Used Solvent Recovery for sale (695)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Germany

Germany

7,870 km

Flexo Printing Machine

Fischer & KreckeFlexpress 16S-8

Call

Condition: ready for operation (used), Year of construction: 2005, A complete 8-color Fischer & Krecke flexographic printing system is available. Number of colors: 8, max. print width: 1250mm, max. material width: 1300mm, repeat print length min./max.: 320mm/800mm, max. mechanical speed: 360m/min, printable materials: PET (min. 12µm)/PP/OPP/LDPE/laminate materials. Inks: solvent-based, drying: thermal oil. Roll diameter: 800mm, core diameter: 76mm/152mm. Including BST Video Web Inspection System Premius, cleaning system Flexpress AutoClean (ACA), viscosity control Bloss Viscolor 1300, automatic roll change and rewind Flying Splice as well as an additional chill roll with a diameter of 460mm. Documentation available. On-site inspection is possible.

Kljdpfevva E Hex Ab Tjn

Listing

Germany

Germany

7,870 km

Air and Fiber Management System

Trützschler/ProtecFBK 536/2400

Call

Year of construction: 1998, condition: ready for operation (used), A filter and recovery system with filling and intermediate shaft and a new control system as peripheral equipment for the production of technical nonwovens and felt is available. Components: Fan, three-phase motor WN 1 8030 T.50, condenser Erko, separator (exhauster) Erko, filling shaft, intermediate shaft. Control cabinet dimensions X/Y/Z: approx. 1200mm/600mm/2200mm, weight: approx. 300kg, year of construction: 2023, total system dimensions X/Y/Z: approx. 3150mm/1100mm/3700mm. Documentation available. On-site inspection is possible.

Ksdpfx Abeww Ivze Tjln

Listing

Germany

Germany

7,870 km

Concentration Plant

CCMAFN 454 U-S

Call

Condition: ready for operation (used), A concentrate system for thickening and concentrating liquids, typically in the production of juices, concentrates or other liquids in the food industry, is available. Evaporator: horizontal, evaporator stages: 4, operating mode: live steam, heat exchange: preheating/recovery/cooling, condensation: semi-barometric milk condensation, flavor extraction: rectification/floor column. Water evaporation: 4840kg/h, inlet quantity: 6600kg/h, inlet dry matter: 12%, outlet quantity: 1760kg/h, final dry matter: 45%, aroma recovery at 150-fold concentration: 42l/h, steam consumption: 1685kg/h, specific steam consumption: 348g/kg, fresh water consumption: approx. 12700l/h. Documentation available. On-site inspection is possible.

Klsdpjv Sugqofx Ab Ton

Listing

Germany

Germany

7,870 km

Reverse Osmosis Module

BWTPermaq Compact 51

Call

Condition: ready for operation (used), A compact and mobile BWT reverse osmosis system including integrated tank is available. Throughput capacity: approx. 160l/h, recovery (WCF): 40%-75%, salt retention rate: over 98%, permeate conductivity: below 20µS/cm, tank volume: 50l, membranes: 1. Machine dimensions X/Y/Z: approx. 350mm/560mm/750mm, weight: approx. 55kg. Documentation available. An on-site inspection is possible.

Kledpfjxc Nhysx Ab Ten

Listing

Germany

Germany

7,870 km

Stenter Frame

BrücknerSPR 2

Call

Condition: ready for operation (used), A package with a Brückner stenter frame and additional elements is available: 1) Brückner stenter frame SPR 2, 2) Goller washing machine, 3) ECO-Heat exhaust air purification system for Brückner stenter frame, 4) Foulard with Küsters control unit and hydraulic unit, 5) Pleva SL 2.1 entry straightening unit, 6) RS Scheuchl heat recovery system, 7) Pleva SL 2P exit straightening unit. An on-site inspection is possible.

Kodew R U Amopfx Ab Teln

Listing

Germany

Germany

7,870 km

Pasta Production Line

Pasta Technologies Group/PavanMASA 540/MRW 540

Call

Condition: ready for operation (used), Year of construction: 2011, A complete pasta line with 2x Cappelletti forming sets is available. 1) Pasta Technologies Group SRL dosing and mixing unit for pasta ingredients such as flour, water, and micro-ingredients. 2) Combined mixer-sheeter Pasta Technologies Group SRL MASA 540, year of manufacture: 2022, dough sheet thickness range: 7mm–8mm, dough sheet width: 540mm, corrugated rollers: 3, pairs of smooth rollers: 1. 3) 2x forming machines GEA/Pavan MRW 540, year of manufacture: 2011, pasta types: Ravioli/Cappelletti, production output Ravioli/Cappelletti: 140/120 strokes/min, dough sheet width: 540mm, machine dimensions X/Y/Z: approx. 1800mm/1700mm/1300mm, weight: approx. 1200kg, filler frame weight: approx. 210kg. Includes 2x Cappelletti tools 3D. 4) Double conveyor belt and waste recovery unit. 5) Dough scrap return system Pasta Technologies Group SRL RS100 with cyclone. 6) Complete system control and management by Pasta Technologies Group QEHD. Documentation available. An on-site inspection is possible.

