Used Emulsion for sale (258)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Lüneburg

Lüneburg

7,734 km

CNC Lathe

DMT KERNCD650

Call

Condition: used, Year of construction: 2006, functionality: fully functional, Turning diameter: 650 mm Turning length: 1,500 mm Total power requirement: 33 kW Center distance: 1,500 mm Swing diameter over bed: 650 mm Swing diameter in recess: 670 Turning diameter: 650 mm

Turning length: 1,500 mm

Total power requirement: 33 kW

Center distance: 1,500 mm

Swing diameter over bed: 650 mm

Swing diameter in recess: 670 mm

Swing diameter over face slide: 260 mm

Face slide travel: 380 mm

Main drive

Drive power AC motor - 40/60/100% duty cycle: 33/27/22 kW

Spindle box

Spindle bore diameter: 106 mm

Spindle diameter in front bearing: 140 mm

Speed range (V constant): 1 - 2,000 rpm

Cross slide

Feed range, face: 0.001 - 1,000 mm/rev

Feed range, face, optional up to: 5,000 mm/rev

Feed range, longitudinal and thread pitch: 0.001 - 2,000 mm/rev

Feed range longitudinal and thread pitch, optional up to: 13,000 mm/rev

Feed force flat: 9,000 N

Feed force longitudinal: 12,000 N

Automatic tool turret

Number of tool stations: 12

With tool drive for 6 stations

Ijdpfjyaaavox Ahyoal

Tool holder system (DIN69880) VDI40

Equipment

SIMENS SINUMERIK 840D sl (Shop Turn with manual functions)

COMBI control station

C-axis with drilling, milling, and engraving cycles

Residual material detection and machining – during roughing and contour pockets

MULTIFIX C forne setup

Three-jaw chuck SMW AUTOBLOK: HI-GRIP HGF260-81-3

Oil emulsion mist filter for work area extraction: MAHLE LTA600

4 driven axial tool holders

2 driven radial tool holders

Listing

Bochum

Bochum

7,667 km

5 ACHS machining center

DMG MORIDMU 125P duo Block

Call

Condition: excellent (used), Year of construction: 2019, Delivery at the beginning of June 2026!!!

Control: CELOS with Heidenhain TNC 640

Milling head: Universal milling head with controlled A-axis HSK63A

Spindle options: Spindle tool holder HSK-A 63

Iaodox Uqykjpfx Ahyjl

Tool magazine: Tool magazine, wheel type, 63 positions HSK63A

Coolant / Chip removal: Through-spindle coolant system, 80 bar, frequency controlled; oil/emulsion mist extraction unit; cooling device with air blast

Measuring / Monitoring: Heidenhain infrared probe SK 40, 3D quickSET; MPC Machine Protection Control

Further options: Operating mode 4

Options for HEIDENHAIN control: Electronic handwheel

Documentation: 1 set documentation in German; electrical schematic in German

Display language: German

Listing

Germany

Germany

7,824 km

Sigma Leader 6

SigmaLeader 6

Call

Condition: ready for operation (used), Year of construction: 2007, controller manufacturer: HEIDENHAIN, This 3-axis Sigma Leader 6 vertical machining center was manufactured in 2007. It features extensive travel capabilities with X-axis at 1250 mm, Y-axis at 810 mm, and Z-axis at 630 mm. Rapid traverse rates reach up to 50 m/min, and it includes a high-capacity tool magazine with 40 positions. If you are looking to get high-quality milling capabilities, consider the Sigma Leader 6 machine we have for sale. Contact us for more information about this machine.

• Axes: 3 / current spindle hours: approximately 33000 / x-axis travel (longitudinal): ranges from 1250 mm to 2000 mm / y-axis travel (transverse): 810 mm / z-axis travel (vertical): 630 mm / b-axis travel (swivel): -60° to +105° / c-axis travel (rotary table): 360° / x/y/z rapid traverse: ranges from 40 m/min to 50 m/min / b/c rapid traverse: ranges from 40 rpm to 50 rpm / acceleration x/y/z: ranges from 5000 mm/sec² to 10000 mm/sec² / acceleration b/c: ranges from 3. 5 rad/sec² to 8. 8 rad/sec² / guides: linear with sliding block with triple circulation of preloaded balls / pallet changeover time: 3 seconds (5-axis)

• Power supply: 400v 50hz 3-phase line / power rating: ranges from 35 kw to 60 kw / rated current: ranges from 60 a to 105 a

• Compressed air pressure: 6 bar / compressed air consumption: 150 nm³/h

• Machine color: gray ral 7008 / protective cover color: yellow ral 1004 / workstation lighting: 2 or 4 / sound pressure level: 77 db(a) to 79 db(a) (standard, 15000 rpm)

• Tool holder: n. 40 din 69871, n. 40 din 69871 (bt40), hsk-a63 din 69893-1 / max. Available power: 27 kw / max. Available torque: 235 nm, 158 nm, 86 nm / programmable indexed spindle angle positions: electronic with 3600 positions

