Used Balancing Machine for sale (83,565)

Bünde

Bünde Wheel Balancing Machine

HOFMANNNG-1

Germany

Germany Universal Balancing Machine for Rotors

HOFMANNUHK 26

Hamburg

Hamburg Balancing machine

TIRAKV 10

+44 20 806 810 84

Odesa

Odesa Vertical balancing machine

97V10 (10kg)

Dieren

Dieren Balancing Machine with Vertical Shaft

CEMBVPECS 30

Discover more used machines

Sonnenbühl

Sonnenbühl Balancing machine

HofmannPTB 21.2

Kerava

Kerava Balancing machine

SchenckH 50 V/B

Germany

Germany Universal Balancing Machine for Rotors

SCHENKH4U

Essen

Essen Balancing machine

SchenckSENSiQ® RTN – 4,7 t – C3

Monheim am Rhein

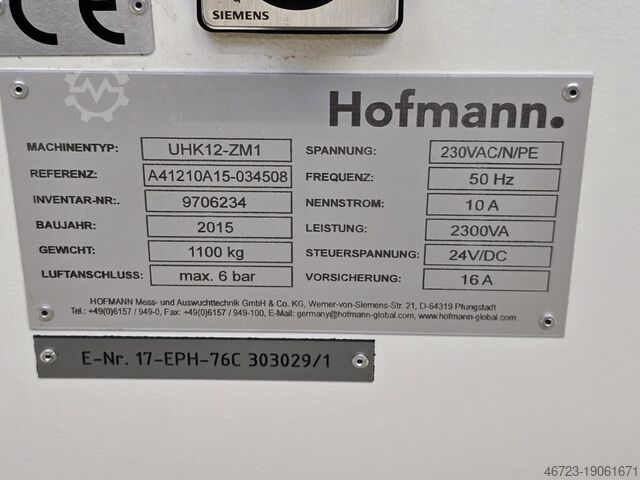

Monheim am Rhein Balancing machine

HofmannUHK 12 - ZM1

Frankenblick

Frankenblick Horizontal Balancing Machine Hofmann KKT

KKTUniversal BA & KA Auswuchtmaschine

Bydgoszcz

Bydgoszcz Balancing Machine

CIMAT

Odesa

Odesa Cardan shaft balancing machine

BVI-03-74

Germany

Germany Balancing Machine for car wheels

HeinlATH-550

Malsch

Malsch Balancing Machine

HOFMANNEO-Re

Hessisch Lichtenau

Hessisch Lichtenau Electrodynamic balance shaft balancing machine, vertical balancing machine; balancing machine, balan

SCHENCK RoTecEBLY

Dreieich

Dreieich Balancing Machine

TIRAK 150 B

Metzingen

Metzingen Balancing Machine

HOFMANNEO-Re / MC 10

Krefeld

Krefeld Balancing machine Schenck TBcomfort, year of manufacture: 2016

SchenckTBcomfort

Germany

Germany Balancing Machine - Vertical

SCHENKVM2/2

Hattingen

Hattingen Balancing machine

MBS BALANCEFlowbench FX 1

Germany

Germany Balancing Machine - Vertical

SCHENKVM3/2

Hattingen

Hattingen Balancing machine

MBS BalanceCB-15 Turbo Balancing Machine

Sachsen

Sachsen Horizontal balancing machine for rotors

HOFMANNUHK 26

Hattingen

Hattingen Balancing machine

MBS Balance1 Tone Horizontal Balancing Machine

Used Balancing Machine (83,565)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84