Kedpfsw Dfgkex Ab Tsln

Listing

Mouscron

Mouscron

7,479 km

Digital printing machine

EpsonS80600

Call

Condition: like new (used), functionality: fully functional, resolution (max.): 1,440 dpi, total width: 2,620 mm, total height: 1,311 mm, year of last overhaul: 2025, For sale: EPSON SureColor S80600 – As good as new

This professional large-format printer was purchased new and has barely been used. The machine recently underwent a major maintenance service worth €3,500, during which all tubing was completely renewed and replaced. As a result, the printer is in excellent technical condition – ready for years of reliable operation.

The Epson SureColor S80600 delivers exceptional print quality on a wide range of materials: from standard signage to high-end displays and interior decoration. All components are designed by Epson itself for seamless operation and outstanding professional results.

Ksdpfjx H Nq Eex Ab Tsln

Eco-solvent 160: environmentally friendly ink with a roll width of 160 cm.

Listing

Legden

Legden

7,634 km

Swap body truck

MERCEDES-BENZAxor 1829 EU5 4x2 LL BDF mit Dautel LBW

Call

Condition: used, mileage: 640,000 km, power: 210 kW (285.52 HP), first registration: 12/2012, fuel type: diesel, overall weight: 18,000 kg, axle configuration: 2 axles, color: white, gearing type: mechanical, emission class: euro5, total width: 2,550 mm, total height: 4,000 mm, Equipment: ABS, air conditioning, electronic stability program (ESP), parking heater, tail-lift, * MB CD radio

* On-board computer with multifunction steering wheel

* Air conditioning

* Sun visor

* Spare wheel

----* 8-speed manual transmission

* Engine brake with constant throttle

* Rear axle differential lock

* Hill start assist

* Full air suspension

----* SAXAS MWX 74-S swap body chassis

* Dautel DS1500VA tail lift

----* Tire size front axle: 295/80R22.5

* Tire size rear axle: 295/80R22.5

* Fuel tank: 180 liters

* AdBlue tank: 75 liters

* Operating hours: 12,007 h

* Technical gross weight: 18,000 kg

* Unladen weight: 7,800 kg

Kljdpfx Abjyhuy Hj Tsn

* Permissible trailer load: 18,000 kg

* Total length: 9,480 mm

* Wheelbase: 5,400 mm

* Safety inspection due: expired

----Vehicle number: 11739----Subject to errors and prior sale----Advertising and various lettering have been digitally removed.-----We are happy to assist you with all formalities arising from the purchase of a vehicle. Simply let us know your requirements and suggestions and we will take care of the rest. Among other things, we can offer you the following services at an additional cost:----* Trade-in of your old vehicle

* TÜV / safety inspection

* Complete export processing

* Financing mediation

* Application for export license plates

* Vehicle delivery

* Vehicle registration

* Recovery and vehicle transport----YOUR VTS TEAM

Listing

Wymysłów

Wymysłów

8,235 km

ATEX industrial process pump on frame – Victor Pumpen GmbH + CEMP EX motor

Przemysłowa pompa procesowa ATEX na ramie – Victor Pumpen GmbH + silnik CEMP EXPrzemysłowa pompa procesowa ATEX na ramie – Victor Pumpen GmbH + silnik CEMP EX

Call

Condition: excellent (used), I am offering a complete industrial process pump with ATEX (EX) explosion-proof design, mounted on a robust steel skid frame. The unit is ready for immediate use in industrial installations, including hazardous (explosive) zones.

Pump manufacturer: Victor Pumpen GmbH (Germany)

Model: R40 KM6TM +2A / 88RF38+693De/6-K

Electric motor: CEMP (Italy)

• Power: 1.5 kW

• Three-phase 230/400 V

• 1,400 rpm

• Protection class IP55

• Explosion-proof execution Ex d IIB T4 Gb

• ATEX / IEC 60034 certification

Kljdpfx Aex Ndbwsb Tjn

Gearbox: Siemens – EX version

• ATEX Certificate II 2D c T120°C

• IP55

• Gear oil: CLP VG 220

• Output speed up to approx. 72 rpm

Features and equipment:

• Complete unit on mounting skid

• Coupling guard

• Connection flanges

• Pressure gauge

• Heavy-duty industrial construction

• Excellent visual condition

Applications:

The pump is designed for transferring oils, fuels, resins, adhesives, solvents, and other process media. It is ideal for use in the chemical and petrochemical industries, paint shops, EX installations, and applications requiring continuous operation and stable pressure.

