Used machining centers with flat or grid table for sale (345)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Woodworking machinery CNC-processing machines Machining centers with flat or grid table

Listing

Bad Honnef

Bad Honnef

7,723 km

Machining center HOLZ-HER 7405 EVOLUTION CONNECT -exhibition machine-

Holz-Her7405 EVOLUTION CONNECT

Call

Condition: new, HOLZ-HER 7405 EVOLUTION CONNECT machining center

-Exhibition machine-

This offer is an equipment package.

The following items and options are already included in the price:

- Material support

- Height-adjustable infeed roller conveyor

- EVOLUTION diamond formatting cutter set

- CAMPUS V8 EVOLUTION CAD/CAM software

- Flat screen 21.5", 16:9

- Workpiece length measurement LASER

- Milling unit 7830

- 7887 tool changer 6-position magazine pick-up

- ECO vacuum system

- Air conditioning unit for switch cabinet cooling

- Tool changer 7874

Fsdpfeu Tid Hex Afnefu

- Angular gear 7869

- Adapter for Clamex milling cutters

- Tool set - 4-axis CLAMEX

- Tool holder HSK-F 63

- Drilling unit XL 7885, 19 spindles

- Manual control unit

- Tool set - EVOLUTION for XL drilling head 7885

- new exhibition machine -

Listing

Bad Honnef

Bad Honnef

7,723 km

MASTERWOOD machining center project TF 100 2.0

MasterwoodProjekt TF 100 2.0

Call

Condition: new, - Edition Partnership -

With our TF 100 2.0 "Partnership Edition" we offer

CNC technology for the highest demands.

And at a sensational price.

Drilling, grooving, milling

Unique in operation and in the

"Partnership Edition" even more so in terms of features:

The TF 100 2.0, specially developed for furniture and interior

TF 100 2.0, specially developed for furniture and interior

than 5 m² production area, it can perform drilling

5 levels of the workpiece, groove sawing work

and also milling work.

The machine impresses with its extremely high

processing speed with maximum precision

and ease of operation. The

standard pre-equipment for angular gears, the optional

the optional CLAMEX and lock case milling cutters can be

can be retrofitted easily and at any time.

The TF 100 2.0 "Partnership Edition" is completely manufactured in

in our large factory in Rimini, the headquarters of

Masterwood, and is 100% "Made in Italy".

----- Technical data -----

Max. workpiece length X: unlimited,

max. workpiece length Y: 1,000 mm,

max. tool thickness Z: 60 mm,

Vertical spindles X - direction: 5 pieces,

Vertical spindles Y - direction: 5 pieces,

Ffjdpfxeu Tiwvj Afnou

Horizontal double drilling spindles X - direction: 2 + 2 pieces,

Horizontal double drilling spindles Y - direction: 1 + 1 piece,

Units: 16 drill head,

Drilling spindle speed: 4,000 rpm,

Distance between drilling spindles: 32 mm,

Motor power: 1.7 kW,

Grooving saw: X - direction,

Saw blade Ø: 125 mm,

Extraction connection Ø: 150 mm,

Dimensions (LxWxH): 1,920 x 2,818 x 1,620 mm,

Weight: 1,500 kg

Listing

Almelo

Almelo

7,575 km

Machining center

CNC-ROUTER DMA-BudgeCraftNesting Professional

Call

Condition: ready for operation (used), Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 50 m/min, rapid traverse Y-axis: 50 m/min, rapid traverse Z-axis: 15 m/min, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, - BudgeCraft CNC ROUTER

- Best Price-Quality CNC

- CNC Router: Wood, Plastic & Aluminum Processing

- High Precision (0.01mm) Milling

- No Annual License Fees

Descriptions:

The most complete CNC machine for wood, plastic, and aluminum. Fully servo-driven for the most complex operations. Starting at €34,500.

- Take advantage of a fixed price for CadCam software and starter kit.

- Assembled in the Netherlands according to the strictest CE standards.

- Powerful 9KW ATC spindle and speeds up to 50m/min.

- Equipped with automatic tool change magazine for up to 16 tools.

- From standard milling jobs to complex projects.

- BudgeCraft offers the highest precision and lowest purchase price for professionals.

Featured Highlights:

* No hidden license fees

* CadCam Professional - translates; Image BMP, JPG, TIF, GIF, PNG vector files

* Formats: Adobe Illustrator, DXF (AutoCAD), EPS, PLT, TXT

* 9kW ATC spindle, air-cooled

* Ready to use

CNC ROUTER:

Precision CNC ROUTER Specifications: Review the technical details of our 0.01mm precision machines.

Work Area & Options: From 1300x2600 - 1600x3200 - 2100x3200mm.

CE Safety: Why our machines are the safest choice for your workshop. Compliant with the New Machine Guidelines 2026.

Full technical specifications available on the Danmar Machines Bv website:

X-Axis work area : 2600, 3200mm

Y-Axis work area : 1300-1600-2100mm

Z-Axis stroke : 200mm

Gantry construction : Yes, servomotors

Spindle motor : 9Kw Servomotor (ATC spindle)

Speed : 1,000-24,000 RPM

X-Axis travel : 50m/min

Y-Axis travel : 50m/min

Z-Axis travel : 15m/min

Holder : ISO30-ER32-ER40

Software : Pegasus PWoodMilling

Vacuum pump : included

Fodex Sx Rfjpfx Afnsfu

Contact us for more information.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Wijchen

Wijchen

7,560 km

CNC Horizontal Machine centers SCM Record 110 AL TVN Prisma 2006

SCMRecord 110 AL TVN Prisma

Call

Condition: used, Year of construction: 2006, Empty weight: 4.000 kg

Price: On request

What are Presale Items at Second Owner?

Presale items are machines that we sell in their current condition ("as-is"). We have purchased these machines based solely on photos and sell them with the information provided in the advertisement. Unfortunately, we do not have additional details, such as exact dimensions or machine specifications. Additionally, these machines are often not yet in stock and have not been inspected by us.

These machines are offered at competitive prices, which means the prices are lower than usual, but the risk lies entirely with the buyer. Please carefully review the information in the advertisement before making a purchase.

If you have any questions, feel free to contact us!

