Used bale presses for sale (217)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Waste management & recycling equipment Presses Bale presses

Listing

Vilnius

Vilnius

8,374 km

Baler

PaalKONTI 425C

Call

Condition: used, Year of construction: 1995, pressing force: 85 t, power: 170 kW (231.14 HP), BALER PAAL KONTI 425 C

Technical specifications:

Manufacturer: Paal

Type: Konti 425C

Year of manufacture: 1995

Feed opening: 102 x 175 cm

Bsdpfx Aaew Tawusqeww

Drive power: 170 kW

Compression force: 85 t

Settings: Horizontal, fully automatic

Roll weight: 500-650 kg

Press weight: 25 t

PRICE ON REQUEST!

Listing

Netherlands

Netherlands

7,548 km

Baler with pre-press flap LP 50 EH1

Presona ABLP 50 EH1

Call

Condition: reconditioned (used), Year of construction: 2005, operating hours: 30,408 h, functionality: fully functional, pressing force: 50 t, filling opening width: 1,100 mm, filling opening length: 1,250 mm, bale width: 1,100 mm, bale height: 720 mm, bale weight: 550 kg, overall weight: 16,000 kg, oil tank capacity: 600 l, year of last overhaul: 2024, Technical data baler:

Manufacturer Presona AB

Type LP 50 EH1

Year of construction 2005

Operating hours 30,408 hours, as of April

Number of pressed bales 198,059 as of April

Pressing force main press 50 tonnes

Specific pressing force 63 N/cm²

Theoretical throughput capacity 530 m³/hour

Throughput capacity under operating conditions 260 m³/hour

Dimensions of feed chute 1,250 x 1,100 mm

Bale chamber volume 2.2 m³

Bale dimensions 1,100 x 720 mm, variable length

Drive power 22 kW

Tying 5-fold vertical, fully automatic

Throughput rates with a

bulk density of 30 kg/cbm 6 up to 7 tonnes/hour

Bulk weight of 50 kg/cbm 7 up to 9 tonnes/hour

Bulk weight of 100 kg/cbm 11 up to 14 tonnes/hour

Bale density (paper/newspapers) 400 to 550 kg/m³

Hydraulic oil tank capacity 600 litres

PLC control Telemecanique TSX Micro

Schneider Magelis control panel

Effective transport dimensions excl. baler 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight press approx. 16 tonnes

Condition of the baler:

The machine was partial overhauled in our workshop and general maintenance work was carried out. After completion of the overhaul work, the press was tested during operation and is available for sale at short notice.

The following overhaul work was carried out:

General work:

Machine cleaned, derusted, primed, partially painted

Wire entry marks in the press channel feed-throughs welded shut and smoothed

Hydraulic unit:

Hydraulic oil tank emptied, tank cleaned, new oil filled

Oil filter and air filter replaced

Leaky oil sight glass on hydraulic oil tank replaced

All hydraulic hoses replaced

Electrics:

Bsdpfx Aju Thhrjaqsww

English language installed in the programme menu

Two key switches in the control panel replaced

Control cabinet replaced

Signal lamp on the control cabinet replaced

Flaps end switch replaced

Electrical system of the turbulator replaced, connected and tested

Press ram:

All four rollers removed from the press ram and replaced

Main hydraulic cylinder dismantled, disassembled and partially overhauled, cylinder tube honed, complete seal set replaced, leak test performed

All plastic wear pads on the press ram replaced

Pre-press:

Both bearings on the pre-press shaft replaced.

Both hydraulic cylinders dismantled, disassembled and partially overhauled, both cylinder tubes honed, complete seal sets replaced, leak test performed.

Scraper flap on the pre-press replaced.

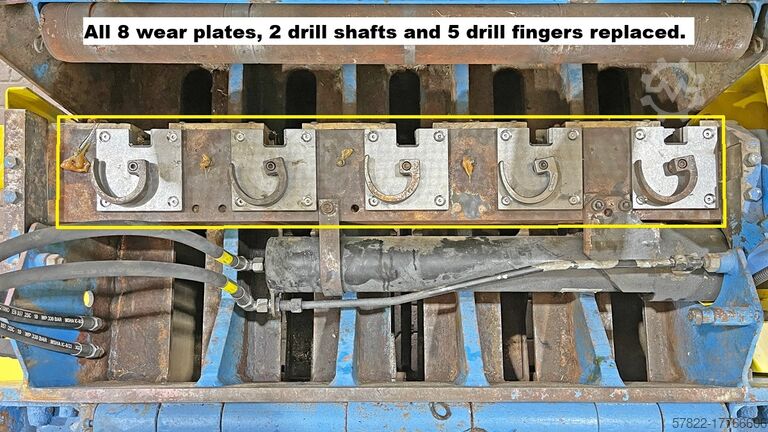

Binding system:

Two complete needles with wire deflection rollers replaced

Needles adjusted and set

All wire deflection rollers in the needle heads replaced

Drill fingers replaced

Two drill shafts replaced

All 8 wear plates on the Drillomat, under the drill fingers, replaced

Scope of delivery:

Only the baler will be sold.

