Used Bundle for sale (399)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Spain

Spain

7,597 km

Complete Production Line (Wood)

MAYPROLC2

Call

Year of construction: 2018, condition: ready for operation (used), This MAYPRO LC2 was manufactured in 2018. It features an industrial PC with proprietary software, PLC integration, and can produce up to 2,000 pallets per 8-hour shift. Minimum and maximum pallet dimensions are 600 mm x 600 mm and 1,500 mm x 1,500 mm, respectively. It includes an automated wood feed system, multi-head nailing, and an integrated stacking system. Total installed power is 20-40 kW. Contact us for more information about this machine.

Cpjdpfx Aox Hlh Tofnju

Application Types

Complete Production

Listing

Oudehorne

Oudehorne

7,511 km

Baler waste press textile press recycle

HSMV-Press 1160

Call

Condition: ready for operation (used), Year of construction: 2009, Brand: HSM

Model: V-Press 1160 plus

Year of manufacture: 2009

Pressing force: 532 kN

Voltage: 400 V

Maximum bale weight: up to 550 kg (depending on the material)

Bale dimensions: 120 x 110 x 120 cm

Machine weight: 2,403 kg

Dimensions of the machine: 180 x 157 x 298.5 cm

Filling opening dimensions: 119.5 cm × 65 cm

Condition: Excellent! Functionally tested.

Cpodox Rybpjpfx Afnsu

FLITS Rental & Sales service: With every machine, we provide one bundle of binding wire (120 wires). Need more binding wire bundles? Request a free quote without obligation.

At FLITS Rental & Sales, you choose speed, clarity, and reliability. We think along with you, respond immediately, and ensure you receive the right machine quickly.

You are very welcome to view the machines at our location. We are located at: Schoterlandseweg 94, 8413NE Oudehorne. Visits are possible by appointment, so we can take all the time needed to inform you properly and show you the right machines.

We are happy to assist you!

Waste press • Paper baler • Cardboard baler • Plastic baler • Waste compactor • Recycling • Textile baler • Waste • Waste processing

Listing

Germany

Germany

7,870 km

Complete manufacturing line for bed slatted frames

Weinig Raimann Linde Koch Panhans GreconHydromat KR KS OPTICUT E14 E16 CNC

Call

Condition: used, Year of construction: 2000, Complete production line for the manufacture of slatted frames.

From woodworking through to final assembly and packaging.

Includes all components such as moulders, saws, profile processing, forklifts, compressors, etc.

The larger machines/plants are from around year of construction 2000.

Consisting of:

Production of solid wood rails:

- 2 x Multiblade rip saws RAIMANN KR 450 + KS 310

- Optimising cross-cut saw GRECON ILLERTISSEN OPTICUT 704R

- Four-sided planer WEINIG HYDROMAT 23

- Stacking unit

Foiling / Finishing of longitudinal rails:

- 2 x Profile wrapping machines FRIZ OPTIMA PU25-PAP

- Foil cutting machine FRIZ FSM 1500

CNC drilling and sawing units:

- KOCH CNC drilling and sawing line with turning and stacking unit

- ISE CNC drilling and sawing unit with stacking unit

- 2 x ISE CNC woodworking centres / drilling units

- ISE CNC machining centre for spring slats

- 2 x Manual slat drilling machines

Single machines:

- GANNOmat CNC drilling and dowelling machine

- Pnahans table routing machine

- 2 x EiMa double mitre saws

- SCM panel saw

- Barth frame press

- 2 x FLOTT column drilling machines

- SAMCO combination sawing and milling machine

- 2 x Multi-spindle drilling machines

- 2 x Belt sanders

- Spray booth

- Various small machines

Assembly:

- Automatic assembly machine for standard slatted frames

- Capping press / line

- 14 x Pneumatic assembly tables

Logistics – operating equipment:

- 3 x LINDE forklift trucks E16 / E20

- 7 x LINDE high-lift/ electric pallet stackers

- WEYCOR wheel loader 95E SUPER

- Atlas-Copco compressor system

- WEIMA single-shaft shredder

- Kärcher ride-on sweeper

- HONDA snow blower

- Extraction system outdoor area

- Batch of mesh boxes & Euro pallets

- Various racking systems

Packaging:

- Shrink tunnel system

- Stationary pallet wrapper

- Mobile pallet wrapper

Codpox S Sb Defx Afnjpu

Materials:

- Remaining stock of timber / spring slats

- Remaining stock of end caps / plastic parts

- Miscellaneous remaining assembly materials

Many more PHOTOS and detailed DATA available on request.