- Machine available from: 2026-05-25

- Year: 2006

- Documentation available: No

- CE marking present: Yes

- CE certificate present: No

- Number of milling spindles [pcs.]: 1

- └ Milling spindle 1:

- - Number of controlled axes [pcs.]: 5

- - Min. spindle speed [rpm]: 600

- - Max. spindle speed [rpm]: 20000

- - Main motor power [kW]: 11

- - C-axis present: Yes

- Type milling table: Beam table

- Tool clamping system: HSK-F63

- Drilling unit present: Yes

- └ Horizontal drill spindles [pcs.]: 6

- └ Vertical drilling spindles [pcs.]: 12

- Saw unit present: Yes

- Tool changer positions [pcs.]: 16

- System/software: Xilog plus

- Safety feature: Safety mat

- Vacuum pump present: Yes

- └ Main motor power [kW]: 5.5

- └ Capacity [m³/h]: 250

- CNC options: Offcut conveyor, Manual control

- Table length [mm]: 3050

- Table width [mm]: 1240

- Z-axis working range [mm]: 200

- X-axis maximum stroke [mm]: 3500

- Y-axis maximum stroke [mm]: 1815

- Z-axis maximum stroke [mm]: 440

- Transport weight [kg]: 4000kg

- Transport packages [pcs.]: 1

Financial information

VAT: The price shown is exclusive of VAT

VAT/margin: VAT deductible for entrepreneurs

Fjdpfx Afox Hfikjnjfu

Delivery and trade-in always possible for everything in the industrial sectors

Glenn Smeets

Listing

Erdmannhausen

Erdmannhausen

7,946 km

Machining center

Hamuel ReichenbacherVision II Sprint

Call

Condition: used, Year of construction: 2006, functionality: fully functional, machine/vehicle number: 1961, controller manufacturer: Siemens, workpiece length (max.): 3,200 mm, workpiece width (max.): 1,400 mm, workpiece height (max.): 72 mm, total length: 18,300 mm, total width: 9,710 mm, number of spindles: 2, number of slots in tool magazine: 60, Retrofitted in 2016

Ffsdpfx Afjx Ezh Tsnsu

Ready for operation

Includes stacking and unstacking gantry crane

Listing

Misterton

Misterton

7,085 km

CNC Machine

Infotec1008 Rotary

Call

Condition: good (used), Infotec 1008 Rotary CNC machine

Ffodpfxsx Ai T No Afnou

adjustable RPM, manual or auto, 3Ph

Listing

Willroth

Willroth

7,740 km

Machining center

MORBIDELLIM 600 F

Call

Condition: excellent (used), Year of construction: 2013, operating hours: 16,750 h, functionality: fully functional, Used MORBIDELLI M600 F

- Complete nesting cell

- Year of manufacture: 2013

- Good condition, fully functional

- Working area x=5000 / y=2120 mm

Fjdsx S Ha Ispfx Afnjfu

- 5-axis spindle

- Drilling head

- 2 vacuum pumps

- Automatic loading and discharge conveyor

- Available by arrangement

- (without tools)

If you have any further questions, please do not hesitate to contact us.

Listing

Силистра

Силистра

9,327 km

CNC nesting machine loading and unloading

Poyraz makinaVigor 1228

Call

Condition: like new (used), Year of construction: 2023, functionality: fully functional, feed length X-axis: 2,800 mm, feed length Y-axis: 2,100 mm, feed length Z-axis: 250 mm, feed rate X-axis: 80 m/min, feed rate Y-axis: 80 m/min, feed rate Z-axis: 30 m/min, controller manufacturer: CNI, controller model: N-Conex, workpiece length (max.): 2,800 mm, workpiece width (max.): 2,100 mm, workpiece height (max.): 60 mm, total height: 2,400 mm, total length: 11,500 mm, total width: 3,700 mm, spindle speed (max.): 24,000 rpm, spindle motor power: 9,000 W, number of spindles: 10, number of slots in tool magazine: 12, Poyraz Makina VIGOR 2128 Flat Table CNC Machining Center (Year of manufacture: 2023)

Very well-maintained CNC nesting machine from first ownership, fully functional and ready for immediate use.

Technical specifications:

Working area: 2100 × 2800 × 250 mm

HSD spindle 9 kW / 24,000 rpm (Italy)

CNI N-Conex control (Linux based on Windows 7)

Becker vacuum pump 250 m³/h, 8 zones

12-position rotary tool changer

Equipment:

– Automatic tool measurement

– Automatic lubrication (Dropsa)

– Automatic labelling (barcode system)

– Loading & lift system

Fodpfxoxwa Erj Afnsfu

– Discharge system with conveyor belt

– Pressure rollers for multi-panel processing

Machine is ideal for furniture production, doors, cabinet parts, kitchens, and interior fittings.

Location: Bulgaria. Inspection possible at any time.