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Listing

Kosorowice

Kosorowice

8,331 km

Bale press

Dixi60s

Call

Condition: ready for operation (used), Pressing force: 60 tons

YEAR OF MANUFACTURE: 2018-2020, price: EUR 5,500

Bale dimensions: 120 x 80 x 110 cm

Bedpfx Aajra Nqhoqjww

Press dimensions: 1900 x 1400 x 2200 mm – height

Press weight: approx. 2,430 kg

Bale weight: up to 500 kg

Oil heating

Motor: 7.5 kW

Brand new showroom baler costs EUR 11,000

Listing

Diepenbeek

Diepenbeek

7,595 km

Baler

BOABOA 2960 K 30 6 P

Call

Condition: used, Year of construction: 1995, functionality: fully functional, input voltage: 400 V, power: 40 kW (54.38 HP), Baler from 1995. Viewing by appointment only.

Bodpfx Aow H Ar Asaqeww

Listing

Helmstedt

Helmstedt

7,830 km

Baler Bale press

AustropressenAP 50

Call

Year of construction: 2008, condition: good (used), Horizontal baling press

Build in 2008

Bwjdpfx Ajg Ibt Noaqow

Bale size 800x1000x1400

Loading height 1250mm

Discover more used machines

Listing

San Giovanni Al Natisone

San Giovanni Al Natisone

8,394 km

COMPACTING PRESS COMAP MOD. SC-10

COMAPSC-10

Call

Condition: used, Year of construction: 1996, pressing force: 1 t, total height: 1,390 mm, SECOND-HAND COMPACTING PRESS COMAP MOD. SC-10 - CE RULES

- Compacting dimensions mm. 1000x700x750

- Loading dimensions mm. 1000x700x1390

- Year 1996

Bwodpfx Aajua Awhjqjw

Listing

Vilnius

Vilnius

8,374 km

Baler

PaalKONTI 425D

Call

Condition: used, Year of construction: 2002, pressing force: 115 t, power: 150 kW (203.94 HP), For sale: Paal Konti 425 D horizontal baler

Technical specifications:

Manufacturer: Paal

Bsdpfxjw Tavke Aaqeww

Model: Konti 425D

Year of manufacture: 2002

Feed opening: 102 x 200 cm

Drive power: 2 x 45, 2 x 75 kW

Pressing force: 115 t

Operation mode: horizontal, fully automatic

Bale weight: 550–850 kg

Pressing weight: 36 t

PRICE ON REQUEST!

Listing

Netherlands

Netherlands

7,548 km

HBC 60 A

Bollegraaf Recycling Solutions B.V.HBC 60 A

Call

Condition: reconditioned (used), Year of construction: 2000, operating hours: 32,169 h, functionality: fully functional, pressing force: 60 t, filling opening width: 1,100 mm, filling opening length: 1,320 mm, bale width: 1,100 mm, bale height: 720 mm, bale weight: 750 kg, overall weight: 22,000 kg, oil tank capacity: 900 l, For sale is a complete baling system consisting of conveyor technology, baling press and wire stations.

Technical data baler:

Manufacturer Bollegraaf Recycling Machinery B.V.

Typ HBC 60A

Year of construction 2000

Hours of operation 32,169 hours, stand November 2024

Press power main press 60 tons

Press power of pre-press max. 25 tons

Feed channel 1,320 x 1,100 mm

Theoretic cycle time 18 sec.

Bale size 1,100 x 720 mm, lenght variable

Driving motor 45 kW

Connected load 60 kW

Tying system 5-fold vertical

Throughput rate at a

bulk weight of 30 kg/cbm approx. 5,5 tons/hour

bulk weight of 50 kg/cbm approx. 10 tons/hour

bulk weight of 100 kg/cbm approx. 16 tons/hour

Bale weight 400 up to 750 kg, depends on material

SPS controller Telemecanique TSX Micro

Machine weight baler approx. 24 tons

Bjdpfx Aaoviwdmsqjww

Scope of delivery:

1 piece chain belt conveyor

1 Bollegraaf HBC 60A baler with whirling unit

1 maintenance platform with access ladder

2 wire stations with deflection rollers for 10 wire reel stands (without wire)

The following repair and overhaul work was carried out:

Hydraulic oil tank emptied, cleaned and refilled with new oil

Oil filter and air filter replaced

Hydraulic block partially resealed

Hydraulic hose on hydraulic block replaced

Wire entry marks on the floor passages welded shut and smoothed

Tying unit cleaned, serviced

Electrical system repaired, door flap contact switch partially replaced

Whirbulator repaired

General maintenance work carried out, lubricated

Machine tested during operation, without the use of materials, in manual mode and in automatic mode, see function video

Comments:

The system has already been completely dismantled, stored and is available for loading at short notice. The documentation (BA, CE, electrical/hydraulic circuit diagram) is available. Viewing is possible by appointment. We accept no liability for the technical details or any errors.