Iaedpfx Aex D Nafohyol

• Measuring system: heidenhain measuring system, electronic fold commutator / positioning accuracy (x/y/z): 0. 008 mm / positioning spread (x/y/z): 0. 006 mm / average reversal error (x/y/z): 0. 002 mm

• Magazine type: chain magazine with 2 directions / number of positions: 40 (standard) - 50 (optional) / tool selection: "random" / tool changer: double-gripper arm, electromechanically driven / min. Tool change time: 1. 5 seconds / chip-to-chip time: 4. 5 seconds / max. Tool weight: 8 kg / max. Tool diameter: 80 mm / max. Tool length: 350 mm / max. Tool dimensions: 300 mm

• At low pressure with oil emulsion: 10 nozzles around the spindle, max. 5 bar at 100 l/min / at high pressure with oil emulsion through the spindle (option): 15 bar at 15 l/min or 30 bar at 30 l/min / chip mixing: 2 parallel screws on the two long sides of the table and a side chip conveyor / cooling system filtration: 60μ filter system with 2 filter inserts and manual bypasscooling system filtration: 60μ filter system with 2 filter inserts and manual bypassinner cooling through spindle (IKZ)

Listing

Karben

Karben

7,833 km

Filter fleece system

HOFFMANNHydrostat HN 0,6

Call

Condition: good (used), functionality: fully functional, Year of construction: 2004, overall weight: 300 kg, input voltage: 400 V, input frequency: 50 Hz, HOFFMANN

FILTER FLEECE SYSTEM WITH REEL

TYPE: HYDROSTAT HN0.6

MACHINE NO.: 0405364

YEAR OF MANUFACTURE: 2004

Technical Data:

Operating Voltage: 400 V, 50 Hz

Footprint incl. sludge tank: approx. 2055 x 1560 mm

Filter area: 0.6 m²

Filtration capacity (based on emulsion): approx. 165 l/min

Inlet height: 488 mm

Paint finish: RAL 9002, textured lacquer

Weight: 300 kg

Equipment:

- Made of sheet steel, fully welded, base dimensions approx. 1500 x 1500 x 280 mm

Filling capacity: approx. 460 l

- 1 gear motor

- 1 reel for winding up used filter fleece

- 1 reel-disposal switch with “reel full” indicator

- 1 coolant level switch

- 2 pump mounts for user-supplied service pumps

- 1 roll of filter fleece, width 1000 mm

- 1 sludge tank

Iaedpsx T Ah Dsfx Ahyol

- 1 complete electrical control system in a dustproof control cabinet with all switching, control, and monitoring devices, motor protection switches for each drive, control transformer, function indicator lamps, filter system wiring according to VDE 0113

- Documentation, 2 copies, German

- EC Declaration of Conformity 98/37, Annex IIB

Listing

Germany

Germany

7,969 km

Used AR Filtrazioni model ARNO 2VFA_YB, year 2018 (internal no. 231086)

AR FILTRATIONIARNO 2

Call

Condition: like new (used), Year of construction: 2018, machine/vehicle number: IntNr231086, Int. No. 231086

1449 Oil/Emulsion Mist Extraction System

AR FILTRATIONI S.R.L.

Extraction Series ARNO 2:

Mechanical AR 5-stage air purifier for emulsion mist/oil smoke

Air flow rate: 2600 m³/h (1.5 kW)

Voltage/frequency: 230/400 V, 50 Hz

Noise level: approx. 70 dBA

Stage 1 – Centrifugal condenser, self-cleaning

Stage 2 – Metal mesh filter, washable

Stage 3 – Pocket filter

Stage 4 – Fine filter mat, washable

Stage 5 – HEPA ultra-fine filter

Overall unit filtration efficiency: up to 99.97%

- Quick and easy maintenance, once per year, high operational reliability

Isdpsx U Dhusfx Ahysal

- Sturdy construction, minimal space required

- Recovery of up to 80% of condensed coolant lubricant

- Design and performance in compliance with current standards

- Approx. €415.00 in energy savings per air purifier

- Reduction of emissions by 9,000 kg CO2/year/unit

- Protects sensitive machine tool components

- Protects both the environment and personnel

Dimensions: approx. 990 x 570 x 1400 mm

Weight: approx. 120 kg

Short delivery times available by arrangement.

The machine can be inspected under power by appointment.

Subject to technical modifications, errors, and interim sale!

Listing

OIching

OIching

8,116 km

Saw

AmadaCM II 100 DG

Call

Condition: used, Year of construction: 2022, controller manufacturer: Sonstige, controller model: Amada, _____

Description:

Year of manuf. : 2022

Material:

Round material:Ø 20 -101.6 mm

Rectangular material:20 - 80 mm

Cut length:10 - 6,000 mm

Saw blade:

Design:Disposable carbide saw blades

Dimensions:Ø 360 x 2.0 mm

Iaodpfxoyad A Uj Ahyol

Saw:

Cutting speed:automatic control

Revolutions:55- 180

Feed rate:0 -30 mm/sec

Drive power:11 kW x 4P

Horizontal clamping pressure:15.2 kN

Vertical clamping pressure:3.9 kN

Feed system:

Drive system:AC servo + ball screw

Feed length:715 mm

Feed speed:30 m/min

Bar loader:

Max. diameter:100 mm

Standard length:6,500 mm

Magazine extension:By 2,000 mm

Sorting section:With 2 switches

Equipment:

Material feed:Bar feeder

Chip disposal:Chip conveyor

Emulsion mist separator:Air Champion

Listing

Soltau

Soltau

7,720 km

5 axis vertical machining centre

YCM5-Achsen UV650

Call

Condition: as good as new (ex-display), Year of construction: 2023, operating hours: 15 h, YCM UV650

Spindle: SK40 / 15.000 rpm, 17kW

toolchanger places: 60

control: Heidenhain TNC640

travel: X:620mm Y:520mm Z:460mm B:-50 / +110 C:360

Iedpfx Aheuxbcisysal

spindle cooling system

Blum laser for tool length measurement

3D probe

el. hand wheel

Emulsion cooling ICS 20bar

outer cooling

cooling gun

chip conveyor

machine dimensions:

L:4250mm W:2310mm H:2.560mm

weight:

appr. 12.500kg

Listing

Janville

Janville

7,536 km

Vacuum mixer

Romaco – FrymakorumaDinex Lab

Call

Condition: used, Year of construction: 2009, Manufacturer: Romaco - Frymakoruma

Model: Dinex Lab

Year: 2009

Type: Vacuum mixer for R&D or small-scale production

Application: liquid and/or viscous (semi-liquid) products = dispersion, homogenization, emulsion, grinding, and pumping of the product

Tank:

Pressure: -1 / 0 bar

Volume: 18 L

Temperature: 130°C

Jacket:

Pressure: 6 bar

Volume: 2 L

Temperature: 180°C

Homogenizer: high-speed agitation

2 modes = Pumping with discharge / Dispersion with high shear force

Tool size: 100 mm

Rotor: 20 x 4 mm

Stator: 30 x 4 mm

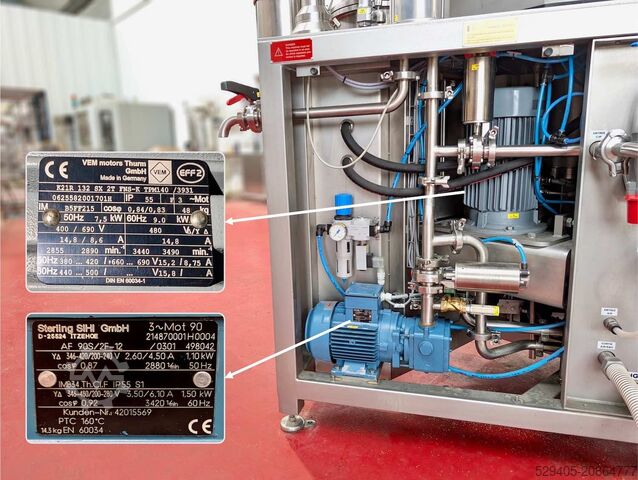

VEM motor 7.5 kW / 2890 RPM

Scraper mixer: slow agitation

SEW 0.37 KW motor

Sterling SIHI LEMA 25 liquid ring vacuum pump

Power 1.1 KW - Max. 16 m³/h.

Ijdpfx Asx R D Elshyoal

CIP (clean in place)

2 x feed hoppers, 1 of which is connected to the jacket with its piping

Air pressure: 6 bar

Water pressure: 6 bar

Temperature control regulator

Single-acting seal: reconditioned by Burgmann

Paper documentation

Weight: 750 kg

Listing

Germany

Germany

7,824 km

HEDELIUS T8 - 2300

HEDELIUST8 - 2300

Call

Condition: ready for operation (used), Year of construction: 2006, operating hours: 7,647 h, travel distance X-axis: 2,300 mm, travel distance Y-axis: 800 mm, travel distance Z-axis: 850 mm, controller manufacturer: HEIDENHAIN, controller model: iTNC 530, overall weight: 18,500 kg, spindle speed (max.): 12,000 rpm, spindle motor power: 26,500 W, tool weight: 10,000 g, number of axes: 5, This 5-axis HEDELIUS T8 - 2300 was manufactured in 2006, featuring a robust vertical machining center design. It boasts a large travel range of 2300/800/850 mm and a high spindle speed up to 12,000 rpm. The machine includes a B-axis NC swivel head, a 40-position tool magazine, and supports a maximum workpiece weight of 2500 kg. Consider the opportunity to buy this HEDELIUS T8 - 2300 vertical machining center. Contact us for more information.