Listing

Almelo

Almelo

7,575 km

Machining center

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Call

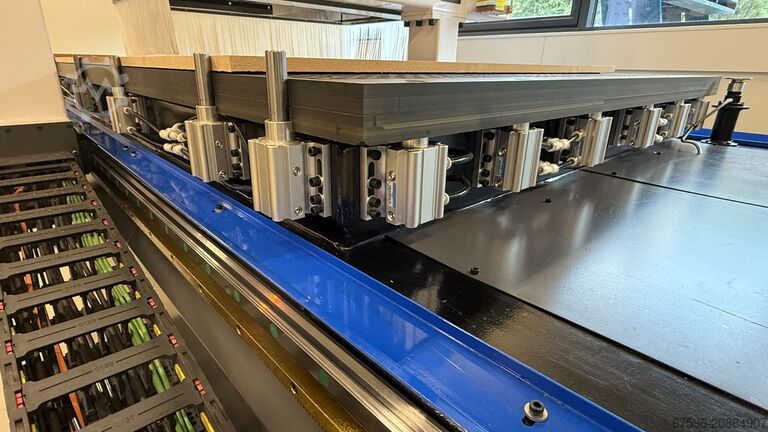

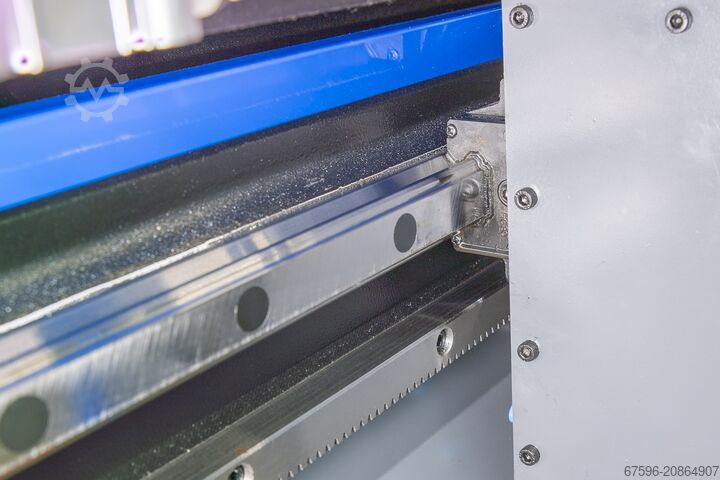

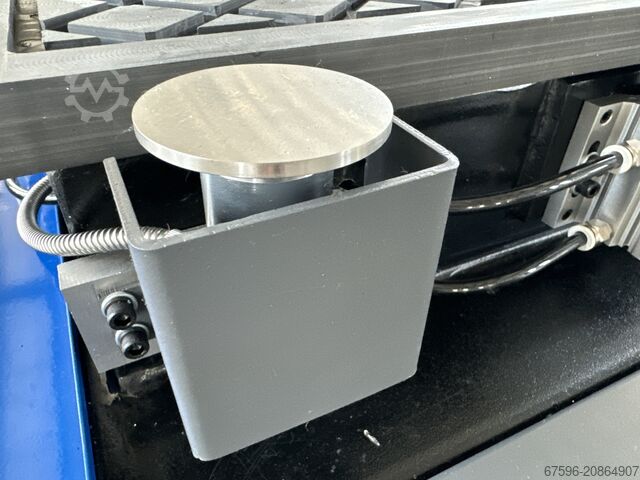

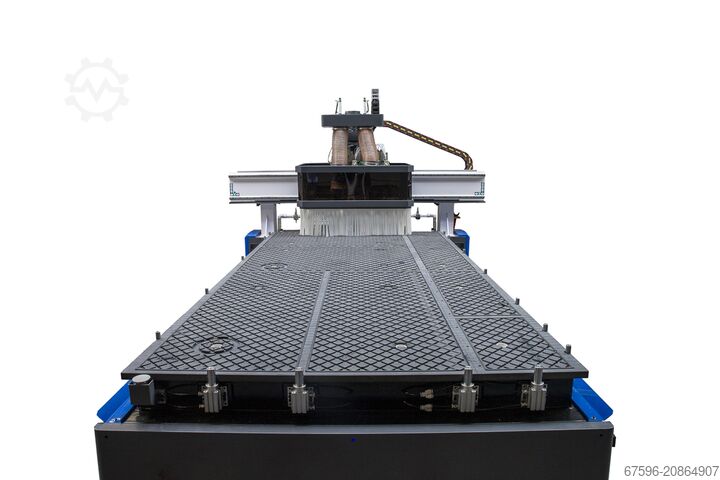

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 40 m/min, rapid traverse Y-axis: 40 m/min, rapid traverse Z-axis: 15 m/min, workpiece height (max.): 350 mm, total length: 3,500 mm, total width: 2,100 mm, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,460 kg, input voltage: 400 V, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, CNC Nesting Machine

The EXPRESS-ROUTER CNC milling machine is the new customized machining center for those who demand precision and reliability. Designed and assembled in the Netherlands according to the strictest European standards. This machine is built for small and medium-sized businesses.

With a robust welded steel chassis, servo drive, automatic tool changer, and smart software integration, this is the ideal solution for everything from cabinet making to complex 3D relief machining.

Why DMA MACHINERY

Ffedpfx Afex R D Rnsneu

- Price & Quality

- Minimal floor space required

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Gantry Router

- Suitable for processing: wood, plastic, aluminum, acrylic, foam, plastic, …etc

- Unlimited possibilities

- No licenses required

- CadCam software Pegasuds (see videos)

- 1 year online helpdesk support

CNC Machines: Fairly priced, for the skilled professional who can do it themselves.

Pay for steel, not for service. Our CNCs for the smart, self-reliant entrepreneur.

Focus on functionality: Your machine, your control, our lowest price.

Choose to do it yourself and save tens of thousands of euros on your new CNC machine.

The power of CNC without overhead costs. For professionals with technical knowledge.

Listing

Italia

Italia

8,629 km

Work center

SCMAccord 42 fx

Call

Condition: ready for operation (used), Year of construction: 2020, functionality: fully functional, Work centre for window and door frame production

Working area X: 5020 mm

Working area Y: 1680 mm

Working area Z: 350 mm

5-axis machining unit complete with BRC group, main spindle power 12 kW, 24,000 rpm, equipped with circular saw blade Ø 350 mm

Ffsdpfx Afjyahnbsnsu

4-axis machining unit for simultaneous counter-profiling, enabling parallel processing and increased productivity, power 21 kW, 24,000 rpm

Vertical and horizontal spindle unit: up to 26 spindles

Spindle rotation speed: up to 8,000 rpm

Tool magazine:

12 tool positions on the head group

48 tool positions at the rear of the machine

16 positions at the front

MATIC table with independent motorised clamps and direct drive

Quick-change system for clamping element replacement

Control system: Maestro

2 vacuum pumps

Very good condition

Listing

Almelo

Almelo

7,575 km

Machining center

DMA Machinery CNC-ROUTERSExpress-1326 ATC ( COMPACT )

Call

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 60 m/min, rapid traverse Y-axis: 60 m/min, rapid traverse Z-axis: 20 m/min, controller manufacturer: syntec, workpiece length (max.): 6,000 mm, workpiece width (max.): 2,100 mm, workpiece height (max.): 350 mm, total height: 2,200 mm, total length: 4,200 mm, total width: 2,100 mm, table load: 1,500 kg, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,800 kg, spindle mount: MK 3, number of slots in tool magazine: 10, input voltage: 400 V, type of input current: three-phase, Equipment: documentation/manual, rotational speed infinitely variable, Cost savings for the end customer: €80,000 instead of €40,000

DMA delivers high-quality CNC machines at unbeatable prices by eliminating expensive service contracts and installation visits. Ideal for professionals who want to maintain full control.