Listing

Dordrecht

Dordrecht

7,498 km

Bollegraaf HBC140s (2x75kW) 2003

BollegraafHBC 140

Call

Year of construction: 2003, operating hours: 43,000 h, condition: repair required (used), machine/vehicle number: HBC 140 2x75kW 2003 (W230-005), Sold by Bollegraaf Recycling Solutions, the original manufacturer of this Bollegraaf baler and conveyor:

Bollegraaf HBC140s Baler (2x75kW).

Baler:

Weight: 47.100 kg

Construction year: 2003

Hardox bottom floor plate only

Plastic valve

Anti-rat cabling

Hours 43.000

This baler can also be sold fully refurbished according to the 'Bollegraaf OEM Certified Refurbishment standards'. This includes 2 year guarrantee.

Contact us for more information or a quotation.

General principles of refurbishment

Cleaning & disassembly

Before the actual refurbishment takes place the baler is completely cleaned and disassembled in our refurbishment workshop.

Tolerances

After the disassembly the tolerances of all steel components are measured and re-welded where necessary, this at least applies to the following components;

• Ram,

• Frame,

• Channel,

• Pre-press-flap

After disassembly and inspection the ram is welded-up again and fitted with new ram wheels.

The protective grids and the pre-press flap are made dent-free and repaired where necessary.

Repainted

After measuring the tolerances and any repair- and welding work, all components are being blasted and coated again.

Hydraulics:

The hydraulic tank is cleaned.

The hydraulic lines & hoses are replaced.

The hydraulic components are repackaged.

The hydraulic oil is replaced.

Bwsdpjkcgynefx Aaqjw

Cabling:

All cabling is checked and replaced if necessary.

All junction boxes are replaced and placed back in easily accessible positions.

Wear parts:

All wearing parts are replaced.

The pins and shafts of the cylinders and the channel are replaced with new ones.

All wearing parts of (both) needle installations and knotters are replaced for new.

Cylinders:

The cylinders are repackaged and, if necessary, provided with a new chrome layer or a new cylinder rod.

MCC Cabinet

The switch box is checked and cleaned.

If necessary, electronic components are replaced with new ones.

The PLC and HMI (human interface) are replaced with the latest Schneider M340 version including the latest software.

Listing

Cyprus

Cyprus

10,432 km

Baling press with feed conveyor

BollegraafHBK 25

Call

Condition: excellent (used), Year of construction: 1998, functionality: fully functional, pressing force: 25 t, filling opening width: 800 mm, filling opening length: 1,050 mm, bale width: 900 mm, bale height: 800 mm, input voltage: 400 V, noise level: 85 dB, power: 18.5 kW (25.15 HP), volume flow: 160 m³/h, Bollegraaf HBK25 offered in Cyprus. The machine is in good condition and includes a floor conveyor belt. The machine is immediately available.

Technical specifications of the baler:

Drive: 18.5 kW

Bale size: 800 x 900 x adjustable

Feed hopper dimensions: 1,050 x 800

Press force: 25 tons

Capacity: 160 m3/hour (depending on material)

Technical specifications of the conveyor belt (approximate):

Length on floor: 3,000 mm

Bsdpfx Aaoxbdgujqoww

Diagonal length: 5,000 mm

Listing

Wentorf bei Hamburg

Wentorf bei Hamburg

7,709 km

Baler

BramidanX30AD

Call

Condition: excellent (used), Year of construction: 2018, Two balers, Bramidan X30 - second-hand - :

Price (for both together) ex location: 17.500.-€ (net)

Please note that one of the two balers has to be repaired - there is a cost estimate of approx. 1.500.-€ (net)!

Bwsdstq Hrispfx Aaqjw

Manufacturer: Bramidan

Type: X30 AD

Machine number PEY395533 (second number on request)

Year of construction: 2018

Pressing force: 30 t

Bale size: WxDxH (mm) 1200 x 800 x 1000

FILLING OPENING: WxH (mm) 1090 x 655

BALE WEIGHT: Cardboard (kg) 275-350, plastic film (kg) 325-425

Recyclable material types: Cardboard, plastic film, paper, PET bottles, aluminum cans, tin cans, hard plastic, textiles, styrofoam.

3 x 230 - 400V, 50Hz, Amp: 25/16

db: 59-60

Weight: 1.650kg

Condition: good - very good

Available: immediately

Location: 21465 Reinbek

Listing

Brakel

Brakel

7,761 km

BTS-MF450HD Special Waste Baler

BTS-MF450HD Spezial-Ballenpresse

Call

Condition: as good as new (ex-display), Year of construction: 2025, The BTS-MF450HD special waste baler is the ideal baler for compacting difficult materials such as PET bottles, food cans and metal containers, big bags, plastic canisters and plastic packaging, but also scrap tyres and car bumpers can be reduced to a minimum of volume with the baler. The special baling press impresses with its ease of use, safe operation and its spacious filling chamber, it is ideal for medium to large amounts of material.

