Used Beverage production for sale (1,142)

Wallern an der Trattnach

Wallern an der Trattnach Shrink capsule applicator

Nortan

Menslage

Menslage MAS DSA-6E Carbonating Unit (2003)

MASKarbonisierung

Fumane (Verona)

Fumane (Verona) Compressor

Ingersoll-RandC100MX3-2SH

+44 20 806 810 84

Geisenheim

Geisenheim Etikettiermaschine 2 Stationen

Conpart

Wallern an der Trattnach

Wallern an der Trattnach Crowncorker semiautomatic for 26mm crow

Discover more used machines

Menslage

Menslage Cortellazzi (SACMI) Integrale Vega 50.50.10 Isobarometric Filler (1998)

Cortellazzi (SACMI)Druckfüller

Fumane (Verona)

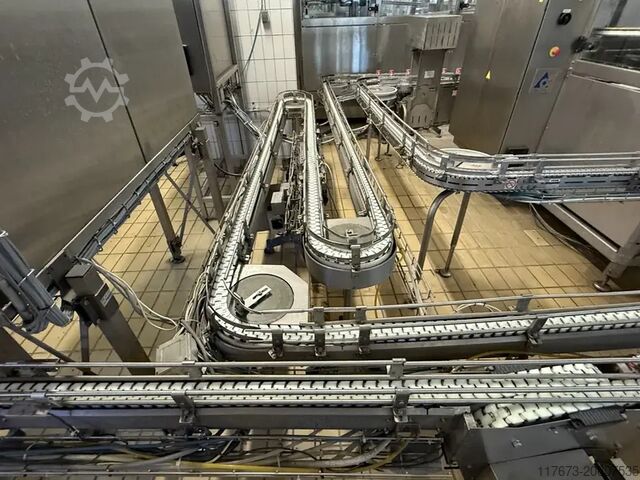

Fumane (Verona) Complete Bottling Line

Wallern an der Trattnach

Wallern an der Trattnach Gabletop filling machine

Schuy + Folmeg Maschinenbau GmbHSchuypack

Menslage

Menslage Logopak 920 PF Self Adhesive Labeler (2007)

LogopakEtikettierer für Selbstklebeetiketten

Fumane (Verona)

Fumane (Verona) Complete Bottling Line

Wallern an der Trattnach

Wallern an der Trattnach BaginBoxFilling funnel

KreuzmayrMaschinenbauBiB Fuelltrichter

Menslage

Menslage Simatec Brewone 12 HL Brewhouse (2022)

SimatecSudhaus

Wallern an der Trattnach

Wallern an der Trattnach Centrifuge Imma 5,5 kW

ImmaMikro Automatik

Menslage

Menslage VDW S 2000 Grinder (2017)

VDWWolf

Wallern an der Trattnach

Wallern an der Trattnach Centrifuge Westfalia 7,5 kW

WestfaliaSA 14

Menslage

Menslage Sealpac RE 20 thermoforming machine (2014)

Sealpac

Oberösterreich, Österreich

Oberösterreich, Österreich KREUZMAYR PA 500 gas

KREUZMAYRPA 500 Gas

Menslage

Menslage Rizzolio RLV2 iso Isobarometric Filler (2018)

RizzolioDruckfüller

Oberösterreich, Österreich

Oberösterreich, Österreich Bag in Box filler

KreuzmayrKBF 2000

Menslage

Menslage ATI Softpress 45 Pneumatic press (2011)

ATIPneumatische Presse

Oberösterreich, Österreich

Oberösterreich, Österreich Series filler

Kreuzmayr MaschinenbauKRF 2

Menslage

Menslage Heuft Tornado W Cold Glue Labeler (2011)

HeuftKaltleim / Nassleimetikettierer

Oberösterreich, Österreich

Oberösterreich, Österreich Pasteurisationplant with Baginbox filler

Kreuzmayr MaschinenbauPAS600+KBF

Menslage

Menslage Framax Modulblock 10/1-C + LLAC-R-SQ (VAR STEP) Atmospheric filler (2014)

Framax ModulblockAtmosphärischer Füller

Oberösterreich, Österreich

Oberösterreich, Österreich Bottlefiller

Kreuzmayr MaschinenbauKRF 4

Used Beverage production (1,142)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84