Used Venture Distributor for sale (317)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Kassel

Kassel

7,808 km

Heating and blower unit

RemkoCLK 120 inkl. Öltank

Call

Condition: new, Year of construction: 2022, functionality: fully functional, power: 121 kW (164.51 HP), volume flow: 7,350 m³/h, nominal heat output: 110 kW (149.56 HP), tank capacity: 1,000 l, fuel: diesel, 10 units of mobile heaters, as new, unused, in original packaging, year of manufacture 2022. REMKO CLK 120 with oil burner and oil tank. Each includes a moisture-resistant thermostat type RT-5. Air distributor head with 2 outlets of Ø 400mm. Each with 2 x warm air hoses, 7.6 m long, including closure strap, Ø 405mm. Single-line extraction set for 1000-liter oil tank. Including quick couplings and device connection hose. Oil tank, diesel tank, heating oil tank, storage tank. Double-walled PE combination tank VET, capacity 1000 liters.

Kodpsxgn Dzofx Ab Toln

Listing

Griesstätt

Griesstätt

8,181 km

Parquet production line

SOEST Oberflächenlinie neuwertigRCR-400-L Reserve & VP-400-1B-2P-2B

Call

Condition: like new (used), Year of construction: 2019, operating hours: 180 h, functionality: fully functional, total length: 8,000 mm, total width: 1,200 mm, total height: 1,300 mm, type of input current: AC, input voltage: 400 V, power: 10 kW (13.60 HP), SOEST Universal Surface Line for oiling, staining, lye treatment, patination, etc.

Primarily intended for parquet surfaces up to 40 cm workpiece width.

1) Roller Machine RCR-400-L Reverse, for applying and removing surface products such as oils, stains, lacquers, etc.

2) Distributor Machine VP-400-1B-2P-2B with one brush, two pad holders, and an additional two brushes, for distributing, working in, or patinating surface media in the pores and/or also for removing, distributing, and working in depending on the desired surface effects.

3) Accessories include two spare application rollers, a material pump (brand new, never used), four replacement brushes, various distributor pads, and a pneumatic brush cleaning machine.

This complete surface finishing line is built for professional industrial use and is configured with a full set of equipment. A considerable amount of accessories for the system, such as extra rollers and cleaning machines, is also included (see photos!).

Very robust construction, all motors frequency-controlled (Siemens). Speeds are steplessly adjustable for both forward and reverse operation. Maximum workpiece width is approx. 410 mm.

The system is in very good condition, with little use—only approx. 180 operating hours—so it can be described as as-new.

This surface processing line was only used as a backup line in parquet production and only for specific surface techniques, which explains the low operating hours (used sporadically from 2019 to 2022).

In 2023, our company downsized and the system has been stored ever since or is immediately available, and therefore remains in nearly brand-new condition!

This system is no longer used in our facility and is therefore being sold. The new price for this line was approx. €87,000 in 2019; the current selling price is negotiable!

Inspection of this surface line is possible by appointment.

If required, we can also offer 10 drying rack trolleys for sale with this system.

Kljdpfsyaiafsx Ab Ten

(The YouTube video serves only as an example video of a similar system configuration!)

Listing

Wiefelstede

Wiefelstede

7,607 km

Power strip adapter

Gifas2800 32A / 16A

Call

Condition: good (used), Power strip, portable power strip, solid rubber power strip, adapter, construction site power strip

-Manufacturer: Gifas, solid rubber distributor adapter 32A / 16A

-Type: 2800 Item No.: 282/301657M/303259/6

Kedpeivumtsfx Ab Toln

-Transport dimensions: 230/230/H130 mm

-Weight: 3 kg

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Wiefelstede

Wiefelstede

7,607 km

Power strip adapter

Gifas63A / 16A

Call

Condition: good (used), Power strip, portable power strip, solid rubber power strip, adapter, construction site power strip