Bedjvug Ekepfx Aaqjww

By baling these valuable and recyclable materials you achieve a volume reduction of up to 90%, a significant saving on your disposal costs and you properly return the material back into the recycling cycle.

Pressing force: 30 Ton

Bale weight: up to 450 kg (material depending)

Bale size: 1000 H (var.) x 1200 W x 800 D mm

Machine size: 3343 H x 1781 W x 1196 D mm

Machine weight: 1600 kg

Transport height: 2300 mm

Loading aperture: 1200 W x 680 H mm

Cycle times: 40 seconds

Motor: 5.5 kW 16 Amp

Power supply: 380 - 400 V (3 phase)

Noise level: 68 dB

Extra-long dual cylinders for even and early compaction of the material

User-friendly lever control

Bale kicker for easy eject the bales

Extra retainer for reducing the material spring back

Reel holder for 4 rolls of strapping

A quality product “Made in Europe”

Suitable for compacting

PET bottles

Food cans and sheet metal containers

Canisters and plastic containers / packaging

Scrap tyres and car bumpers

Big bags

Cardboard and plastic film / foils

Other difficult valuable materials

Optional extras

Machine colour RAL

PLC auto compaction cycles with bale full light and E-stop with locking key

Sliding top door

Strapping rolls / bale wire

Motor 11 kW 32 Amp

Demo-Video shows BTS-MF550HD Special Waste Baler.

Can Baler, Can Waste Baler, PET Baler, PET Compactor, Tyre Baler, Tire Baler, Scrap Tyre Baler, Scrap Tire Baler, Tyre Compactor, Tire Compactor, Can Baler, Waste Baler, Waste Compactor, Cardboard Baler, Film Baler, Foil Baler, Packaging Plastic Film Foil, Bailer, Baling Press, Garbage Press, Trash Compactor, Baling Compactor, Paper Press, Waste Paper Press, Cardboard Press, Cardboard Compactor, Foil Press, Paper Baling Press, Waste Baler, Residual Waste Compactor

Listing

Vilnius

Vilnius

8,374 km

Baler

PaalLikon 200

Call

Condition: used, Year of construction: 1994, pressing force: 30 t, power: 22 kW (29.91 HP), LIKON 200C Horizontal Baler

Technical Data:

- Motor power: 22 kW

- Year of manufacture: 1994

- Equipped with oil cooler

- Horizontal tying: 4-fold

- Pressing force: 30 t

- Overall dimensions of the press: 10,000 x 2,000 x 2,750 mm

- Net weight of the press: 10 t

- Feed opening dimensions: 1,400 x 700 mm

- Bale dimensions: 700 x 1,100 x 1,000–1,200 mm (variable length)

- Includes hydraulic oil

Bsdpfx Asw S Hpzeaqsww

- Without tying wire

- No conveyor belt; previously operated in a print shop exclusively processing dry-shredded print waste

- Operating hours: 62,639

The press is in good condition and ready for immediate use.

PRICE ON REQUEST!

Listing

Netherlands

Netherlands

7,548 km

112

MACPRESSE EUROPA S.R.L.112

Call

Condition: reconditioned (used), Year of construction: 2002, operating hours: 43,954 h, functionality: fully functional, pressing force: 200 t, filling opening width: 1,020 mm, filling opening length: 2,000 mm, bale width: 1,100 mm, bale height: 1,100 mm, overall weight: 50,800 kg, oil tank capacity: 3,100 l, Technical data baler:

Manufacturer MACPRESSE EUROPA S.R.L.

Typ 112

Year of construction 2002

Operating hours 43,954 hours, stand March

Press power main press 200 tons

Specific press capacity 16,5 kg/cm²

Feed channel 2,000 x 1,020 mm

Filling volume 2,65 cm³

Bwsdpfxsu Thgzs Aaqjw

Theoretic throughput rate 795 m³/h

Bale size 1,100 x 1,100 mm, length variable

Driving motor 2 x 75 kW

Tying system 5-fold horizontal, full automatic

Throughput rate at MSW approx. 48 up to 54 tons/h, depends on material

Volume hydraulic oil tank 3,100 l

Machine weight baler approx. 50,8 tons

Scope of delifery:

1 piece baler MACPRESSE, type 112

1 operating manual with CE declaration, electrical and hydraulic circuit diagram

Comments:

The machine is currently in our workshop for overhaul. We assume that the press will be completely overhauled in approx. 4 weeks and can then be tested.

The documentation (Manual, CE, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Listing

Dordrecht

Dordrecht

7,498 km

Bollegraaf HBC140s (2x75kW) 2008

BollegraafHBC 140

Call

Year of construction: 2008, operating hours: 40,000 h, condition: good (used), machine/vehicle number: HBC 140 2x75kW 2008 (00191), Sold by Bollegraaf Recycling Solutions, the original manufacturer of this Bollegraaf baler and conveyor:

Bollegraaf HBC140s Baler (2x75kW).

