirement (incl. access to feeder, delivery, and central control desk): 950 × 525 cm (374 × 206.69 in.)

- Press height: 230 cm (90.55 in.)

- Weight (including paper stacked in feeder and delivery): approx. 18,000 kg (approx. 39,690 lbs)

- Total power requirements: approx. 50 kW

- Compressed air supply: 6 – 7 bar

Listing

Germany

Germany

7,829 km

Bench drilling machine

OptimumOPTIdrill DH 18V

Call

Condition: new, Year of construction: 2024, New machine

Year of manufacture: 2024

Robust drilling machine featuring a powerful OPTIMUM brushless drive. Key highlight: menu-guided control for operating modes drilling/tapping.

Knodpfx Asw Rhk Rjgzjf

- Smooth-running and high-performance brushless drive

- Optimal power transmission via aluminium pulleys combined with a toothed GATES quality V-belt

- High running smoothness thanks to precision-ground multi-spline drive

- Concentricity guaranteed at less than 0.015 mm, measured at the quill

- Drilling spindle with precision ball bearings

- Membrane keypad; dust- and water-resistant, easy to clean

- High-quality OPTIMUM quick-action drill chuck included as standard

- Separate emergency stop pushbutton

- Precisely machined worktable with diagonal T-slots, 360° rotatable

- Integrated coolant channel surrounding the worktable

- Large, height-adjustable safety guard with interlock switch for maximum operator protection

- Drilling depth stop

- V-belt guard with safety switch

- V-belt tensioning mechanism

- Solid, large base plate with reinforced ribs at the rear

Technical specifications:

Column diameter: 60 mm

Dimensions (LxWxH): approx. 552 x 445 x 850 mm

Weight: approx. 64 kg

Drilling capacity (steel): 18 mm

Continuous drilling capacity (steel): 16 mm

Tapping capacity (steel): M10

Table size: 230 x 245 mm

Speed range: 100 – 6000 rpm

Number of speed ranges: 5

Total power connection: 1.5 kW

Mains voltage: 230 V

Quill stroke: 65 mm

Spindle taper: MT 2

Throat depth: 130 mm

Including quick-action drill chuck 1–13 mm

Including machine vice BMP 100

Availability: short-term

Location: Flörsheim

Listing

Freising

Freising

8,128 km

Bottle cleaning system

Krones

Call

Year of construction: 2000, condition: used, Bottle washing machine (with chemical dosing) Manufacturer: Krones Model: Lavatec Kes Year of manufacture: 2000 Performance: 39,000 bottles/h

Additional title: Bottle washing machine

Knedpfx Agow Taxfjzof

Capacity: 39000 Bottles/h

Length: 12700 mm

Width: 4700 mm

Height: 3500 mm

Formats: 0,33 l Vichy, 0,33 l Euro, 0,35 l Lemonade, and 0,5 l NRW

Operation / Control: Simatic S7-300

Position: free standing

Base construction: Single-end machine, self-supporting housing on dome feet

Features: H2 extraction, label press, bottle tables, ladders, walk-on platforms, various spare parts, another 400 baskets of 22 bottles each Concentrate dosing station

Layer patterns: 22 bottles per basket row

Listing

Karczmiska Pierwsze

Karczmiska Pierwsze

8,486 km

Storage tank

Call

Condition: used, tank capacity: 50,000 l, The tank was previously used for food products (juices, concentrates). Dimensions: diameter approx. 295 cm, length 900 cm. I have several units available. Free loading, transport within the EU possible.

Knedpfx Ajxn Uqksgzsf

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Compressor

SIADVITO 1920

Call

Condition: used, Year of construction: 2017, Used compressor SIAD VITO 1920 year 2017

Mechanical configuration and compressor structure

The Used compressor SIAD VITO 1920 year 2017 features a vertical reciprocating design with three compression stages. SIAD Macchine Impianti manufactured this unit in 2017 for demanding industrial applications, such as high-throughput bottling lines.

The compressor uses a crankshaft made of cast iron, which rotates on spherical roller bearings. Steel connecting rods link the crankshaft to ductile iron crossheads. Moreover, a directly mounted flywheel transmits power through V-belts, while an external bearing support prevents shaft deflection caused by belt tension.

In addition, the machine’s construction ensures mechanical stability even under dynamic loads. Consequently, it achieves reliable operation in continuous-duty environments.

Pneumatic circuit and flow regulation

The Used compressor SIAD VITO 1920 year 2017 compresses air using dry-lubricated cylinders mounted on single-chamber distance pieces. Filled PTFE seals ensure durability and chemical resistance. Furthermore, flat-disc or concentric valves regulate intake and discharge flows, and their design allows quick access for maintenance.