• NC swivel head B-axis: +92° / -92°

• Max pendulum operation: 2 × 850 mm

• Rapid traverse: 60 m/min

• Feed force: X/Y 5000 N, Z 9000 N

• Spindle:

• Max torque: 158 Nm

Iedpox E Ebwjfx Ahysal

• Front spindle bearing diameter: 70 mm

• Tool clamping (pull-in force): 12 kN

• Tool magazine/changing:

• Tool positions (standard): 40

• Tool positions (Magnum): 80

• Max tool diameter: 125 mm (180 mm with adjacent positions empty)

• Max tool length: 330 mm

• Tool change time (approx.): 3.5 s

• Chip-to-chip time: vertical 6.0 s / horizontal 6.5 s

• Table/capacity:

• Fixed table (L×W): 2000 × 920 mm

• T-slots: 6 × 18 H12

• Rotary table: 1 × 18 H8

• Max. workpiece weight: 2500 kg

• Machining capacities:

• Drilling in St 52 with carbide: 40 mm

• Tapping: M24

• Milling in St 52: 500 cm³/min

• Distances (reference):

• Z travel vertical (L2): 850 mm

• Spindle nose to swivel axis (L3): 300 mm

• Spindle nose to table surface (L4): 40 mm

• Z travel horizontal (L5): 1000 mm

• Spindle axis to table surface (L6): 210 mm

• Y travel (L7): 800 mm

• Table center to travel start/end (L8/L9): 400 / 400 mm

• Power/weights:

• Total connected load: 25 kVA

• Machine weight (standard): approx. 17,000–17,500 kg

• Hours:

• Operating hours: 21,100 h

• Spindle hours: 7,647 h

Additional equipment

• Chip conveyor

• Internal coolant through spindle, 40 bar

• Paper belt filter

• Oil and emulsion mist separator

• Rotating viewing windows (2)

• Cleaning guns (2)

• Renishaw touch probe

Technical Specification

Taper Size SK 40

Listing

Germany

Germany

7,694 km

Machining Center - Vertical

YCMTV2110B

Call

Condition: used, Year of construction: 2012, x-travel 2100 mm

y-travel 1020 mm

z-travel 762 mm

Ijdpfx Ahex Sr A Usyjal

Control Fanuc MXP-200FP

spindle speed 6000 U/min

spindle capacity ca. 22 kW

max. torque on the spindle ca. 550 Nm

tool taper SK 50

table surface area 2300 x 1020 mm

max. table load 3000 kg

T-slots 6 x 22 mm

T-slot - distance 150 mm

3-Axis CNC Machining Center

Equipment/Accessories:

- Automatic tool changer with chain magazine, 40 stations

- max. tool-Ø: 120/240 mm

- max. tool length: 350 mm

- coolant system with internal coolant supply and filter

- emulsion mist extraction

- electronic handwheel

- 2 pcs. magnetic clamping plates 800 x 400 mm

- various tool tapers SK50

- chip conveyor

Listing

Germany

Germany

7,969 km

Branded AR Filtrazioni model ARNO 2VFA_YB, year 2018 (IntNr231087)

AR FILTRATIONIARNO 2

Call

Condition: like new (used), Year of construction: 2018, machine/vehicle number: IntNr231087, IntNo231087

AR FILTRATIONI S.R.L.

1449 Oil/emulsion mist extraction system

Extraction unit series ARNO 2:

Mechanical AR 5-stage air cleaner for emulsion mist/oil smoke Air flow rate 2600 m3/h (1.5kW)

Voltage Frequency 230/400 50 V Hz

Noise level dBa approx. 70

Stage 1- Centrifugal condenser, self-cleaning

Stage 2 - Metal mesh filter, washable

Stage 3 - Pocket filter

Stage 4 - Fine filter mat, washable

Stage 5 - Hepa ultra-fine filter

Filter performance of the entire unit: up to 99.97%

- Quick and easy maintenance, once a year, high operational reliability

- Robust design, low space requirement

- Recovery of up to 80% of the condensed cooling lubricant

- Design and function in accordance with current standards

- Energy savings of approx. 415.00 euros per air purifier

- Reduction in emissions of 9,000 kg CO2/year/system

- Protects the sensitive parts of the machine tool

Iaedex U Dhnepfx Ahyjl

- Protects the environment and people

Dimensions: approx. 990 x 570 x 1400 [mm]

Weight: approx. 120 [kg]

Delivery time at short notice by arrangement.

The machine can be inspected by appointment.

Changes and errors in the technical data and information as well as prior sale reserved!

IntNo231084

AR FILTRATIONI S.R.L.

Extraction series ARNO 2:

Mechanical AR 5-stage air purifier for emulsion mist/oil smoke Air flow rate 2600 m3/h (1.5kW)

Voltage Frequency 230/400 50 V Hz

Noise level dBa approx. 70

Stage 1- Centrifugal condenser, self-cleaning

Stage 2 - Metal mesh filter, washable

Stage 3 - Pocket filter

Stage 4 - Fine filter mat, washable

Stage 5 - Hepa ultra-fine filter

Filter performance of the entire unit: up to 99.97%

- Quick and easy maintenance, once a year, high operational reliability

- Robust design, low space requirement

- Recovery of up to 80% of the condensed cooling lubricant

- Design and function in accordance with current standards

- Energy savings of approx. 415.00 euros per air purifier

- Reduction in emissions of 9,000 kg CO2/year/system

- Protects the sensitive parts of the machine tool

- Protects the environment and people

Dimensions: approx. 990 x 570 x 1400 [mm]

Weight: approx. 120 [kg]

Delivery time at short notice by arrangement.

