Used Central Lubrication System for sale (9,734)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Königsbrunn

Königsbrunn

8,086 km

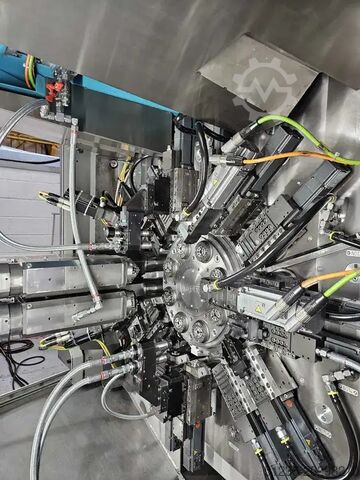

KUKA Central Hand ZH 150/180

KUKA5 x ZH 150/180 generalüberholt

Call

Condition: refurbished (used), PRICE ON REQUEST!

- 5 x used & tested

Fjdpfxog A Iv Es Agrepb

completely overhauled, all wear parts renewed

- completely measured

- gear backlash

axle 4 - 0,02 WM

axle 5 - 0,02 WM

axle 6 - 0,02 WM

- Central hand readjusted

- Endurance test 8 hours at 100 % load

- Delivery in a special box (insured shipping)

- Central hand in exchange

(without exchange on request)

- Gearbox overhaul of axles 1-6

- 12 months warranty

18 months possible for extra charge

IMMEDIATELY more than 100 central hands in stock, different models. Just ask!

Also an express overhaul of your KUKA central hand possible - from delivery 48 - 72 hours.

In addition, we also offer the repair of ABB wrists.

Listing

Montichiari

Montichiari

8,240 km

Central lathe

PONTIGGIA LEOPOLDSFE 800 X 3000

Call

Condition: used, CENTER HEIGHT 800 MM

DISTANZA OF THE CENTERS 3000 MM

MAX DIAMETER TURNABLE ON BED 1570 MM

MAX TURNABLE ON THE CARRIAGE 1120 MM

BED WIDTH 700 MM

WEIGTH ADMIT BETWEEN CENTERS 6000 KG

SPINDLE SPEED 8 - 350 mm

SPINDLE BORE 102 MM

TAILSTOCK : DIAMETER QUILL 135 MM STROKE 300 MM NOSE ATTACHMENT 80 METRIC

MOTOR POWER 25 HP

PLATFORM 1200 MM

DRO HEIDENHAIN 2 AXIS

SQUARE TOOL TURRET

RAPID FEED

PROTECTIONS ON THE SPINDLE AND GUIDES

Fedpfxerzt Haj Agrspb

Listing

Parma

Parma

8,284 km

Central lathe

AdriaCS 6250 DTPC

Call

Condition: new, Year of construction: 2024, functionality: fully functional, spindle bore: 105 mm, New parallel lathe

Brand ADRIA

Model CS 6250 DTPC: 2000x 250 mm

Year 2024

Condition New

Useful turning length 2000 mm

Height of centers 250 mm

Width of guides 390 mm

Bar passage 103 mm

Turning diameter on the bed 500 mm

Turning diameter without recess 710 mm

Recess length 240 mm

Spindle attachment Cam Lock DIN ISO702-2 N.8

Rapids on the carriage

Fedpfxjwq El Te Agropb

Threads Metric - inches - D.P.

Motor and Kw 7.5

Equipped with: Self-centering chuck simple guide with 3+3 reversible jaws, fixed tailstock, brake and emergency stop pedal, Mobile steady rest, Fixed steady rest (MM 120-260)

And with rear casing, removable chip collection tank, Tool coolant system, halogen lamp, electromagnetic brake pedal with double lever, Type C turret with n. 5 tool holders

2-Axis height display (included)

Documentation: Instruction book and CE Certificate

Listing

Domnești

Domnești

9,232 km

Steam generator 100 m³ + central unit 0.4 Gcal

Baschild

Call

Condition: excellent (used), CTS 3G C 400* - Superheated water boiler with manual wood waste feeding

Thermal output: 400,000 kcal/h.

Pressure: 4 bar.

Superheated water temperature: 150°C.

Control thermostat, safety thermostat, thermometer.

Fuel: wood waste

Smoke exhaust: cyclone, forced-draught fan, connecting ductwork

Fjdpfxsw Ev Tws Agrspb

Steaming chamber net capacity: 100 m³/batch

DVK-I 100 m³ - 1 unit, 8.5 x 9 m x h 4.3 m

Control system: Baschild Italy

Sliding door

Oxyvent overpressure system

Stainless steel tanks and radiators on 3 sides

Includes turnkey connections from boiler to steaming chamber and a complete boiler room with distributor, collector, pumps, expansion vessel, etc.

Listing

București

București

9,243 km

Central string

ROMANIASN 1800x3000

Call

Condition: ready for operation (used), Romanian Lathe SN 1800x3000

Manufacturer Uppetrom 1 MAY

Chuck diameter 1800 mm

Fpsdpfx Agjv Uaufsrjb

Max swing over bed 1800 mm

Length between centers 3000 mm

Max swing over slide 1450 mm

Max weight of work piece between centers 25,000 kg

Movie with machine underpower available

Listing

Turkey

Turkey

9,823 km

Centrale à béton

FABO CENTRALE À BÉTONCENTRALE À BÉTON

Call

Condition: new, functionality: fully functional, fuel type: electric, Year of construction: 2026, • Tous nos produits sont conçus avec soin et couverts par une garantie d'un an !

• Formation à l'installation et à l'exploitation gratuite.

Les centrales à béton fixes de la série COMPACT offrent des solutions pratiques et efficaces pour satisfaire tous les niveaux de besoins. Les installations de centrales à béton stationnaires allient une capacité maximale et une efficacité optimale.

La série COMPACT garantit un fonctionnement aisé et une efficacité optimale tout en maintenant des coûts abordables. De plus, cette usine utilise de manière précise les ressources de l'entreprise, ce qui se traduit par un gain de temps qui se transforme en revenus accrus.

SPÉCIFICATIONS TECHNIQUES:

Modèle: COMPACT 110

Capacité de production: 100 m3

Type de malaxeur : Malaxeur à double arbre – 2 m3

Tremie agrégé: 4 x 20 m3

Ciment pesant: 900 kg

Additifs pesant: 40 kg

Pesage de l'eau: 700 lt

Silo à ciment en option.