Listing

Berlin

Berlin

7,943 km

Stenter Frame

MonfortsMONTEX 5000

Call

Year of construction: 2001, condition: ready for operation (used), Working width: 2200mm, number of fields: 6, with Three-Roller Foulard Beta, straightening unit Mahlo, weft unit Mahlo Movicat for punching basis weight samples, turret winder Brückner, heat recovery in the exhaust air 1x air/air stage and 1x air/water stage and electrostatic filter for cleaning the exhaust air.

Kjdpfjpy Eufsx Ab Tsln

Listing

Wald

Wald

8,005 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2021, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2021

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

Klodpfx Aotxakxsb Tjn

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Wald

Wald

8,005 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

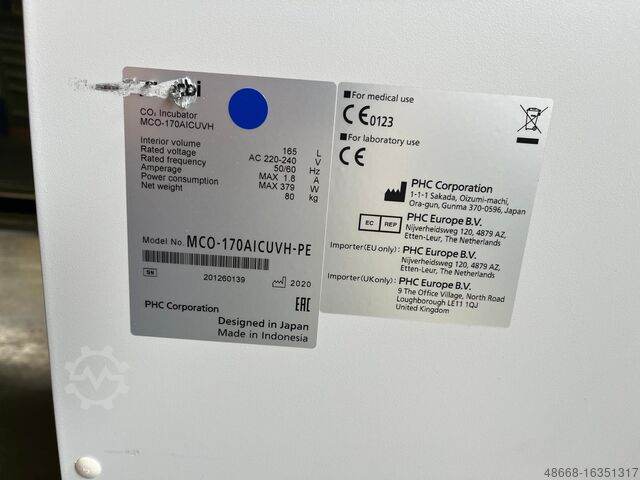

Year of construction: 2020, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2020

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions.

- Condensation control: this prevents unwanted condensation in the chamber and possible contamination.

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

Kodpfx Abetxaczs Tjln

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Wald

Wald

8,005 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2020, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2020

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

Kjdpotxarcjfx Ab Toln

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions.

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Legden

Legden

7,634 km

Minibus

SKODAOctavia Combi Scout 4x4

Call

Condition: used, mileage: 282,000 km, power: 110 kW (149.56 HP), fuel type: diesel, gearing type: automatic, first registration: 03/2019, next inspection (TÜV): 01/2026, emission class: euro6, color: grey, number of seats: 5, Equipment: ABS, air conditioning, all wheel drive, central locking, electronic stability program (ESP), immobilizer system, soot filter, Special Equipment:

Equipment Package: Light & Design, Business Package Amundsen, front and rear parking sensors, Driver Assistance System: Forward Collision Warning with City Emergency Brake (Front Radar Assist), Driver Assistance System: Adaptive Cruise Control (ACC) with Front Radar Assist (up to 160 km/h), Driver Assistance System: Drive Mode Selection, electrically operated luggage/cargo compartment cover, variable load compartment floor, rear seatback release in luggage compartment, metallic paintwork, fog lights with cornering function, LED headlights with adaptive light distribution (AFS)

Additional Equipment:

Three-point seat belts in the rear, front passenger airbag deactivatable, driver/passenger airbags, traction control (ASR), Equipment Package: Green tec, electrically adjustable and heated exterior mirrors (both sides), exterior mirrors in body color, onboard computer, brake assist, glasses compartment, roof antenna, electronic differential lock (EDS), Driver Assistance System: Hill Start Assist (Hill Holder), Driver Assistance System: automatic headlight activation (headlight assistant), rear electric windows, tinted windshield, front cup holders, leather handbrake lever grip, LED taillights, rear window wiper, interior mirror with auto-dimming function, Isofix child seat mountings on rear seat, body: 5-door, dual-zone Climatronic climate control, driver’s side knee airbag, head airbag system, rear headrests, front headrests, height-adjustable steering column (steering wheel), length-adjustable steering column (steering wheel), steering column adjustable (vertical/axial), reading light, Line-In audio input (USB) in center console, alloy wheels, rear center armrest, center console, model update, engine: 2.0 L - 110 kW TDI, engine drag torque control (MSR), multifunction display, tire repair kit, tire pressure monitoring system, split folding rear bench (1/3-2/3), low emissions Euro 6d-TEMP, rough road package, front side airbags, electronic power steering (Servotronic), height-adjustable front seatbelts, electrically adjustable driver seat (with memory), seat cover/upholstery: fabric/leather, front seat heating, left sun visor with mirror, right sun visor with mirror, 12V socket in front center console, doors with warning lights, automatic door unlocking and hazard warning light activation on impact, exterior door handles in body color, tinted glazing, lashing eyes in luggage/cargo area, seatbelt warning system front/rear, tire size front: 225/50 R 17, tire size rear: 225/50 R 17, curb weight: 1,594 kg, max. trailer load: 2,000 kg

Vehicle number: 11469—subject to errors and prior sale—advertisements and various lettering have been digitally removed.