The machine can be inspected by appointment.

Changes and errors in the technical data and information as well as prior sale reserved!

Listing

Wiefelstede

Wiefelstede

7,607 km

Oil-water separation system for compressors

Domnick HunterES2150

Call

Condition: good (used), Emulsion splitting plant, oil-water separation system

-The cost-effective and permanently reliable

The solution to the problem is usually the oil/water-

Separation for dispersed condensates.

Purified water meets legal requirements

Iajdsb A S I Hopfx Ahyel

Regulations regarding sewer discharge.

-Dimensions: 750/350/H830 mm

-Weight: 10 kg

Listing

Soltau

Soltau

7,720 km

Vertical machining center

RödersRXP600DSH

Call

Condition: reconditioned (used), Year of construction: 2012, functionality: fully functional, Equipment: chip conveyor, documentation/manual, Röders RXP600DSH

- HSK63F spindle max. 30,000 rpm

- 24-position tool changer

- Emulsion cooling with 40 bar internal coolant supply (IKZ)

- Extraction system

- Laser tool measurement

Iedpfx Ahex I A Imoyoal

- 3D probe

- Thermal package

- Prepared for automation

The machine is already at our facility in Soltau. We will upload pictures shortly.

Listing

Janville

Janville

7,536 km

Vacuum mixer

VMI RayneriTrimix (TXR) 10 litres

Call

Condition: used, Year of construction: 1998, Manufacturer : VMI Rayneri

Model Trimix (TXR) 10 litres

Year : 1998

Type : Vacuum mixer

Application : Dispersion, dissolution, homogenisation, deaeration, heat exchange > gels, creams, pomades, …

Total volume : 10 Litres

Empty weight : 300 kg

Power : 3.5 KW

Power supply: 230 V

Pressure : 2 bars

Isdpfx Ahsx R Di Deysal

Temperature : 120°C

Jacket + insulation

Mixing :

– Anchor blade with scrapers: 0 – 60 rpm

– Counter agitation: 0 – 180 rpm

– Dispersion/emulsion turbine: 200 – 3000 rpm

Sold with water temperature controller :

Manufacturer : SOLEV

Model : RE 50-3-SC-R-20-2D

Year : 1998

Heating capacity : 3 KW

Documentation available

Listing

Olching

Olching

8,116 km

Cylindrical grinding machine

EMAG WEISSW 11-CNC

Call

Condition: used, _____

Description:

Year of manuf. : 2020

Control : Sonstige WEISS CNC

Centre width : 6 mm

In Generel:

Iaodpfx Ahjv Armcjyol

ear of construction:2020

Control system:WEISS CNC

Centre width:6 mm

Centre height:200 mm

Grinding wheel dimensions:400x60 mm + 0x60 mm

Workpiece headstock:

Speed:1 rpm

Workpiece weight max.:25 kg

Sanding diameter max.:390 mm

Mounting:MK4

Grinding headstock:

Peripheral speed:2 m/s

Grinding disc dimensions right:0 x 60 mm

Grinding disc dimensions left:400 x 60 mm

X-axis:380 mm

Z-axis:1,1 mm

B-axis:torque motor, infinitely variable

Tailstock:

Pinole diameter: mm

Pionole stroke:45 mm

Mounting:MK 4

Cylinder fine adjustment:+/- 0.04 mm

Equipment:

Positioning sensors:Direct scales

Grinding spindles:2x grinding spindle (left/right)

GAP / Crash Controll:Structure-borne sound (Sensotronik)

Balancing:MPM balancing device

Workpiece measurement:Marposs PF ME

Automation:Robot interface prepared

Set-up mode:Electronic handwheel

Emulsion mist separator:Mechanical

Dresser:For external grinding wheel left/right

Accessories:Various grinding discs + flanges

Listing

Brno-město

Brno-město

8,348 km

Vertical machining center

HwacheonVesta 1000 12K

Call

Condition: good (used), Year of construction: 2016, In good technical condition and fully functional.

Built in 2016.

Machine includes 4-axis TSUDAKOMA, workpiece probe, and tool probe.

Drives Axis drives (X/Y/Z) 1,000 / 550 / 500 mm

Distance table surface - spindle surface 130 - 630 mm

Axis guide - linear rolling LM

Table work surface 1,100 x 502 mm

Load capacity 700 kg

Table surface configuration mm 5x T-slot (width 18, pitch 80)

Maximum spindle speed 12,000 rpm

Spindle power (10 min./continuous) kW 18.5 / 11

Rapid feeds (X/Y/Z) m/min 36 / 36 / 30

Working feed (X/Y/Z) mm/min 1 - 24,000

Sliding motor (X/Z) kW 1.8 / 1.8 / 3.0

Iaodpfx Ajx Tti Sohysl

Automatic tool change

Tool taper - BT40

Clamping bolt - MAS P40T-1 (45°)

Number of tool positions: 24

Max. tool diameter mm Ø 80 / Ø 150 (without secondary tool)