Kodpfx Aboivum Eo Tjln

-Manufacturer: Gifas, solid rubber distributor adapter 63A / 16A

-Transport dimensions: 230/230/H130 mm

-Weight: 3 kg

Listing

Prüm

Prüm

7,698 km

Agricultural machine

KugelmannA1201

Call

Condition: new, Year of construction: 2024, overall weight: 265 kg, empty load weight: 265 kg, operation weight: 265 kg, _____Basic equipment > Hydraulically driven single-chamber spreader with feed auger and spreading disc. > Spreader hopper and distributor made of stainless steel. > Dimensions (W x H x L): 1050 x 950 x 1800 mm. > Unladen weight approx. 265 kg. > Incl. tarpaulin cover. > Incl. manual operation. > Incl. rear extension. (Length determined by axle load calculation) Mounted spreader, A1201 B1050 H950 L1800 Carrier vehicle: Multihog MXC Batch/Serial number: 40941 Special equipment - Discharge welded - K-basis 2 control system, fixed wiring harness, microprocessor control in CAN-BUS technology. Regulation of all drives in a closed control loop (with feedback). Functions: - Adjust spreading width - Adjust spreading density - Beacon on/off - Work light on/off - Spreader operation/pause - Illuminated buttons and rotary controls - Data logging - Speed simulation - x2 button - Complete wiring incl. wiring harness separation - Terminal box for mounting outside the cabin Rear apron W 1500 x H 500 Yellow beacon Agitator shaft set - Improves functionality regarding bridging with damp, poor quality spreading material. Auger reversing - Allows reversing of auger direction at the press of a button on the unit in case the feed auger is blocked or jammed. Location: 54595 Prüm

Klsdpew Ibbqefx Ab Tjn

Discover more used machines

Listing

Gola

Gola

8,267 km

Spare parts for Heckert milling machines

WMW Fritz HeckertF315, F400, FSS400, FW450, FU350

Call

Condition: new, functionality: fully functional, Spare parts for Fritz Heckert milling machines F315, F400 - even for the oldest ones.

We offer a full range of spare parts for milling machines – the old and new German WMW HECKERT milling machines F315, F400, FSS-350MR, FSS-400MR, FU-350MR, FU-450MR, FU-350ApUG, FU-450ApUG, FU-350MRApUG, FU-450MRApUG.

Kodpfx Abovtnfpo Teln

In our stock one can find: milling machine head and all gears for it, dividing heads, lunette/rests, all electromagnetic clutches and brakes, shafts, bevel gears, worms and worm gears, pulleys, levers, longitudinal and cross screws, nuts, oil pumps, cooling pumps, spindles, quills, hydraulic dividers/distributors etc.

All the original parts for Heckert milling machines we can offer directly from stock, ready for immediate shipment. All parts are new, executed in German quality, and meet the highest technical standards.

Listing

Duxford

Duxford

7,214 km

Liebherr Hausgerate LGPv 1420 Freezer

Liebherr HausgerateMediline LGPv 1420

Call

Condition: used, This listing is for a Liebherr Hausgerate LGPv 1420 Freezer

The unit is in full working condition and is ready for immediate release

The Liebherr LGPv 1420 is a large-scale laboratory freezer designed for optimal storage and accurate temperature management. It integrates Profi electronic controllers that ensure precise temperature control, providing a reliable solution for environments that require large storing capacities, such as in research and laboratory settings.

Key Features:

Dynamic Cooling System: Ensures uniform temperature distribution and rapid cooling.

Profi Electronic Controller with Integrated Real-Time Clock: Allows precise monitoring and temperature control, ensuring optimal performance.

castors (Two with Brakes): For easy mobility and stability when required.

Ergonomic Handle: Built-in for convenient door operation.

Plastic-Coated Grid Shelves & CNS Inner Liner: Durable, easy-to-clean interior surfaces.

Glass Door with Ceiling Light (Separately Switchable): For clear visibility of stored items with an aesthetic touch.

Hot-Gas Defrost System: Minimizes downtime by enabling very short defrost cycles.

Security Package:

Integrated Data Memory: Stores alarm events and temperature profiles for documentation and monitoring.

Visual & Audible Temperature and Door Alarms: Alerts you to temperature fluctuations or if the door is left open.

Mains-Independent Power Supply: Keeps the electronic controller operational even in the event of a power failure.

Infrared & RS 485 Interface: Enables external documentation and system monitoring.

Volt-Free Contact for Alarm Forwarding: Allows connection to external warning systems.

Maximum Temperature Stability: Adheres to IEC 60068-3 standards for consistent performance.

3-Point Calibration: Provides highly accurate and reliable temperature control.

Access Port for External Temperature Sensor: Allows you to integrate additional monitoring systems if needed.

Lock: For added security to prevent unauthorized access.

Product Specifications:

Product Type: LGPv 1420

Kledpjxhf Uyjfx Ab Ten

Capacity: 1427 Liters

External Dimensions (W x D x H): 1430 x 830 x 2150 mm

Internal Dimensions (W x D x H): 1250 x 700 x 1550 mm

Energy Consumption: 8,887 kWh (per 24 hours)

Temperature Range: -10°C to -26°C

Manufacturer: Liebherr

Advantages of Using LGPv / LKPv Freezers with Profi Electronic Controllers:

These large-scale laboratory freezers provide a high-quality solution for storing temperature-sensitive items. The Profi electronic controller ensures both stability and accuracy, making them an ideal choice for environments where temperature consistency is critical.

The dynamic cooling system, combined with the hot-gas defrost system, ensures minimal disruption to operations, allowing these units to maintain an ideal storage environment.