The control logic adjusts flow automatically based on final delivery pressure. Therefore, the system supports two or three-step unloading (0–100% or 0–50–100%). When operating under partial load, pneumatically actuated unloader devices open the intake valves to reduce energy consumption.

As a result, the compressor optimizes efficiency without compromising reliability. Similarly, operators benefit from adaptive control in variable process conditions.

Knodjw Ag U Tepfx Agzef

Cooling and lubrication systems

The compressor cools its components using a closed-loop water-glycol system. This configuration stabilizes the thermal load during continuous operation. An electrically driven gear pump circulates the lubrication oil throughout the crankcase and the external bearing support.

In fact, the lubrication system includes an in-line heat exchanger, fine filtration, and integrated pressure regulation. Technicians should fill the system with ISO VG 150 mineral oil (e.g., AGIP ACER 150) or, alternatively, a compatible synthetic such as Mobil Rarus 827.

Additionally, the system incorporates temperature sensors and flow monitors that continuously verify operating conditions. Thus, any deviation from normal parameters prompts immediate intervention.

Performance specifications and operating characteristics

The Used compressor SIAD VITO 1920 year 2017 delivers up to 1920 m³/h of free air (FAD) at 40 bar. It draws 265 kW of shaft power at a nominal speed of 750 RPM. The unit compresses air in three stages, and each stage includes a dedicated safety valve.

Operators can expect the compressor to intake air at temperatures from 0 to 40 °C and discharge it at a maximum of 45 °C. Under normal operating conditions, the unit maintains a sound pressure level of 85 ±3 dB(A), assuming a free-field environment

Listing

Ostfildern

Ostfildern

7,958 km

Coordinate measuring machine

TesaMH3D

Call

Condition: excellent (used), Year of construction: 2004, functionality: fully functional, measuring range X-axis: 460 mm, measuring range Y-axis: 500 mm, measuring range Z-axis: 420 mm, workpiece weight (max.): 100 kg, total height: 2,380 mm, type of input current: AC, total width: 1,030 mm, total length: 14,000 mm, overall weight: 200 kg, ambient temperature (max.): 35 °C, ambient temperature (min.): 13 °C, operating temperature: 20 °C, pressure: 4 bar, Manual 3D measuring machine with Reflex control panel for measuring complex geometry, such as distance, angle, position, squareness, concentricity, parallelism, etc. Accuracy 0.003mm or better. Requires compressed air. Without under-table. You need a stable workbench or similar.

Knodpfx Aovq I Sdjgzef

Listing

Gifhorn

Gifhorn

7,792 km

Drying system

GEA Niro AtomizerSpray Dryer MSD

Call

Condition: good (used), functionality: fully functional, Equipment: documentation/manual, Spray Dryer:

- Manufacturer: Niro Atomizer

- Model: MSD

Knjdsxgg Hbopfx Agzof

- Capacity: up to 1,900 kg/h water evaporation

- Design: Three-stage dryer

- Drying air volume: 45,000 kg/h

Evaporators/High Concentrators:

- Manufacturer: GEA/Laguilharre

- Throughput: 12,500 l/h

Including big bag and sack emptying station

Evaporator (Pre-concentrator)

- Make: GEA

- Model: RM20

- Capacity (feed): 20,000 l/h

- Operating principle: MVR and TVR (hybrid)

Listing

Sittard

Sittard

7,617 km

Telehandler

MagniRTH 4.18 Smart | 2022

Call

Condition: new, functionality: fully functional, power: 55 kW (74.78 HP), gearing type: hydrostat, fuel type: diesel, fuel consumption per hour: 8 l/h, fuel tank capacity: 180 l, color: red, overall weight: 14,750 kg, empty load weight: 14,750 kg, operation weight: 14,750 kg, lifting power: 4,000 kg/m, lifting height: 17,600 mm, tire size: 18 R19.5, tire condition: 100 %, drive condition: 100 %, axle configuration: 4x4, number of seats: 1, emission class: euro4, mast type: telescopic, Year of construction: 2022, operating hours: 1 h, Equipment: all wheel drive, === KEY SPECIFICATIONS ===

Year: 2022

Operating hours: 1 h

Max lifting capacity: 4,000 kg

Max lifting height: 17.60 m

Max outreach: 14.70 m

Rotation: 400° (limited)

Stabilizers: Telescopic (four outriggers)