We are happy to assist you with all formalities related to the purchase of a vehicle. Please let us know your requests and suggestions—we take care of everything. Among other things, we can offer the following services for an additional charge:

* Trade-in of your old vehicle

* TÜV / SP inspection

* Complete export processing

* Financing arrangements

* Application for export license plates

* Vehicle transport/delivery

* Vehicle registration

* Recoveries and vehicle transport

—YOUR VTS TEAM

Klodpfx Ajyhk Exjb Ton

Listing

Fröndenberg/Ruhr

Fröndenberg/Ruhr

7,692 km

Blast house, blast cabinet, sandblasting

OTI Oberflächentechnik

Call

Condition: excellent (used), Year of construction: 2008, Blast house, blast cabinet, sandblasting system

Accessible by forklift truck

There are two cabinets, one for black steel and one for stainless steel.

Kjdpfx Aoyhqdnob Teln

Complete with filter unit and recovery system

Viewing is recommended.

Listing

Iași

Iași

9,095 km

Horizontal machining center

SWBA321

Call

Condition: repair required (used), Year of construction: 2015, functionality: not functional, machine/vehicle number: 2460039, Technical specifications:

# Working area: X 300 mm; Y 500 (725) mm; Z 375 mm

# Axis configuration: 3 LINEAR AXES (X, Y, Z) + 1 rotary axis (A – rotary table with indexing head)

- Direct angular measuring system with up to 50 rpm, accuracy +/- 5”

# Maximum workpiece clamping dimension/weight: Ø575 x 830 mm / max. 360 kg

# Rapid traverse: X/Y/Z 65/75/75 m/min; Positioning accuracy Tp: 0.008 mm

# Spindle center distance: 300 mm

# Spindle speed: 1 – 17,500 rpm

# Spindle interface: DIN 69893-HSK-A63 (with internal coolant supply)

# Automatic tool changer: 2 x 32 tools; chip-to-chip average time: 2.5 sec

# Maximum tool dimensions: Ø75 mm / length: max. 275 mm / up to 7.5 kg

Electrical data:

# Mains voltage: 3x400V / 50Hz

# Connected load: approx. 85 kVA / 125A

Ksdpfexxrnbox Ab Tjln

Dimensions:

# Installation area: approx. 3.6 x 6 x 3.7 m

# Weight: approx. 10,500 kg

Equipment includes:

# CNC control: Siemens 840D SL

# Linear measuring systems: Heidenhain linear scales

# Chip extractor: Knoll Type 550 K-1

# Oil cooling system

# Cooling system for shaft, guides, and control cabinet

# 2 oil lubrication systems

# Oil filtration system (up to 80 bar): Knoll VRF450-2450 (can supply 2 machines simultaneously)

# Oil vapor extraction/recovery system: IFS Vario E2000 (2,000 m³/h)

# Fire suppression system: Kraft & Bauer

# Part detection P/Y: with low-pressure air monitors

# In-process measurement: Marposs T25

# Tool breakage detection and length measurement: inductive sensor

# Tool presence monitoring in spindle

Machine status: NOT OPERATIONAL

- Spindle tool and part presence sensors

- Tool breakage sensors

- Tool magazine piston and slide system door open/close (2 units)

- Tool magazine pistons and tool retainer slide system (2 units)

- A-axis position encoder

- Inductive and magnetic sensors (4 units each)

- Chip extraction conveyor requires repair

- Chiller for spindle cooling/heat exchanger

- Communication module Murr

- X axis linear scale

- Emulsion chip conveyor level sensor

- Hydraulic pump

- Motor for hydraulic pump (repairable)

- Heat exchanger unit

- Electric Siemens contactors for electrical cabinet (3 units)

- Safety door lock Euchner

- Emulsion filtration unit is shared with another machine (SW BA321 2460038)

Note: Machine is NOT WORKING and offered as described.

Listing

Iași

Iași

9,095 km

Vertical machining center

FANUCA04B-0102-B133#BBH

Call

Condition: repair required (used), Year of construction: 2017, functionality: not functional, machine/vehicle number: P177ZG753, Technical characteristics:

# Machining Workspace: X 500 mm; Y 400 mm; Z 330 mm

# Axis Description: 3 LINEAR AXES (X, Y, Z) + 1 rotary table axis (A-axis) with index dividing head, direct angular measurement system, number of revolutions 50 min⁻¹, accuracy +/- 5"

# A-axis Swivel Range: +/-170˚

# Maximum Clamping/Workpiece Dimensions: 650 x 400 mm; max. weight 300 kg

# Rapid Traverse: X/Y/Z 54 m/min

# Spindle Speed: 100–10,000 rpm, spindle motor power 11 kW

Ksdpfx Aboxxt Ehs Tjln

# Spindle Taper: BBT30 (with internal cooling)

# Automatic Tool Changer: 1x21 tools, chip-to-chip average time 1.5 sec

# Maximum Tool Size: Ø40 mm / length max. 200 mm / 2 kg

Electrical connection:

# Voltage: 3x400V/50Hz

# Installed Power: approx. 20 kVA / 22A

Dimensions:

# Installation space: approx. 1.65 x 3.2 m (with chip conveyor) x 2.8 m

# Weight: approx. 8,500 kg

Equipment includes:

# This 4-axis FANUC Robodrill α-D21LiB5 was manufactured in 2016. Ideal for precision machining, this vertical machining centre offers robust performance and reliability.