Listing

Wetter (Ruhr)

Wetter (Ruhr)

7,681 km

Cut-to-length and slitting line

Bindelinie Coilverpackung Titan BöhlBinde- und Stapelanlage

Call

Condition: ready for operation (used), Year of construction: 2004, For sale is a packaging line, currently still in production and available for inspection under power. The system consists of the following main components:

Cpsdpjx Sqlusfx Afneu

- Bundle loader and tipper by Eich

- Integration unit by TITAN

- Oiling station by Eich - Steidle

- Wrapping station by Böhl

- Centering table with gripper by Eich

- Stacking area feed by Eich

- Shipping preparation by STU

- Electrical control system by wpe GmbH

- Safety device by Hengstebeck & Eich

Technical data:

- Max. bundle diameter: 1,500 mm

- Max. bundle weight: 6,000 kg

- Max. single ring width: 600 mm

- Band thickness: 0.1 – 4.0 mm

- Stack package weight: 6,000 kg

- Stack package height: 1,400 mm including pallet

The strapping system is sold including complete documentation and software. Dismantling and transport can be organized by us.

Listing

Henstedt-Ulzburg

Henstedt-Ulzburg

7,678 km

Folding machine

Heidelberg StahlfolderKH 78/6-KL

Call

Condition: good (used), Year of construction: 2007, • PFH-82 pallet feeder with TREMAT suction head and extra stacking table

• Swivel-mounted touch monitor, MCT control system

• 1st folding station 1.BUH-82 with 6 folding pockets

• Soft-PU folding rollers

• Downstream knife shafts with various tools

• Cross-folding unit BCUH-78, KL version with 2 folding knives

• Additional swiveling control panel at the cross-folding unit

• Noise protection hood

• Compressor

Connected with:

B) Automatic Bundle Delivery

Make: Palamides

Type: delta-703

Format: 76 x 30 cm

Year of manufacture: 2009

Machine no.: 2307

• Working width 700 mm with triple banding

• Quick set-up mode without tools

• Automatic format detection and waste gate for consistent production without misaligned sheets in the stack

• Small format equipment for minimum 90x65 mm

• Pressing station with pre- and main press rollers with up to 3.5 t pressing force

• Package pressing

• Jogger station

• Banding of stacks in the magazine chute

• Banding with paper and plastic

• Robust and reliable electronic impulse welding system (EIS)

Cpedpex R Ui Iofx Afnju

• Package lift output (single-operator handling for folding machine and Palamides)

• Delivery system is mobile for quick changeovers between different machines

• Various operating modes: shingle or single sheet feeding

• Quick adjustment, counter, stick bundling

Technical Data:

• Package height min.: 20 mm

• Package height max.: 150 mm

• Performance: 600 packages/h per cycle

• Speed: 15 – 200 m/min (up to 60,000 items/h)

• Infeed height: 410 – 1000 mm

• Electrical connection: 6 kW

• Compressed air: 6 bar dry air, to be supplied by the customer

Please contact us for further details.

Listing

Henstedt-Ulzburg

Henstedt-Ulzburg

7,678 km

Folding machine

Heidelberg StahlfolderKH 78/82-4-KTL-Aut

Call

Condition: good (used), Year of construction: 2009, Combination Folding Machine

• Automated combination folding machine

• MCT control with preset system

• PFH-82 pallet feeder with TREMAT suction head

• First folding station 1.BUH-82/4 with 4 motorized, individually adjustable combination folding plates

• Motorized, adjustable soft PU folding rollers

Cpjdsx R Uibjpfx Afnsu

• Subsequent knife shafts with lift function

• Crossfold unit, KTL version with 2 fold knives and 1 horizontal folding plate

• Motorized adjustable functions

• FFP pneumatic window folding plate with motorized stop

• ACC-2.4 control unit

• Swiveling touch monitor for machine operation

• Soundproof hood

• Twinstacker TSH-70, 2009, bundle delivery with

• Press function and 2-level roller delivery to the left

• Compressor

Listing

Duxford

Duxford

7,214 km

2014 Mueller PyroPure P4003 Pure Steam Condensing System

MuellerPyroPure P4003

Call

Year of construction: 2014, condition: used, This listing is for a Mueller PyroPure P4003 Pure Steam Condensing System.