Pricing and Availability:

Liebherr offers its laboratory refrigerators and freezers through authorized dealers and distributors. Prices vary by location, but the Liebherr LGPv 1420 is typically available for professional environments where large storage capacity and precise temperature control are required. For specific pricing, it’s best to contact Liebherr or your local distributor.

For more details, you can refer to Liebherr's official website or look for trusted suppliers and retailers.

This model provides an advanced solution for laboratories that require large freezer capacities and high precision for storing sensitive materials.

Listing

Duxford

Duxford

7,214 km

SAS Super80 Air Sampler

SASSuper80

Call

Condition: used, This listing is for a SAS Super80 Air Sampler

The unit is in full working condition and is ready for immediate release.

The SAS Super series (by SAS / Bioscience International, also referenced under other distributors) are impaction‑type microbial air samplers. They draw a known volume of air through a sampling head so that airborne microorganisms are impacted onto an agar contact plate (or Petri dish) for subsequent incubation and colony counting.

These instruments are commonly used in cleanrooms, pharmaceutical manufacturing, hospitals, and other controlled environments to assess airborne microbial contamination.

Good combination of high airflow + relatively compact unit; allows efficient sampling of large volumes in minimal time.

Kjdpfx Aoxv Abasb Toln

Wide usage and long track record (models from this family have been used since the late 1970s/80s) which implies reliability and a mature support ecosystem.

Flexible head options (aluminium, stainless steel, resin), choice of plate types (contact plates or standard Petri dishes) in some variants.

Strong traceability / data capture features, which are important for regulated environment

Listing

Wachtendonk

Wachtendonk

7,618 km

Three-way tipper van

MERCEDES-BENZSprinter 517 43 DOKA 5,5t 3-S-KIPPER PENDELB AHK

Call

Condition: used, mileage: 150 km, power: 125 kW (169.95 HP), first registration: 02/2026, fuel type: diesel, overall weight: 5,500 kg, color: white, gearing type: mechanical, emission class: euro6, number of seats: 7, loading space length: 3,600 mm, loading space width: 2,100 mm, loading space height: 450 mm, Equipment: ABS, air conditioning, central locking, electronic stability program (ESP), soot filter, Are you looking for a different model, engine specification, dimensions, or further features?

Feel free to contact us.

We offer financing and leasing on attractive terms – also available for the Netherlands, Austria, and new ventures!

----Vehicle: Wheelbase: 4325 mm

* 6-speed manual gearbox

* Double cab

* Twin rear wheels

* Gross vehicle weight: 5.5 tonnes

* 90 km/h speed limiter

* Digital tachograph 4.1

Technology/Comfort: Digital radio

* Acoustic package

* Apple CarPlay/Android Auto

* MBUX multimedia system

* Smartphone integration package

* “Tempmatic” air conditioning

* Cruise control

* Electrically adjustable, heated and extended side mirrors

* Height- and reach-adjustable multifunction steering wheel

* Light sensor

* 93L main fuel tank

* 22L AdBlue tank

* Comfort driver’s seat with armrest

* Passenger double bench

* 7 seats

* Black leatherette seats

* Electrical pre-equipment, programmable special module

* Hill start assist

* On-board computer with colour display

* Toll system preparation

* Central locking with remote control

* Electric front windows

* Fuel filter with water separator

Safety:

* All-season tyres

* Reinforced front axle

* Reversing camera pre-installation

* Crosswind assist

* Lane keeping assist

* Rain sensor

* Intelligent speed assistant

* Reversing warning system

* Fog lights with cornering function

Kljdpowm Tvxsfx Ab Ton

* Attention Assist

* Battery master switch

* Halogen headlights

* Outline marker lights

* Side marker lights

* Adaptive brake lights

* Seat belt warning system

* EU underride guard

Three-way tipper:

* Smooth steel floor

* Removable aluminium drop sides

* Pendulum top-hinged and drop-down lower sideboards

* Tie-down eyes fitted to bed

* Steel cab guard with ladder rack

* Two small toolboxes under the body

* Lateral underrun protection

* Wheel protection with mud flaps

* Side marker lights

* Tow hitch: 3.5t towing capacity (AHK ball head, 12V 13-pin trailer socket)

Additional body-specific extras available at a surcharge.

----Note:

Please call briefly before your visit – we will ensure your desired vehicle is on site.

If the vehicle is not located in Wachtendonk, we are happy to deliver from our inventory.

Bespoke bodies available upon request.

Your vehicle partner since 1996.

Call or email us now – we look forward to assisting you!

No liability for printing or typographical errors. Subject to prior sale or error.