Baler:

Weight: 47.100 kg

Construction year: 2008

Hardox bottom floor plate only

Variable channel pressure control

Plastic valve

Hydraulic pump driven by frequency inverter

Anti-rat cabling

Oil in-depth filtration

Modem

Hours 40.000

This baler can also be sold fully refurbished according to the 'Bollegraaf OEM Certified Refurbishment standards'. This includes 2 year guarrantee.

Contact us for more information or a quotation.

General principles of refurbishment

Cleaning & disassembly

Before the actual refurbishment takes place the baler is completely cleaned and disassembled in our refurbishment workshop.

Tolerances

After the disassembly the tolerances of all steel components are measured and re-welded where necessary, this at least applies to the following components;

• Ram,

• Frame,

• Channel,

• Pre-press-flap

After disassembly and inspection the ram is welded-up again and fitted with new ram wheels.

The protective grids and the pre-press flap are made dent-free and repaired where necessary.

Repainted

After measuring the tolerances and any repair- and welding work, all components are being blasted and coated again.

Hydraulics:

The hydraulic tank is cleaned.

Bwedpfx Ajkcgf Hsaqjw

The hydraulic lines & hoses are replaced.

The hydraulic components are repackaged.

The hydraulic oil is replaced.

Cabling:

All cabling is checked and replaced if necessary.

All junction boxes are replaced and placed back in easily accessible positions.

Wear parts:

All wearing parts are replaced.

The pins and shafts of the cylinders and the channel are replaced with new ones.

All wearing parts of (both) needle installations and knotters are replaced for new.

Cylinders:

The cylinders are repackaged and, if necessary, provided with a new chrome layer or a new cylinder rod.

MCC Cabinet

The switch box is checked and cleaned.

If necessary, electronic components are replaced with new ones.

The PLC and HMI (human interface) are replaced with the latest Schneider M340 version including the latest software.

Listing

Brakel

Brakel

7,761 km

BTS-MF75 Waste Baler, Cardboard, Foil

BTS-MF75 Ballenpresse Waste Baler

Call

Condition: new, Year of construction: 2024, functionality: fully functional, Waste Baler BTS-MF75 in stock and available straight away

The BTS-MF75 is the ideal waste baler for compacting your loose cardboard and plastic film waste into a bale of up to 75 kg. With a can crush insert baler is even suitable for crushing individual sheet metal and plastic containers and also cans. The baling press impresses with its ease of use, safe operation and its large filling volume.

By baling these valuable and recyclable materials you achieve a volume reduction of up to 90%, a significant saving on your disposal costs and you properly return the material back into the recycling cycle.

Pressing force: 3.5 Ton

Bale weight: up to 75 kg (material depending)

Bale size: 1000 H (var.) x 700 W x 500 D mm

Machine size: 2335 H x 1040 W x 750 D mm

Machine weight: 278 kg

Transport height: 2335 / 1800 mm (on request)

Loading aperture: 700 W x 698 H mm

Cycle times: 24 seconds

Motor: 1.5 kW 13 Amp

Power supply: 220 - 240 V (1 phase)

Noise level: 68 dB

User-friendly lever control

Bale trolley for removing the bales

Retainer for reducing the material spring back

Bwsdpfx Aevah S Asaqsw

Reel holder for 2 rolls of strapping

A quality product “Made in Europe”

Suitable for compacting

Cardboard

Plastic film and foils

Cans and light sheet metal containers

Canisters and light plastic containers

Clothes

Light valuable materials

Optional extras

Machine colour RAL

Can crusher insert

PLC auto compaction cycles with bale full light and E-stop with locking key

Strap eject for easy removal of bales

Strapping rolls

Power supply 380 - 400 V (3 phase)

Waste Baler, Waste Compactor, Cardboard Baler, Film Baler, Foil Baler, Packaging Plastic Film Foil, Bailer, Baling Press, Garbage Press, Trash Compactor, Baling Compactor, Paper Press, Waste Paper Press, Cardboard Press, Cardboard Compactor, Foil Press, Paper Baling Press, Waste Baler, Residual Waste Compactor

Listing

Vilnius

Vilnius

8,374 km

Baler

BAUER300

Call

Condition: used, Year of construction: 1994, pressing force: 40 t, power: 22 kW (29.91 HP), We sell/rent the BAUER 300 baler.

Technical specifications:

Secondary raw material baler installation

Manufacturer: BAUER

Model: 300

Year of manufacture: 1994

Power: 22 kW

Pressing force: 40–50 t

Dimensions (L x W x H): 10,300 x 2,000 x 3,000 mm

Tipping weight: approx. 400 kg

Bodpfx Aow S Hpboaqoww

PRICE ON REQUEST!