The unit is in full working condition and is ready for immediate release.

This Unit was installed new in 2015 by Freestead Process Technology.

This Unit is fitted with a Allen Bradley Compact Logix PLC and Panel View plus 1000 HMI's-

Product Overview:

The Mueller P4003 is a high-capacity pure steam condensing system, part of the trusted PyroPure series. Designed for pharmaceutical manufacturing, this system produces pyrogen-free and endotoxin-free water-for-injection (WFI) by condensing pure steam. Built to meet or exceed U.S. Pharmacopoeia (USP) standards for WFI, as well as CE marked and FDA compliant with 3.1B material certification. It is a versatile solution for facilities requiring both pure steam and WFI quality distillate. Its robust design and advanced features ensure reliable operation, compliance, and minimal maintenance.

Key Specifications:

Model Number: P4003

Capacity: 100 gallons per hour or 379 litres per hour of WFI-quality distillate.

Codjxv Agcspfx Afnspu

Pure Steam Inlet: 807 pounds per hour or 366 kilograms per hour.

Coolant Requirement: 978 gallons per hour or 3702 litres per hour.

Pure Steam Output Compliance: Pyrogen-free and endotoxin-free, meeting USP WFI standards.

Core Features

High-Quality Output:

Produces pyrogen-free steam and WFI-quality distillate, ideal for pharmaceutical-grade applications.

Utilizes a tangential nozzle design for optimal impurity separation in the pure steam generator.

Efficient Design:

Fully drainable components eliminate contamination risks and ensure clean operation.

Electro-polished 316/316L stainless steel with a maximum surface roughness of 20 Ra for all product contact areas.

USP Class VI-certified elastomers for enhanced safety and regulatory compliance.

Ease of Maintenance:

Removable tube bundle in the condenser allows for easy cleaning and inspection of critical surfaces.

Requires only 24 inches of clearance on all sides for service and maintenance.

Minimal instrumentation with just one control loop simplifies operation and reduces potential downtime.

Installation Flexibility:

Can be integrated with a PyroPure pure steam generator for dual production of pure steam and WFI.

Optional stand-alone design for remote installation at the point of use, adding versatility to your setup.

Applications:

Pharmaceutical Manufacturing: Sterile environments, autoclave processes, and critical cleaning procedures.

Biotechnology: Providing WFI for sensitive biological processes.

Healthcare: Humidification and sterilization in clean rooms or hospital sterilization units.

Listing

Duxford

Duxford

7,214 km

2014 Mueller PyroPure WFI System

MuellerPyroPure

Call

Year of construction: 2014, condition: used, This listing is for a Full Mueller PyroPure WFI System.

The unit is in full working condition and is ready for immediate release.

This Unit was installed new in 2015 by Freestead Process Technology.

This system is in immaculate condition as the sites steam requirements were “Turned on Time”of the Steam Generator's is 65,000 hours, but as this unit is 1 of 2 generators in an alternating system it does not indicate the "Steam Production Time".

The Mueller PyroPure WFI System stands out as a high-performance, integrated solution for the pharmaceutical and biotechnology industries, focusing on the production, storage, and distribution of ultra-high-purity Water for Injection (WFI). Below is an in-depth look at its components, capabilities, and specifications.

Key Components

2x Mueller P7310 Pure Steam Generator

High Capacity: Generates from 0 to 700 kg/hr of pure steam, suitable for high-volume operations.

Operational Flexibility: Can operate alternately with another unit of the same model, maximizing efficiency and reducing downtime.

Regulatory Compliance: Meets USP WFI standards, ensuring suitability for pharmaceutical applications.

Maintenance-Friendly Design: Features an external evaporator for easy access and servicing, minimizing contamination risks.

Advanced Control: Equipped with an Allen Bradley Compact Logix PLC and an intuitive operator interface terminal (OIT) for real-time monitoring and control.

Safety Mechanisms: Includes pressure relief valves and temperature controls to ensure safe operation.

Energy Efficiency: Designed to optimize energy consumption, especially when alternating operations between units.