Fpsdpfoxvw H Rex Agreb

COMPACT-110 se compose de :

• Trémie de stockage d'agrégats

• Trémie de pesée d'agrégats

• Convoyeur de pesée d'agrégats

• Convoyeur de transfert d'agrégats

• Malaxeur à double arbre

• Châssis du malaxeur, plates-formes de marche, échelle

• Trémie de pesée d'eau

• Trémie de pesée de ciment

• Trémie de pesée d'adjuvant

• Compresseur d'air

• Convoyeur à vis pour le ciment

• Silo à ciment boulonné

• Filtre supérieur, soupape de sécurité et accessoires

• Salle de commande avec climatisation

• PC et système d'automatisation

• Panneau de commande et d'alimentation

POUR PLUS D’INFORMATIONS, N’HESITEZ PAS A NOUS CONTACTER!

Listing

France

France

7,674 km

Centrale à béton / usine à béton

CONSTMACH Centrale à BétonCentrale à béton de type sec 100 m3

Call

Condition: new, functionality: fully functional, power: 75 kW (101.97 HP), color: other, Year of construction: 2025, Equipment: cabin, CONSTMACH DRYMIX 100 is a fully automatic dry type concrete plant without a mixer. Concrete components are transferred directly into the transit mixer after weighing, without any mixing process. This feature provides a significant advantage, especially in projects where concrete needs to be transported over long distances. DRYMIX 100 offers high efficiency and durability thanks to its fixed, non-mobile structure, and can be used safely in many regions of the world due to its adaptable design for different climatic conditions.

This model can be integrated with cement silos with capacities ranging from 50 to 500 tons. When supplied in cement bags, it is easily transferred to silos thanks to the blasting bunker and silo filling systems. In plants used in cold regions, the system is heated with hot steam generators and insulated panels, while in hot climates, concrete temperature is maintained at the ideal level with cooling units. Furthermore, aggregate pre-feeding systems eliminate the need for a feeding ramp, saving space on site.

The user-friendly automation system is supported by top-class SIEMENS and SCHNEIDER brand electronic components. The PLC control system manages the production process fully automatically and ensures maximum accuracy with high-precision weighing systems.

DryMix-100 Dry Type Concrete Plant Technical Specifications

Production Capacity: 100 m³/h

Weight: 33 tons (excluding cement silo)

Total Motor Power: 70 kW

Electric Generator Requirement: 200 kVA

Required Operating Area: 700 m²

Aggregate Storage Bunker: 4 x 25 m³

Aggregate Weighing Bunker: 3 m³

Aggregate Weighing Belt: 1000 x 11,100 mm

Fsdoxqg A Rjpfx Agropb

Aggregate Transfer Belt: 1000 x 10,800 mm

Cement Weighing Bunker: 1,200 kg

Water Weighing Bin: 600 liters

Additive Weighing Bin: 50 liters

Air Compressor: 500 liters, 5.5 kW

Cement Silo: Capacity options ranging from 50 to 500 tons

Control Type: Fully Automatic

Why Choose the DRYMIX 100 Concrete Batch Plant?

CONSTMACH DRYMIX 100 is the most suitable solution for long-distance concrete transportation requirements. Its mixerless structure, low maintenance cost, and high production capacity increase operational efficiency. Thanks to its structure that can be adapted to all weather conditions, it offers the same quality whether in the freezing cold of Siberia or the scorching heat of the Middle East. Its advanced automation system ensures maximum accuracy with minimal human intervention. At CONSTMACH, we offer a reliable investment with world-class engineering quality, a fast service network, and spare parts supply. By choosing DRYMIX 100, you can add long-lasting, efficient, and high-performance production power to your projects.

What Do We Do at Constmach?

Constmach is a leading machine manufacturer serving the construction and mining industries with a wide range of products. Our product portfolio includes concrete block making machines, stationary and mobile concrete plants, stone crushing machines, stone crushing and screening plants, sand washing machines, sand making machines, asphalt plants, conveyor belt systems, jaw crushers, and mobile crushing plants. With its high quality standards, innovative production approach, and customer-focused solutions, Constmach stands out as a reliable brand in both national and international markets. Our products continue to be the preferred choice of industry professionals due to their durability, efficiency, and long-lasting performance.

Listing

France

France

7,674 km

Centrale à béton / usine à béton

CONSTMACH Centrale à BétonCentrale à béton compacte 30 m3/h

Call

Condition: new, functionality: fully functional, power: 55 kW (74.78 HP), fuel type: hybrid, color: other, Year of construction: 2025, Equipment: cabin, hydraulics, onboard computer, CONSTMACH Compact-30 compact concrete mixing plant offers a superior solution in terms of both portability and production performance with its compact structure and high efficiency. Installation is extremely fast and requires only a flat ground, eliminating the need for additional concrete infrastructure work. This feature saves time and costs on site. Thanks to its steel-legged cement silos and metal-walled aggregate bunker system, it offers easy installation without requiring additional construction. This plant can be equipped with pan, single-shaft, or planetary mixer options, suitable for ready-mix concrete, dry concrete, and precast concrete production.

The Compact 30 features a high-tech automation system with SIEMENS and SCHNEIDER branded electronic components. Thanks to its PLC-controlled, fully automatic structure, the production process is easy, safe, and uninterrupted. Its user-friendly interface provides maximum control and flexibility to the operator during production. Despite its compact structure, it offers long-term use with high quality and durability.

Compact-30 Compact Concrete Batching Plant Technical Specifications

Fedexqg Adepfx Agrepb

Production Capacity: 30 m³/s

Transport Position Dimensions: 12 x 2.2 x 2.2 m

Weight: 13 tons

Total Motor Power: 50 kW

Required Electric Generator: 80 kVA

Mixer Options: Pan – Single Shaft – Planetary

Working Area: 200 m²

Aggregate Storage Bunker: 4 x 6 m³

Aggregate Weighing Bunker: 0.75 m³

Aggregate Transfer Bucket Volume: 0.75 m³

Mixer Wet Concrete Volume: 0.5 m³

Cement Weighing Bunker: 300 kg

Water Weighing Bin: 200 liters

Additive Weighing Bin: 20 liters

Air Compressor: 300 liters – 4 kW

Cement Silo: Capacity options ranging from 50 to 500 tons

Control Type: Fully Automatic

Why Choose the Compact-30 Compact Concrete Batch Plant?

CONSTMACH combines low investment costs with high production performance with its Bucket Compact 30 model, produced with years of engineering experience. It offers maximum reliability to its users with its CE-compliant production, high-quality components, and worldwide service network. The Compact 30 provides both the power of fixed plants and the flexibility of mobile systems, ensuring you get the most out of your investment in the shortest time possible. Its durability, easy maintenance, and energy efficiency offer long-term operational advantages. CONSTMACH is the right choice for professionals seeking quality and consistency in concrete production.