Best regards,

Pimenta Automobile

Listing

Konstanz

Konstanz

8,021 km

Generator

HELVETICA POWER‼️30KW/38KVAHPYU04030ASR Euro5

Call

Condition: new, Year of construction: 2024, functionality: fully functional, overall weight: 1,100 kg, fuel type: diesel, color: yellow, power: 30 kW (40.79 HP), output current: 54 A, output voltage: 400 V, output frequency: 50 Hz, type of output current: three-phase, nominal power: 30 kW (40.79 HP), nominal power (apparent): 38 kVA, continuous power: 30 kW (40.79 HP), continuous power (apparent): 38 kVA, total length: 2,110 mm, total width: 1,000 mm, total height: 1,350 mm, rotational speed (max.): 1,500 rpm, motor manufacturer: Yunnei STAGEV, type of cooling: water, HELVETICA POWER offers: 30 KW 38 KVA Generator / Diesel Generator

⭐️ Stage V (EU) / Euro 5 compliant – suitable and approved according to current European emission standards.

⭐️ Oil-tight chassis, ideal for construction sites, industry, agriculture, and many other applications.

⭐️ CE-compliant in accordance with applicable regulations

⭐️ Sound-insulated (Super Silent) design

⭐️ Equipped with emergency power switch / ATS (Automatic Transfer Switch) unit for backup power operation

⭐️ Digital control panel plus integrated remote control

⭐️ Yunnei Stage V diesel engine designed for continuous operation

⭐️ Stamford type (licensed CN): CE-certified high-quality brushless synchronous alternator with 100% copper winding

⭐️ AVR system (automatic voltage regulation dependent on load)

⭐️ The generator is delivered with a practical, heavy-duty yellow tarpaulin truck cover

Warranty / Guarantee / Service

⭐️ One-year factory warranty!

⭐️ Optional: up to 2-year extended warranty, significantly exceeding industry standards (extendable upon request).

⭐️ Our insurance partner: Allianz Suisse / Allianz Germany (for Europe)

⭐️ Service available throughout Switzerland and Europe.

Payment / Delivery

⭐️ Payment: due at purchase.

⭐️ Delivery available throughout mainland Europe for an additional charge.

🚚 Pickup: from our warehouses in Kefikon (TG, Switzerland) or Konstanz (Germany)

🚚 Worldwide delivery upon request

👍 Dealer inquiries welcome – contact us!

⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️

More Models & Configurations

⭐️ Other power ratings available (approx. 7 kW to 100 kW)

⭐️ Stage V (EU) / Euro 5 compliant versions

⭐️ Alternative engine options available (e.g. Cummins, Deutz, Volvo)

⭐️ Optional features: larger tank, auxiliary tank, tank and water heating

Kjdpfewbkkpjx Ab Tjln

⭐️ Many versions available from stock in CH / DE.

⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️⭐️

Keywords: power generator, generator, emergency generator, backup generator, power unit, energy generator, power supply unit, standby power unit, emergency power supply, NEA, backup power, replacement power, backup power supply, power supply, power source, autonomous power supply, off-grid operation, site power, construction site generator, event power, camping power, outdoor power supply, diesel generator, petrol generator, gas generator, inverter generator, synchronous generator, asynchronous generator, three-phase generator, single-phase generator, 230V generator, 400V generator, high-voltage generator, small generator, industrial generator, professional generator, high-performance generator, silent generator, super silent generator, sound-insulated generator, mobile generator, portable generator, stationary generator, home backup power, commercial power, industrial power, agricultural generator, construction equipment, workshop power, server backup, PV backup, hybrid generator, ATS, automatic transfer switch, power distributor, CEE generator, high-voltage connection, generator with AVR, voltage regulator, power maker, power device, backup power device, diesel power unit, construction site power unit, 22KW 28KVA 30KW 38KVA 34KW 43KVA 44KW 55KVA 19KVA 15KW 38KVA 30KW 63KVA 50KW 125KVA 100KW 100KVA 80KW

Listing

Concordia Sagittaria

Concordia Sagittaria

8,373 km

Electro-hydraulic press 150 Ton

AXAPM 150/15

Call

Year of construction: 2023, condition: new, AXA MOVING CYLINDER ELECTRO-HYDRAULIC PRESS.

150-ton power.

Automatic double speed with rapid.

Moving cylinder stroke 816 mm transverse.

Internal clearance from shoulder to shoulder mm 1500

Klsdpfx Aslruhdob Tjn

Rod stroke mm 300

GALTECH distributors.

- 2MP block.

- No. 2 VIVOIL external gear unidirectional pumps. One for rapid approach and return (calibrated

at 20 bar) and one with adjustable pressure with handwheel to set the required power.

- Pressure relief valve with mechanical lock to prevent overpressure.

- Standard pressure gauge to display power output.

- INTECH electrical panel certified according to current regulations and with independent CE marking.

