Used Mesh Welding Line for sale (14,757)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Emskirchen

Emskirchen

7,991 km

Back Lining Machine

MATADOR11b

Call

Condition: used, Fälzelgerät - Back Lining Machine MATADOR 11b

Online-Video-Inspection by Skype-Video

Cjdpfx Afeh Axzzopegn

We would be very pleased with your visit - more machines on Stock

Available Immediately - Can be inspect

On Stock Emskirchen / Nürnberg - Can be test

Listing

Emskirchen

Emskirchen

7,991 km

Casing In Line

KolbusBF 40T

Call

Condition: used, Year of construction: 1980, machine/vehicle number: 558, Buchstraße-Hardcover / Casing In Line Kolbus BF 40TYear 1977 - Serial-No. 558

Format / Size min. 100x125mm - max. 270x365mm

Cgsdpfx Aonug Ensfpen

Buchblock Dicke / Book block thickness 6 - 70mm

Leistung / Mechanical speed max. up to 40 Takte/min.Buchstraße Ausstattung / Casing in Line consists of:

Fliessdreischneider / Three knife Trimmer Wohlenberg Modell 44

Rundungsstation / Rounding Station

Hinterklebestation für Gaze Kapitalbandstation / head-tailbanding and backlining station

Deckenanleger / Case Bending Station

Falzeinbrennstation / Pressing Unit Kolbus FE

Pressing Stations with Heated Joint Forming

Online-Video-Inspection by Skype-Video

We would be very pleased with your visit - more machines on Stock

Available Immediately - Can be inspect

On Stock Emskirchen / Nürnberg - Can be test

Listing

Emskirchen

Emskirchen

7,991 km

Back Lining Machine

MaiorBLM

Call

Condition: used, Fälzelgerät - Back Lining Machine Maior BLM

Online-Video-Inspection by Skype-Video

We would be very pleased with your visit - more machines on Stock

Available Immediately - Can be inspect

On Stock Emskirchen / Nürnberg - Can be test

Cjdpfxsh Axz Te Afpsgn

Listing

Emskirchen

Emskirchen

7,991 km

Guillotine

Schneider SenatorSEN78 E-LINE

Call

Condition: used, Year of construction: 2000, Schneidmaschine - Guillotine Schneider Senator SEN78 E-LINEYear 2000 - Serial-No. M-078E-004-10/30-09

Schnittbreite max. 780mm / Cutting width max. 780mm

Programm - Duisplay / Program - Display

Lufttisch - Chromtisch / Light guard - chrome table

Cgodpfx Aeh Ayarsfpsn

CE-Zeichen-Zulassung / CE Certificate

Elektr. Anschluss / Power supply 3 Phase 380V - 10A

Ersatzmesser / Spare knives

Online-Video-Inspection by Skype-Video

We would be very pleased with your visit - more machines on Stock

Available Immediately - Can be inspect

On Stock Emskirchen / Nürnberg - Can be test

Listing

Emskirchen

Emskirchen

7,991 km

Cutting Line Autotrimm PACE

Polar137XT-AT

Call

Condition: used, Year of construction: 2004, machine/vehicle number: 7441238, Schneidlinie Autotrimm PACE / Cutting Line Autotrimm Polar 137XT-AT PACE

Schneidlinie Lift Rüttler Ablader / Cutting Line Lift Jogger UnloaderYear 2004 - Serial-No. 7441238

Schnittbreite / Cutting width max. 1370mm

Autotrimm

Programm - Duisplay / Program - Display

Lufttisch - Chromtisch / Light guard - chrome table

große-Luft-Seitentische / large airbed side tables

Lichtschranke / Light guards

Ersatzmesser / Spare knives

CE-Zeichen-Zulassung / CE Certificate

Elektr. Anschluss / Power supply 3 Phase 380V - 10AStapellift / Stack Lift Polar LW 1000-4

Baujahr / Year 2004 - Serial-No. 7493313

Palettengröße / Pallet size max. 800 x 1.200mm

Cedpfx Afsiqvbmopjgn

Wannengröße / Size of platform 840 x 1.270mm

Hub / Stroke max. 850mm

Tragkraft / Carrying capacity max. 1.000kgRüttelautomat Luftausstreichwalze / Automatic Jogger air-removing roller Polar RAH-4

Entladung zur Hintertischbeschickung / unloading for rear-table feeding

Baujahr / Year 2004 - Serial-No. 7484103

Tischgröße / Size of table 900 x 1.150mm

Ausschiebeformat / Pusher size . 750 x 1.140mm

Lagenhöhe / Height of ream min. 30mm - max. 140mmStapelregal / Piling-board shelf Polar STR-1000-4

Baujahr / Year 2006 - Serial-No. 7475003

Format min. 420 × 570mm - max. 750 × 1.140mm

Größe Regalboden / Size of shelf board 900 × 1.170mm

Lagenhöhe / Height of ream min. 30mm - max. 140mm

Tragkraft / Carrying capacity max. 600kg

Anzahl Pufferplätze / Number of buffer spaces 5Ablader / Unloader Polar TR 130ER-4-

Einsatzbereich / Application for Size min. 400 x 400mm - max. 780 x 1.120mm

Nutzengröße / Label size min. 105 - 148mm

Lagenhöhe / Height of ream min. 40mm - max. 165mm

Stapelhöhe / Pile height max 1.300mm

Tragkraft / Carrying capacity max. 200kgSpäneförderband / Waste Conveyor Busch

Online-Video-Inspection by Skype-Video

We would be very pleased with your visit - more machines on Stock

Available Immediately - Can be inspect

On Stock Emskirchen / Nürnberg - Can be test

Listing

Emskirchen

Emskirchen

7,991 km

Jogger with Air Removal Rollers

Schneider SenatorProfi-Line 0077

Call

Condition: used, Year of construction: 2003, Rüttler mit Ausstreichwalze - Jogger with air removal rollers Schneider Senator Profi-Line 0077Year 2003 - Serial-No. P-7359003