Included in the purchase price:

- CNC controller "SYNTEC"

- CNC nesting/milling CAD/CAM

- PEGASUS Professional CAD/CAM including online training/helpdesk

- Starter kit with cutting and drilling tools for CNC sheet metal processing

• Spare parts supply: In the event of a defect within 12 months, after diagnosis (photo/video), spare parts will be supplied free of charge. • Labor costs not included: You can replace the part yourself or commission an external service provider.

• Low-maintenance designs.

• Digital commissioning: Via app or TeamViewer, direct online service. This means technician visits can be avoided, saving both time and costs.

• 24/7 online support.

Digital support as an alternative

• Video tutorials: Clips for calibration or parts replacement.

• Exploded diagrams: Components immediately identifiable.

Functionality in focus: Your machine, your management, our best price.

Usable working area: 3,200 x 1,600 mm (standard sizes available).

Z-axis: 200 mm.

Automatic tool changer with 9 kW router spindle.

Ffodpfjx Rz Auex Afnsu

Up to 26 spindle positions.

Row drilling unit optional. Grooving unit optional.

CadCam nesting software.

Pressure rollers (for uneven materials) optional.

Becker VTLF2.250 vacuum pump.

All axes servo-driven.

Heavy-duty CNC milling machine

Type "NESTING"

Working area: 1,300 x 2,600 mm (standard sizes available)

Z-axis: 200 mm

ATC 9 kW router spindle

Drilling unit optional

Grooving unit optional

CadCam nesting software

Pressure rollers (for uneven materials) optional

Becker VTLF2.250 vacuum pump

All axes servo-driven

Listing

Almelo

Almelo

7,575 km

Machining center

CNC nesting Machine CE-DUTCH normeringCNC Best solution 3022

Call

Condition: new, Year of construction: 2026, functionality: fully functional, Cost savings for the end user €80,000 vs. €40,000

DMA supplies high-quality CNC machines at bottom prices by eliminating expensive service contracts and on-site installation visits. Ideal for professionals who prefer to remain in control themselves.

The purchase price includes:

- CNC control “SYNTEC”

- CNC Nesting/Milling CadCam

- PEGASUS Professional CadCam including online training/helpdesk

- Starter kit of cutting and drilling tools for sheet metal machining CNC machining centers.

• Parts supply: In the event of a defect within 12 months, components will be shipped free of charge after diagnosis (photo/video).

• Excluding labor costs: Replacement of the part is done by you or outsourced at your discretion.

• Designed with minimal maintenance requirements

• Digital preparation: via app or TeamViewer for direct online service. This makes technician visits unnecessary, resulting in significant cost and time savings.

• Online service: 24/7

Ffodpfsxx Uc Uex Afnsu

Digital Support as an Alternative

• Video manuals: Clips covering calibration or part replacement

• Exploded view diagrams: Instantly identify the necessary component

Focus on functionality: Your machine, your management, our lowest price.

You can call or WhatsApp us for more information and/or to make an appointment.

WhatsApp:

Listing

Izdebnik

Izdebnik

8,473 km

Cnc machining center

MorbidelliM100

Call

Condition: excellent (used), Year of construction: 2018, functionality: fully functional, Work in X, Y, Z axes

Working area 3100 x 1340, Z axis = 180 mm

Horizontal drills on X axis – 6 pcs

Horizontal drills on Y axis – 4 pcs

Vertical drills on X axis – 8 pcs

Vertical drills on Y axis – 6 pcs

Two tool magazines: side – 11 positions and transfer – 14 positions

Grooving saw on X axis

Ffedpfx Afjx Upffonou

Spindle 8 kW, air-cooled, 600–24,000 RPM, HSKF63

Becker Vacuum Pump 2.2 kW

Option for dual-field operation

X axis speed – 25 m/min (programmable) – 56 m/min (vector)

Y axis speed – 50 m/min (programmable) – 56 m/min (vector)

Z axis speed – 15 m/min

Listing

San Giovanni Al Natisone

San Giovanni Al Natisone

8,394 km

2000 Saom T55

SaomT55

Call

Condition: used, Year of construction: 2000, 2000 SAOM T55 CNC pantograph used, not tested, as seen and liked.

Fsdpfx Afjx Ttxgsnofu

Listing

Eibelstadt

Eibelstadt

7,938 km

CNC milling machine

FlexiCAMEco 1515

Call

Condition: used, Year of construction: 2001, functionality: fully functional, Machine Data

• Gantry system with fixed table and moving portal for minimal footprint

• Base, bridge, and bridge columns made from steel, welded in one piece, stress-relieved and machined

• Main machine assemblies are ribbed welded constructions, optimized for the best stiffness-to-weight ratio, vibration damping, and high acceleration

• Each machine design is verified and optimized via finite element analysis (FEA) to ensure maximum quality, performance, and safety

• Easily accessible machine table for straightforward loading and unloading with forklift or overhead crane

• Ground precision linear guides with high preload and additional cover bands for optimal chip removal on all axes

• Brushless digital A/C servo motors and controllers on all axes

• Dual-sided, synchronized drive on the X-axis (gantry drive)

• Rack and pinion drive on X and Y axes

• Precision ball screws with double pillow block support on the Z-axis

• Precision planetary gearboxes with low backlash

• Fully enclosed cable drag chains protect cable harnesses from chips and dust

• High-quality shielded cable drag chain wiring ensures superior protection against faults and failures

• X-axis working area: 1,540 mm

• Y-axis working area: 1,540 mm

• Z-axis clearance: 150 mm

• Z-axis travel: 200 mm

• Network connection via Ethernet

• Remote maintenance via Internet

FlexiCAM Control

• DIN-ISO 66025 G-code compatible

• Includes TCP/IP network interface

• 256 MB RAM

• Simple operation via handheld control unit with display

Spindle with Manual Tool Change

• Power consumption: 2.2 kW

Ffodpsx E Ttbefx Afnou

• 5,000–24,000 rpm, steplessly programmable

• Cooling by integrated electric fan

Extraction System for Manual Tool Change

• Hose connection diameter: 80–90 mm

FlexiCAM Midrange Vacuum Table (Side Channel Blower)