Drive type: Diesel

Transmission: Automatic (hydrostatic, 2-speed forward/reverse)

Drive: 4WD

Steering modes: Front / Concentric / Crab

Cab type: Enclosed cabin with air conditioning

Heated cabin: Yes

Remote control: No

Telescopic boom: Yes

Forks / Jib / Winch included: Pallet forks included

Tyres: Rough terrain (445/65 R19.5)

Engine manufacturer: Deutz TCD 3.6 L4 – 55.4 kW (74 HP)

Emission class: Stage IV

Weight: 14,750 kg

CE certification: Yes

=== HIGHLIGHTS ===

Carefully selected from reliable sources with verifiable history

CE certified and fully documented

Compact rotating telehandler with 400° rotation and excellent manoeuvrability

Deutz Stage IV engine with hydrostatic transmission for smooth operation

Comfortable cabin with air conditioning and heating

Available directly from stock in Sittard

=== CONDITION ===

New or nearly new machine – fully checked, maintained and tested by certified professionals. Inspection available on request.

=== LOCATION & DELIVERY ===

Located in Sittard, Netherlands. Worldwide delivery possible. Price on request (EXW / excluding VAT).

The Magni RTH 4.18 Smart is a compact rotating telehandler with a lifting height of 17.6 metres and a capacity of 4 tonnes. With a 400° rotating upper structure and telescopic stabilisers, this machine offers maximum versatility and stability, even on confined job sites. Powered by an efficient Deutz Stage IV engine and equipped with a comfortable air-conditioned cabin, it is an ideal solution for everyday use.

=== DELIVERY ===

Crane loading available on request for smooth dispatch. Flexible delivery options tailored to your destination and logistics preferences. Transport professionally organised by the internal logistics team

Kedpet Svn Eefx Agzjnf

Listing

Berlin

Berlin

7,940 km

Combi laminating machine

NordmeccanicaSuper Combi 3000

Call

Condition: used, Year of construction: 2013, • Web width: 1300 mm

• Max mechanical speed: 400 m/min (depending on materials and process)

Kodpexg Hqaefx Agzenf

• Substrate types: Film, foil, paper, and combinations thereof

Main Components and Features

Automatic web tension control across all unwinds and rewinds

Motorized adjustment for nip pressure and web alignment

Touchscreen HMI for process control and recipe management

Modular design for easy access and maintenance

Web inspection and defect detection (if installed)

Corona Treatment Unit

Nordmeccanica Solventless Mixing Unit Continuous, inline mixing of two-component adhesive system

Equipped with:

Precision gear pumps for both A and B components

Automatic ratio control and monitoring

Pumps for continuous filling to ensure uninterrupted production

Easy-access design for cleaning and maintenance

Drying Tunnel

Equipped with 2 thermal oil heating batteries

Provide stable and efficient heat transfer

Maintain consistent tunnel temperature, essential for proper adhesive drying

Integrated with 2 modulating valves

Automatically adjust the thermal oil flow

Enable fine control of tunnel temperature for different lamination applications

LEL (Lower Explosive Limit) Monitoring System Zellweger LEL sensor. Continuously monitors solvent vapor concentration

Listing

Karczmiska Pierwsze

Karczmiska Pierwsze

8,486 km

Evaporation station for apple concentrate

Call

Year of construction: 2005, condition: used, functionality: fully functional, Evaporation station for apple concentrate with an input juice capacity of 24,000 liters

Kjdpoxn Ugfofx Agzsnf

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Complete Bottling Line

Call

Condition: used, operating hours: 4,800 h, Used SIG Combibloc – like new

Aseptic line for dairy and juice – advanced technical configuration

The used SIG Combibloc processes dairy products and juices in 65 ml, 125 ml, and 200 ml formats. Notably, the line achieves a nominal output of 26,500 packs per hour. Furthermore, the manufacturer has fully packed the line for immediate shipment, and it has only completed 4800 working hours. It is in near-new condition. Therefore, this line presents an excellent opportunity for rapid deployment.

Sterilization and aseptic filling system

The line features a hydrogen peroxide (H₂O₂) supply and concentration control system, installed in 2023. This unit plays a crucial role: it sterilizes the carton packs before filling, ensuring that aseptic conditions are met according to the strictest standards.

Immediately following sterilization, the process continues with the SIG Combibloc CFA 1224 aseptic filling machine, also installed in 2023. This machine includes all original accessories. In 2024, the operator added a conversion kit, which significantly increases the filler’s speed while still maintaining sterility and reliability. As a result, the line performs at higher throughput without sacrificing safety.