Format / Size max. 790 x 1090mm

Platzbedarf / Space required 1370 x 1700mm

Einsatzhöhe / Infeed high 165mm

CE-Zeichen-Zulassung / CE Certificate

Elektr. Anschluss / Power supply 3 Phase 380V - 1,75/2,2kW

Online-Video-Inspection by Skype-Video

We would be very pleased with your visit - more machines on Stock

Available Immediately - Can be inspect

On Stock Emskirchen / Nürnberg - Can be test

Codpfx Aoh Aya Defpogn

Listing

Emskirchen

Emskirchen

7,991 km

Fälzelgerät / Back Lining Machine

SchmedtFälzelgerät

Call

Condition: used, Fälzelgerät / Back Lining Machine Schmedt Fälzelgerät

Online-Video-Inspection by Skype-Video

Csdpfx Afjtzc I Depegn

We would be very pleased with your visit - more machines on Stock

Available Immediately - Can be inspect

On Stock Emskirchen / Nürnberg - Can be test

Listing

Root

Root

8,011 km

Pasteurization line

Pasteurizationline

Call

Condition: good (used), Machine used for pasteurization vegetables.

Csdpfxorwn Hbe Afpogn

Listing

Rosmalen

Rosmalen

7,545 km

Window production line

WEINIGConturex C4500

Call

Condition: good (used), Year of construction: 2011, Weinig Conturex C4500 CNC Window production machine

Description;

Year of construction: 2011

Working width 25-260mm

Working heigth 10-150mm

Powergrip clamping table 3.000 mm

Workpiece length 180-4500 mm

First processing unit

- 20 kW Motor

- HSK 63F toolholder

- Speed electr. adjustable 0-18.000 t.p.m. (left-right)

- Tooldiameter max 330 mm

- Sawblade diameter 280 mm

- Toolwarehouse 18 positions (100mm distance)

Second processing unit

- 20 kW Motor

- HSK 63F toolholder

- Speed electr. adjustable 0-18.000 t.p.m. (left-right)

- Tooldiameter max 330 mm

Csdpeydkzxefx Afpjgn

- Sawblade diameter 280 mm

- Toolwarehouse 18 positions (100mm distance)

Powergrip outfeed

Tool warehouse 110 positions (87,5 mm distance)

Waste conveyorbelt

Full description on request

Available approx. wk 30/31 - 2026

(Despite our great care all changes, mistakes in technical data, prices and all information is subject to (typing) errors. No guarantee on printed data!

Availability subject to prior sales).

(Alle Änderungen und Irrtümer in den technischen Daten, Angaben und Preisen vorbehalten! Keine Garantie auf gedruckte Daten!.

Verfügbarkeit vorbehaltlich Zwischenverkauf).

Prices excl. advertisement cost MachineSeeker / Preise exkl. Inserierungskosten MaschinenSucher

Best woodworkingmachines from the Netherlands Holland

Die besten holzbearbeitungsmaschinen aus die Niederlande

De beste gebruikte machines uit Nederland

Listing

Switzerland

Switzerland

8,269 km

Used Aseptic Fllling Line SIPA GEA for milk up to 48.000 bph

AERZEN

Call

Condition: used, Year of construction: 2018, operating hours: 900 h, machine/vehicle number: LC524, Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph

GEA ASEPTIC BLOW FILL SYSTEM ABF 2.0

Fully aseptic blowing, filling and capping system featuring H2O2-based preforms sterilization.

Introduction to the Aseptic Filling Line SIPA GEA for Milk up to 48,000 bhp

The used aseptic filling line SIPA GEA for milk up to 48,000 bottles per hour delivers a highly efficient and technologically advanced solution for the packaging industry. Specifically, this system ensures high-quality standards and food safety by using machines from 2018. Moreover, it processes milk in 235 ml bottles with plastic screw caps and a 38 mm neck. The line has only 900 operating hours.

SIPA SFR 24 EVO Blow Molding Machine of SIPA and GEA aseptic line

The SIPA SFR 24 EVO blow molding machine, manufactured by GEA in 2018, produces high-quality bottles from PET preforms. As a result, it maintains continuous and uninterrupted production, ensuring efficiency. In addition, the SFR 24 EVO model optimizes energy consumption and shapes containers with precision, making it ideal for high-performance lines like the Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph.

GEA Filling Machine

Csdpfx Ajyhcivefpegn

The GEA filling machine, also from 2018, controls the core of the system. Since it fills milk in an aseptic environment, it preserves the organoleptic and microbiological properties of the product. Furthermore, the SIPA and GEA aseptic line doses the product with precision and operates reliably, reducing waste and improving overall efficiency. Consequently, it enhances productivity while maintaining strict hygiene standards.

Arol Capping Machine for Secure Sealing

The Arol capping machine, built in 2018, securely seals bottles with plastic screw caps. Likewise, it ensures a tight closure and matches the 38 mm neck perfectly. As a result, its integration into the line guarantees fast and uniform capping, preventing leaks and maintaining product integrity.

Aerzen GM25S Compressor

The Aerzen GM25S compressor, from 2018, powers the blow molding process. In particular, it supplies high-quality compressed air, which the machine requires for shaping PET bottles. Notably, its efficiency and reliability support seamless production. Therefore, it plays a crucial role in maintaining high-speed output.