Durable Construction: Made from high-quality stainless steel for longevity and hygienic conditions.

1x Mueller P4003 Pure Steam Condensing System

Condition: This unit is in full working condition and ready for immediate release. Installed new in 2015 by Freestead Process Technology.

Capacity: Produces 100 gallons per hour (379 litres per hour) of WFI-quality distillate, with a pure steam inlet capacity of 807 lb/hr (366 kg/hr).

Compliance: Meets stringent USP WFI standards, is CE marked, and FDA compliant with 3.1B material certification.

Core Features:

Utilizes a tangential nozzle design for superior impurity separation.

Drainable components to minimize contamination risks, with electro-polished 316/316L stainless steel ensuring hygienic operation.

Easy maintenance due to a removable tube bundle in the condenser and minimal instrumentation, requiring just 24 inches of clearance for service.

1x Ormandy Newade WFI Storage Vessel

Condition: This 2000L WFI storage vessel is also in full working condition, installed in 2015 by Freestead Process Technology.

Capacity: Perfectly balances storage efficiency for mid-sized operations with its 2000 litres capacity.

Design Flexibility: Available in both horizontal and vertical configurations, customisable based on specific facility layouts.

Material Excellence: Made from high-grade austenitic and Duplex stainless steel, ensuring durability and resistance to corrosion.

Compliance: Adheres to key industry standards such as PD5500, ASME VIII, and EN 13445, and is CE marked under the Pressure Equipment Directive.

Codpsxv Af Eefx Afnspu

1x Fristam FPE742/185A Centrifugal Pump

Condition: This robust 5.5KW sanitary pump is operational and ready for immediate use, also installed in 2015 by Freestead Process Technology.

Hygienic Design: Features close internal clearances (as ...

Listing

Netherlands

Netherlands

7,514 km

Tube Cutting Machine

DurmaHD-TC60170

Call

Year of construction: 2019, condition: ready for operation (used), This Durma HD-TC60170 was manufactured in 2019. It features a 3kW IPG Fiber laser source, capable of 2.5D cutting, and handles up to 170mm pipes and 120x120cm tubes. It includes an exhaust system, spatter guard, bundle loader for serial work, and a chain loader for smaller jobs. The machine has a 6.5 meter inlet and a 4.5 meter outlet, extendable to 6 meters. Contact us for more information about this machine.

Application Types

Cutting

Cjdpfxex D Ir Tj Afnjpu

Listing

Nürtingen

Nürtingen

7,970 km

Shrinking machine

KALLFASSSuper Wrap 950 + Universal 950 HV

Call

Condition: refurbished (used), Year of construction: 2006, functionality: fully functional, Manufacturer: Kallfass Verpackungsmaschinen GmbH

Type: Bundle wrapping machine Super Wrap 950 de Luxe In-Line

Year of construction: 2006

Dimensions: approx. 2500 x 1650 x 2100 mm (LxWxH)

Weight: approx. net 800 kg / gross 880 kg

Technical Data:

Technical data:

Film: flat film, up to approx. 120 µm

Film roll width: max. top 920 mm, bottom 920 mm

Working height: 815 - 915 mm

Passage height: 500 mm

Power connection: 400 V three-phase current

Rated current: 7.2 A

Compressed air connection: 6 bar

Compressed air consumption: approx. 25 L/cycle

Touch panel: Siemens TP177

Control system: Siemens S7

This particularly versatile banding machine works with 2 flat film rolls.

The product is fed fully automatically via an in-line conveyor belt.

The sealing system is permanently heated, thermostat-controlled and therefore maintenance-free.

The film rolls are simply placed on the machine and the film is removed by a motor

Manufacturer: Kallfass GmbH

Type: Shrink tunnel Universal 950 HV

Cpsdpfxsvfd Rfe Afnou

Year of construction: 2006

Dimensions: approx. 2400 x 1400 x 1550 mm (LxWxH)

Weight: approx. net 750 kg / gross 820 kg

Technical Data:

Technical data:

Tunnel passage width: 900 mm

Tunnel passage height: 500 mm

Length of the heated tunnel hood: 1700 mm

Length of the additional insulating hood: 2200 mm

Tunnel outlet, extended: approx. 600 mm

Working height: 800 - 900 mm

Power connection: 400 V three-phase current

Rated power: 39 KW

Rated current at 400 V: 56 A for single operation

Particularly powerful shrink tunnel with bottom and laterally adjustable

for precise control of the hot air outlet for optimum shrinking results even with

shrinking results even with difficult product contours. Equipped with 2

hot air blowers and infinitely adjustable bar chain transport.