Listing

Koenigs-Wusterhausen

Koenigs-Wusterhausen

7,972 km

Concrete pump truck

MERCEDES-BENZActros 2632 6x4 Betonpumpe Schwing 24m

Call

Condition: used, mileage: 318,699 km, power: 235 kW (319.51 HP), first registration: 09/2006, fuel type: diesel, overall weight: 26,000 kg, axle configuration: 3 axles, next inspection (TÜV): 04/2026, color: blue, gearing type: semi-automatic, emission class: euro3, Equipment: ABS, air conditioning, * ABS

* ASR (traction control)

* On-board computer

* Cruise control

* Hill-start assist

* Analog tachograph

* Electric window regulators

* Electrically adjustable mirrors

* Mirror heating

* Central locking

* Roof hatch

* Rear window

* Longitudinal and transverse differentials locks

* AP axles

* Steel bumper

* Air dryer

* Air-suspended driver's seat

* 16-speed

* Suspension: leaf spring

* Payload: 6,080 kg

Kodpfx Abew S Agpj Teln

* Retarder: engine brake

----Body: Schwing concrete pump P 2023-110/75 RB, 4-section, Z-fold, 4 arms, distributor boom KVM 24-4 H (Vector), max. vertical reach 23.1 m, max. horizontal reach 19.5 m, max. depth reach 13 m, slewing range 370°, delivery line (pipe DN) 125, 3 m end hose, max. output 114 m³/h, max. delivery pressure 80 bar, radio remote control + cable remote, fully hydraulic 4-point outriggers, oil cooler, centralized lubrication, high-pressure water pump. Read operating hours: Pump 5,133 h, Boom 6,369 h, Water pump 555 h, HP-pump 45 h, Agitator 9,820 h, Vibrator 581 h----Low folding height (under 5 m), also ideal for indoor operation!

Sale to commercial customers only. FOR EXPORT SALES, ONLY THE NET PRICE IS PAYABLE!!!!! ALL INFORMATION SUBJECT TO CHANGE, ESPECIALLY EQUIPMENT AND ACCESSORIES. All contracts for sale, invoices, pro forma invoices, orders, and sales discussions are subject to our general terms and conditions (see legal notice/imprint).

Listing

Macclesfield

Macclesfield

7,018 km

Hot foil stamping machine

GietzFSA 790

Call

Condition: reconditioned (used), Year of construction: 1995, functionality: fully functional, Gietz FSA 790 EFF high speed foil stamping , embossing and die cutting machine

Offered fully reconditioned by exclusive Gietz UK distributor

Max format 790 x 560 mm : max speed 5,500 sheets / hr

High speed MABEG suction feeder : : 6 heating zones : 3 x electronic servo longitudinal foil feeds : transverse foil feeds : programmable foil feed with servo drives : non stop delivery

Kledpfsxp Ntvex Ab Ten

Photos show machine in production before reconditioning

Listing

Brendola

Brendola

8,307 km

Tipper truck

IVECOEUROCARGO 180E32

Call

Condition: new, functionality: fully functional, fuel type: diesel, fuel: diesel, color: white, driver cabin: day cab, emission class: euro6, number of seats: 3, Year of construction: 2026, Equipment: crane, IVECO EUROCARGO 180E32

Year: 2026

DIESEL / Euro 6E

Mileage: 0 km

Manual gearbox / Engine displacement: 6,728 cc / 235 kW

GVW: 18,000 kg

Payload: 6,970 kg / Wheelbase: 4,185 mm

Equipment:

- Air conditioning

Bodywork:

- Tipper body: 4,400 x 2,550 x deck height 1,400 mm

- Crane PM 18024 SP + JIB 513.20

. Antenna

. Proportional distributor

Kedsx Sdc Hopfx Ab Tsln

. Radio

. 4 stabilizer legs

. Winch preparation

Listing

Rzeszów

Rzeszów

8,578 km

Bitumen Emulsion Sprayer/Asphalt Sprauer

TICABAsphalt Sprayer/Bitum Sprayer BS-500 PRO

Call

Condition: new, functionality: fully functional, Year of construction: 2025, BS-500 PRO

Even the best road coating wears during exploitation. Heavy traffic, unfavorable weather conditions, and other factors negatively affect the asphalt. Bitumen pressure distributor BS-500 PRO – is the number-one equipment to protect the load-bearing structure of the road with surface treatment. The model has a safe and inexpensive heating system, responsible for maintaining the required temperature of the emulsion. The 500-liter emulsion tank is insulated with solid mineral wool.