These two modules together form the technical core of the Used line like new brand SIG Combibloc. Consequently, they deliver consistent, controlled, and efficient operation across multiple formats.

Accessory application and primary packaging

Knedpfx Aowc Ucrsgzof

After filling, the system proceeds to the Geyssel 533 automatic straw applicator (2023), which applies straws to the packs. This function is especially important for consumer-oriented formats, particularly those designed for children or on-the-go consumption.

Next, the line transfers products to the Meurer tray packer for SIG formats (2023). This machine groups the filled packs into stable trays for handling and distribution. Subsequently, the process reaches the HTW450 double stacker tray packer by SIG Combibloc, installed in 2024, which stacks trays in two levels. Thanks to this configuration, the system maximizes storage efficiency and simplifies palletizing.

Altogether, these machines ensure smooth downstream flow, as well as effective primary and secondary packaging.

Flow management and conveying

In addition, the line includes a Meurer HSP 4 – S KF accumulator (2023), which regulates product flow between modules and prevents bottlenecks. This feature proves essential during high-speed operations or brief downstream interruptions.

Likewise, the Meurer conveyor system (2023) transfers packs smoothly between each station. Since all modules are synchronized, the line operates without unplanned downtime. Moreover, this modular architecture allows for future upgrades if production requirements increase.

Technical conclusion of the Used line like new brand SIG Combibloc

In summary, the Used line like new brand SIG Combibloc offers a comprehensive aseptic packaging solution for both dairy and juice products.

Trust Seal

Dealers certified through Machineseeker

Listing

Wald

Wald

8,005 km

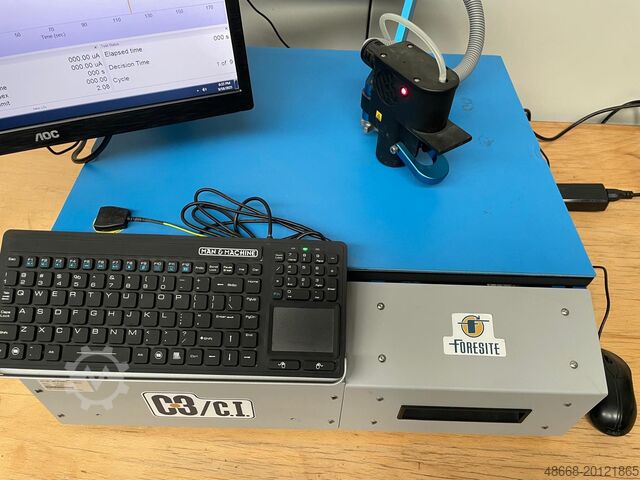

Critical Cleanliness Control Tester

ForesiteC3 / C.I.

Call

Condition: ready for operation (used), Foresite C3 / C.I. Critical Cleanliness Control Tester Analytics Technology

Year of manufacture: 2011

The C3 is unique among electronics cleanliness quality testers. It remains the only tester on the market that indicates whether a specific, critical area of a PCBA (Printed Circuit Board Assembly) is clean.

Simply select the components and/or circuit areas most sensitive and vulnerable to contamination and/or reliability issues, and test a small area (0.1 in²). The C3 quickly provides feedback as to whether potentially detrimental residues, often caused by manufacturing processes, are present.

Once the critical areas to be tested have been identified, the operator simply inserts a new disposable test cell into the vapor head and manually positions the head via the articulated arm over the test area. The weight of the arm and vapor head seals the test cell on the test surface. The operator then starts the automated testing sequence. Within 7-10 minutes, the operator knows whether the tested product area meets cleanliness standards. The C3 can be used directly in the production area.

At the end of the test, the cell can be easily removed using the cell ejector on the head. The test sample in the cell, efficiently extracted from the small test area using steam, can undergo further analysis to identify specific contaminants and their concentrations. The entire test is simple and straightforward for the operator, with results not dependent on operator skill. The use of Pro-Site single-use test cells and extraction solution prevents cross-contamination of samples.

You are welcome to arrange an inspection.

We can also organize cost-effective shipping for you!

You will receive a proper invoice.

For foreign customers, a net invoice can also be provided, provided a valid VAT ID number is available.

Subject to prior sale.

Visit our shop and take a look at our other offerings as well.

Brand names and trademarks mentioned are the property of their respective owners and are used solely for identification and product description purposes.

Kodpfx Asxhcklsgzonf

Technical data deviations and errors in the description of the item may occur and are subject to change.