• T-slot profiles, individual ball valves, 6 zones

• Side channel blower: 7.5 / 9 kW

• Approx. 558 m³/h (50 Hz) or 654 m³/h (60 Hz)

Safety Devices

• CE-compliant to DIN EN 13849

• Includes EMC filter, emergency stop

• Light barrier system controlled by machine controller

Listing

Eibelstadt

Eibelstadt

7,938 km

CNC milling machine

FlexiCAMPro 2030

Call

Condition: used, Year of construction: 2002, functionality: fully functional, Machine Data

• Gantry-type machine with fixed table and moving portal for minimal footprint

• Base frame, bridge, and bridge uprights made from welded, stress-relieved, and machined steel in one piece

• Main machine assemblies consist of ribbed welded constructions engineered for optimal stiffness-to-weight ratio, vibration damping, and high acceleration

• Each machine design is verified and optimized using finite element analysis (FEA) to ensure maximum quality, performance, and safety

• Easily accessible machine table for straightforward loading and unloading via forklift or overhead crane

• Ground precision linear guides with high pre-load and additional cover tape for optimal chip removal on all axes

• Brushless digital A/C servo motors and controllers on all axes

• Dual-side synchronised drive on the X-axis (gantry drive)

• Rack-and-pinion drive on the X and Y axes

• Precision ball screw drives with dual-end bearing units on the Z axis

• Precision planetary gearboxes with low backlash

• Enclosed cable drag chains protect the drag chain cabling against chips and dust

• High-quality shielded drag chain cables offer maximum protection against interference and failures

• X-axis travel: 3,120 mm

• Y-axis travel: 2,190 mm

• Z-axis clearance: 200 mm

• Z-axis stroke: 280 mm

• Network connectivity via Ethernet

• Remote service via Internet

Panel-Based CNC Control System

• Touchscreen display

• Multifunction keyboard with integrated touchpad

• Integrated industrial PC with Windows 7 Professional, hard drive, and Ethernet

• Comprehensive remote maintenance functionalities

• Includes hand-held unit with electronic handwheel

• MCP with rotary switch for feed and spindle override

• Mobile control cabinet

Hand-held Operating Device

• Fast, increment-precise positioning

• Handwheel with magnetic detent

• Coarse, medium, and fine positioning

• 2-channel emergency stop

• Protection class IP65

Milling Spindle

• Max. spindle power: 4 kW

• Max. speed: 30,000 rpm

• ISO-25 tool taper

• Max. tool diameter (shank): 12 mm

• Air-cooled

• Pneumatic tool taper clamping

• Dry, clean, oil-free compressed air required on customer side (< 0.1 μm, < 7 bar)

Automatic Tool Changer / Linear

• Linear tool magazine mounted outside the working area

• Basic configuration: 4 slots

• Up to 20 slots ISO-25

Extraction Unit for Automatic Tool Change

• Hose connection diameter: 110 mm

• Automatic up/down function for tool change

Tool Length Sensor

• Automatic tool length measurement via M command

• Hard metal contact plate

• Measuring accuracy: 0.001 mm

• Contact force: 1.5 N

Tool Length Sensor

• Automatic tool length measurement via M command

• Hard metal contact plate

• Sensor mounted outside the working area

2x Side Channel Blowers

• Max. power consumption: 7.5 kW

• Maximum airflow: 650 m³/h

• Rated voltage: 400 V

• Rated current: 14 A

• Pressure: 39,500 Pa

Ffedpfxex E Tmbs Afnju

Listing

Niepołomice

Niepołomice

8,485 km

Machining center

BUSELLATOJET 130

Call

Condition: ready for operation (used), Year of construction: 2006, functionality: fully functional, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,345 mm, travel distance Z-axis: 150 mm, input voltage: 400 V, Equipment: documentation/manual, The machine is serviced and 100% operational.

Axes: X-3050mm, Y-1345mm, Z-150mm

Fjdpfex Tfqhsx Afnofu

The machine is in very good condition and is continuously used in the company.

Additionally equipped with a 1550x1250mm grid table. Reads DXF files.

Listing

Liverpool

Liverpool

6,962 km

CNC Machining Centre for SIPS Panels

CosmecConquest 515

Call

Condition: good (used), Year of construction: 2019, CNC machine with fixed table and dual drive gantry, five axis interpolating electrospindle. Particularly suitable for SIPS panels, woodworking, plywood, MDF, plastics and thermo formed prodcuts.

Ffsdpfx Aevpv Nbjfnju

6120mm x 1605mm Working field in X / Y axis

6850mm X axis stroke

1970mm Y axis stroke

1080mm Z axis stroke

Max height / panel passge 700mm

C axis rotation + / - 360 degrees

12kw electrospindle with programmable speeds from 500 - 22,000 rpm

12 Position automatic toolchanger

Auxiliary 2 position toolchanger

250m3/hr vacuum pump

2 Field phenolic working table suitable for vacuum cups

Hoist points to fix jigs [ series of threaded holes on table for mechanical fixing ]

Set of 3 disappearing stops

OSAI Series 10 CNC control including [ for example ]

PC with Windows XP [ or higher ]

Interactive programming

Paramteric programming

3D interplolation

Cutter radius compensation

Extraction requirements 2200m3/hr

Weight 5235kg

Year - 2019 CE

FULL ORIGINAL SPECIFICATION SHOWN IN IMAGES

Listing

Siedlce

Siedlce

8,431 km

CNC Milling router C2131 PREMIUM

CORMAKFrezarka CNC CORMAK C2131 PREMIUM

Call

Condition: new, Year of construction: 2026, PREMIUM VERSION MODELS ARE CHARACTERIZED BY HIGH RIGIDITY AND MAXIMUM RESOLUTION PRECISION, WORKING IN FULL INTERPOLATION IN EACH X, Y, Z AXIS.

High-class CNC milling machine designed for the subtractive processing of materials, due to the whole range of configurations, it is used in many industries: industrial, electronics, welding, carpentry, advertising, etc. These are efficient and precise machines equipped with user-friendly CNC control systems.

The price quoted is for the machine itself, excluding additional equipment, installation, transport and training.

Design

Welded steel rigid construction,

The gate arms are made of hardened, thick, powder-coated sheet metal, which has increased stiffness, which translates into the quality of the processed detail.