Operational Condition and Limited Use

The Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph processed only around a hundred production cycles, keeping the machines in excellent condition. Thus, the limited use ensures optimal performance and minimizes wear, making this system nearly new in operational terms. Additionally, well-maintained components extend the machine’s lifespan, reducing the need for costly replacements.

Line Efficiency and Performance

The Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph combines high-performance machines designed specifically for milk processing. Consequently, it enables fast and efficient production while meeting strict aseptic standards. Moreover, the line reaches speeds of up to 48,000 bottles per hour, making it a strategic choice for producers competing in high-demand markets. Similarly, it supports companies looking to improve productivit...

Listing

Italy

Italy

8,269 km

Used Olive Oil Processing Line 350 kg-h

Toscana Enologica Mori

Call

Condition: used, Year of construction: 2001, operating hours: 962 h, machine/vehicle number: LC535, Technical Specifications & Performance Data

This used bottling line from Toscana Enologica Mori is designed around an olive oil processing capacity of up to 350 kg/h, making it a robust, second hand solution for producers seeking reliable industrial packaging performance with premium edible oils. Upstream extraction throughput is matched with downstream packaging compatibility for small to medium bottling speeds, depending on the filler selected.

Rated upstream capacity: approx. 350 kg/h (olive processing)

Product handled: Olive oil and other still, non-carbonated edible oils

Container materials: Glass, PET, aluminum/tinplate cans; optional bag-in-box integration

Bottle/can formats: Typical range from 100 ml to 1 L bottles; cans up to 5 L (format dependent)

Filling compatibility: Supports integration of gravity, vacuum, or flowmeter/mass-flow systems

Cgedpfx Afoyhch Eopon

Fill type flexibility: Up to two fill-type configurations can be supported to suit product viscosity and format

Capping options: ROPP aluminum caps, plastic screw caps, tamper-evident pourers

Labeling options: Self-adhesive (PSL), hot-melt wrap-around, or neck/body label combinations

Construction: Hygienic stainless-steel contact parts for food-grade operation

Advanced Automation & Control Systems

The line features centralized controls for consistent, repeatable packaging quality in beverage production environments handling still liquids. Automation elements are designed to minimize operator intervention while enabling fine process control.

Control panel: Centralized operator interface with PLC-based logic and recipe management

Automation: Variable speed drives for conveyors and pumps; level, presence, and jam detection sensors

Electrical: Standard industrial 3-phase connection (e.g., 400 V, 50 Hz); installed power per module available in the manuals

Safety: Fully guarded with interlocks, emergency stops, and lockable main disconnect; safety features included

Documentation: Manuals available for setup, operation, and maintenance

Production Line Integration Capabilities

Engineered for seamless integration, the line can interface with upstream processing modules and downstream packaging components common to a modern used bottling line.

Upstream compatibility: Washers, crushers/destoners, malaxers, decanters, separators, and buffer tanks

Downstream compatibility: Rinsers, fillers, cappers, labelers, inkjet/laser coders, case packers, and palletizing

Format changeovers: Quick-change parts for caps and guides; recipe-driven adjustments for speeds and dwell times

Conveying: Modular conveyors with accumulation options for steady flow and reduced micro-stops

Machine Condition & Maintenance History

Year of manufacture: 2001. Current status: READY FOR OPERATION. This second hand system presents with standard cosmetic wear consistent with age, with core functi...

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Pieralisi Used Complete Line Jumbo 3 2000 for oil production - 3 tons per hour

PieralisiJUMBO 3

Call

Condition: used, Year of construction: 2000, machine/vehicle number: LC590, Technical Specifications & Performance Data

This second hand complete oil production line is engineered for continuous olive oil extraction with industrial reliability and efficiency. Designed and manufactured by Pieralisi, the JUMBO 3 configuration delivers consistent throughput for food-grade processing and can be integrated downstream with bottling equipment for industrial packaging operations.

Manufacturer: Pieralisi

Model: JUMBO 3

Production capacity: 3 tons per hour

Application: Edible oil extraction and clarification

Line composition: Leaf remover, washer, crusher, malaxers (7 units total), decanter, separator, conveyors

Year of manufacture: 2000

Configuration: Complete process line, suitable for integration with a used bottling line for final packaging

Advanced Automation & Control Systems

The Pieralisi JUMBO 3 platform is known for robust process control across extraction stages. The line supports synchronized operation from fruit preparation through separation, ensuring stable throughput and repeatable quality. Quick adjustments on the malaxers and decanter support optimization for different olive batches and temperatures.

Process-stage synchronization for steady 3 t/h throughput

Adjustable malaxing parameters for yield and quality optimization

Consistent separation and clarification via decanter and final separator

Operator-friendly controls supporting safe and reliable operation

Production Line Integration Capabilities

Engineered as a complete process solution, this second hand line interfaces easily with upstream fruit intake and downstream industrial packaging or bottling equipment. Conveyors enable smooth material handling between stages, while modular elements facilitate format and process adjustments.

Inline integration with depitting, storage, and bottling/packaging lines

Conveyor-based transfers between preparation, malaxing, and separation

Flexible setup for edible oil production workflows

Machine Condition & Maintenance History

The complete line has been dismantled and stored. Components are complete as listed, ready for inspection and recommissioning at the new site.

Operational status: dismantled and in storage

Complete core components included as listed

Operational Performance & Versatility

With a 3 tons per hour capacity, the line delivers stable performance across critical stages of oil extraction. The seven malaxers provide thermal and residence-time flexibility to balance yield and flavor profile. The decanter and final separator ensure efficient solids-liquid separation and product clarity suitable for edible oil standards.