Max. tool length / weight mm / kg 300 / 8

Tool-to-tool change time: Section 2.5

Chip-to-chip change time: Section 4.3

Magazine and change disk design with rotating arm

Power consumption: 30 kVA

Tank capacity for spindle lubrication/cooling: l 6 / 20

For cooling emulsions: l 380

Machine dimensions: Height mm 2,670

Floor area (length x width) mm 3,335 x 2,200

Weight: 6,500 kg

Control system: Fanuc 0i-MD

Air blowing of the spindle

Machine adjustment elements

Machine protective cover

Screw conveyor in the work area

Cooling system

Safety door

Ethernet interface

Listing

Kaufungen

Kaufungen

7,815 km

Machining center

DMGMilltap 700

Call

Condition: good (used), Year of construction: 2017, 1 used machining center

Brand DMG

Type Milltap 700

Year of manufacture 2017

Serial number A00007

with interchangeable pallet and robot automation

Control system: Siemens 840D SL

Travel paths: X 700 mm Y 420 mm Z 380 mm

Table size 840 x 420 mm

Spindle

Speed: 10,000 rpm

Tool holder: DIN30

25-position tool changer

Dimensions and weight

Dimensions: 2,500 mm x 1,650 mm x 2,950 mm

Iodpfx Aov T Rtishyeal

Weight: approx. 3,400 kg

Condition

Condition: Used

Functional: Tested and fully functional

Other equipment and included accessories:

Tool changer

Chip conveyor

Internal tool cooling with high-pressure system 40 bar

Preparation 4-axis

Oil and emulsion separator

Air blown through spindle center

Nano package

Renishaw measuring kit

WH 3 workpiece loading and unloading system with 6-axis Fanuc robot

PGN 50 special gripper unit

Listing

Vilnius

Vilnius

8,376 km

Vertical machining center

HaasUMC-500

Call

Condition: like new (used), Year of construction: 2022, functionality: fully functional, travel distance X-axis: 610 mm, travel distance Y-axis: 406 mm, travel distance Z-axis: 406 mm, workpiece weight (max.): 200 kg, table width: 500 mm, spindle speed (min.): 10,000 rpm, Equipment: chip conveyor, For sale: HAAS UMC-500 5-Axis Universal Machining Center

Condition: Absolutely brand new machine. Only one part was produced for test machining. The equipment has been unused and stored for 2 years.

Main technical specifications

Travel:

X-axis: 610 mm

Y-axis: 406 mm

Z-axis: 406 mm

Table:

Diameter: 500 mm

Maximum workpiece weight: 200 kg

5-axis rotary/trunnion table (trunnion type)

Spindle:

Inline direct-drive

10,000 rpm

30 HP (22.4 kW)

CAT 40 taper (40T)

Isdpfx Ahexg Nd Njyjal

Through-spindle coolant: 300 psi (21 bar)

Tool changer:

30 tool positions

Side-mount, high speed

Precision and compensation:

Temperature compensation

DWO/TCPC – Dynamic Work Offset and Tool Center Point Control

Rigid Tapping

Equipment and features:

Haas NGC CNC control (FANUC compatible)

1 GB memory

Ethernet connection, WiFi connectivity

USB port, color 15” LCD display

Early power-failure detection module

Memory lock (keyswitch)

Spindle coolant system

Protective enclosure with doors

Internal lighting

Centralized lubrication system

Top cover

Measurement and calibration equipment:

Renishaw WIPS wireless intuitive probing system

(Haas Visual Programming System, macros, spindle orientation, coordinate rotation and scaling)

Rotary-Axis calibration tool

RJH remote jog handle with color display

Chip and coolant systems:

Coolant tank – 95 gallons (360 L)

Initial fill with Blaser coolant emulsion

Chip conveyor (belt type – CONVEYOR-H)

High-pressure air system

Documentation:

Original machine documentation (in English)

Application

Haas UMC-500 is a compact yet powerful universal 5-axis machining center designed for the production of complex, multi-sided, and free-form surface parts. Suitable for simultaneous 5-axis machining as well as 3+2 machining, significantly reducing setup operations and ensuring high accuracy.

If you have further questions, we are happy to assist.

Listing

Soltau

Soltau

7,720 km

Machining center

Röders TecRXP400DS/RXD5

Call

Condition: reconditioned (used), travel distance X-axis: 310 mm, travel distance Y-axis: 294 mm, travel distance Z-axis: 210 mm, overall weight: 3,000 kg, spindle speed (max.): 50,000 rpm, Used HSC machine RXP400DS/ RXD5

-overhauled-

The machine is completely overhauled, tested and measured in our company. The machine again meets the new machine tolerance!

Working area:

- X-axis: 200 mm

- Y-axis: 294 mm

- Z-axis: 200 mm

- Drives of the linear axes:

Linear motors in all axes.

- Drives of the rotary axes:

Highly dynamic direct drives with integrated cooling.

- Feed rates 0 - 40,000 mm/min in all linear axes.

- Network connection:

- Tool measuring laser:

Diameter and contour measurement, wear monitoring

and breakage control of the milling tools.