Listing

Brakel

Brakel

7,761 km

BTS-MF450 Waste Baler, Cardboard, Foil

BTS-MF450 Ballenpresse Waste Baler

Call

Condition: as good as new (ex-display), Year of construction: 2025, The BTS-MF450 is the ideal waste baler for compacting your loose cardboard and plastic film waste into a bale of up to 450 kg. The baling press impresses with its ease of use, safe operation and its spacious filling chamber, it is ideal for medium to large amounts of material.

By baling these valuable and recyclable materials you achieve a volume reduction of up to 90%, a significant saving on your disposal costs and you properly return the material back into the recycling cycle.

Pressing force: 30 Ton

Bale weight: up to 450 kg (material depending)

Bale size: 1000 H (var.) x 1200 W x 800 D mm

Machine size: 3000 H x 1781 W x 1196 D mm

Machine weight: 1300 kg

Transport height: 2300 mm

Loading aperture: 1200 W x 680 H mm

Cycle times: 40 seconds

Motor: 5.5 kW 16 Amp

Power supply: 380 - 400 V (3 phase)

Noise level: 68 dB

Dual cylinders for even compaction of the material

User-friendly lever control

Bale kicker for easy eject the bales

Retainer for reducing the material spring back

Reel holder for 4 rolls of strapping

A quality product “Made in Europe”

Suitable for compacting

Cardboard

Plastic film and foils

Big Bags

Clothes

Light valuable materials

Optional extras

Machine colour RAL

PLC auto compaction cycles with bale full light and E-stop with locking key

Sliding top door

Strapping rolls

Bwjdpfx Aaevamafoqew

Motor 11 kW 32 Amp

Waste Baler, Waste Compactor, Cardboard Baler, Film Baler, Foil Baler, Packaging Plastic Film Foil, Bailer, Baling Press, Garbage Press, Trash Compactor, Baling Compactor, Paper Press, Waste Paper Press, Cardboard Press, Cardboard Compactor, Foil Press, Paper Baling Press, Waste Baler, Residual Waste Compactor

Listing

Vilnius

Vilnius

8,374 km

Baler

HomaBP3000P

Call

Condition: defective spare-parts repository (used), Year of construction: 1992, pressing force: 30 t, power: 15 kW (20.39 HP), CHEAP SALE BALER WITH DEFECT!

Technical data:

Manufacturer: Homa

Type: BP3000P

Year of manufacture: 1992

Filling opening: 1050 x 820 mm (LxW)

Drive power: 15 kW

Pressing force: 30 t

Settings: horizontal, fully automatic

Bale size: 800 x 900 mm

Bale weight: approx. 300 kg

Machine weight: approx. 5,650 kg

Bsdpfx Aaew S E T Sjqjww

Defect – Oil has leaked from the system, water may have entered the system!

PRICE 5,500 EUR (EXW Lithuania, Vilnius)

Listing

Brakel

Brakel

7,761 km

BTS-MF60HD PET and Can Waste Baler

BTS-MF60HD PET-Dosen-Presse Can Baler

Call

Condition: as good as new (ex-display), Year of construction: 2025, The BTS-MF60HD is the ideal special waste baler for compacting your difficult and hard materials such as Cans, PET, Metal Buckets, Metal Containers, but also Plastic Canister and much more recyclable materials can be compacted easily and safe to a minimum of its size. The special waste baler impresses with its ease of use and safe operation, finished bales can be easily removed with the automatic bale ejector.

By baling these valuable and recyclable materials you achieve a volume reduction of up to 90%, a significant saving on your disposal costs and you properly return the material back into the recycling cycle.

Pressing force: 13 Ton

Bale weight: 25 - 60 kg (material depending)

Bale size: 650 H (var.) x 600 W x 400 D mm

Machine size: 2144 H x 1267 W x 1328 D mm

Machine weight: 706 kg

Transport height: 2144 mm

Loading aperture: 890 H x 600 W x 400 D mm

Cycle times: 25 seconds

Motor: 2.2 kW 16 Amp

Power supply: 220 - 240 V (1 phase)

Noise level: 68 dB

Top loading Special Waste Baler

User-friendly lever control

Bwjdjvbq Rkspfx Aaqsw

Automatic bale kicker for easy bale removal

Retainers for reducing the material spring back

Cross Strapping Tying System to keep difficult materials in bale

Reel holder for strapping rolls

A quality product “Made in Europe”

Suitable for compacting

PET bottles

Cans and sheet metal containers

Canister and plastic containers

Cardboard and plastic film and foils

Optional Extras

Machine colour RAL

Strapping rolls

Power supply 380 - 400 V (3 phase)

Can Compactor, Can Press, PET Compactor, PET Press, Baler PET bottles, PET Bottle Baler, Ballenpresse, Papierpresse, Altpapierpresse, Kartonpresse, Kartonagenpresse, Folienpresse, Papierballenpresse, Abfall-Ballenpresse, Abfallpresse, Presse Wertstoff, Müllverdichter, Müllpresse, Restmüllpresse

Listing

Brakel

Brakel

7,761 km

BTS-Plastic Foil Compactor

BTS-Folienverdichter BTS-Foil Compactor

Call

Condition: new, Year of construction: 2025, The BTS-Plastic Foil Compactor is the solution to keep large bulky packaging film under control. With its space-saving footprint and secure stand you can easily reduce all foil waste to a minimum of volume. The retaining ring in the plastic foil compactor prevents annoying expansion so that the foils stay where they belong. The filled bags can be baled by using a waste baler or disposed of in a recycling bin.