High-throughput crusher feeding multiple malaxers

Seven malaxers: 2 double and 3 single units (7 malaxing sections total)

Cgodpfxoyhb Aus Afpon

Decanter centrifuge for primary separation

Final separator for polishing and clarity

Installation Requirements & Site Preparation

Recommissioning requires appropriate floor space for the process modules and conveyors, utility hookups, and material flow planning from fruit reception to clarified oil storage an...

Listing

Italy

Italy

8,269 km

Used complete isobaric glass line for wine - 2000BPH

Cobert

Call

Condition: used, operating hours: 3,000 h, machine/vehicle number: LC595, Technical Specifications & Performance Data

This used bottling line is configured for glass bottle handling and combines proven European packaging machinery for efficient beverage production. It integrates a filling machine, wirehooder, pasteurizer, case sealer, and auxiliary equipment to support end-to-end industrial packaging operations. Ideal for second hand acquisition, the line offers reliable performance with CE-marked components and a balanced mix of capacities for medium-scale beverage production.

Containers: Designed for Glass bottle handling

Key equipment and models: cobert SUPREMA filling machine; ROBINO & GALANDRINO VITTORIA 83 wirehooder; RIVI Engineering mesh pasteurizer 1P; SIAT SM11-S case sealer; OMAC lobe pump; FACCIO G. cork orienter

Component years: 1986 (wirehooder), 1993 (pasteurizer), 2007 (case sealer), 2008 (cork orienter)

Pasteurizer capacity indicator: Mesh area 6.5 m²

Electrical data (case sealer): 380/415V, 50Hz, 3PH, 1.08A, 260W

Compliance: CE markings on components

Advanced Automation & Control Systems

The line is equipped with independent control panels per machine for flexible operation and maintenance. The SIAT SM11-S case sealer features three-phase power and fixed speed controls suited for consistent end-of-line sealing. Emergency stop controls and illuminated indicators are present on operator stations, supporting safe and efficient operation. Quick adjustments on the case sealer and dedicated orienting controls on the cork orienter streamline format setup.

Power architecture: Three-phase systems on end-of-line case sealer

HMI/controls: Dedicated operator panels on each machine

Safety: Emergency stop devices and CE-compliant guards

Production Line Integration Capabilities

Codpfx Aeyhb Ahsfpjgn

Configured for inline operation, the equipment set provides a coherent flow from filling and closure application through thermal treatment and carton sealing. The wirehooder interfaces downstream of bottle closure for sparkling applications, while the pasteurizer integrates within the thermal treatment step. End-of-line case sealing allows seamless integration with upstream conveyors and pack handling.

Inline integration between filling, closure application, pasteurization, and case handling

Auxiliary lobe pump supports product transfer and utility circulation

Cork orienter enhances closure logistics and line ergonomics

Machine Condition & Maintenance History

The line comprises robust, industry-standard machinery known for long service life and maintainability. Components display CE compliance and typical operator safety features. Offered as a second hand configuration, it is presented as ready for operation subject to standard installation, commissioning, and routine checks according to manufacturer guidelines.

Operational Performance & Versatility

Designed for glass bottle beverage production, the equipment supports core processes including filling, wirehood application, thermal pasteurization, and secondary packaging. The dedicated cork orienter and wirehooder streamline sparkling or specialty product closures, while the end-of-line case s...

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Used Filling Line For Edible Oil In PET 1L Bottles

ICS

Call

Condition: used, Year of construction: 2000, machine/vehicle number: LC348, Used Filling Line For Edible Oil In PET 1L Bottles

Capacity: 6.000 bph x 1,0 L

Blow Molding Machine

KOSME KSB 3000 – 2001. – 2 pcs x 3.900 bph

Box for preforms with transport to the blower

Compressor for cooling moulds MTA S.R.L. – 2000

KOSME bottle air conveyor – 1999

AISI 304 stainless steel

Electrical control cabinet with PLC

Built-in air filters

Codpeyhbzdsfx Afpegn

It transports bottles from blower to filler

Filling Monoblock

Filler and capper – ICS-Slovenia – 1995 – 6.000 L/h

Labelling Machine

Labeller ICS – 1995 – paper labels, cold glue

Conveyor belts ICS – 1995

Packer in transport boxes 3×5 bottles – ICS – 1995

Shrink Wrapper

Shrink wrapper SMIPACK-packer in foil 2×5 bottles – 2013

Pallet Wrapper

Pallet wrapper ZLATOROG-Slovenia – 1999

Compressor

KAESER low and high pressure compressors – 2000

Refrigeration dryer

There are spare parts worth

It has complete technical documentation

Required space for equipment: 600 m2

Required installed power (equipment, compressors, refrigerators): 495 kW

The Used Filling Line For Edible Oil In PET can be seen in full production function until December 15, 2022

Listing

Netherlands

Netherlands

8,269 km

Used complete CSD can bottling line – 14,000 cans/hour

Call

Condition: used, Year of construction: 2011, operating hours: 35,000 h, machine/vehicle number: LC581, Used Complete CSD Can Bottling Line – 14,000 cans/hour – Overview

This second hand, complete CSD can bottling line is engineered for carbonated soft drink (CSD) beverage production and industrial packaging at up to 14,000 cans per hour on 250 ml format. The core of the line is an Ortmann Herbst isobaric can filler with 45 valves, paired with a Ferrum 706 6-head can seamer (can ends size 200). The scope includes depalletizing, can washing, filling and seaming, tunnel pasteurization, in-line inspection, coding, secondary packaging, palletizing, and end-of-line handling, providing a turnkey used bottling line solution.