Technical Specifications

Engine power (petrol, air cooled)-4.3 kW (5.8 hp)

Emulsion tank capacity-500 l

Productivity-28 l/min

Nozzles on the spraying bar- 7 pcs

Kljdpfx Abevuacco Tjn

Spraying width-1.7 m

Diesel cleaning system

Spraying bar is modularised, consisting of 3 sections, with rubber protection plates that protect against contamination and emulsion in unplanned areas

Remote control of the spraying bar

Electric starter

Tank self priming function

Emulsion tank heating system

Ability to connect a third party compressor for cleaning the spraying bar

Listing

Eisingen

Eisingen

7,910 km

Temperature control technology

HB-ThermFlow

Call

Condition: excellent (used), Several HB-Therm flow meters and water distributors available

Condition: as new – from cleanroom production

The following versions are available:

Ksdpfx Asw D Eh Ijb Toln

3-way

5-way

6-way

12-way

13-way

16-way

Note:

Original new prices can be found in the attached documentation.

I purchase all machines and peripheral devices directly from customers at a fair price.

The subsequent sales price is calculated reasonably so that all three parties – seller, buyer, and myself as the intermediary – make a small, fair deal.

Unsolicited purchase offers from various used machinery dealers are therefore not welcome.

Listing

Lithuania

Lithuania

8,364 km

Meat processing machine

HyShprizHySpriz RK50U 3-in-1 Forming System for

Call

Condition: new, Year of construction: 2025, total length: 600 mm, total width: 600 mm, total height: 1,400 mm, warranty duration: 12 months, overall weight: 300 kg, input voltage: 400 V, power: 1.5 kW (2.04 HP), pressure: 9.8 bar, tank capacity: 50 l, HySpriz RK50U 3-in-1 Forming System for Meat Snacks, Pet Sticks & Mini Salami | Up to 1500kg/shift

Made in Ukraine. 18 month full warranty. RK50U — universal casing-free forming system for meat sticks, jerky & sausage production

HydroShpriz RK50U is a powerful piston-driven filling and forming machine engineered for small and mid-size manufacturers starting production of meat sticks, salami snacks, pet food, kibbeh, fruit bars, and more. Ideal for dry-cured snacks without alginate casing. Strong, compact, and easy to operate — it’s the perfect choice to start your line and grow with Trade-In options.

⸻

Kedomrpvyepfx Ab Tsln

Technical specifications

• Drive: hydraulic piston

• Piston force: 94 kN

• Power: 1.5 kW, 380 V, 50 Hz

• External dimensions: 1050×550×950 mm

• Weight: approx. 300 kg

• Material: full stainless steel, food-grade

• Certification: CE certified, built for continuous 8-hour production cycles

⸻

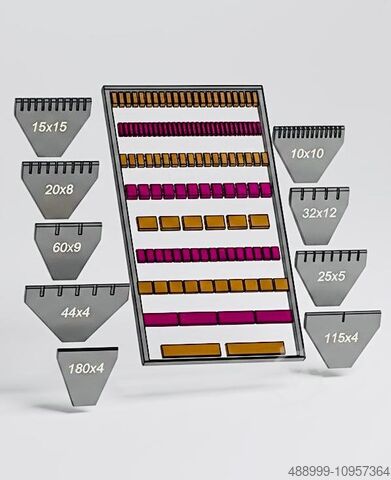

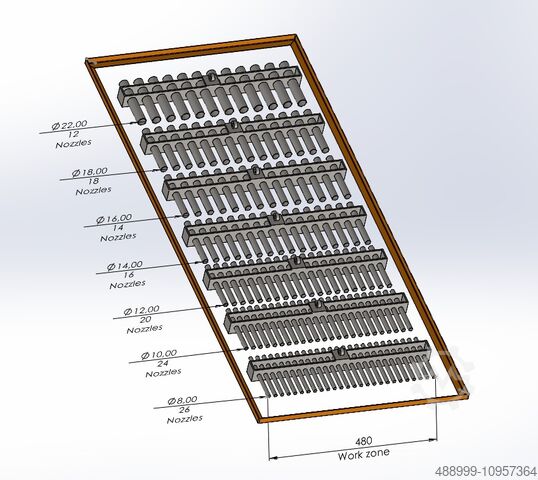

Configuration & possibilities

• Gearbox-driven filler for thick and sticky emulsions down to –2 °C

• Multi-nozzle head: up to 25 lanes simultaneously

• Round nozzle set: 8 mm to 22 mm for meat or fish sticks

• Flat nozzle set: 25 mm to 200 mm width, 3–5 mm height — ideal for jerky/strips

• Sausage stuffing set: for traditional casing sausages

• Overhead tray holder: for direct forming onto drying racks

• Trolley integration: fits perfectly with our 30-row drying racks (60 trays)

• Integrated time-based portioning unit with ±8% accuracy

• 24V remote signal: compatible with automatic clippers (PolyClip, Compa, etc.)