What Do We Do at Constmach?

Constmach is a leading machine manufacturer serving the construction and mining industries with a wide range of products tailored to their needs. Our product portfolio includes concrete block making machines, stationary and mobile concrete plants, stone crushing machines, stone crushing and screening plants, sand washing machines, sand making machines, asphalt plants, conveyor belt systems, jaw crushers, and mobile crushing plants. With its high quality standards, innovative production approach, and customer-focused solutions, Constmach stands out as a reliable brand in both national and international markets. Our products continue to be the preferred choice of industry professionals due to their durability, efficiency, and long-lasting performance.

Listing

France

France

7,674 km

Centrale à béton / usine à béton

CONSTMACH Centrale à BétonCentrale à Béton Stationnaire de 60 m3

Call

Condition: new, functionality: fully functional, power: 125 kW (169.95 HP), color: other, Year of construction: 2025, Equipment: cabin, CONSTMACH Stationary-60 concrete plant is an excellent solution for medium-scale and long-term ready-mix concrete projects. Equipped with a fully automatic control system, this plant offers high efficiency and continuous production capacity. Its flexibility to produce all types of concrete allows it to easily adapt to different project requirements. With its durable steel construction, CE-compliant production, and low maintenance needs, it is a plant model trusted by professionals.

Stationary-60 can be configured with pan, single-shaft, twin-shaft, or planetary mixer options depending on project conditions. It can work with cement silos with capacities ranging from 50 to 500 tons, and cement filling is easily done thanks to the integrated blast bunker. Furthermore, this model can be equipped according to climatic conditions, ensuring efficient concrete production with heating systems in cold regions and cooling units in hot climates. Aggregate pre-feeding systems eliminate the need for ramps, offering flexibility in field use. In limited spaces, bucket transport systems facilitate installation.

FIXED 60 Fixed Concrete Batching Plant Technical Specifications

Production Capacity: 60 m³/h

Weight: 38 tons (excluding cement silo)

Total Motor Power: 125 kW

Electric Generator Requirement: 200 kVA

Mixer Options: Pan - Single Shaft - Twin Shaft - Planetary

Working Area Requirement: 700 m²

Aggregate Storage Bunker: 4 x 20 m³

Aggregate Weighing Bunker: 1.5 m³

Fedpfx Agjxqgzyerspb

Aggregate Transfer Belt: 800 x 22,000 mm

Mixer Wet Concrete Volume: 1 m³

Cement Weighing Bunker: 600 kg

Water Weighing Bin: 300 liters

Additive Weighing Bin: 30 liters

Air Compressor: 500 liters - 5.5 kW

Cement Silo: Options ranging from 50 to 500 tons

Control Type: Fully Automatic

Why Choose the Stationary 60 Concrete Plant?

CONSTMACH FIXED 60 is a concrete plant that stands out in the industry in terms of both performance and durability. It ensures uninterrupted production with its long-lasting components, high-quality production standards, and superior automation system. Its adaptability to different climatic conditions, energy efficiency, and modular structure provide a more than satisfactory return on your investment. CONSTMACH's strong technical service support, extensive spare parts network, and international production experience make the Stationary-60 not just a plant, but a long-term business partner. If you are looking for a reliable, high-capacity, and economical concrete plant, the CONSTMACH Stationary-60 is the right choice for you.

What Do We Do at Constmach?

Constmach is a leading machine manufacturer serving the construction and mining industries with a wide range of products. Our product portfolio includes concrete block making machines, stationary and mobile concrete plants, stone crushing machines, stone crushing and screening plants, sand washing machines, sand making machines, asphalt plants, conveyor belt systems, jaw crushers, and mobile crushing plants. With its high quality standards, innovative production approach, and customer-focused solutions, Constmach stands out as a reliable brand in both national and international markets. Our products continue to be the preferred choice of industry professionals due to their durability, efficiency, and long-lasting performance.

Listing

France

France

7,674 km

Centrale à béton mobile

CONSTMACH Centrale à béton mobileCentrale à béton mobile de 30 m3/h

Call

Condition: new, functionality: fully functional, power: 55 kW (74.78 HP), color: other, Year of construction: 2025, Equipment: cabin, CONSTMACH MOBICOM 45 mobile concrete mixing plant is an innovative production solution that combines high performance with a compact design. With its structure requiring minimal preparation time and low installation costs on construction sites, it is an excellent choice for projects that frequently change locations. All equipment is designed to fit into a single 40 ft container, eliminating the need for extra permits or special equipment for road transport. Quick setup is possible without the need for a mobile crane, and the plant can be easily transported to different construction sites with the help of a truck. The mixer's position close to ground level allows the produced concrete to be transferred directly to the transit mixer via a conveyor belt.

MOBICOM 45 can be equipped with pan, single-shaft, or planetary mixer options according to user needs. The low feed height of the aggregate bunker allows the bucket to fill directly without a ramp. The advanced automation system is supported by SIEMENS and SCHNEIDER branded electronic components, and the entire production process is precisely controlled by advanced PLC-based software. It can be used with a cement silo or a bagged cement system, ensuring full compatibility with different production scenarios.

Mobicom 45 – Mobile Concrete Batching Plant Technical Specifications

Production Capacity: 45 m³/h

Transport Position Dimensions: 8 (L) x 2.3 (W) x 2.5 (H) meters

Weight: 9.5 tons

Total Motor Power: 55 kW

Required Electric Generator: 80 kVA

Mixer Options: Pan – Single Shaft – Planetary

Required Operating Area: 200 m²

Aggregate Storage Bunker: 4 x 6 m³

Aggregate Weighing Bunker: 1 m³

Aggregate Transfer Belt: 800 x 15,250 mm

Fpedpoxqgzgjfx Agrjb

Mixer Wet Concrete Volume: 0.75 m³

Cement Weighing Bunker: 450 kg

Water Weighing Bin: 300 liters

Additive Weighing Bin: 20 liters

Air Compressor: 300 liters, 4 kW

Cement Silo: Options ranging from 50 to 200 tons

Control Type: Fully Automatic

Why Should You Choose the Mobicom 45 Mobile Concrete Batch Plant?

At CONSTMACH, we prioritize quality, speed, and reliability in concrete production. MOBICOM 45 can be set up quickly on your construction site thanks to its compact design and reduces your production costs with its high efficiency. Its dimensions, which comply with international transportation standards, allow for easy transport between projects. It guarantees maximum performance with its long-lasting material quality, automation technology, and low maintenance requirements. With the CONSTMACH guarantee, you gain not just a machine, but a professional solution that increases continuity and profitability in production.