Function guarantee, no warranty

Listing

Werberg

Werberg

8,219 km

Göbel Drent Vision

GoebelDrent Vision

Call

Condition: good (used), Year of construction: 2003, 10 colours endless with coating unit UV

Cjdpfx Afema Rq Rjnepu

max. web width 520 mm, minimum web width 200 mm

UV system IST

automatic reel splicer

Video web inspection

Print format 22'' and 25 3/6'' (10 printing units each)

Cross cutter

Bundle delivery

Print > roll/sheet or roll/roll

etc.

Listing

Luckenwalde

Luckenwalde

7,960 km

Exhaust system

ESTANA-K 6000 B

Call

Condition: used, Year of construction: 2014, type of input current: three-phase, input voltage: 400 V, overall weight: 700 kg, volume flow: 5,150 m³/h, suction capacity: 5,150 m³/h, noise level: 89 dB, input current: 14 A, power: 7.5 kW (10.20 HP), negative pressure: 3,690 Pa, input frequency: 50 Hz, ambient temperature (min.): 5 °C, protection type (IP code): IP6K0, ambient temperature (max.): 40 °C, We are offering this used ESTA NA-K 6000 B extraction system, year of manufacture 2014.

Voltage: 400 V

Number of phases: 3

Frequency: 50 Hz

Power: 7.5 kW

Current: 14.4 A

Sound pressure level: 89 dB(A)

Pre-filter: 32 µm

Protection class: IP 6X

Maximum airflow: 5,150 m³/h

Maximum negative pressure: 3,690 Pa

Water capacity: 290 l

Weight: 700 kg

Year of manufacture: 2014

Operating temperature range: +5 to +40 °C

If you have any questions or require further information, please feel free to send us a message or call us.

This unit was used for the extraction of grinding dust/mist in connection with grinding processes (including grinding robots/grinding cells) and is ideal for reliable wet dust collection of particles.

Cjdpfx Afsx Stb Eenspu

✅ ATEX/DEKRA certification present (visible sticker)

✅ Heavy-duty industrial design, suitable for continuous operation

✅ Excellent addition/bundle for grinding cells (Krugmann/robotic systems)

Technical data (available):

Manufacturer: ESTA Apparatebau GmbH & Co. KG

Model: NA-K 6000B

Year of manufacture: 2014

Power: 7.5 kW

Connection: 3~ 400 V / 50 Hz

Current consumption: approx. 14.4 A

Weight: approx. 700 kg

Inventory No.: 03375

Scope of delivery / Collection:

Delivery as shown in the photos. Collection from site. Dismantling/loading by purchaser or as per agreement.

Listing

Germany

Germany

7,870 km

Stone Production Plant

OmagTronic S22 140-90

Call

Year of construction: 2001, condition: ready for operation (used), A paving stone production line Omag, which has been continuously optimized and upgraded to the latest technical standards, is available. Overhauls: 1) Conversion for an additional hydraulic unit for additional load in 2020. 2) Conversion to servo-vibration with Siemens S7 control in 2016. 3) Conversion to digital path measurement of mould and ram in 2017. 4) New core filling carriages in 2017. Plant components: 1) Board destacker and board stacker including roller conveyor. 2) Board feeder (advance) and board conveyor (scraper) to the lifting frame. 3) Board turner. 4) Horizontal and vertical bundling units Ridder & Signode, years of manufacture: 1994 and 1983. 5) Trafo lifting platform including motors and without control, year of manufacture: 1983. 6) Doppler including hydraulic unit, year of manufacture: 2004. 7) Stone packer Omag K1400 including hydraulic unit, year of manufacture: 1997. The line has no base boards. 8) Stone finisher Omag S22 140-90, year of manufacture: 2001. Documentation available. An on-site inspection is possible.