Technical Specifications & Performance Data

Core Monoblock: Can Filler–Seamer

Filler: Ortmann Herbst, isobaric, 45 valves (year: 1980)

Seamer: Ferrum 706, 6 heads (year: 1982)

Product type: Carbonated soft drinks (CSD)

Nominal capacity: 14,000 cans/hour on 250 ml

Can end: 200 end (industry size 200)

Monoblock configuration: filler–seamer integrated block for minimized DO pickup

Csdpeyhbpzsfx Afpogn

Formats & Throughput

Primary can size: 250 ml

Line speed: up to 14,000 cph (format- and product-dependent)

Process Equipment Included

Kaeser compressor package with booster and two air receivers (p.y. 2010, start 2011)

CIP station, three tanks (p.y. 2011)

Syrup room with cooling system (p.y. 2011)

Nagema mixer (p.y. 1992)

Five ready-to-drink tanks, 100 hl each, steel with food-grade lining

Beverage filter (p.y. 2011)

Frezart can depalletizer (p.y. 2009, start 2011)

Two can washers adapted to 250 ml (p.y. 2011)

Hermis tunnel pasteurizer (p.y. 2015)

Stratec can fill level inspector (p.y. 2000)

Victor can printer / coder (p.y. 2020)

Kisters packaging machine (p.y. 1993)

Keber palletizer (p.y. 1997)

Sita pallet wrapper (p.y. 2011)

Complete conveyor system interconnecting all machines + two can accumulation turntables (p.y. 2011)

Thermo-shrink labeling line for blank cans (p.y. 2015)

Advanced Automation & Control Systems

In-line quality control: Stratec can fill-level inspection for continuous monitoring and reject of out-of-spec containers

Product identification: Victor industrial can printer for date/lot coding

CIP capability: three-tank CIP station supports hygienic cleaning cycles for filler and product pathways

Integrated conveying and accumulation: conveyors with two turntables provide smooth flow and buffer management to protect uptime

Detailed electrical and controls documentation is available on request.

Production Line Integration Capabilities

Upstream

Depalletizing of empty cans (Frezart) and transfer to washing

Dual can washers adapted for 250 ml format

Syrup room with cooling, beverage filtration, and mixing (Nagema) for consistent syrup preparation

Compressed air supply package (Kaeser) with booster and storage

Filling & Seaming

Isobaric filling with 45-valve Ortmann Herbst filler ensures stable carbonation retention

Ferrum 706 can seamer with 6 heads for reliable double seam integrity on 200 ends

Downstream

Hermis tunnel pa...

Listing

Georgia

Georgia

8,269 km

Used complete filling Krones CSD PET line – 22.000 bph

GEA

Call

Condition: used, Year of construction: 2010, operating hours: 47,000 h, machine/vehicle number: LC582, Used Complete Krones CSD PET Bottling Line – 22,000 BPH – Overview

This second hand, ultra-clean Krones CSD PET bottling line is a complete, high-efficiency solution for beverage production and industrial packaging across carbonated soft drinks, cider, sparkling water, still water and CO2-mixed juices. Built by Krones and GEA in 2010 and kept in production with OEM service, the line delivers up to 22,000 bottles per hour (0.5 L) and 18,000 bph (1.5 L), combining a Contiform S12M blow molder directly coupled to an ultra-clean isobaric filler-capper bloc. It is a market-ready used bottling line designed for reliability, hygiene, and quick format changeovers in PET.

Technical Specifications & Performance Data

Manufacturer: Krones and GEA

Year of manufacture: 2010

Working hours: approx. 47,000

Nominal capacity: 22,000 bph (0.5 L) | 18,000 bph (1.5 L)

Products handled: carbonated soft drinks, cider, sparkling water, still water, juices with CO2

Filling technology: Ultra-clean, isobaric, volumetric PET filling

Current product: Apple juice with water and CO2

Neck finishes: PCO 1810, PSO 28 mm, 1810/1881 short neck

Controls: Siemens Simatic S7 PLC platform

Main Equipment Scope

CIP: Krones VarioClean F AUT fully automatic CIP system, 4 x 5000 L, 30 m³/h

Process: GEA TDS plant with flash pasteurizer, mixer, carbonator, degasser and process tanks

Preforms: Preform tipper/kipper and feeding conveyors; Krones Contifeed RS preform feeding system; Prejet Linear preform cleaning unit

Caps: Cassner cap feeding with cap rinsing and sterilization

Blow molder: Krones Contiform S12M, directly connected to the ultra-clean bloc (no air conveyor)

Filler/Capper bloc: Krones Volumetric VODM-PET 2.160-66-103 with integrated capper; Krones Vario Dos filler-bloc cleaning

Coding and inspection: Domino DDC 3 laser coder; Krones Checkmat 731 FM-X+L filling level inspector; Krones Checkmat 731 EM label inspector

Conveying and testing: SYNCO bottle conveyors; Krones Flowliner bottle leak tester

Labeller: Krones Contiroll OPP 720-15, double roll-feed wrap-around labels with hot glue

Secondary packaging: Krones VarioPro FS shrink–tray packer; Krones Multico S packet conveyors; Twin Pack handle applicator

Pack coding: Leisinger Jet 3 ink coder

Palletizing: Krones Robopox Modulpal (2016)

Advanced Automation & Control Systems

Line Control & PLC

Siemens Simatic S7-series PLC for coordinated line control, interlocks and diagnostics

Integrated filler-bloc cleaning via Krones Vario Dos for validated ultra-clean cycles

Recipe and parameter management supporting fast changeovers between PET formats

Quality Assurance & Traceability

Laser date coding (Domino DDC 3) on primary packaging; inkjet coding (Leisinger Jet 3) on packs

In-line inspection with Krones Checkmat systems for fill level and label presence/position

Leak detection via Krones Flowliner for container integrity

Production Line Integration Capabilities

Upstream (Preforms to Bottles)

Automated preform handling: tipper, conveyors and Krones Contifeed RS for steady feed

Preform cleaning (Prejet Linear) to protect blowing ...