What Do We Do at Constmach?

Constmach is a leading machine manufacturer serving the construction and mining industries with a wide range of products tailored to their needs. Our product portfolio includes concrete block making machines, stationary and mobile concrete plants, stone crushing machines, stone crushing and screening plants, sand washing machines, sand making machines, asphalt plants, conveyor belt systems, jaw crushers, and mobile crushing plants. With its high quality standards, innovative production approach, and customer-focused solutions, Constmach stands out as a reliable brand in both national and international markets. Our products continue to be the preferred choice of industry professionals due to their durability, efficiency, and long-lasting performance.

Listing

Heilbronn

Heilbronn

7,928 km

Motan Centralconveying (art.1232)

MotanZentralversorgung (art.1232)

Call

Condition: good (used), Year of construction: 2007, Motan Centralconveying control Metronet Light für 8x Abscheider

year: 2007

price: 3.750 €

contact: Mr. Rainer Eckerle

Fpsdjrun Sdopfx Agreb

Listing

Karsin

Karsin

8,083 km

Multiblade Flanders saw WD FR8 with centralizer

wdfr8

Call

Condition: good (used), functionality: fully functional, Multiblade Foiler WD FR8 with centering device

2x floating saws

maximum saw blade distance 550 mm

maximum cutting height 165 mm

maximum clearance: width 880 mm x height 180 mm

central lubrication system

Fpedjqwgy Njpfx Agrob

hydraulic roller lifting system

feed speed continuously adjustable in the range of 0-250 m/min

centering conveyor at the entrance to the machine

full hudraulics

strong solid body

robust line not afraid of challenges

Auction

Ends in

d

h

min

s

Auction ended

Gelderland

Gelderland

7,560 km

CNC horizontal machining center

BiesseRover A 1536 G FR

Condition: ready for operation (used), Year of construction: 2012, functionality: fully functional, machine/vehicle number: 81399, travel distance X-axis: 3,765 mm, travel distance Y-axis: 1,585 mm, travel distance Z-axis: 170 mm, swivel angle C-axis (max.): 360 °, TECHNICAL DETAILS

X-axis travel: 3,765 mm

Y-axis travel: 1,585 mm

Z-axis travel: 170 mm

C-axis: 360°

Worktable zones: 9

MACHINE DETAILS

Dimensions & Weight

Dimensions (L x W x H): 13,500 mm x 2,450 mm x 2,400 mm (l x w x h)

Transport weight: 2,500 kg

Transport packages: 4

EQUIPMENT

Central lubrication

Fpjdpfx Agsx Rbpbsrjb

12 kW electrospindle, ISO 30, air-cooled

Biesse WORKS

Biesse NEST MODULE

Air conditioning

16-position rotary magazine

2x vacuum pump 250 m³/h

BH 17 L drilling unit

Loading and unloading system

Auction

Ends in

d

h

min

s

Auction ended

Bayern

Bayern

8,005 km

Bridge crane

KonecranesS05M12063 / 6,3 t

Condition: ready for operation (used), functionality: fully functional, Year of construction: 2024, machine/vehicle number: 10000987991, overall weight: 5,110 kg, load capacity: 6,300 kg, main lifting speed: 4,000 mm/min, lifting height: 5,200 mm, 6.3t S-DG Double-Girder Overhead Crane

TECHNICAL DETAILS

Crane rail type: 60 × 40

Load capacity: 6,300 kg

Span: 17.100 m

Maximum deflection of crane bridge at rated load: 22.8 mm

Wire Rope Hoist

Max. lifting capacity of hoist 1: 6,300 kg

Hoist classification: 1.2 + 1.2 m (D_min)

Lifting height: min. 4.9 m / max. 5.20 m

Type of trolley: double rail trolley

Wire rope control: with hook drift

Hook type/size: RSN2.5V

Speeds

Hoisting speed at rated load: min. 0.08 m/min to max. 4.0 m/min

CSR speed at partial load: max. 6.00 m/min

Trolley travel speed: max. 20 m/min

Crane travel speed: max. 40 m/min

MACHINE DETAILS

Weight of crane including hoist: 5,110 kg

Electrical Data

Supply voltage: 3 Ph / 400 V / 50 Hz

Control voltage: 48 V

Area of application: indoors

Ambient temperature: min. 5 °C to max. 40 °C

Motor Power

Main hoist motor: 4.5 kW

Duty cycle main hoist motor: 60% ED

Trolley travel motor: 1 × 0.45 kW

Duty cycle trolley travel motor: 40% ED

Crane travel motors: 2 × 0.65 kW

Fpodpfox Nvlbjx Agrjb

Duty cycle crane travel motors: 40% ED

EQUIPMENT

DynADrive inverter control

Control Pro Performance

4-stage hoist limit switch

Hoist brake

Wire rope drum

Gearbox

Overload protection

Load spectrum recorder

Slow/stop limit switches for trolley and crane travel

Crane equipped with REMOX516MI radio remote control

Includes signal horn (sound level 98 dB)

Includes spare transmitter for radio remote control

Includes storage cabinet for remote control

Rope angle features

Safety festoon line approx. 30 m long, along central support row

Includes mains disconnect switch and power feed at any point

Rising main (fixed installed cable) to be provided by customer

Note: Further technical details can be found in the attached quotation.

Auction

Ends in

d

h

min

s

Auction ended

Województwo wielkopolskie

Województwo wielkopolskie

8,115 km

Machining center

Optimat WeekeBP 155

Condition: ready for operation (used), Year of construction: 1998, functionality: fully functional, machine/vehicle number: 0-250-05-2654, travel distance X-axis: 3,950 mm, travel distance Y-axis: 1,943 mm, travel distance Z-axis: 400 mm, controller model: HOMATIC-2000 IPC, No reserve price – guaranteed sale to the highest bidder!

The machine is equipped with a C-axis!