Work table

The work table is made using hybrid technology,

It has T-slots enabling manual clamping of material with dimensions of 2010 x 3010mm,

Dissection table with four independent vacuum sections.

Drive

SERVO motors used to drive high-power machine tools provide appropriate acceleration and speed in individual directions,

The X and Y axes are equipped with high-quality toothed bars, praised by users, which ensure high durability and precision,

The Z axis is driven by a high quality ball screw.

All axles move on rail guides.

The machine is equipped with a tool height sensor,

Linear bearings: trapezoidal rails, Hiwin carriages.

Spindle

The spindle design uses high-quality machine bearings, which are characterized by very quiet operation and guarantee increased durability.

Tool height measurement sensor - included.

The spindle speed range is from 4,500 to 18,000 rpm.

Tool clamping using ER32 collets

Software

OPTIONALLY The latest UCanCAM V12 software in Polish language version (the software provides the ability to import files from Corel, Autocad, etc. File import/export, text editor and input and many other functions)

The software enables quick and easy design of elements, which the program then converts to so-called G-code. It is also possible to import ready files from other programs.

The machine is equipped with a function of remembering the last G-code path (In the event of a failure or power outage, it starts working from the last point without losing time or material.)

DSP control

Digital Signal Processing - digital signal processing.

The machine's DSP controller has its own processor and RAM, which ensures failure-free operation and simple operation of the machine.

The controller ensures smooth operation of the device and accuracy during processing.

There is no need to reinitialize the program after a power loss.

The memory built into the controller allows the machine to operate without having to load the program each time.

We offer machine tools with real CE EU DTR - certified by the best in the EU.

Technical parameters

Spindle 5.5kW / 18000rpm inverter, air cooled

Work area 2150x3200mm

Maximum spindle height 350mm

Control DSP

Program resolution 0.001mm

Software UCanCAM V12 in Polish language version(optional)

Power supply 400V

Libra 1450 kg

Fedpsiz S Haofx Afnofu

Machine dimensions 2680x3600x2200mm

Table height 715mm

Vacuum pump 7.5 kW (optional)

Underpressure 440 mbar

Guides linear

Drivetrain toothed rack (Z axis - ball screw)

Axle drives hybrid servo drives

Listing

Siedlce

Siedlce

8,431 km

CORMAK NST2131-16D CNC milling machining

CORMAKNST2131-16D

Call

Condition: new, Year of construction: 2026, The CORMAK NST2131-16D LOADING/UNLOADING CNC milling machine machining center was created for companies that prioritize high processing power, economic efficiency and machine reliability. This automatic nesting center offers huge possibilities, especially in its most popular version, equipped with an innovative storage and pushing unit, enabling smooth loading and unloading of boards with a full working area and effective collection of finished elements on a specially adapted table.

Thanks to the use of a reinforced structure and solid components, the CORMAK CNC Router is able to cut several boards simultaneously in one cycle, ensuring continuous production even in the case of heavy loads.

The attributes of this advanced machine include those ensuring precise and very fast processing of materials:

Fedpfx Afjwn Dz Isnjfu

pneumatic pins, strips and actuators ensuring automatic plate basing

efficient milling unit

intelligent quick selection of tools from the 12-piece "revolver" type magazine

LCD control panel with industrial control software included

Siemens, Schneider and Phoenix electronics

feeder and receiver table - ADDITIONALLY PAID OPTION

In addition, the center is equipped with an advanced nesting algorithm and tool path optimization, which allows for flexible production and efficient use of materials. The vacuum chip extraction system and the central lubrication system ensure not only cleanliness and safety of work, but also long-term reliability of the machine.

Overall, the CORMAK NST2131-16D CNC milling machine machining center is an ideal solution for companies looking for efficient, reliable and versatile machines for processing materials, capable of meeting even the most demanding industrial productions.

Technical parameters

Field Working 2100x3100 mm

Z axis 300 mm

INOVANCE servo drives (1.3kw for XY, 850w for Z-axis), with planetary gear

Spindle power 9 kW

HQD air-cooled spindle (optional oil mist)

Spindle speed from 6000 to 24000 rpm

Power supply 400 V, 3PH, 50HZ

Re-positioning accuracy 0.01 mm

Linear bearings trapezoidal rails, Hiwin carriages

Vacuum, hybrid material clamping

Vacuum pump 2x7.5 kW (optional)

SYNTEC 60WE software

Dimensions 10300x3600x2430 mm

Weight 2050 kg

Equipment

HQD spindle air cooled, Premium version

Tool measurement sensor included

Tools, sleeve set, leveling feet and other accessories

Listing

Siedlce

Siedlce

8,431 km

CNC milling machine C2131 IND

CORMAKFrezarka CNC CORMAK IND 2131 (2100x3100)

Call

Condition: new, Year of construction: 2026, CNC MILLING MACHINE C2131 IND (working area 2100 x 3100 mm) dynamic and precise milling plotter based on components from global manufacturers equipped, among others, with spindle of Italian production HSD.

Fedpfjvup Unjx Afnofu

Work table

Sectional table with six independent vacuum sections, made of rigid and resistant HPL panels, controlled directly from the control cabinet,

Each section has holes into which the vacuum from the vacuum pump is fed via a system of tubes,

The main openings in the vacuum table have plugs to accommodate different material formats,

Table equipped with buffers in two axes! Pneumatic positioners to ensure that the material is always positioned in the same place,

Spindle

High-quality brushless spindle from a renowned manufacturer, 9 kW, powered by inverter, with overload protection .

Milling electro-spindle with innovative AIR cooling system.

3.Drive

Energy-efficient YASKAWA high-performance AC servo drives, controlled by a digital controller, provide excellent machining quality while maintaining high operating speeds in each direction,

Brushless AC servo motors driving the X, Y axes transfer the drive via high-performance planetary gears

The Z axis, where positioning precision is crucial, is driven by a reinforced ball screw.

The door is moved along the X and Y axes by HIWIN guide rails and bevel gears, which guarantee many years of trouble-free operation, and are made of high-quality hardened and tempered steel.

Construction

The rigid table structure , made of ribbed steel, excludes vibrations during the production process.

5 Tool magazine and tool measuring sensor

The machine is equipped with a 12-position linear tool magazine, a set of ISO30 cones and ER32 bushings.