# CNC Control: Model 31i model b5

# 4th axis and tailstock: Fanuc DDR-TiB 178DU039 2017/08 and TSUDAKOMA tailstock

# Chip extractor & coolant filtration unit max. 40 bar: Mosnic model 1641/2010

# Spindle, Guideways, and Electrical Cabinet Cooling Systems

# Oil Vapor Absorption/Recovery System: Bristol model B 1000 EF

# Fire suppression: Kraft & Bauer

# Part presence detection: with low pressure air sensors

# Automation: Lateral door automatic and interface ready for automation

# In-process inspection: Renishaw TRS2

# Documentation: incomplete

Machine condition:

NOT WORKING

# Hydraulic unit defective

# Two emulsion pumps

# Guideway lubrication pump

# Safety switch Euchner

Listing

Iași

Iași

9,095 km

Horizontal machining center

SW Schwäbische WerkzeugmaschinenBA321

Call

Condition: repair required (used), Year of construction: 2015, functionality: not functional, machine/vehicle number: 2460038, Technical specifications:

Machining workspace: X 300 mm; Y 500 (725) mm; Z 375 mm

Axis configuration: 3 linear axes (X, Y, Z) + 1 rotary table axis (A), index dividing head

- Direct measuring system, angular, rotation speed: max. 50 min⁻¹, accuracy: +/- 5''

Maximum clamping/part dimensions: Ø 575 x 830 mm; maximum weight: 360 kg

Rapid traverse rates: X/Y/Z = 65/75/75 m/min; positioning accuracy Tp: 0.008 mm

Spindle spacing: 300 mm

Spindle speed range: 1–17,500 rpm

Spindle taper: DIN 69893-HSK-A63 (internal coolant supply)

Automatic tool changer: 2 x 32 positions; average chip-to-chip: 2.5 s

Maximum tool diameter: Ø 75 mm; maximum tool length: 275 mm; maximum tool weight: 7.5 kg

Electrical data:

- Supply voltage: 3x400 V / 50 Hz

- Installed power: approx. 85 kVA / 125 A

Kljdjxxrc Sjpfx Ab Tsn

Machine dimensions:

- Installation area: approx. 3.6 x 6 x 3.7 m

- Weight: approx. 10,500 kg

Equipment includes:

- CNC control: Siemens 840D SL

- Linear axis measuring systems: Heidenhain linear scales

- Chip conveyor: Knoll Typ 550 K-1

- Oil cooling system

- Shaft, guideway, and switch cabinet cooling system

- 2 oil lubrication systems

- Oil mist extraction/recovery system: IFS Vario E2000 (2,000 m³/h)

- Fire protection: Kraft & Bauer

- Workpiece presence detection (P/Y): Low pressure air sensors

- In-process measurement: Marposs T25

- Tool breakage control and length measurement system: Inductive sensor (BRK)

- Tool support detection in working spindle

Machine status: NOT OPERATIONAL / NON-FUNCTIONAL

Installed components:

- Sensors for tool presence in spindle & part presence

- Hydraulic pump

- Hydraulic unit level & temperature sensors (Parker)

- Tool magazine piston & sliding door system (2 units)

- Communication module: Murr

- A-axis position encoder

- Hydraulic switches (Parker, 4 units)

- Emulsion filtration unit is shared with another machine (SW BA321 2460038)

- High-pressure pump from emulsion filtration system

Listing

Iași

Iași

9,095 km

Vertical machining center

FANUCRobodrill ᾱ-D21MiB5

Call

Condition: used, Year of construction: 2017, functionality: fully functional, machine/vehicle number: P17XZG 044, Technical characteristics:

# Machining workspace: X 500 mm; Y 400 mm; Z 330 mm

# Axis description: 3 LINEAR AXES (X, Y, Z) + 1 rotary table axis A (indexing divider head) with direct angular measuring system, max. rotational speed 50 rpm, precision +/- 5 seconds

# Axis A swivel range: +/-170˚

# Maximum clamping/workpiece dimensions: 650 x 400 mm; max. weight 300 kg

# Rapid traverse speed (X/Y/Z): 54 m/min

# Spindle speed: 100–10,000 rpm; spindle motor power: 11 kW

# Spindle interface: BBT30 (with through-spindle coolant)

# Automatic tool changer: 1x21 tools / chip-to-chip average time 1.5 sec

# Maximum tool size: Ø40 mm / length max. 200 mm / 2 kg

Electrical connection:

# Voltage: 3x400V/50Hz

# Installed power: approx. 20 kVA / 22A

Dimensions:

# Installation space: approx. 1.65 x 3.2 (with chip conveyor) x 2.8 m

Klodpexxrb Iefx Ab Tsn

# Weight: approx. 8,500 kg

Equipment includes:

# This 4-axis FANUC Robodrill α-D21LiB5 was manufactured in 2016. Ideally suited for precision machining, this vertical machining center delivers robust performance and high reliability.