TECHNICAL DETAILS

Travel distances

X-axis: 3,950 mm

Y-axis: 1,943 mm

Z-axis: 400 mm

Vertical drilling unit X-direction

Drill spindles: 16

Z-stroke: 60 mm

Drilling depth: max. 38 mm

Rotational direction: clockwise/counterclockwise

Speed: 1,500 - 5,900 rpm

Drive: 1.5 kW

Drill chuck: d= 10 mm

Total drill length: 70 mm

Drill diameter: max. 20 mm (15 spindles), 1 spindle up to 25 mm, max. 35 mm (1 reinforced spindle)

Spindle spacing: 32 mm (15 spindles)

Spindle type: individually controllable

Extraction: central

Vertical drilling unit Y-direction

Fodpfx Aox Sqm Ssgrspb

Drill spindles: 15

Z-stroke: 60 mm

Drive: 1.5 kW

Rotational direction: clockwise/counterclockwise

Speed: 1,500 - 5,900 rpm

Drill chuck: d= 10 mm

Drilling depth: max. 38 mm

Total drill length: 70 mm

Drill diameter: max. 20 mm, 1 spindle up to 25 mm

Spindle spacing: 32 mm (15 spindles)

Spindle type: individually controllable

Arrangement: Y-direction

Horizontal drilling unit X-direction

Drill spindles: 4

Drilling depth: max. 38 mm

Drilling height Z-direction: 38 mm

Rotational direction: counterclockwise

Speed: 4,800 rpm

Drill chuck: d= 10 mm

Total drill length: 70 mm

Drill diameter: max. 20 mm

Spindles: individually controllable

Horizontal drilling unit Y-direction

Drill spindles: 2

Drilling depth: max. 38 mm

Drilling height Z-direction: 38 mm

Rotational direction: clockwise

Speed: 4,800 rpm

Drill chuck: d= 10 mm

Total drill length: 70 mm

Drill diameter: max. 20 mm

Spindle type: individually controllable

Router motor

Drive power: 7.5/10 kW (S1/S6 duty cycle)

Speed range (stepless): 750 - 18,000 rpm

Cooling: liquid recirculation cooling

Bearings: hybrid bearings (ceramic)

Extraction: central

Tool changer magazine

Magazine positions: 30 tool positions

Tool weight: max. 5 kg

Tool change time: approx. 8 - 10 seconds

MACHINE DETAILS

Control: HOMATIC-2000 IPC

Liquid recirculation cooling: 18,000 l/min

Power: 7.5 / 10 kW

S1/S6 operation

EQUIPMENT

Integrated CNC axis (360° rotational)

Torque support

Main spindle (motor power 7.5 / 10 kW, HSK F63)

Workpiece support system 1,500 mm

Workpiece console K-table 1,500 mm

Gantry extension Y-direction 120 mm

Compressed air connection strip with quick couplers

Extraction hood for additional router motor

Router 5 kW with Hydro quick-release clamping system

Left-side safety guard with door

Safety tread mat 3,250 mm

Control cabinet left

Note: For further details regarding the machine’s equipment, please refer to the attached documents.

Auction

Ends in

d

h

min

s

Auction ended

Kranj

Kranj

8,443 km

5-axis machining center

SCMRECORD 132 Prisma

Condition: ready for operation (used), Year of construction: 2006, operating hours: 19,857 h, functionality: fully functional, travel distance X-axis: 4,400 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 180 mm, number of slots in tool magazine: 72, TECHNICAL DETAILS

X-axis travel: 4,400 mm

Y-axis travel: 1,300 mm

Fedpfx Ajx Sri Ijgrspb

Z-axis travel: 180 mm

Milling unit power: 15 HP

Tool change: automatic

Number of tool positions: 3 x 24 slots

EQUIPMENT

Worktable with traverse

Auxiliary unit for heavy parts

Pneumatic clamps for door and window production

Vacuum pump 250 m3/h

Automatic lubrication

Waste conveyor

Listing

Oak Forest

Oak Forest

851 km

Multi-spindle machine

INDEXMS22-8

Call

Condition: excellent (used), Year of construction: 2024, INDEX MS22-8

Mfd. 2024

2 NCU

(4) Y-Axis

SL Control

Cutting hours: 1,000

Turnkey Available

Located in Europe

4-Meter IEMCA SIR MS22-8/43/P

Rack loader 50 Hz D9-13-19-25

Bar length 4300 mm

with drilling unit and minimum quantity lubrication unit

additional end-of-bar sensor

Bar stock 500mm (D12-D24)

Fedex Ddcuspfx Agropb

Bar stock 340 mm (D5-D11).

Additional storage chain for 22 bars

with Profinet interface.

1 11007253

(21711)

1 set (8 pieces) bar stock pushers,

external clamping for bar stock diameters D7-D10 mm,

internal clamping for bar stock diameters D13-D18 mm, consisting of:

8 bar stock pushers D12

8 rotating sleeves D12

1 10287026

(21712)

1 set (8 pieces) bar stock pushers,

external clamping for bar stock diameters D11-D16 mm,

internal clamping for bar stock diameters D19-D24 mm, consisting of:

8 bar stock pushers D18

8 rotating sleeves D18

1 10536056

(21713)

1 set (8 pieces) bar stock pushers for bar diameters D17 mm-D22 mm,

consisting of:

8 bar stock pushers D23

8 rotating sleeves D23

1 10414481

(21702)

1 set (8 pcs.) of internal clamping sleeves D12mm

for bar diameters D13 mm - D18 mm

Drill diameter D8 mm.

1 10472413

(21704)

1 set (8 pcs.) of external stops D12 mm

for bar diameters D13 mm - D18 mm

pre-machined.

1 10264327

(21703)

1 set (8 pcs.) of internal clamping sleeves D18mm

for bar diameters D19 mm - D24 mm

Drill diameter D15mm.

1 10058206

(21705)

1 set (8 pcs.) of external stops D18 mm

for bar diameter D19 mm - D24 mm

pre-machined.

1 12123486

Drill for drilling unit consisting of:

1 indexable insert drill D 15 mm

10 indexable inserts for steel

2 solid carbide drills D 8 mm

Listing

Warren

Warren

1,239 km

Gear Honing Machine

PräwemaSYNCHROFINE 205 HSD A-W

Call

Condition: good (used), Year of construction: 2019, machine/vehicle number: 25653, Equipped with:

-Automatic Central Lubrication System

-Machine Guard

-Indramat - MTX and Sercos CNC Control

-The standard machine is equipped with CNC-control make Indramat - MTX and SERCOS-interface

-Tool Dressing (Automatic dressing cycle of the dressing master and honing wheel tip diameter by a diamond coated dressing roll. The dressing cycle of workpieces can be pre-selected)

-Electronic Indexing Unit

-Operator and Maintenance Manual

-All Electrical Drawings

-PLC Language in English

-Software and Hardware for Remote Diagnosis

-High Precision Control of the Stock Allowance Material

-Manual Loading on Spindle for Prototypes

-Software for Infeed Optimized Cycle Type Reduction (Adaptive Honing)

-Software for Vario Speed Dressing

-Software for Calibration of Master Gears

-Software for Timing Gears (including additional sensor for the hole of 4mm)

