Used Indexers for sale (1,259)

Grebenau

Grebenau Indexing device

WalterHU 160 N/R

Germany

Germany Indexing Device

WMWDU 250 AS

Germany

Germany Indexing Device

TOS - KURIMDU 250 AS

+44 20 806 810 84

Germany

Germany Revolving Indexing Machine

MIKRONMultistar CX-24/1500R

Sonneberg

Sonneberg Indexing head, presumably Deckel

Discover more used machines

Borken

Borken Plastic testing melt flow index testing

Zwick / RoellMflow Fließprüfgerät

Radom

Radom Index Cutting Machine

Weber RSM 600Index Cutting Machine

Hövelhof

Hövelhof Special drilling machine with rotary indexing table

Technica4298-950

Duxford

Duxford Labinco L295 Solubility Index Mixer

LabincoL295

Duxford

Duxford Funke Gerber Solubility 7610 Index Mixer

Funke Gerber7610

Bünde

Bünde Indexing Device

JUNGOTA 76

Helmstedt

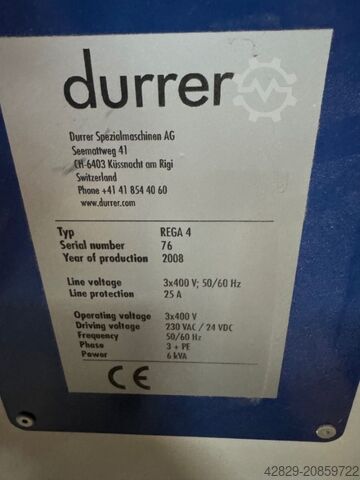

Helmstedt Index cutting machines

DurrerREGA 4

Germany

Germany Rotary Indexing Table

Everwand & Fell/VerMotecVulkan/Vartant

Germany

Germany Revolving Indexing Machine

PFIFFNER HYDROMATHB 32-45/16

Dietzenbach

Dietzenbach Rotary Indexing Table

HAURK 6-1200

Tata

Tata Vertical rotary indexing table 400x620

DrillMaticTA325/P/H/12/2/1/-180°

Tatabánya

Tatabánya Rotary table, indexing table, positioner

WEISS PositioniertischTC 700 T (3327)

Lipie

Lipie INDEX GS42

INDEXGS42

Velen

Velen Indexing Device

WMTTeiltisch HV8

Schijndel

Schijndel Dürrer index cutting machine Rega 6 (1993)

DürrerRega 6

Tönisvorst

Tönisvorst Round Table / Indexing Table

unbekannt400 mm

Hessisch Lichtenau

Hessisch Lichtenau 180° index table, rotary table with base made of aluminum system profile; positioning table, rest po

BOSCH REXROTH

Hessisch Lichtenau

Hessisch Lichtenau Dividing head with tailstock, dividing device, indexing head

DECKEL

Hessisch Lichtenau

Hessisch Lichtenau Rotary table with mechanical drive, dividing table, indexing device

WMWD 315 k

Ennepetal

Ennepetal Indexing Device

WMW HECKERT

Used Indexers (1,259)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84