• Optional vacuum connection: for better product density and shelf-life

⸻

Production capacity

• From 20 kg to 1,600 kg per 8 hours depending on product shape, tray format and nozzle type

⸻

Availability

✔️ In stock at official distributors in:

• Austria

• Poland

• United Kingdom

• Lithuania

• Australia

• South Africa

• United States

Delivery worldwide. Training, test batch, and spare parts included.

⸻

Made in Ukraine. CE sertified industrial forming system

• meat snack production

• pet food production

• jerky, salami, kebab machine

• food processing equipment

Listing

Straubing

Straubing

8,143 km

Vertical machining center

DatronM8Cube

Call

Condition: excellent (used), Year of construction: 2014, Datron M8 Cube with rotary swivel table (4th + 5th axis)

Ksdpsx Rpl Dsfx Ab Teln

HSC Pro control V9

Year of manufacture: 2014

Machine operating hours: approx. 8,800 hours

2kW HF spindle, 6,000 rpm up to 60,000 rpm with direct shank tool clamping system

HIB HF spindle cooling unit

15-position automatic tool changer

3D probe Renishaw

Precision tool length probe

Microjet minimum quantity lubrication system with 4-nozzle spray unit

Vacuum table with 500mm x 500mm working area

1 x T-slot plate

1 x short-stroke clamp

3-fold vacuum distributor

The machine is in very good condition.

The machine can also be purchased without the rotary swivel table (4th + 5th axis).

Listing

Topole

Topole

8,077 km

BT VCE150A narrow aisle truck

TOYOTA BTVCE150A

Call

Condition: new, Year of construction: 2023, Brand new system stacker with elevating cabin designed for storing and retrieving loads as well as for order picking in very narrow work aisles.

Type (group): Order picking (high storage)

Operating mode (guidance): Induction loop

Year of manufacture: 2023 forklift (in production, delivery May/June)

Serial no.: 6959414

Nominal load capacity: 1500 kg

Center of gravity: 600 mm

Lifting height: 10,250 mm

Lifting height (platform): 8600 mm

Order picking height: 10200 mm

Ksdpsiyprcsfx Ab Tsln

Mast type: Triplex

Height of the folded mast: 4460 mm

Mast height extended: 11040 mm

Total length of the truck (head folded): 3846 mm

Forklift width: 1270/ 1520 mm

Ground clearance: 60 mm

Own weight (without battery): 6790 kg

Battery (weight): 1760 kg

Turning radius: 1698 mm

Working corridor: 1760 mm

Distance between shelves: 1850 mm

Forks: 1200 mm

Travel speed with/without load: 10/ 12 km (programmable)

Lifting/lowering speed: 0.4/ 0.4 m/s

Traction battery (acid): TAB Standard 48V8EPZS1240Ah + BFS

Rectifier (high efficiency): Polar Q420LOG 24/ 36/ 48V, 20-180A (programming, analytics)

Braking system: electro-mechanical

Rollers/wheels: Vulkollan (PU)

Signal generator (no wiring): included

Net price: EUR 97,700 / piece without shipping and assembly/commissioning

The narrow aisle forklift comes from the official distributor of Toyota Material Handling Poland.

If you are interested, please contact us.

Listing

Macclesfield

Macclesfield

7,018 km

Gietz Hot Foil stamping press

GietzFSA 790 EFF

Call

Condition: ready for operation (used), Year of construction: 1997, functionality: fully functional, Gietz FSA 790 EFF high speed foil stamping , embossing and die cutting machine

Offered fully reconditioned by exclusive Gietz UK distributor

Max format 790 x 560 mm : max speed 6,000 sheets / hr

Top EFF specification

High speed MABEG suction feeder : 6 heating zones : 3 x electronic servo longitudinal foil feeds : 3 x transverse foil feeds : 3 line hologram capability : non stop delivery

Kljdpfx Abox Ezkus Ten

Listing

Pollenzo

Pollenzo

8,138 km

HOMAG TRIMMING AGGREGATE

HOMAG2-056-11-3020

Call

Condition: used, functionality: fully functional, Ferwood code: AGG0188 - Manufacturer code: 2-056-11-3020 - Condition: Used - Functionality: Fully operational - Compatible machine: CNC HOMAG BOF - HOMAG BAZ - WEEKE VENTURE - BHC - CENTATEQ - If interested, we offer an overhaul service, please contact us. Weight and transport dimensions: 8 kg, 46x39x27 cm.

Ksdpfx Absvu Tqte Toln

Trust Seal

Dealers certified through Machineseeker

Listing

Pollenzo

Pollenzo

8,138 km

ELECTROSPINDLE

OMLAT

Call

Condition: used, functionality: unexamined, Ferwood Code: RU0000078 - Manufacturer Code: 5816 - Condition: Used - Functionality: Not tested - Compatible Machine: CNC IMA BIMA - HOMAG BAZ - HOMAG BOF - WEEKE VENTURE - WEEKE BHC - WEEKE BHP/BP - If interested we offer a revision service, contact us.