-Software for Shortening of Workpiece Change-Over Time

-Clamping Cylinder

Fedjw Iquyopfx Agrepb

-RITTAL Cooling Unit

-Lighting for Working Area

-Installation of Vibration Detecting Sensors

-Coolant Unit

-Electrostatic Oil Mist Exhauster IFS With Rigid Piping

-Internal Automation

-Pallet Ring Conveyor System FlexLink (L-form shape see approved layout)

-Parallel - Double Gripper

-Pick and Placer Between Pallet Conveyor and Internal Loader

-Extended Loading Length of the Pick and Placer

Specifications:

Workpiece:

-Part Diameter: 20-150 mm

-Maximum Face Width: 70 mm

-Part Weight: 20 kg

-Number of Teeth: 6-150

-Module: 1-5 mm

Workpiece Spindle:

-Maximum Speed: 6000 1/min

-Installed Power: Approx. 25 kW

Tool:

-OD of Honing Wheel: 270 mm

-Widths of Honing Wheel: 20-70 mm

-Honing Wheel Material: Ceramics

Tool Spindle:

-Maximum Speed: 2000 1/min

-Installed Power: Approx. 25 kW

Machine:

-Total Connected Load, Approx: 70 kVA

-Floor Space (w x l x H):

-Total Weight, Approx: 11 Ton

-Bosch Rexroth MTX Control CML 85

Longitudinal Slide, Z-Axis:

-Linear Drive

-Drive Torque: 3,700 Nm

-Infeed Speed: 60 m/min

-Theoretical Infeed: 200 m/min

-Drive Length, Maximum: 400 mm

Cross Slide, X-Axis:

-Linear Drive

-Drive Momentum: 2,150 Nm

-Infeed Speed: 60 m/min

-Theoretical Infeed: 200 m/min

-Drive Length, Maximum: 1050 mm

Swiveling Axis, W-Axis:

-AC-Servo Drive: 10,000 1/min

-Setable Gear Transmission: i=5000:1

-Swiveling Angle: -90 Degrees / +16 Degrees

Workpiece Spindle, C-Axis:

-Direct Drive, Maximum RPM: 7,000 1/min

-Drive Power: 30 kW

-Drive Torque: 112 Nm

-Digital Measuring System

Tool Spindle, B-Axis:

-Direct Drive (hollow spindle drive), Maximum RPM: 2000 1/min

-Drive Power: 30 kW

-Drive Torque: 150 Nm

-Digital Measuring System

Listing

Niagara Falls

Niagara Falls

1,569 km

Throughfeed machining center

KrüsiKrüsimatic G2

Call

Condition: excellent (used), Year of construction: 2010, functionality: fully functional, Two machines in one, made by the best Swiss CNC manufacturer. 1. Log milling 2.Timber Framing. This machine produced machined log structures for 6 years, (dormant since), of high precision and quality, for very discerning buyers. For progressive builders who want to automate milled log structures up to 8" x 12" material, or use strictly for timber framing. Best suited for USA or Canada customer, for easy truck transport. Delivery, set-up, calibration, operational training arranged at cost.

Self-contained

Compact design, only 10 feet deep, 8 feet wide.

All processes are performed inside the enclosure.

Cut-offs fall into and are removed from a central pit.

Mill shavings are extracted by air suction, leaving work area remarkably clean.

So quiet, you can have a conversation beside the working machine.

Fjdpswvwl Aofx Agrjpb

Listing

Oak Forest

Oak Forest

851 km

Multi-spindle machine

INDEXMS-22-8

Call

Condition: used, Year of construction: 2024, INDEX MS22-8

Mfd. 2024

2 NCU

(4) Y-Axis

SL Control

Cutting hours: 1,000

Turnkey Available

Located in Europe

4-Meter IEMCA SIR MS22-8/43/P

Rack loader 50 Hz D9-13-19-25

Bar length 4300 mm

with drilling unit and minimum quantity lubrication unit

additional end-of-bar sensor

Bar stock 500mm (D12-D24)

Bar stock 340 mm (D5-D11).

Additional storage chain for 22 bars

with Profinet interface.

1 11007253

(21711)

1 set (8 pieces) bar stock pushers,

external clamping for bar stock diameters D7-D10 mm,

internal clamping for bar stock diameters D13-D18 mm, consisting of:

8 bar stock pushers D12

8 rotating sleeves D12

1 10287026

(21712)

1 set (8 pieces) bar stock pushers,

external clamping for bar stock diameters D11-D16 mm,

internal clamping for bar stock diameters D19-D24 mm, consisting of:

8 bar stock pushers D18

8 rotating sleeves D18

1 10536056

(21713)

1 set (8 pieces) bar stock pushers for bar diameters D17 mm-D22 mm,

consisting of:

8 bar stock pushers D23

8 rotating sleeves D23

1 10414481

(21702)

1 set (8 pcs.) of internal clamping sleeves D12mm

for bar diameters D13 mm - D18 mm

Drill diameter D8 mm.

1 10472413

(21704)

1 set (8 pcs.) of external stops D12 mm

for bar diameters D13 mm - D18 mm

pre-machined.

1 10264327

(21703)

1 set (8 pcs.) of internal clamping sleeves D18mm

for bar diameters D19 mm - D24 mm

Drill diameter D15mm.

1 10058206

(21705)

1 set (8 pcs.) of external stops D18 mm

for bar diameter D19 mm - D24 mm

pre-machined.

1 12123486

Drill for drilling unit consisting of:

1 indexable insert drill D 15 mm

10 indexable inserts for steel

2 solid carbide drills D 8 mm

Fsdexnrtcspfx Agrspb

Listing

Warren

Warren

1,239 km

Cylindrical Grinding Machine

ToyodaGL32M-63

Call

Condition: good (used), Year of construction: 2013, TOYODA (JTEKT) GL32M-63 CNC UNIVERSAL CYLINDRICAL GRINDER

Equipped with:

CBN Grinding Wheel

Flagging

Steady Rest

Workhead Mounted Rotary Dresser

Marposs P3SE System Monitoring

Toyoda In Process Gaging

Marposs E20N Acoustic Controller

Air Gap Eliminator

Workpiece Collision Control

Coolant Pumps W/Magnetic Separator

Pendant Control

RH Workhead with Center

LH Workhead with Center

Work Rests

Worklight

Light Curtains

Stacklight

Extra Wheels

Specifications:

-Grind Center to Floor: 1,000 mm

-Swing Over Table: 320 mm

-Distance Between Centers: 630 mm

-Grinding Diameter Range: 10 - 150 mm

-Floor Space (Base machine w/auxiliary equipment): 3,400 x 5,000 mm

-Net Machine Mass (approx.): 10,500 kg

Grinding Wheel:

-Type: CBN Wheel

-Wheel Size (OD): 350 mm

-Maximum Wheel Width: 60 mm

-Surface Speed: 120 m/s

Wheelhead:

-Spindle Bearing: TOYODA STAT Bearing

-Slide: V and Flat

-Feed System: Ballscrew

-Rapid Feed (on diameter): 30 m/min

-Minimum Incsrement (on diameter): 0.0001 mm

Workhead:

-Type: Dead Spindle

-Work Speed (Max): 500 rpm

-Center Taper: MT #4

Footstock:

Fedpfxjrtrzpe Agrepb

-Type: Hydraulic

-Taper Compensation: Manual

-Maximum Center Retraction: 60 mm

-Center Taper: MT #4

Motors:

-Wheel Drive Motor: 15 kW, Belt-Drive

-Wheelhead Feed Servomotor: 1.3 kW

Tank Capacities:

-Wheel Spindle Lubrication Oil: 80 L

-Hydraulic/Lubrication Oil: 20 L

Trust Seal

Dealers certified through Machineseeker

Listing

Warren

Warren

1,239 km

Oil Hole Drilling Machine

INGERSOLLAODH-1050

Call

Condition: good (used), Year of construction: 2013, total length: 3,990 mm, total height: 2,500 mm, total width: 2,280 mm, overall weight: 8,500 kg, INGERSOLL CM SYSTEMS AOHD AGILE OIL HOLE DRILL

Equipped with:

Siemens 840D Control

(2) Drill Heads

20-Tool Rack

HSK 50A Taper

(2) 7" 3-Jaw Chucks

(2) Tailstocks

(2) Steady Rests

Chip Auger

Chip Conveyor

Mist Collector

Hydraulic System

Q R 2 Lube System

Air Compressor

Specifications:

Maximum Length: 1050 mm (41.3")

Minimum Length: 180.0 mm (7.1")

Maximum Stroke: 250.00 mm

Maximum Main Journal Diameter: 115.0 mm (4.5")

Maximum Pin Journal Diameter: 100.00 mm (3.9")

Maximum Swing Diameter: 250.0 mm (9.84")

X-Axis Travel: 1450 mm (57.1")

Y-Axis Travel: 150 mm (5.9")W/HSK 50

Z-Axis Travel: 305.0 mm (12.0")

A-Axis Travel: 360 Degree

B-Axis Travel: 90 Degree

Feed Rate (Z): 1 m/min Maxim (40"/min max)

Position Accuracy of X,Y,Z Axes: .010 mm (.00039")

Position Accuracy of A & B Axes: .03 Degree

Position Repeatability of X,Y,Z Axes: .005 mm (.0002")

Position Repeatability of A & B Axes: .005 Degree

Spindle Power: 5.5 kW (7.5 hp)

Spindle Speed: 0-6,900 RPM

Tool Adaption: HSK 50E or A

Tool Storage (ATC): 20 Total - 10 Per Spindle W/HSK 50

Lubrication - Slides & Ball Screws: Automatic Central Lubricator

Fjdpfx Ajrtrx Regrjpb

Approximate Floor Space (LxWxH): 4.0 x 2.3 x 2.5 m (13.1 x 7.5 x 8.2 Ft)

Approximate Machine Weight: 8,500 kg (18,740 #)

Listing

Warren

Warren

1,239 km

Vertical turning lathe

PittlerPV315

Call

Condition: good (used), Year of construction: 2019, machine/vehicle number: 25728, Equipped with:

Hydraulic Unit

Sinumerik 840D sl CNC Control

Slim Line Operator Panel OP012 W/12 TFT-Color Display

Fjdpfx Agsw Iqumsrspb

19" Machine Control Panel

20 Tool ATC

CAPTO C6

Multifunctional Tool Carrier For Turning and Driven Tools

One Fixed Tool Unit

Assembled To The Compound Slide W/Coolant Thru The Turning And Drilling

Tools, Coolant For The Driven Spindle From The Outside

Drilling Spindle

Additional Drill Spindle For Orientation

Chip Conveyor

Coolant Equipment

-Including piping and shut-off valve and flow control switch

-To supply coolant to tools for coolant and flushing through the cutting tools

-To supply coolant for flushing the work piece and chuck

-To supply coolant for flushing the working area

Paper Band Filter

Immersion Cooler

High Pressure Coolant Pump, 40 Bar Through Tools

Flushing Pistol, Hand Held

Air Cleaner - Mechanical Separation "Mist Collector"

Tool Life Display

Remote Diagnostics

Signal Lamp

Automatic Door For Loading W/Shuttle

Load and Unload Shuttle

Swivel Loader

Automation Cell Tuned for Part

Pallet Conveyor For 20 Raw And Finished Parts Pallets

Pallets Designed for Part 596500

Handling System

SPC Station (Maximum O 270 mm, Maximum H 150 mm, Maximum Wt. 12 kg)

NIO Station (Closing forward leading gravity)

Skiving Software (Hardware: Software and user surfaces for skiving technology)

Measuring Probe (For measuring diameters and length of the workpiece in the machine)

Measuring Software for Teeth Measuring (MDK and Flank Line, Software and User)

Measuring Program (Automatically measuring program for measure the position of the

two gears to each other, after using sister tools)

SPC (Every X workpieces the MDK needs to be measured)

Tool Changer (Precut, measurer and final cut)

Skiving Tool Identification (Hardware, software for the identification of the skiving

tool after tool change)

Hydraulic Diagrams

Coolant Diagrams

Lubrication Diagrams

Electrical Wiring Diagrams

Hardcopy of Diagrams

CF Certificates

Specifications:

Workpiece Spindle:

-Speed: 0-7000 l/min

-Power: 55,2 - 59,7 kW

Tool: Capco C6

Tool Spindle:

-Speed: 0-6000 l/min

-Power: 29 - 41 kW

Machine Weight, Floor Space and Voltage Supply:

-Operating Voltage: 400V, 3 Phases, 50 Hz

-Control Voltage: 24 V

-Lighting Voltage: 240 V, 50 Hz

-Floor Space: 2,700 x 2,600 mm

-Height: 4,000 mm

-Total Weight, Approximate: 16,000 kg

Longitudinal, Z-Axis:

-Stroke: 800 mm

-Rapid Rate: 24 m/min

-Feed Force: 12 kN

Transverse, X-Axis:

-Stroke: 900 mm

-Rapid Rate: 24 m/min

-Feed Force: 12 kN

Tool Spindle, B-Axis:

-Range: -20 / +90 Degree

Y-Axis for Spindle Unit:

-Stroke: 200 mm

-Rapid Rate: 12 m/min

-Feed Force: 6 kN

C-Axis Main Spindle:

-Positioning Accurace: 9"

Multifunctional Tool Carrier:

-Power: 29 kW at 100% ED

-Power: 41 kW at 44% ED

-Torque: 141 Nm at 100% ED

-Torque: 212 Nm at 44% ED

-Spindle Speed: 0-6000 min-1

-B-Axis for Stepless Motion in a Range Of: -20/+90 Degree

Tool Magazine:

-Maximum Tool Diameter: 100 mm

-Approximate Tool Length: 300 mm

-Approximate Tool Weight: 12 kg

Swivel Loader:

-Maximum Workpiece Diameter: 270 mm

-Height: 150 mm

-Weight: 16 kg

Listing

Warren

Warren

1,239 km

Gearwheel shaping machine

Fellows70-15

Call

Condition: good (used), Year of construction: 1973, FELLOWS 70-15 GEAR SHAPER - Model 70-15 Fellows heavy duty vertical gear shaping machine , suitable for

the manufacture of external straight spur gears up to 70" pitch diameter, as well as internal spur gears and splines within a range of 0" to 88" pitch diameter, regardless of shaper-cutter radius. This unique feature, combined with the machines 15" face-width capacity and 1.7DP cutting capability in steel, provide a formidable platform for producing a wide range of larger geared part members.

Equipped with:

* Machine Main Base With Work-table, Upper Column,

Cutter Ram and Slide of "Super Robust" Construction

* Machine with "Saddle Backoff" Method of Cutter Relieving

* Cutter Spindle 6.25" diameter w/Standard Straight Spur Guide

* Cutter Positioning via Stroke Jog-Button

* Rapid Rotation of Work Spindle for Trueing Work-Piece

* Rapid Saddle Traverse for Traversing Saddle Relative to Work

* Automatic Depth Feed Mechanism for One to Four Cuts, With 4 Speed Motor

Providing Speed Change on Finishing Cut

Fpjdortrxijpfx Agrsb

* Assorted Work and Feed Change Gears

* Assorted Stroke Change Gears

* 2" Riser Plate

* Main Drive Motor 15HP, 650/220 rpm, 240 Volt 60Hz w/Westinghouse Rectifier

Unit for AC

* Power Forced Lubrication to Working Elements with "Lubriquip Lub Controller"

* Coolant Tank, Pump, and Piping, With Chip Pan

* Full Complement of Electrics

* Assorted Guards, Covers

* 84" T-Slotted Table

* Hydraulic System

* Work Lamp

* Work Platform

* Cutter Adaptor

* Manuals

Specifications:

Max. Diameter External Gear Cut (Nominal): 70"

Max. Diameter Internal Gear Cut (Nominal): 88"

Max. Diameter Workpiece Accommodated: 104"

Worktable Diameter: 84"

Max. Permissible Weight of Workpiece & Fixture: 36,000 Lbs.

Max. Distance Workspindle Centerline to Centerline of Cutter Spindle: 35"

Min. Distance Workspindle Centerline to Centerline of Cutter Spindle: 0"

Max. Work & Fixture Clearance Height w/Cutter Spindle in Upper Position: 28"

Max. Diametral Pitch (full length teeth): 2 DP

Max. Diametral Pitch (stub teeth): .75 DP

Max. Diameter Pitch (30P.A. splines): 2-5/5 DP

Diameter of Cutter Spindle: 6.25"

Max. Stroke Length: 19.118"

Max. Face-Width (nominal): 15"

Stroking Speeds (infinitely variable): 5 to 122 S.P.M.

Max. Infeed of Cutter Ram: .0020 inch/min.

Min. Infeed of Cutter Ram: .0005 inch/min.

Max. Rotary Feed Per Stroke (per 1" of cutter diameter): .0068"/Min.

Min. Rotary Feed Per Stroke (per 1" of cutter diameter): .0006"/Min.

Approximate Machine Dimensions: 192"L x 144"W x 150"H

Approximate Machine Weight: 95,000 Lbs.

Listing

Warren

Warren

1,239 km

Bevel gear generator

GleasonPhoenix 450HC

Call

Condition: good (used), Year of construction: 2000, gear diameter: 449 mm, Equipped with:

Fanuc 150MB CNC Control

Dry Cutting

Cutter Shroud

Chip Evacuation System

Auto Doors

Hydraulic System

Lubrication System

Work light

Stack Light

Specifications:

Largest Speed Ratio: 10:01

Work Area (Continuous):

Largest Depth of Teeth: 15.24 mm

Largest Width of Tooth Face: 50.8 mm

Work Area Axis:

Horizontal Movement X Axis: -114 - 178 mm

Vertical Movement Y Axis: -178 - 190 mm

Movement of the Carriage Baseplate Z-Axis: -10.16 - 500 mm

Workpiece Headstock Swiveling Range B-Axis: -3 - 90 Degree

Maximum Distance Machine Center to Spindle Side: 165 mm

Number of Teeth: 5-200 Inclusive

Max. Gear Pitch Dia. of Typical 35 Deg. Spiral Angle Gear Using

Max. Cutter Dia. 12" Cutter at the Following Ratios:

Face Milling

1 x 1 - 13.5" - 342.9mm

2 x 1 - 16.0" - 406.4mm

5 x 1 - 17.7" - 450.0mm

Face Hobbing (210mm Dia. Cutter)

1 x 1 - 10.560" - 268.22mm

2 x 1 - 10.286" - 275.00mm

5 x 1 - 11.810" - 300.00mm

Milling Head Diameter:

Helixact: 100,125,169,200,250,320mm

Continuous Gumption Procedure, Teichloroethylene: 102 - 210 mm

Workpiece Spindle:

Drilling of Large Diameters: 5 3/64"

Cone Upward Gradient on 304.8 mm (1 Foot): 21/32"

Deep One of the Cone: 5.29"

Diameter of the Whole Spindle Perforating: 3.35"

Speeds:

Fjdpfx Aeruakgsgrepb

B-Axle Workpiece Headstock Drag Axis: 30 Degrees

A-Axle Workpiece Spindle Number of Revolutions: 0 83 min-1

X-Axis Horizontal: 80 mm/sec

Y-Axis Vertically: 80 mm/sec

Z-Axis Carriage Baseplate: 80 mm/sec

Space Requirement L x W x H (Approximate): 4.75 x 3.40 x 2.54m / 188" x 134" x 100"

Machine Weight (Approximate): 10980 kg / 24,156#

We make it easier for you to find: "central lubrication"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Central Lubrication System (9,734)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you