Cjdjyhbmtspfx Afpsgn

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Used complete bottling line for CSD in PET and glass - 8000 bph

Atlanta

Call

Condition: used, Year of construction: 2019, machine/vehicle number: LC591, Technical Specifications & Performance Data

This complete used bottling line is engineered for beverage production with PET and glass bottles. Optimized for water and carbonated soft drinks, it combines reliable filling, labeling, and end-of-line packaging with robust utilities and process equipment. The line integrates components from reputable manufacturers to deliver consistent quality and uptime in industrial packaging environments.

Production speed: up to 8,000 bottles per hour

Compatible bottle formats: 0.33L, 0.5L, 0.75L, 1.0L, 1.5L, 2.0L

Containers: PET and Glass bottles

Main filler/capper/rinser: Sinkrofill 40/50/10/10, 50 filling heads, 3–5 capping heads

Blow molder: Easy Blow 4L (4,200 bph nominal)

Labelers: Gernep Rollfed 8-480-1RA (foil/OPP) and Gernep Soluta 10-640 3SK (paper), up to 10,000 bph

Pack & handle application: SMI LSK 30 T Ergon shrink wrapper, SMI Pack HA-25 SX handle applicator

Pallet logistics: Sinkrotech APM-6000-JU palletizer; Atlanta Mytho-A pallet wrapper; auxiliary manual wrapper

Process & utilities: GEA pasteurization station HTF 3000PIN/19; GEA CIP station; Trane Tracer CH535 CGAX/SXAX chiller; Therminus steam boiler (456 kW); Kaeser compressors (CSDX 165 and N 502-G boosters)

Inspection & coding: FT System control for volume/cap/label; Hitachi UX printer

Advanced Automation & Control Systems

The line features modern automation and quality assurance for stable operation and repeatable product quality. A PLC-controlled architecture coordinates rinsing, filling, capping, labeling, and packaging, while inline inspection and coding ensure compliance and traceability.

PLC/HMI: PLC installed for centralized control and recipe management

Inspection: FT System for volume, cap presence/position, and label verification

Electrical: 400V, 50 Hz, 16A reference (component level)

Coding: Hitachi UX inkjet printer for date/lot marking

Changeovers: Designed for multiple bottle formats across PET and glass

Safety: Standard guarding and emergency-stop circuits across stations

Production Line Integration Capabilities

Built for flexible beverage production, the line integrates upstream preform handling and blow molding with downstream conveying, labeling, and packaging. Vetromeccanica air conveyors and line conveyors provide smooth bottle transport and accumulation.

Upstream: Preform conveyor and hopper, Easy Blow 4L blow molder

Conveyors: Vetromeccanica Eolo air and line conveyor systems

Format flexibility: 0.33L to 2.0L across PET and glass

End-of-line: Shrink packaging, handle application, palletizing, and pallet wrapping

Utilities integration: Chiller, steam boiler, compressors, air tanks, water treatment

Machine Condition & Maintenance History

The used bottling line remains in production and can be started during an on-site visit for demonstration. Manuals an...

Cgedpfsyhbibox Afpon

Listing

Italy

Italy

8,269 km

Used complete line for still wine - 5000 BPH

MAS PACK

Call

Condition: used, machine/vehicle number: LC596, Technical Specifications & Performance Data

This used bottling line is configured for glass bottle handling with a comprehensive sequence from filtration to case packing and palletizing. It is a second hand solution engineered for industrial packaging and beverage production, integrating well-known European manufacturers. The configuration covers rinsing, filling, capping (flush cork and aluminum), capsule application (heat-shrink and polylaminate), adhesive labeling, and end-of-line packaging.

Container type: Glass bottles

Core monoblock: MBF Syncrofill 1200.25/1200.30LV/360.4SR/240.4AV/240 (rinsing–filling–capping)

Filtering: Seitz Orion plate filtration group

Bottle preparation: SICK Blancamat 8 bottle washer (pre-labeling)

Capsule application: Nortan Prisma 40 (heat-shrink), Robino & Galandrino Astra 6 (polylaminate)

Labeling: Cavagnino & Gatti CG E8-4-2NPS (3 stations: front/back/neck), Pago PAG.876 carton labeler

Conveying/accumulation: MBF accumulation table (conveyor)

Case handling (option set 1): Bortolin & Kemo FOC 23 30 case erector, MA 88/1 divider inserter, IAM 2T AP case packer, MARA HM case sealer, PAC 2000 palletizer

Case handling (option set 2): Mas Pack MAS 1200 case erector (400 Vac, 2 kW), Mas Pack Minipack 21/4 case packer (400 Vac, 6 kW), Mas Pack Seal 1200 case sealer, Mas Pack Exacta R Astride divider inserter

Auxiliary equipment: PREO E0P051 4R2 hotmelt units, Ber PDC 30 carton scale

Cgjdpfeyhbhqjx Afpon

Selected component years: 2011 (Mas Pack MAS 1200, Seal 1200), 2015 (Mas Pack Minipack 21/4, Exacta R Astride), 2001 (Ber PDC 30)

Certifications: CE markings on Mas Pack modules

Advanced Automation & Control Systems

The line combines automated capsule application, adhesive labeling with multi-station control, and end-of-line carton forming, gluing, and packing. Modules feature integrated safety circuits and CE-compliant controls. Hotmelt application is handled by PREO melters for reliable carton sealing. Quick adjustments across labeling stations and format handling enable efficient changeovers within glass bottle families.