- Chuck control, 1st chuck

- Emulsion cooling with mechanical oil mist extraction

Iaodpfx Aelzhhcehyel

-RMS Main Job Manager

- Spindle max. 60,000 rpm HSK 25

- Tool changer 12-way row, optional tool changer conversion to chain

- High-precision option

- Remote maintenance via Teamviewer

- Transport dimensions of machine:

W 2,425 x L 1,925 x H 2,140 mm

- Weight: Approx. 3,000 kg

A viewing of the machine in operational condition is possible at any time. You are also welcome to find out more about the type and scope of our overhauled machines on our website or on our Hüttmann YouTube channel.

Listing

Germany

Germany

7,804 km

Cylindrical Grinding Machine

JUNKERJumat 6S 10-10

Call

Condition: used, Year of construction: 2007, Technical details:

weight of the machine ca.: 24 t

dimensions of the machine ca.: 3900 x 3500 x 2500 m

-the machine has no B axis

-two grinding spindles with one grinding wheel each -

The transport instructions can be found in the documentation (attachment).

including Hoffmann KSM filter system

Iodpex Aq Etsfx Ahyoal

Loading list available

Operating data v. : Operating time: 21727 h / production time: 11960 h

Machine documentation: 1 set of circuit diagrams, electrical plans, operating instructions

Accessories: 2 replacement measuring heads Marposs S/500; prism supports

Other: Hoffmann KSM filter system

Machine condition: according to age, due to processing with emulsion

*

Listing

Olching

Olching

8,116 km

Vertical lathe

EMAGVL 3

Call

Condition: used, _____

Description:

Year of manuf. : 2008

Control : Fanuc 18i-TB

Turning diam. : 130 mm

Turning length : 110 mm

In Generel:

Year of manufacture:2008

Control system:Fanuc 18i-TB

Turning diameter:130 mm

Turning length:110 mm

Rotation diameter:200 mm

Workpiece height max.:110 mm

Spindle:

Technology:Motor spindle

Speed:7,500 rpm

Power:24 kW

Torque:158 Nm

C-axis:0.001°

Clamping cylinder:Full clamping cylinder

Iajdpfx Aowkcldjhyjl

Tool carrier (X/Z):

Technology:Star turret

Number of stations:12

Tool holder:VDI 40

Tool drive:6,000 rpm, 40 Nm

X-axis:400 mm

Z-axis:200 mm

Equipment:

Measuring systems:Direct (glass scales)

Chip disposal:Chip conveyor

Coolant supply:High-pressure pump

Automation:Circulating workpiece storage

Emulsion mist extraction:Mechanically prepared

Trust Seal

Dealers certified through Machineseeker

Listing

Soltau

Soltau

7,720 km

5-axis milling machine

RödersTecRXP500DSC

Call

Condition: refurbished (used), Year of construction: 2010, functionality: fully functional, travel distance X-axis: 450 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 240 mm, overall weight: 6,000 kg, spindle speed (max.): 42,000 rpm, 5-axis HSC milling machine Röders RXP500DSC with linear direct drives in all axes and torque drives in the rotary axes.

Travels: X450mm, Y400mm, Z240mm

Ijdpfx Aott Argehyoal

Spindle / table distance: approx. 315mm

- Linear direct drives in all axes - wear-free

Specification:

- Tool changer places: 19

- Cooling unit for drives, motors, spindle and cable cabinet

- Measuring laser for the fully automatic measuring of milling tools (length / diameter / contour / cone angle) as well as wear monitoring including tool cleaning before measuring

- Handbox

- Remote maintenance

- Automatic 3D probe including calibration ball in the tool changer

- Minimal quantity lubrication

- emulsion cooling

- Spindle HSK40E with max. 42.000 rpm

- Spindle compensation

- Zero point clamping system Erowa integrated in the machine table

- manual operating of chuck clamping

- Automation package for retrofitting the machine with a pallet changer

- Handbox

The machine is overhauled in our house and is now in almost new condition. The machine can be inspected and tested under power after completion at our site. Please make an appointment with us!

Listing

Olching

Olching

8,116 km

CNC turning and milling centre

DMG MORICTX Beta 1250 TC 4A + Gantry Loader

Call

Condition: used, Year of construction: 2013, controller manufacturer: Siemens, controller model: 840 Dsl, _____

Description:

Year of manuf. : 2013

Control : Siemens 840 Dsl

Turning diam. : 340 mm

Turning length : 1185 mm

In General:

Year of manufacture:2013

Control system:Siemens 840 Dsl

Turning length:1,185

Swing diameter:540 mm

Bar capacity:75

Main spindle:

Technology:Direct drive spindle

Speed:5,000 rpm

Max. power:32 kW

Max. torque:360 Nm

Chuck:SMW KNCS -N 260-78

C-axis:0.001°

Flush:Chuck flush

Sub spindle:

Technology:Direct drive spindle

Speed:5,000 rpm

Max. power:32 kW

Max. torque:360 Nm

Chuck:SMW KNCS -N 260-78

C-axis:0.001°

Flush:Chuck flush + flush through spindle

Tool carrier I (X/Y/Z/B):