Cpodpew R Uziofx Afnou

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Complete Bottling Line

Call

Condition: used, operating hours: 30,000 h, Used CFT can filling line for soft drinks – 12,000 cans per hour

Introduction and Production Capacity

The Used CFT can filling line for soft drinks – 12,000 cans per hour delivers a complete solution for filling carbonated beverages in aluminum cans. CFT designed the line in 2017 and configured it to handle two Slim formats, which are commonly used in the soft drink industry. Specifically, the system processes up to 12,000 cans per hour, meeting the output requirements of medium-scale industrial facilities. As of 30/06/2025, the owner will release the line for sale. Therefore, this represents a valuable opportunity for facilities seeking to expand their production capacity.

Depalletizing and Initial Inspection

Initially, the CFT depalletizer automatically separates empty cans and feeds them into the production flow. Then, a HEUFT inspection unit checks each container for visual defects and dimensional non-conformities. As a result, the system ensures that only clean, undamaged cans move forward for rinsing. In addition, this early inspection step reduces the risk of line stoppages later in the process.

Can Conveyance and Rinsing

Next, CFT cable conveyors transport the accepted cans to a dual-channel rinser. The CFT rinser cleans the interior of each can using pressurized water jets or sterile air. Consequently, the machine maintains hygiene standards in line with food and beverage regulations. Moreover, the dual-channel configuration improves throughput while reducing contamination risks. Notably, this section plays a key role in maintaining microbiological safety.

Filling

After rinsing, a CFT monoblock handles the filling and seaming stages with 12 filling valves and 4 seaming heads. The machine processes cans of 150 ml and 330 ml efficiently. It also controls pressure and temperature precisely to prevent CO₂ loss during the filling of carbonated soft drinks. Furthermore, this phase supports both performance and product integrity. In effect, it ensures consistent quality in high-speed conditions.

Full Can Inspection and Rejection

Following the filling stage, another HEUFT unit inspects the filled cans to verify fill levels, seal integrity, and the absence of leaks. When it detects non-compliant cans, an automated HEUFT rejection module removes them from the line. As such, this step protects the quality of downstream operations. Additionally, it avoids the unnecessary packaging of defective units. Overall, the system minimizes waste and downtime.

Conveyance and Packaging

Subsequently, CFT conveyors move the approved cans to an SMI shrink wrap packer. The packer forms bundles in several formats: 4×3 (12 cans), 6×4 (24 cans), and 2x2x3 (12 cans). In this way, the flexible configuration supports various packaging and distribution strategies. Besides improving logistics, this packaging versatility allows rapid changeovers between product sizes.

Csdpfx Ajx H Tiljfnepu

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Shrink Wrapper

AtlantaCombigiotto 90-M

Call

Condition: used, Year of construction: 2008, Machine Overview

Automatic tray plus film packer ATLANTA COMBIGIOTTO 90-M designed for secondary packaging of bottles with 90° side infeed. The machine forms a corrugated tray and wraps the product with neutral shrink film, then conveys it through a shrink tunnel to obtain stable, retail-ready bundles. Ideal for beverage lines handling PET, glass or HDPE bottles. Reference No. FA56. Year 2008, overhauled in 2022. Condition: Ready for operation. Indicative output up to 25 packs/min, depending on product and format.

Operating concept: automatic grouping of bottles, tray forming/loading, film wrapping and shrink-tunnel consolidation.

Packaging configuration: Tray + neutral film (shrink).

90° infeed enables compact layouts and easy connection to existing conveyors.

Key Technical Data

Make / Model: ATLANTA COMBIGIOTTO 90-M

Operating type: Automatic

Infeed orientation: 90° side infeed

Packaging: Tray + film (neutral)

Tray magazine/formation: Available

Nominal capacity: up to 25 bundles/min (format and product dependent)

Year: 2008 (overhauled 2022)

Condition: Ready for operation

PLC: SIEMENS S7 E 300

Automation & Control

Industrial PLC-based control with operator HMI for recipe selection, speed setpoints and diagnostics.

Inverter-controlled drives for smooth acceleration and product handling.

Photoelectric sensors for product presence, jam and film detection.

Temperature-controlled shrink tunnel for consistent film performance.

Interlocked access doors with safety monitoring for guarded zones.

Line Integration

Upstream: accepts bottles from conveyor with 90° transfer to the infeed section; integrated selection/divider to create pack patterns before tray loading.