Toolholders included: ISO30 and toolholder sleeves of size:

1/2’ - 6 pcs; 1/8’ - 2 pcs; 3-4mm - 2 pcs; 5-6mm - 4 pcs; 7-8mm - 2 pcs; 9-10mm - 2 pcs.

6 Software, INDUSTRIAL CONTROL:

The machine is controlled by a SYNTEC industrial controller as in large machining centres. Included with the controller: keypad and LCD display. Optional latest software UCanCAM V12

Vacuum pump (optional) and extraction foot.

The use of a vacuum pump significantly increases the clamping force of the workpieces on the machine table, so that the material does not move.

The extraction foot is penumatic, located at the spindle, and allows the connection of any chip extractor, keeping the machining clean, safe and at the same time maintaining the precision of the work

Technical specifications

Working area 2100x3100 mm

Z axis 300 mm

Structure Arm in cast iron / table in welded steel

Drives hybrid servo motors (AC LEADSHINE) 1500W

Hybrid table

Spindle power 9 kW

Shimpo gearbox

Spindle speed 6000 to 24000 rpm

Power supply 400 V, compressed air min. 8 bar

Repositioning accuracy 0.01 mm

Linear bearing trapezoidal rails, Hiwin carriages

Material clamping vacuum, hybrid

Vacuum pump (optional) 7.5 kW, 8 independent vacuum sections

Software (optional) UCanCAM V12

Trust Seal

Dealers certified through Machineseeker

Listing

Siedlce

Siedlce

8,431 km

CNC milling machine C2131 ATC

CORMAKFrezarka CNC CORMAK C2131 ATC

Call

Condition: new, Year of construction: 2026, CORMAK C2131 ATC PREMIUM (2100 x 3100 mm) is a dynamic and precise milling plotter based on components from world manufacturers, suitable for the heaviest tasks, which is perfect for industrial-scale production.

Constant quality control and the components used in the machine's construction guarantee high quality processing of materials such as: wood, wood-like boards, MDF, OSB, PVC, HPL, plywood, plexiglass, dibond, carbon, alucobond.

1. Work table

Sectioning table with FOUR independent vacuum sections, made of stiff and durable HPL plates,

Each section has holes to which negative pressure from a vacuum pump is supplied through a pipe system,

The main holes in the vacuum table have caps that allow you to attach various formats of materials,

2. HQD spindle

Brushless spindle from a renowned high-class manufacturer with a power of 9 kW , powered by an inverter, with overload protection.

Milling electrospindle equipped with an innovative AIR cooling system .

3.Drive

Energy-saving high-class drives Leadshine servo drives with 1500W power and high holding torque (Dual on the Y axis)

controlled by the NK-105 G3 digital controller ensure excellent quality machining while maintaining high working speeds in individual directions.

Brushless servo motors driving the X and Y axes transmit power through high-class planetary gears.

The Z axis, where positioning precision is crucial, is driven by a reinforced ball screw.

The gate is moved along the X and Y axes using HIWIN guide strips and helical toothed gears, which guarantee many years of failure-free operation and are made of high-quality, hardened and hardened steel.

Fjdpfovupcrex Afnjfu

4. Construction

The structure of the sliding gate is made of cast iron, which achieves incredible stiffness and absorbs vibrations generated during processing very well.

5. Magazine for 8 tools + tool measurement sensor

The machine is equipped with an 8-position linear tool magazine, a set of ISO30 cones and ER32 bushings

The set includes holders: ISO30 and sleeves for mounting tools with dimensions:

1/2" - 6 pcs.; 1/8" - 2 pcs.; 3-4mm - 2 pcs; 5-6mm - 4 pcs; 7-8mm - 2 pcs; 9-10mm - 2 pcs.

Each CNC milling machine is equipped with a precise Z-axis tool height sensor, which eliminates time for measurement corrections after each tool change.

6. Vacuum pump and extraction foot

The use of a vacuum pump significantly increases the clamping force of the processed details on the machine table, thanks to which the material does not move.

4 independent vacuum sections.

Technical parameters

Workspace 2100x3100mm

Z axis 300mm

Construction Arm - cast iron / table - welded steel

Drives Leadshine servo drives with a power of 1500W

Table tee/hybrid

Spindle power 9 kW

Spindle Air-cooled HQD (oil mist optional)

Spindle revolutions from 6000 to 24000 rpm

Power supply 400 V, compressed air min. 8 bar

Re-positioning accuracy 0.01mm

Linear bearings trapezoidal rails, Hiwin bogies

Fixing the material vacuum, hybrid

Pump vacuum 2x7.5 kW (optional)

Software UCanCAM V12 in Polish language version

Dimensions 4070 x 2870 x 1900 mm

Weight 2050 kg

Listing

Siedlce

Siedlce

8,431 km

CORMAK NST2131129A CNC milling machining

CORMAKNST2131129A

Call

Condition: new, Year of construction: 2026, The CNC milling machine CORMAK NST2131129A LOADING/UNLOADING was created for companies that prioritize high processing power, economic efficiency and machine reliability. This automatic nesting center offers huge possibilities, especially in its most popular version, equipped with an innovative storage and pushing unit, enabling smooth loading and unloading of boards with a full working area and effective collection of finished elements on a specially adapted table. The CNC router CORMAK is able to cut several boards simultaneously in one cycle, ensuring continuous production even in the case of heavy loads.

The attributes of this advanced machine include those ensuring precise and very fast processing of materials:

Automatic loading and unloading system through specially designed suction cups and its transfer with automatic homing to the horizontal drilling zone

Intelligent quick selection of tools from the "revolver" magazine of 12 pieces

Efficient 2 drilling units and HQD and HSD spindles (industrial spindles on ceramic bearings

Pneumatic homing pins, LCD control panel with control software included

Large protective cover

With extendable pins for locating the processed material - 6 pieces

Electronics from Siemens, Schneider and Phoenix

Feeder and unloader table

Additionally, the center is equipped with an advanced nesting algorithm and tool path optimization, which enables flexible production and efficient use of materials. The vacuum chip extraction system and the central lubrication system ensure not only cleanliness and safety of work, but also long-term reliability machines.