By collecting and compacting this valuable and recyclable material you achieve a volume reduction of up to 90%, a significant saving on your disposal costs and you properly return the material back into the recycling cycle.

Foil Compactor size: 1000 H x 450 W x 420 D mm

Foil Compactor weight: 5.5 kg

Foil Compactor colour: RAL 9006 silver

Foil Compactor Bag volume: 240 Ltr.

Foil Compactor Bag weight capacity: up to 15 kg

Bodpsvbrfcefx Aaqjww

Easy collecting the packaging films

Clean and safe working environment

Retaining ring prevents the annoying material expansion of the foils

Optimum utilization of bags

Reduces frequency of waste collection

A quality product “Made in Germany”

Suitable for collecting and compacting

Bulky packaging films and foils

Foam foils

Optional extras

BTS-Foil Bags 240 Ltr.

Plastic Foil Compactor colour RAL

(minimum order 40 units)

BTS-Waste Baler for plastic film and foils

Plastic Film Compactor, Foil Compactor, Plastic Film Collector, Foil Collector, Sack Holder

Trust Seal

Dealers certified through Machineseeker

Listing

Brakel

Brakel

7,761 km

BTS-MF200MK Waste Baler, Cardboard, Foil

BTS-MF200MK Ballenpresse Waste Baler

Call

Condition: as good as new (ex-display), Year of construction: 2025, The BTS-MF200MK is the ideal multi chamber waste baler for compacting your loose cardboard and plastic film waste into a bale of up to 200 kg. Various materials can be collected into two or more chambers installed next to each other and once a chamber is filled the rollable compaction head will be moved

over and the material can be baled.

By baling these valuable and recyclable materials you achieve a volume reduction of up to 90%, a significant saving on your disposal costs and you properly return the material back into the recycling cycle.

Pressing force: 16 Ton

Bale weight: up to 200 kg (material depending)

Bale size: 1000 H (var.) x 1100 W x 800 D mm

Machine size: 2506 H x 3260 W x 1269 D mm

Machine weight: 1400 kg

Transport height: 2506 mm

Loading aperture: 1100 W x 800 H mm

Cycle times: 34 seconds

Motor: 2.2 kW 16 Amp

Power supply: 220 - 240 V (1 phase)

Noise level: 68 dB

User-friendly lever control

Bale trolley for removing the bales

Short processing time because there is always a chamber available for loading

Retainer for reducing the material spring back

Reel holder for 8 rolls of strapping

Bwjdpfxjva Hupe Aaqjw

A quality product “Made in Europe”

Suitable for compacting

Cardboard

Plastic film and foils

Big Bags

Clothes

Light valuable materials

Optional extras

Machine colour RAL

PLC auto compaction cycles with bale full light and E-stop with locking key

Extra chamber (up to 6 chambers in total)

Strapping rolls

Twin Chamber Waste Baler, Multi Chamber Waste Baler, Waste Baler, Waste Compactor, Cardboard Baler, Film Baler, Foil Baler, Packaging Plastic Film Foil, Bailer, Baling Press, Garbage Press, Trash Compactor, Baling Compactor, Paper Press, Waste Paper Press, Cardboard Press, Cardboard Compactor, Foil Press, Paper Baling Press, Waste Baler, Residual Waste Compactor

Listing

Brakel

Brakel

7,761 km

BTS-MF40 Waste Baler, Cardboard, Foil

BTS-MF40 Ballenpresse Waste Baler

Call

Condition: new, Year of construction: 2025, functionality: fully functional, The BTS-MF40 is the ideal waste baler for compacting your loose cardboard and plastic film waste into a bale of up to 40 kg. The baling press impresses with its ease of use, safe operation, it is ideal for small material volume and producing compact and easy-to-handle bales.

By baling these valuable and recyclable materials you achieve a volume reduction of up to 90%, a significant saving on your disposal costs and you properly return the material back into the recycling cycle.