# CNC control: FANUC Series 31i-B5

# 4th axis and tailstock: FANUC DDR-TiB 178DU039 (2017/08) and TSUDAKOMA tailstock

# Chip conveyor & high-pressure coolant filtration unit (max. 40 bar): Mosnic model 1641/2010

# Spindle cooling system, guideways and control cabinet cooling

# Oil mist extraction/recovery system: Bristol model B 1000 EF

# Fire suppression system: Kraft & Bauer

# Part presence detection: with low-pressure air sensors

# Automation: automatic side door and interface, automation-ready

# In-process control: Renishaw TRS2

# Documentation: incomplete

Machine status: WORKING

Listing

Iași

Iași

9,095 km

Horizontal machining center

SW Schwäbische WerkzeugmaschinenBX621

Call

Condition: repair required (used), Year of construction: 2012, functionality: not functional, machine/vehicle number: 2560001, Technical specifications:

Kljdpfxexxkd Us Ab Ten

# Machining workspace: X 600 mm; Y 525(890) mm; Z 400 mm

# Axis configuration: 3 linear axes (X, Y, Z) + 1 rotary axis (A, rotary table) and 2 rotary axes (C, indexer head) with direct angular measurement system, 50 rpm, accuracy +/- 5 arcseconds

# Maximum clamping/part dimensions: Ø 600 x 1420 mm; max weight 600 kg

# Rapid traverse speeds: X/Y/Z 50/60/50 m/min; positioning accuracy Tp: 0.02 mm

# Distance between spindles: 600 mm

# Spindle speed: 1–6000 rpm

# Spindle taper: DIN69893-HSK-A100 (with internal coolant supply)

# Automatic tool changer: 2 x 20 tools, average chip-to-chip time 4.25 s

# Tool maximum: Ø75 mm / length max. 275 mm / 7.5 kg

Electrical specifications:

# Voltage: 3x400V/50Hz

# Installed power: approx. 85 kVA / 125A

Dimensions:

# Installation space (W x H x L): approx. 5.8 x 3.3 x 5.05 m

# Weight: approx. 10,500 kg

Equipment includes:

# CNC control: Siemens 840D SL

# Linear axis measuring devices: Heidenhain linear scales

# Chip conveyor: Knoll Type 550 K-1

# Oil cooling system

# High-pressure oil filtration system, up to 80 bar: Knoll KF200/1200

# Shaft, guideway, and electrical cabinet cooling systems

# 2 oil lubrication circuits

# Oil mist absorption/recovery system

# Tool breakage and length measurement: Blum Novotec

# Work spindle tool presence detection system

Machine condition:

NOT OPERATIONAL

# Automatic operator doors

# Tool magazine

# Axis protection covers for work area

# Z-axis ballscrew and

# Z-axis linear guides

# Hydraulic overheating

# Hydraulic pump (250 bar)

Listing

Iași

Iași

9,095 km

Vertical machining center

CHIRONFZ 15K S FA

Call

Condition: repair required (used), Year of construction: 2009, functionality: not functional, machine/vehicle number: 281-06, Technical Specifications:

# Machining Workspace: X 550 mm; Y 400 mm; Z 360 mm

# Axis Description: 3 linear axes (X, Y, Z) + 1 rotary axis (rotary table A) and 2 rotary axes (B, indexer head)

with direct angular measuring system, maximum 50 rpm, accuracy +/- 5 seconds

# A axis swivel: +/-110˚

# Max. clamping/part dimensions: Ø 247 x 830 mm; max. weight 360 kg

# Rapid traverse rate: X/Y/Z 40/40/40 m/min

Kledpfx Aexxivceb Ton

# Distance between divider heads B1/B2: 250 mm

# Spindle speed: 1–10,000 rpm

# Spindle taper: DIN69893-HSK-A63 (with internal coolant)

# Automatic tool changer: 1x48 tools / chip-to-chip time approx. 2.5 sec

# Max tool diameter: Ø82 mm / max. length 250 mm / 5 kg

Electrical connection:

# Voltage: 3x400V/50Hz

# Installed power: approx. 45 kVA / 80A

Dimensions:

# Installation area: approx. 4.4 x 2.3 x 3.1 m

# Weight: approx. 8,500 kg

Equipment includes:

# CNC control: Siemens 840D Powerline

# Chip conveyor: Spring Knoll

# Oil cooling system

# High-pressure oil filtration system, max. 80 bar: Knoll HL 450/1200

# Shaft, guideways, and electrical cabinet cooling system

# 2 oil lubrication systems

# Oil mist extraction/recovery: LTA AC3002

# Fire protection: Kraft & Bauer

# Presence detection: with low pressure air sensors (part present)

# In-process control: Marposs T25

# Tool breakage monitoring: Blum Novotech

# Tool presence detection system in spindle

# Documentation: incomplete

Machine condition:

NOT OPERATIONAL

# Cover for tool magazine

# Tool magazine presence sensor (BERU)

Trust Seal

Dealers certified through Machineseeker

Listing

Iași

Iași

9,095 km

Vertical machining center

CHIRONFZ 15K S FA

Call

Condition: repair required (used), Year of construction: 2007, functionality: not functional, machine/vehicle number: 191-89, Technical characteristics:

- Machining workspace: X 550 mm; Y 400 mm; Z 360 mm

- Axis configuration: 3 linear axes (X, Y, Z) + 1 rotary table axis A and 2 rotary divider head axes B, equipped with direct angular measuring system, max rotation speed 50 rpm, accuracy +/- 5"

- Axis A swivel range: +/- 110°

- Max. clamping/part dimensions: Ø 247 x 830 mm; max. weight 360 kg

- Rapid traverse rate: X/Y/Z 40/40/40 m/min

- Distance between divider heads B1/B2: 250 mm

- Spindle speed: 1–10,000 rpm

- Spindle interface: DIN69893-HSK-A63 (with internal coolant supply)

- Automatic tool changer: 1x48 positions / chip-to-chip average 2.5 sec

- Max. tool diameter: 82 mm / max. tool length: 250 mm / max. tool weight: 5 kg

Electrical specifications:

- Supply voltage: 3x400V/50Hz

- Installed power: approx. 45 kVA / 80A

Dimensions:

- Installation space: approx. 4.4 x 2.3 x 3.1 m

- Weight: approx. 8,500 kg

Equipment includes:

- CNC control: Siemens 840D Power Line

- Chip conveyor: Spring Knoll

- Oil cooling system

- High-pressure oil filtration system (max. 80 bar): Knoll HL 450/1200

- Shaft cooling system, guideways and control cabinet

- 2 oil lubrication units

- Oil mist extraction/recovery: LTA

- Fire protection: Kraft & Bauer

- Part presence P/Y detection: with low-pressure air sensors

Kodpfx Aexxi Rmjb Tsln

- In-process inspection: Marposs T25

- Tool holder presence detection in spindle

- Documentation: incomplete

Machine status:

NOT OPERATIONAL: Hydraulic power unit motor burned out.

Listing

Iași

Iași

9,095 km

Vertical machining center

CHIRONFZ 15K S

Call

Condition: repair required (used), Year of construction: 2007, functionality: not functional, machine/vehicle number: 191-88, Technical specifications:

# Working area: X 550 mm; Y 400 mm; Z 360 mm

Kedpfx Ajxw Uplsb Toln

# Axis configuration: 3 linear axes (X, Y, Z) + 1 rotary table axis A and 2 rotary axes B with indexing head, direct angular measuring system, max. speed 50 rpm, accuracy +/- 5"

# A-axis swivel: +/-110˚

# Max. clamping/part size: Ø247 x 830 mm; max. weight 360 kg

# Rapid traverse rate: X/Y/Z 40/40/40 m/min

# Distance between dividing heads B1/B2: 250 mm

# Spindle speed: 1-10,000 rpm

# Spindle interface: DIN69893-HSK-A63 (with internal coolant supply)

# Automatic tool changer: 1x48 tools, tool-to-tool average 2.5 sec

# Max. tool diameter: Ø82 mm / max. tool length: 250 mm / max. tool weight: 5 kg

Electrical system:

# Voltage: 3x400V/50Hz

# Installed power: approx. 45 kVA / 80A

Dimensions:

# Installation footprint: approx. 4.4 x 2.3 x 3.1 m

# Weight: approx. 8,500 kg

Equipment includes:

# CNC control: Siemens 840D Power Line

# Chip conveyor: Spring Knoll

# Oil cooling unit

# Oil filtration system up to 80 bar: Knoll HL 450/1200

# Shaft, linear guide and electrical cabinet cooling system

# 2 oil lubrication systems

# Oil mist extraction/recovery unit: LTA AC3002

# Fire suppression: Kraft & Bauer

# Part presence check with low-pressure air sensors

# In-process control: Marposs T25

# Tool support monitoring system at spindle

# Documentation: incomplete

Machine condition:

NOT OPERATIONAL

# Operator protection screen damaged – operator panel functional

# Tool magazine chain

# Ballbar X

# Ballbar Y

# Pullbar spindle

# Axis drive power supply X

# Axis drive power supply Y

# Main drive power supply

# Complete hydraulic unit defective

Listing

Iași

Iași

9,095 km

Horizontal machining center

SW Schwäbische WerkzeugmaschinenBA 321

Call

Condition: used, Year of construction: 2016, functionality: fully functional, machine/vehicle number: 2460065, Technical specifications:

# Machining Workspace: X 300 mm; Y 500(725) mm; Z 375 mm

Klsdjxw Ttijpfx Ab Tjn

# Axis Configuration: 3 linear axes (X, Y, Z) + 1 rotational table axis (A) and 2 rotational axes (B) with indexer head

- Direct angular measuring system, maximum rotational speed: 50 min⁻¹, accuracy: +/- 5"

# Maximum clamping/part dimensions: Ø 575 x 830 mm; maximum workpiece weight: 360 kg

# Rapid traverse: X/Y/Z 65/75/75 m/min; positioning accuracy Tp: 0.008 mm

# Spindle distance: 300 mm

# Spindle speed: 1–17,500 rpm

# Spindle taper: DIN69893-HSK-A63 (internal coolant supply)

# Automatic tool changer: 2x32 tools, chip-to-chip average 2.5 sec

# Maximum tool size: Ø75 mm / max. length 275 mm / 7.5 kg

Electrical connection:

# Voltage: 3x400V/50Hz

# Installed power: approx. 85 kVA / 125A

Dimensions:

# Installation space: approx. 3.6 x 6 x 3.7 m

# Weight: approx. 10,500 kg

Equipment includes:

# CNC control: Siemens 840D SL

# Linear axis measuring device: Heidenhain linear scales

# Chip conveyor/extractor: Knoll Type 550 K-1

# Oil cooling system

# Oil filtration system max 80 bar: Knoll 550 K-1 450_2450 (can service 2 machines simultaneously)

# Shaft cooling system, guideways, and control cabinet

# 2 oil lubrication units

# Oil vapor absorption/recovery system: IFS Vario E2000 (2,000 m³/h)

# Fire protection: Kraft & Bauer

# Part presence detection: with low-pressure air sensors

# In-process control: Marposs T25

# Tool breakage monitoring and length measurement: inductive sensor

# Toolholder detection system in working spindle

# Documentation: Manuals only (printed)

Machine condition:

Operational / In working condition.

Listing

Iași

Iași

9,095 km

Horizontal machining center

SW Schwäbische WerkzeugmaschinenBA 321

Call

Condition: used, Year of construction: 2016, functionality: fully functional, machine/vehicle number: 2460062, Technical Specifications:

# Machining Workspace: X 300 mm; Y 500 (725) mm; Z 375 mm

# Axis Description: 3 Linear Axes (X, Y, Z) + 1 Rotational Table Axis (A-axis) with index divider head, equipped with direct angular measuring system, number of revolutions: 50 minˉ¹, accuracy +/- 5"

# Maximum Clamping / Part Size: Ø 575 x 830 mm; maximum weight 360 kg

# Rapid Traverse Rate: X/Y/Z: 65/75/75 m/min; Positioning Accuracy Tp: 0.008 mm

# Distance Between Spindles: 300 mm

# Spindle Speed: 1–17,500 rpm

# Spindle Interface: DIN69893-HSK-A63 (with internal coolant supply)

# Automatic Tool Changer: 2 x 32 tool positions, chip-to-chip average time: 2.5 sec

Kljdpfexw Syujx Ab Ten

# Max. Tool Dimensions: Ø75 mm / Maximum Length: 275 mm / Maximum Weight: 7.5 kg

Electrical Specifications:

# Voltage: 3x400V / 50Hz

# Installed Power: approx. 85 kVA / 125A

Dimensions:

# Installation Footprint: approx. 3.6 x 6 x 3.7 m

# Weight: approx. 10,500 kg

Equipment Includes:

# CNC Control: Siemens 840D SL

# Linear Axis Measuring System: Heidenhain linear scales

# Chip Conveyor: Knoll Type 550 K-1

# Oil Cooling System

# High-Pressure Oil Filtration System (max 80 bar): Knoll VRF 450_2350

# Cooling System for Shaft, Guides, and Switchboard

# 2 Oil Lubrication Units

# Oil Vapor Extraction/Recovery System: IFS Vario E2000 (2,000 m³/h)

# Fire Suppression System: Kraft & Bauer

# Part Presence Detection: via low-pressure air sensors

# In-Process Control: Marposs T25

# Tool Breakage Monitoring and Length Measurement: inductive sensor

# Tool Holder Detection in Work Spindle

Machine Condition: Operational

We make it easier for you to find: "solvent recovery"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Solvent Recovery (695)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you