Technology:Milling spindle on traveling column

Milling spindle speed:12,000 rpm

Max. power:22 kW

Tool holder:Capto C6

Iaedjxl Nfqepfx Ahyol

X-axis:450 mm

Y-axis:200 mm

Z-axis:1,200 mm

B-axis:+/- 110°

Position sensors:Direct scales (glass scales)

Tool carrier II (X/Y/Z):

Technology:Tool turret on cross slide

Tool drive:Direct drive

Speed:10,000 rpm

Power:14 kW

Torque:34 Nm

X-axis:195 mm

Y-axis:80 mm

Z-axis:1,200 mm

Tool holder:VDI 40

Number of tool stations:12

Automation:

Technology:Portal loader with stacking magazine

Workpiece diameter:50 - 200 mm

Max. workpiece height:230 mm

Max. workpiece weight:15 kg

Number of stacking attachments:20

Max. load capacity per stacking attachment:40 kg

Equipment:

Chip disposal:Chip conveyor

Coolant supply:Internal coolant system, 80 bar

Tool magazine:Chain magazine, 120 stations

Workpiece measurement:Renishaw touch probe

Tool breakage monitoring:Swivel wire

Automation:Portal loader with stacking magazine

Emulsion mist separator:Mechanical

Setup operation:Electronic handwheel

Workspace door:Automatic

Chuck:2x SMW KNCS 260

Tool holders:Various Capto C6 holders

Listing

Olching

Olching

8,116 km

5-axis machining centre

DMGDMG DMC 80 FD duoBLOCK

Call

Condition: used, _____

Description:

Year of manuf. : 2008

Control : Siemens 840

Speed : 8000 rpm

Movement X/Y/Z : 800/800/800 mm

Tool holder : HSK 100

In General:

Year of manufacture:2008

Speed:8,000 rpm

Tool holder:HSK 100

Control system:Siemens 840 D

Iodswx A Hqepfx Ahyjal

Travel X/Y/Z:800/800/800 mm

Table speed:700 rpm

Spindle:

Technology:Geared spindle

Speed:8,000 rpm

Max. power:28 kW

Max. torque:727 Nm

Tool holder:HSK-100

Turning function:Spindle clamping

NC swivel head:

Technology:Universal milling head

B-axis:0.001°

NC- Millturn table:

Max. speed:700 rpm

Clamping surface:800 x 630 mm

Max. table load:800 kg

Tool magazin:

Technology:Chain magazine

Number of stations:120

Tool changer:Double gripper

Equipment:

Chip disposal:Chip conveyor

Coolant supply:IKZ system, 80 bar

Coolant temperature control:Immersion cooler

Position measuring systems:Direct in all axes

Automation:2-fold pallet changer

Turning function:Spindle clamping + rotary table

Workpiece measurement:Preparation for measuring probe

Process monitoring:Operating mode 4

Set-up mode:Electronic handwheel

Emulsion mist separator:Mechanical separator

Listing

OIching

OIching

8,116 km

CNC turning and milling centre

DMG MORICLX 450 TC

Call

Condition: used, Year of construction: 2024, controller manufacturer: Siemens, controller model: 840 Dsl - Operate, _____

Description:

Year of manuf. : 2024

Control : Siemens 840 Dsl - Operate

Turning diam. : 400 mm

Turning length : 1100 mm

Main spindle:

Technology:Motorspindle

Speed:5.000 rpm

Power (max.):17 kW

Torque (max.):345 Nm

Clamping cylinder:Hollow clamping cylinder

Bar capacity:67 mm

Workpiececlampig:3-Jawchuck, Schunk Rota THW 315-104

Sub spindle:

Technology:Motorspindle

Speed:5,000 rpm

Power (max.):17 kW

Torque (max.):345 Nm

Clamping cylinder:Partially hollow clamping cylinder

Workpiececlamping:3-Jawchuck, SMW Autoblok 250 BB

Movement in Z:1.200 mm

Thrustforce (Tailstockfunction):2,5-6 kN

Tool carrier (X/Y/Z/B):

Technology:Travelling column with millingspindle

Speed:12.000 rpm

Power (max.):10,5 kW

Torque (max.):90 Nm

Taper:HSK-A63

Swivelrange in B:+/- 120°

In general:

Toolmagazine:Chainmagazine, 60 Stations

Ijdpfox Ih Rtox Ahyjal

Movement in X/Y/Z:750/200/1.100 mm

Rapid travers in X/Y/Z:40 m/min

Equipment:

Positionsensor:Direct scales in X/Y

Chip disposal:Chip conveyor

Coolant supply:Internal coolant with Paperbeltfilter and Highpressure, 20 bar

Workpiecemeasurement:Renishaw RMP 40

Toolbreakagecontrol:Blum Z-Nano

Toolmonitoring:Easy Tool Monitor

Automation:Automationpackage (Automatic Door, electrical Interface Robo2Go)

Emulsion mist separator:Meachanical extraction, AFS 1100

:Set-up operation. Electronic handwheel

Technology cycle:Alternating speed

Digital Manufacturing:IoT Connector

Further Equipment:Spindlechiller, Rinsing pistol

We make it easier for you to find: "emulsion"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Emulsion (258)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you