Listing

Lorquí

Lorquí

7,920 km

HOT BREAK MANZINI UHV-30 INOX

MANZINIUHV-30

Call

Condition: excellent (used), functionality: fully functional, The Manzini UHV-30 INOX Hot Break unit is a thermal system designed for the rapid inactivation of pectinolytic enzymes by instant heating of fruits such as tomatoes. This process is essential for preserving the viscosity of the final product, especially in the production of high-quality tomato pulp or paste. The equipment allows for efficient solids extraction and a significant improvement in the texture of the concentrate.

INCLUDES:

Ksdpfxjwnzcvj Agzjnf

* Robuschi vacuum pump

* 2 CFS pumps

* 2 centrifugal pumps

* 2 Bardiani valves

Production may vary depending on the product.

Listing

Deinze

Deinze

7,478 km

CNC lathes

HegenscheidtPN 190 CNC PORTAL WHEELSET LATHE

Call

Condition: ready for operation (used), controller model: Siemens Sinumerik, empty load weight: 35,000 kg, total length: 7,000 mm, total width: 2,300 mm, total height: 3,300 mm, PORTAL WHEEL LATHE

Siemens CNC control

track wheel diameter range: 540 1400 mm

axle length: max 2600 mm

max track: 1435 mm

max. workpiece weight: 5 tons

main power: 100 kW

cutting speed: max 500m/min

Knodpfx Aov St E Eogzsf

Railset lathe / Railway lathes / Rail lathe

high machining accuracy in terms of concentricity and surface quality

optimal force parallelogram

measuring system for diameter and profile wear

measuring system for CL+CR determination

measuring system for determining the concentricity of the drive shaft

measuring system for wheel and axle brake discs

re-profiling of all common locomotive, passenger car and wagon wheel sets

planning of axles and wheel brake discs

rim processing

axle processing

marking groove turning

Chip shredder included

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Various Equipment

UATTP-110K

Call

Condition: used, Year of construction: 2001, Used equipment for the treatment and the preparation of water

It is a reverse osmosis that produces a filling water called TABLE WATER.

Manufacturer: UAT – UNIVERSAL AQUA TECHNOLOGIES, INC. – USA

Model: TP-110K

Year of production: 2001

Capacity: 12,000 L / h

Operating hours: 9,810

Volts: 380 – Hz 50 – Ph 3

Description of equipment:

-MM FILTER

-INPUT WATER TREATMENT

Ksdpfxjvgul Aj Agzjnf

-REVERSED OSMOSIS UAT – UNIVERSAL AQUA TECHNOLOGIES, INC. USA, 2001

-DEMINERALIZED WATER TANK 12 m3

-PUMPING BLOCK FOR MINERALIZATION

-MINERALIZER

-MINERALIZED WATER TANK

-PUMPING BLOCK FOR WATER DISINFECTION AND DELIVERY TO FILLERS

Technological description of table water production:

a) General

The plant for the production of table water has a capacity of 12,000 l/h.

It consists of:

Sand filter

Device for reverse osmosis (TP-110K)

Product water tank

Pump for mineralization of product water

Mineralizer

Mineralized water tank

System for ozonation (disinfection) of mineralized water

Machine for washing and filling (polycarbonate) PC bottles.

The plant is located in one room. Automatic serving is foreseen, with all necessary blocking and regulation, due to the safety and simplicity of the process itself.

b) Raw water supply

Tap water is supplied to the room where the water preparation plant is located. From the supply pipe through the inlet water valve, the water passes through the multi-layer sand filter and enters the RO device through the solenoid valve.

c) Reverse osmosis

After passing through the sand filter, the incoming water passes through the 5 jim filter and through the throttle valve enters the housings in which the membranes are located and where the physical process of separation (separation) of water from mineral substances in suspended and non-suspended forms.

Reverse osmosis, as a membrane separation process, removes bacteria, viruses, organic matter and salts from water. The effect of salt removal is 95-99%, which depends on the separation factor of the membrane itself, thus after the reverse osmosis process, sterile, bacteriologically correct water is obtained, which contains a small amount of salt, and the resulting the water of high quality.

The membrane is a key part of the reverse osmosis device and the efficiency of the RO process largely depends on its characteristics. In the device for reverse osmosis, reverse osmotic membranes based on a spiral coil were used, which proved to be the best in the industrial application of this highly efficient process. The water is forced over the membrane, the part that passes through the membrane is called permeate, and the part that contains everything that the membrane retained is called concentrate (retentate), which is discharged into the sewer as waste water.

We make it easier for you to find: "concentricity"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Concentricity (261)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month