Ffedpjunw N Aefx Afnsu

In general, the CORMAK NST2131129A CNC milling machine machining center is the ideal solution for companies looking for efficient, reliable and versatile machines for processing materials.

Technical parameters

Working area 2100x3100 mm

Z axis 300 mm

Construction:

Arm - cast iron / table - welded steel

12-piece umbrella-type tool magazine, ISO30 standard

Tool length measurement sensor

XYZ axis automatic lubrication system

INOVANCE servo drives (1.3kw for XY, 850w for Z-axis), with planetary gear

Table - T-shaped / hybrid / feeding and receiving

Two-layer, multi-hole, vacuum bakelite work table with rubbers and mounting screws, with positioning system

9 kW spindle power

HQD air-cooled spindle (optional oil mist)

Spindle speed from 6000 to 24000 rpm

Power supply 400 V, 3PH, 50HZ

Repositioning accuracy 0.01 mm

Linear bearings trapezoidal rails, Hiwin trolleys

Vacuum, hybrid material fixing

Vacuum pump 2x7.5 kW (optional)

SYNTEC 60WE software

Dimensions 10300x3600x2430 mm

Weight 2050 kg

Optional equipment - paid:

Vacuum pump: e.g. Becker KVT 5.5kW or 7.5kW

Top-class safety barriers

The latest UCanCAM V12 software

Possibility to add oil mist

Listing

Siedlce

Siedlce

8,431 km

CNC milling machine C2141 ATC

CORMAKFrezarka CNC CORMAK C2141 ATC

Call

Condition: new, Year of construction: 2026, CORMAK C2141 ATC PREMIUM (2100 x 4200 mm) is a dynamic and precise milling plotter based on components from global manufacturers, suitable for the toughest tasks, which works great in industrial production.

Constant quality control and components used in the machine construction guarantee high quality processing of materials such as: wood, wood-like boards, MDF, OSB, PVC, HPL, plywood, plexiglass, dibond, carbon, alucobond.

1. Work table

Sectioning table with four independent vacuum sections, made of rigid and durable HPL boards,

Each section has holes to which negative pressure from the vacuum pump is supplied through a system of pipes,

The main holes in the vacuum table have plugs that allow you to attach different formats of materials,

2. HQD spindle

Brushless spindle from a renowned high-class manufacturer with a power of 9 kW , powered by an inverter, with overload protection.

Ffedpfx Afjvupu Uonsu

Milling electrospindle equipped with an innovative AIR cooling system .

Adapted to automatic tool changing, which shortens machining time due to the lack of downtime associated with manual cutter change.

3.Drive

Energy-saving high-end drives Leadshine servo drives with 1500W power and high holding torque (Double on the Y axis)

controlled by the NK-105 G3 digital controller , they ensure excellent quality machining while maintaining high working speeds in individual directions.

Brushless servo motors driving the X and Y axes transmit power via high-quality planetary gears.

The Z axis, where positioning precision is crucial, is driven by a reinforced ball screw.

The movement of the gate along the X and Y axes is carried out by means of HIWIN guide rails and helical gear wheels, which guarantee many years of trouble-free operation and are made of high-quality hardened and tempered steel.

4. Construction

The construction of the sliding gate is made of cast iron, which achieves incredible rigidity and absorbs vibrations generated during processing very well.

5. 8-tool magazine + tool measurement sensor

The machine is equipped with an 8-position linear tool magazine, a set of ISO30 cones and ER32 collets

The set includes holders: ISO30 and sleeves for mounting tools in the following dimensions:

1/2" - 6 pcs.; 1/8" - 2 pcs.; 3-4mm - 2 pcs.; 5-6mm - 4 pcs.; 7-8mm - 2 pcs.; 9-10mm - 2 pcs.

6. Vacuum pump and suction foot (optional)

4 independent vacuum sections.

The pneumatically operated extraction foot is located at the spindle and allows for the connection of any chip extraction system, maintaining the cleanliness of the processing, safety and at the same time maintaining the precision of the work.

7. Software, INDUSTRIAL CONTROL :

Control NK-105 G3

The machine supports the latest version of CAD/CAM software.

OPTIONALLY The latest UCanCAM V12 software

Technical parameters

Working Field 2100x4200mm

Z-axis 300mm

Design Arm - cast iron / table - welded steel

Drives 1500W Leadshine servo drives

Table T-shaped / hybrid

Spindle power 9kW

Spindle Air cooled HQD (oil mist optional)

Spindle revolutions from 6000 to 24000 rpm

Power supply 400 V, compressed air min. 8 bar

Re-positioning accuracy 0.01mm

Linear bearings trapezoidal rails, Hiwin trolleys

Material fixing vacuum, hybrid

Vacuum pump vacuum 2x7.5 kW (option)

Software UCanCAM V12 (option)

Dimensions 5070x2870x1900mm

Weight 3350 kg

Listing

Siedlce

Siedlce

8,431 km

CNC Milling router for stone&wood M1325

CORMAKM1325 PREMIUM 1300x2500

Call

Condition: new, Year of construction: 2026, Multifunctional, efficient milling machine, designed for working with stone, manufacturing tombstones but also for wood materials, MDF, plywood, plexiglas. Made of steel and cast iron.

Features

Rigid device with a precise resolution and full interpolation in each of the X, Y, Z axes

Tool height sensor

Central lubrication

Double vented control panel

Strengthened design

Water table for material cooling

Strengthened guiding rolls - improve inserting and removing workpieces

Capabilities

tombstone manufacturing

(all kinds of stones, ceramics, glass, granite, marble, etc.)

stone reliefs, engraving, milling, etc.

wooden materials, MDF, plexiglas, plywood, etc.

Fsdei Ab Akopfx Afnofu

Technical data

Working area 1300x2500 (1500x3000mm)

Z-axis 400 mm (raised gantry)

Spindle 5.5 kW flood coolant

Inverter 7.5 kW

Controller DSP - digital data processing + RichAuto-AutoNow-A11E control

Linear guides Hiwin

Software Artcam

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. Check our offer on our website.

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used machining centers with flat or grid table (345)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- Bed Type Milling

- Bed Type Milling Machine

- Center Lathe

- Cnc Turning And Milling Center

- Flat Bed Cnc Lathe

- Flat Bed Grinding Machine

- Gear Griding Machine

- Machine Table

- Machining Center

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month