Adhesive labeling with 3-station control for front/back/neck labels

Automated heat-shrink and polylaminate capsule application

Hotmelt application via PREO E0P051 4R2 units

CE-compliant electrical panels on Mas Pack packaging modules

Operator-friendly HMI/controls at packaging stations (per module)

Production Line Integration Capabilities

Designed for inline operation, the system integrates filtration, monoblock rinsing–filling–capping, labeling, and complete end-of-line packaging. The conveyorized accumulation table assists with buffer management for steady flow between wet and dry ends. The end-of-line can be configured with either Bortolin & Kemo or Mas Pack equipment to match site preferences and spare parts policy.

Inline glass bottle processing from filtration to palletizing

Format changeovers supported across labeling and capsule application

Compatible with divider inserters for 6-bottle patterns

Carto...

Listing

Zevenbergen

Zevenbergen

7,503 km

CNC Hor. Production line with 14 pallets

MazakFH 880 PMC

Call

Condition: used, Year of construction: 1997, travel distance X-axis: 1,300 mm, travel distance Y-axis: 1,100 mm, travel distance Z-axis: 1,000 mm, controller manufacturer: Mazatrol, controller model: M-Plus, overall weight: 36,000 kg, tool weight: 2,200 g, CNC Horizontal Machining Centre with Palletech

Table size 800 x 800 mm.

Cgjdpfx Afsyddfdspsn

Table NCRT.

Number of pallets 14.

Movement x-Axis 1300 mm.

y-Axis 1100 mm.

z-Axis 1000 mm.

Table indexing 0,001°.

Number of tools in magazine 237 pieces.

Maximum spindle speed 35-7.000 min.

Tool taper DIN 69871A-50.

CNC control M-plus

If you have any questions concerning the machine, please do not hesitate to contact us by phone or e-mail.

Feel free to view our other advertisements for a complete overview of our stock.

Listing

Wiefelstede

Wiefelstede

7,607 km

Reinforcing steel mesh bending machine 3.1 m semi-automatic

MBSMBM 030

Call

Condition: good (used), Year of construction: 2000, Reinforcing steel mesh bending machine, bending machine for reinforcing steel mesh

-Manufacturer: MBS, Reinforcing steel mesh bending machine type MBM 030

-Passage width: 3120 mm

-Operation: Foot switch, semi-automatic

Cgsdpfx Aoydpndofpon

-Dimensions: 720/3965/H1140 mm

-Weight: 1170 kg

Listing

Pollenzo

Pollenzo

8,138 km

Drilling Line

PRIESSBMA DLS-CNC

Call

Condition: used, machine/vehicle number: 006500, Position 1: Vertical Storage Systems PRIESS-BMA DLS-CNC

Position 2: CNC for Flexible Drilling PRIESS-BMA DLS-CNC

Position 3: CNC Flexible Drilling & Inserting PRIESS-BMA DLS-CNC

Position 4: CNC Flexible Drilling & Inserting PRIESS-BMA DLS-CNC

Csdpfx Ajwucmvofpjgn

Position 5: Brushing Machines PRIESS-BMA DLS-CNC

Position 6: Roller Conveyors PRIESS-BMA DLS-CNC

Trust Seal

Dealers certified through Machineseeker

Listing

Iserlohn

Iserlohn

7,695 km

Welding machine

DALEXVARIO MIC 400L

Call

Condition: excellent (used), Year of construction: 1999, Welding machine make DALEX Type:VARIO MIC 400L year 1999

in very good condition, little used.

Cjdpfxefgvvas Afpjgn

Listing

Hauzenberg

Hauzenberg

8,224 km

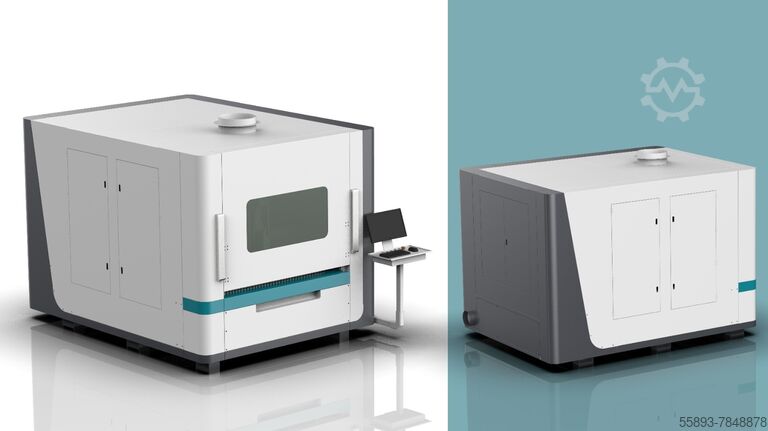

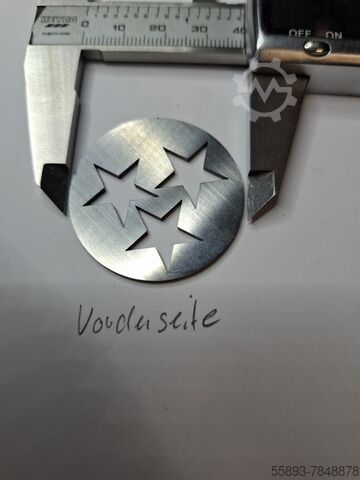

Laser cutting machine

Ledi LaserLG-1530 6kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 6,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 30 mm, sheet thickness stainless steel (max.): 15 mm, sheet thickness aluminum (max.): 12 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 3,000 mm, door opening height: 600 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 6kW fiber laser

Delivery time: approx. 6-8 weeks

Our commitment is to provide highly precise, long-term stable, yet cost-effective laser machines.

