Used Packer for sale (290)

Menslage

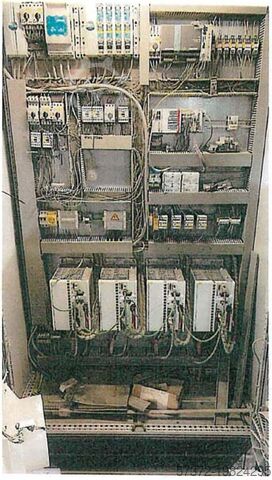

Menslage RICO, ADELSKI, PAC SYSCONA, ICS, ANKER, Keyence Line for Returnable Glass Bottles (2011)

RICO, ADELSKI, PACAbfülllinie für Glasflaschen (Mehrweg)

Menslage

Menslage Krones, Sidel - Line for Non-Returnable PET bottles (2010)

Krones, Sidel

Menslage

Menslage KOSME KSB 4RG Kosme - GyM- SMI (2016)

KOSMEKosme - GyM- SMI

+44 20 806 810 84

Menslage

Menslage Krones 14.000 bph Line for Non-Returnable PET Bottles (2004)

KronesAbfülllinie für PET (Einweg)

Menslage

Menslage Elopak, Shikoku S-PS80HA Aspetic carton filling (2007)

Elopak, ShikokuAspetische Karton Abfülllung

Discover more used machines

Menslage

Menslage Framax DEPAL, RLA, Modulblock RFCI Line for Non-Returnable Glass Bottles (2016)

FramaxAbfülllinie für Glasflaschen (Einweg)

Menslage

Menslage PROCOMAC / PE / ZECCHETTI/BARDI/ACMI/ROBOPAC Line for Returnable Glass Bottles (2001)

PROCOMAC / PE /Abfülllinie für Glasflaschen (Mehrweg)

Menslage

Menslage KHS Blomax 16C, Innofill, etc. Aseptic PET filling line (2005)

KHSAseptische PET-Abfülllinie

Menslage

Menslage Krones Contiform, Mecafill, Variojet Line for Non-Returnable PET Bottles (2002)

KronesAbfülllinie für PET (Einweg)

Lanaken

Lanaken Paper Production Line 7500 mm

Valmet / Beloit

Łask

Łask Beverage production machine

TETRA PAK A3 COMPACT FLEX 200/250 EDGECOMPLETE LINE IN AS NEW CONDITION

Zelo Buon Persico

Zelo Buon Persico Automatic 'L'-sealer with tunnel

ULMASLAU 80-60 + TR 65-150

Stary Sącz

Stary Sącz PET 2L beverage water bottling line

NAGEMA BF60KOMI 160

Buseck

Buseck Vacuum machine

VakuMitEST 20 LC

Przemyśl

Przemyśl Beverage production machine

ELOPAK SHIKOKU ASEPTIC FILLING LINES-PS80HA

Graz

Graz Mobile exhaust system

FelderRL 300

Graz

Graz Woodturning machine / lathe

DrechselmeisterSTRATOS FU-230

Germany

Germany Sleeve Wrapper

Sema

Germany

Germany Tube Filling Line

IWK/Laetus/Mettler/SkinettaTZK200/TFS30/CPS-R/CP145/PAL1400

Germany

Germany Filling and Packaging Line

ElopakS-PS80HA

Germany

Germany Stone Production Plant

OmagTronic S22 140-90

Germany

Germany Filling, Labelling and Packing Plant

Stork/Silmo/Robino & Galandrino/AdelskiVV-24/ST XII/Monoblocco Fenix 3/P2004 Longcap

Emmeloord

Emmeloord 2007 Record Scorpion compact

RecordScorpion compact

Berlin

Berlin Bottle Filling Line

Kettner / Krones / Schneider

Berlin

Berlin Filling, Sealing and Labelling Line

Lieder/Multivac/Buhmann/Mesutronic

Used Packer (290)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84