Downstream: discharge conveyor after shrink tunnel for connection to inspection, case handling or palletizing.

Signals and handshakes typically include start/stop, fault, emergency stop circuit integration and speed reference.

Mechanical interface and layout drawings available on request for line engineering.

Condition & Maintenance

General overhaul performed in 2022.

Machine presented as ready for operation.

Preventive maintenance recommended: periodic checks of film path, knife/sealing components, tray magazine/erector, lubrications and conveyor wear parts.

Performance & Versatility

Suitable for a wide range of cylindrical or square bottles commonly used in beverages.

Typical pack patterns achievable for bottles (e.g., 2×2, 3×2, 4×3, etc.) depending on container size and tray dimensions.

Neutral shrink film for clear presentation; tray provides rigidity and stacking strength.

Cjdpfx Afsx H Thzenjpu

Consistent bundle quality via controlled film wrapping and thermal shrink process.

Listing

Germany

Germany

7,870 km

Fiber Laser Cutting Machine

ADIGELASERTUBE LT722D

Call

Year of construction: 2021, operating hours: 66,828 h, condition: ready for operation (used), Main Drive

Laser power 2.5 kW

Additional Equipment

Automatic tube bundle loader for initial lengths between 3200 and 6500 mm

Loading with an overhead crane possible

4000 kg loading capacity

Special lift loader equipment for square, rectangular, and flat-oval tubes

Tube separation with length measuring station

Equipment for a 6500 mm bundle loader for pipes with sensitive surfaces

Artube nesting software included

Codpfx Ajx D Nnisfnspu

This ADIGE LASERTUBE LT722D was manufactured in 2021. It's designed for laser processing of tubes, handling materials like mild steel and stainless steel. It supports various tube shapes, including round, square, and rectangular, with dimensions up to 140 mm. Features include a PRECITEC AK-HP cutting head, automatic tube bundle loader, and a robust unloading system. Ideal for high-quality laser cutting operations. Contact us for more information about this machine.

Application Types

Cutting

Listing

Germany

Germany

7,870 km

Complete Production Line (Wood)

HEESEMANNHEESEMANN BÜRKLE

Call

Year of construction: 2001, condition: ready for operation (used), This HEESEMANN BÜRKLE wood production line was manufactured in 2001. It features a comprehensive oil application line, including RBO vacuum feeding Tornado SC 1300, HEESEMANN MFA 8 with cross-lengthwise brushes, and BÜRKLE SLC 1400 roller application machines. Enhanced with a new Siemens control system in 2024, consider the opportunity to buy this HEESEMANN BÜRKLE wood production line. Contact us for more information.

Codjx D Rh Rjpfx Afnepu

Application Types

Complete Production

Listing

Germany

Germany

7,870 km

Other (Wood)

CASATIBIG 2600

Call

Year of construction: 1995, condition: ready for operation (used), This CASATI BIG 2600 was manufactured in 1995. It features a double-knife system with both upper and lower knives that trim veneer bundles from both sides simultaneously, ensuring precise cuts. The machine offers a substantial working width with a usable cutting length of 2600 mm, ideal for preparing veneers for furniture and doors. Consider the opportunity to buy this CASATI BIG 2600. Contact us for more information.

Cedpfxsx D Hv Do Afnopu

Application Types

Other Woodworking Machinery

Listing

București

București

9,242 km

Complete edge-banding and drilling line for 6 sides

NanxingNB860EC + ND712DTL

Call

Condition: new, Year of construction: 2026, functionality: fully functional, Edge banding machine – NB860EC - Machine with 6 edge band magazines and servo feed

• Robust machine structure and most of the machine's mechanical parts are machined with advanced CNC machines for greater stability and longer life without deformation;

• Combines multiple functions in one machine, including pre-milling, pre-heating, pre-melting, end trimming, servo fine cutting, servo scraping, surface scraping and polishing, spraying, all in one process.