Our machines are ideal for workshops and repair businesses.

A perfectly developed cutting parameters library is included in the delivery, as well as first-class service.

Please also consider our attractive leasing/loan purchase offers.

- Machine without automatic shuttle table!

Loading takes place on the long side of the machine

- Very space-saving

- Extremely energy-efficient cutting system

- Requires only approx. 4 x 4.5 meters of floor space

- 6kW laser source from MaxPhotonics (G5/German configuration)

- Laser generator with wall-plug efficiency exceeding 30%

- Suitable for aluminum

- Top quality – book your inspection now!

Cutting capacity:

- Steel sheet up to 30 mm (maximum)

- Stainless steel sheet up to 15 mm (maximum)

- Aluminum sheet up to 12 mm (maximum)

- Brass sheet up to 8 mm (maximum)

- Travel range: 1500 x 3000 mm (for large format)

- Machine control system in German

- Safety light curtain for maximum operator protection

- Extensive collision protection measures for the cutting head

- Large laser safety windows for process observation

- Comprehensive cutting parameter library

- Incl. nesting module

- Very easy to operate

- Powerful laser chiller

- Machine control system in German

- German service and spare parts supply

- Powerful laser chiller

Csdpfxexw T Nke Afpogn

- Exhaust filter system optionally available (5.5kW with frequency converter for pleasantly quiet operation)

Leasing or hire purchase possible through our financing partner.

Sale only to commercial customers.

Delivery / consulting / sales only within Germany, Austria, and Switzerland.

Machine dimensions approx.:

Length: 4.0 m

Height: 2.3 m

Width: 4.5 m

Total weight: approx. 4500 kg

Need different laser power, table design, or table size? No problem.

I would be happy to make you a suitable offer.

For example, 2kW machine from 29,990 euro

Not sure which laser power suits your application?

Of course, I can perform cutting trials according to your requirements. Much is possible here.

Listing

Hauzenberg

Hauzenberg

8,224 km

Laser cutting machine

LD-LaserLG-1325 3kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: Max Photonics, laser power: 3,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 22 mm, sheet thickness stainless steel (max.): 12 mm, sheet thickness aluminum (max.): 12 mm, table width: 1,300 mm, travel distance X-axis: 2,550 mm, travel distance Y-axis: 1,260 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 2,600 mm, door opening height: 1,000 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, new laser cutting machine with 3kW fiber laser

Our goal is to offer high-precision, long-term stable, and yet affordable laser machines. Our machines are ideal for workshops and repair businesses. A perfectly developed cutting parameter library is included, as is first-class service.

Please also take note of our attractive leasing and hire-purchase offers.

- Machine without automatic shuttle table

- Very space-saving design

Cgjdpfxoxa Ahns Afpjn

- Extremely energy-efficient cutting system

- Only about 4 x 4 meters installation area required

- 3kW laser source from MaxPhotonics (G5/German configuration) – suitable for aluminum

- Top quality, schedule a viewing now!

Cutting capacities:

- Mild steel up to 22mm

- Stainless steel up to 12mm

- Aluminum up to 12mm

- Brass up to 5mm

- Travel range: 1260 x 2550mm (suitable for medium-size sheets)

- Machine control interface in German

- Safety light curtain for maximum operator protection

- Extensive collision protection for the cutting head

- Large laser protection window for process observation

- 3-gas selection (compressed air, nitrogen, oxygen)

- Extensive cutting parameters library

- Including nesting module

- Very easy to operate

- Powerful laser chiller

- German service and spare parts availability

- Extraction/filter system optionally available (5.5kW with frequency converter for exceptionally quiet operation)

Leasing and hire-purchase available via our financing partner

Sale exclusively to commercial customers. Delivery / consulting / sales only in Germany / Austria / Switzerland.

Machine dimensions approx.:

Length: 4.0m

Height: 2.3m

Width: 4.0m

Total weight: approx. 3500kg

Need different laser power, table configuration, or table size?

No problem. I am happy to prepare a tailored offer.

Example: 2kW machine from €29,990

Not sure which laser power is right for your application? Of course, I can perform cutting trials according to your requirements. There is a wide range of possibilities.

Listing

Hauzenberg

Hauzenberg

8,224 km

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser Ecoline

Our commitment is to offer highly precise, long-term stable, yet affordable laser machines.

Our machines are ideal for workshops and repair businesses. Included in delivery is a perfectly optimized cutting parameter library as well as first-class service support.

Please also take note of our attractive leasing and hire-purchase offers.

Cost-effective Entry Into Laser Cutting Technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approximately 3.0 x 3.0 meters of installation space

- Top quality – schedule a viewing now!

Cutting capacity:

- Mild steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

- Travel range: approx. 1300 x 1300mm

- Support table size: approx. 1300 x 2500mm (allows for full mid-format sheet loading)

- Machine control in German

- Manual front door

- Comprehensive collision protection measures

- Large front viewing window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

- Extensive cutting parameter database

- Incl. nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy to operate

- Powerful laser chiller

Sale exclusively to commercial customers.

Delivery / consulting / sales only within Germany / Austria / Switzerland.

Machine dimensions (approx.):

Width: 3.2 m

Height: 2.3 m

Length: 3.3 m

Total weight: approx. 2,800 kg

Need a different laser power, table design, or table size?

No problem. I am happy to provide a customized quotation.

Cgjdpfxoitu Srs Afpjn

Not sure which laser power is suitable for your application?

We are happy to conduct test cuts based on your requirements. Wide range available – from 0.5 kW up to 20 kW laser power.

We make it easier for you to find: "mesh welding line"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Mesh Welding Line (14,757)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you