Pressing force: 2 Ton

Bale weight: up to 40 kg (material depending)

Bale size: 600 H (var.) x 535 W x 460 D mm

Machine size: 1756 H x 718 W x 644 D mm

Machine weight: 187 kg

Transport height: 1756 mm

Loading aperture: 522 W x 490 H mm

Cycle times: 20 seconds

Motor: 1.5 kW 13 Amp

Power supply: 220 - 240 V (1 phase)

Noise level: 68 dB

User-friendly lever control

Bale trolley for easy bale removal

Retainers to prevent material spring back

Reel holder for strapping rolls

A quality product „Made in Europe“

Bedpsvahudefx Aaqsww

Suitable for compacting

Cardboard

Plastic film and foils

Cans and light sheet metal containers

Canisters and light plastic containers

Clothes

Light valuable materials

Optional Extras

Machine colour RAL

Can crusher insert

PLC auto compaction cycles

Strapping rolls

Power supply 380 - 400 V (3 phase)

Waste Baler, Waste Compactor, Cardboard Baler, Film Baler, Foil Baler, Packaging Plastic Film Foil, Bailer, Baling Press, Garbage Press, Trash Compactor, Baling Compactor, Paper Press, Waste Paper Press, Cardboard Press, Cardboard Compactor, Foil Press, Paper Baling Press, Waste Baler, Residual Waste Compactor

Listing

Brakel

Brakel

7,761 km

BTS-MF300LH Waste Baler, Cardboard, Foil

BTS-MF300LH Ballenpresse Waste Baler

Call

Condition: as good as new (ex-display), Year of construction: 2025, The BTS-MF300LH is the ideal waste baler for compacting your loose cardboard and plastic film waste into a bale of up to 300 kg. Due to the compact design and low height of under 2 meters this baler is perfect for rooms with limited ceiling heights. The baling press impresses with its ease of use, safe operation and its large filling volume.

By baling these valuable and recyclable materials you achieve a volume reduction of up to 90%, a significant saving on your disposal costs and you properly return the material back into the recycling cycle.

Pressing force: 20 Ton

Bale weight: up to 300 kg (material depending)

Bwsdpfx Aeiwgcmoaqow

Bale size: 1100 H (var.) x 1200 W x 800 D mm

Machine size: 1986 H x 1800 W x 1100 D mm

Machine weight: 1140 kg

Transport height: 1986 mm

Loading aperture: 1200 W x 600 H mm

Cycle times: 45 seconds

Motor: 2.2 kW 16 Amp

Power supply: 220 - 240 V (1 phase)

Noise level: 68 dB

Auto control panel with bale full light and E-stop with locking key

Strap eject for easy removal of bales

Retainer for reducing the material spring back

Low height, perfect for limited ceiling heights

Hour counter

Reel holder for 4 rolls of strapping

A quality product “Made in Europe”

Suitable for compacting

Cardboard

Plastic film and foils

Big Bags

Clothes

Light valuable materials

Optional extras

Machine colour RAL

Strapping rolls

Power supply 380 - 400 V (3 phase)

Waste Baler, Waste Compactor, Cardboard Baler, Film Baler, Foil Baler, Packaging Plastic Film Foil, Bailer, Baling Press, Garbage Press, Trash Compactor, Baling Compactor, Paper Press, Waste Paper Press, Cardboard Press, Cardboard Compactor, Foil Press, Paper Baling Press, Waste Baler, Residual Waste Compactor

Listing

Brakel

Brakel

7,761 km

BTS-MF75MK Waste Baler, Cardboard, Foil

BTS-MF75MK Ballenpresse Waste Baler

Call

Condition: as good as new (ex-display), Year of construction: 2025, The BTS-MF75MK is the ideal multi chamber waste baler for compacting your loose cardboard and plastic film waste into a bale of up to 75 kg. Various materials can be collected into two or more chambers installed next to each other and once a chamber is filled the rollable compaction head will be moved over and the material can be baled.

By baling these valuable and recyclable materials you achieve a volume reduction of up to 90%, a significant saving on your disposal costs and you properly return the material back into the recycling cycle.

Pressing force: 3.5 Ton

Bale weight: up to 75 kg (material depending)

Bale size: 700 H (var.) x 700 W x 500 D mm

Machine size: 2005 H x 2050 W x 872 D mm

Machine weight: 562 kg

Transport height: 2005 mm

Loading aperture: 700 W x 500 H mm

Cycle times: 35 seconds

Motor: 1.5 kW 13 Amp

Power supply: 220 - 240 V (1 phase)

Noise level: 68 dB

User-friendly lever control

Bale trolley for removing the bales

Short processing time because there is always a chamber available for loading

Retainer for reducing the material spring back

Reel holder for 4 rolls of strapping

A quality product “Made in Europe”

Suitable for compacting

Cardboard

Plastic film and foils

Bwodpeva Hq Dsfx Aaqsw

Cans and light sheet metal containers

Canisters and light plastic containers

Clothes

Light valuable materials

Optional extras

Machine colour RAL

Can crusher insert

PLC auto compaction cycles with bale full light and E-stop with locking key

Extra chamber (up to 6 chambers in total)

Strapping rolls

Power supply 380 - 400 V (3 phase)

Twin Chamber Waste Baler, Waste Compactor, Cardboard Baler, Film Baler, Foil Baler, Packaging Plastic Film Foil, Bailer, Baling Press, Garbage Press, Trash Compactor, Baling Compactor, Paper Press, Waste Paper Press, Cardboard Press, Cardboard Compactor, Foil Press, Paper Baling Press, Waste Baler, Residual Waste Compactor

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used bale presses (217)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you