Klsdpfx Aov Azgfsb Ton

Listing

Pollenzo

Pollenzo

8,138 km

HOMAG CNC CLAMP FOR NARROW PIECES

HOMAG

Call

Condition: used, functionality: fully functional, Ferwood Code: RU0011480 - Manufacturer Code: - Condition: Used - Functionality: Fully functional - Compatible Machine: CNC WEEKE VENTURE - WEEKE BHC - HOMAG BOF - HOMAG BAZ - HOMAG CENTATEQ - If interested we offer an overhaul service, contact us.

Ksdpfxev I A Rpe Ab Tsln

Listing

Częstochowa

Częstochowa

8,375 km

Tire Recycling / Shredding System

3E-GrabTradeTIRE RECYCLING LINE

Call

Condition: new, Year of construction: 2025, The 3E Machinery tire recycling system is a state-of-the-art, modular industrial line engineered for the efficient processing of used passenger, truck, and industrial tires into clean fractions such as rubber granules, steel, and textile fibers. This installation provides high throughput, low energy consumption, and full compliance with environmental protection standards.

Comprehensive Tire Processing Technology

• The system comprises several processing stages that guarantee complete material downsizing and separation:

• Pre-cutting and primary shredding of whole tires

• Multi-stage size reduction with dual-shaft and four-shaft shredders

• Granulation and fine milling of rubber

• Magnetic separation of steel

• Air and cyclone separation of textile fibers

• Final purification and classification of rubber granulate

This process enables the production of high-quality rubber granules in various sizes (from 30 mm down to 1–4 mm), as well as clean steel suitable for recycling.

System Throughput and Application Range

• Throughput: from 500 kg/h to over 10,000 kg/h

• Material types: passenger car tires, truck tires, industrial tires, solid tires, bead-reinforced tires

• Final output products:

o rubber granules (30 mm, 10 mm, 1–4 mm)

o rubber powder

o steel

o textile fibers

• Optional low-noise and low-dust engineering packages available

The layout can be customized to match the client's required capacity and available plant space.

Kodpfx Aox Aidbob Tsln

Why partner with our company – Official European Representative of 3E Machinery

• Competitive pricing without intermediary markups. We offer equipment directly from the factory in China, without additional distributor or agent margins, ensuring highly competitive pricing while maintaining full manufacturer quality.

• Comprehensive technical and commercial support. Based on client specifications, we select the appropriate line configuration, define process parameters, capacity, and technology scope—ensuring a perfect match for each project.

• Full assistance throughout the entire procurement cycle. We support customers from the initial inquiry, through technical discussions, payment terms, and to the conclusion of the final agreement with the manufacturer.

• Logistics and transportation support. We assist with organizing international transport, customs clearance, and required documentation so delivery proceeds smoothly and without complications.

• Extensive experience in the recycling industry. As a long-standing European representative of 3E Machinery, we provide practical know-how and market expertise that greatly simplifies the purchasing process.

Listing

Polska

Polska

8,289 km

Fully Automatic Thermal Film Laminator

Wenzhou Guangming Printing Machinery Co.SWAFM 1050

Call

Condition: excellent (used), Year of construction: 2018, functionality: fully functional, Very good technical and visual condition.

The machine in continuous operation – test and presentation possible.

Availability: January 2025

Location: European Union

Machine imported, installed, and under service care by the official GMB distributor.

Only one user.

The best-selling model of GMB's automatic laminator.

A renowned manufacturer specializing exclusively in laminating machines since 1985. Exporting to 150 countries, GMB holds a 40% share of the domestic Chinese market and international exports.

Automatic Pallet Feeder

Front and side-lay margin control

Touchscreen controller

Large diameter chrome-plated calender

Electromagnetic heating – rapid heating within 90 seconds

Stable operating temperature

Hydraulic pressure

Pneumatic sheet separation unit

Anti-curl bar

Automatic high-capacity stacker – pallet-based output

MODEL: SWAFM-1050

Max Sheet Size: 1050 x 820 mm

Min Sheet Size: 300 x 300 mm

Laminating Speed: 65 m/min

Paper Thickness: 105 – 500 g/m2

Gross Power: 35 kW

Total Weight: ok. 3000 kg

Kedpovkg H Tjfx Ab Toln

Dimensions (szer. x głęb. x wys.) ok. 5800 x 2200 x 1900 mm

Pressure system: Hydraulic

Max. pressure in hydraulic system: 8 MPa

We make it easier for you to find: "venture distributor"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Venture Distributor (317)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month