• Intelligent PC control, feed guide, belt pressing rollers, fine cutting and scraping

are controlled by a servo motor. Corner rounding is adjusted pneumatically. Machine speed 16/20/24 m/min;

• Nesting kit design

• Fine refilling and corner rounding via HSK25

TECHNICAL DATA

Panel length: ≥120 mm; ≥200 mm with rounded corners

Panel width: ≥60 mm

Min. Panel size:

120× 120mm; 120× 60mm long edge; 200*80 mm short edge

Panel thickness: 9-60 mm

Thickness C=edge: 0.4-3 mm

Feed speed: 16/20/24 m/min

Power supply: 380 V; 50 Hz

Required air pressure: 0.7 MPa

Distance between panels ≥50

Cpjdpfjx Uplxjx Afnou

Console 2

Dust collection outlet Φ 125 mm*5

Total power: 28 Kw

Approximate weight: 3,000 kg

Overall dimensions: 5,930*1,050*1,850 mm

6-sided drilling CNC and double workstation ND712DTL

The ND712D is designed to have 2 independent workstations of 1200+650 mm, integrating 2 machines into one, thus doubling efficiency with less space required. The integrated, high-rigidity machine body structure gives the entire machine a longer service life and fast, stable machining. The optimized drill layout makes drilling more efficient.

TECHNICAL DATA

Total power: 52.36 kW

Machine size: 7400 * 4,620 * 2,650 mm

Power supply: 380V/50Hz 3 phases

Air supply: 0.6-0.7MPa

Total weight: 7,850 kg

Control system: SYNTEC

Panel size: Length: 250-2,800 mm / Width: 250-650/1200 mm / Thickness 10-60 mm

Maximum travel speed:

( X) Axis /U ) - 135 m/min

Y axis - 75 m/min

Z axis - 30 m/min

Transmission mode

X axis - Rack and pinion

Y axis - Rack and pinion

Z axis - Ball screw

Drilling blocks: Top 2+2; Bottom 1+1

Vertical drills (top): 19*4

Horizontal drills (top): X: 3 × 8 + Y: 2 × 8

Vertical drills (bottom): 9 × 2

Maximum drilling diameter: Φ35mm

Distance between holes: 32 mm

Rotation speed: 5000 rpm

Shank diameter: Φ10mm

Main shaft: 4* ER25

Power: 2*3.5kw; 2*5.5kw max. 18000rpm

Listing

Helmstedt

Helmstedt

7,830 km

Saddle stitcher

Müller MartiniSupra

Call

Condition: good (used), functionality: fully functional, Size: max 340 x 260 mm; min 90 x 115 mm

Size (without lap): max 340 x 250 mm; min 90 x 115 mm

lap: max 15 mm

folio lap: min 6 mm

low folio lap: min 8 mm

Product size, stitching unit: max 340 x 260 mm; min 210 x 155 mm

booklet thickness: max 6 mm

Mechanical speed 1:1: max 25,000 t/h

Mechanical speed 1:2: max 30,000 t/h

equipment

gathering chain & feeder

- 8 station gathering track

- 8 single base

- 6 feeders 416

- product gluer 423

stitching unit

- stitching unit 430

- 15" inch chain pitch

- wire unwind device

- thickness control/ plus-minus

- 4 stitching heads

three knife trimmer

- three knife trimmer 426

knives

- 2 sets of knives

delivery

- compensating stacker Robusto

optional Equipment: --- not included ---

Codpfx Afsu S Ncbenopu

- crane system

- bundle feeder

- print roll feeder

- additional stations

- card gluer

- div. conveyor belts

- compensating stacker

- strapping machines

- wrapping machines

- palletizer

Listing

Germany

Germany

7,700 km

Bar Automatic Lathe - Multi Spindle

SCHUETTEAF51

Call

Condition: used, Year of construction: 1987, Technical details:

number of spindles: 8

spindle passage: 51 mm

Article: multi spindle automatic lathe

Manufacturer: Schütte

Type: AF51

Yob: 1987

eight main spindles

max. bar diameter D=51mm

control SIEMENS SIMATIC S5

pick up in pos. 7, for rear machining

thread cutting drive

independent feed in positions 2/3

electronical trip dog control “Balluff”

clear text display Wöhrle

coolant pump

magnetic cartridge filter

oil running

incl. bar loader IEMCA PRA 40/37/F, yob 1987, (bundle type)

Painting in light blue and light grey

The configuration of tooling will be different like pictures.

Cjdpfx Ajiay Sfjfnopu

Please, contact us for getting more information and pictures on mail(at) or

*

Trust Seal

Dealers certified through Machineseeker

Listing

Germany

Germany

7,700 km

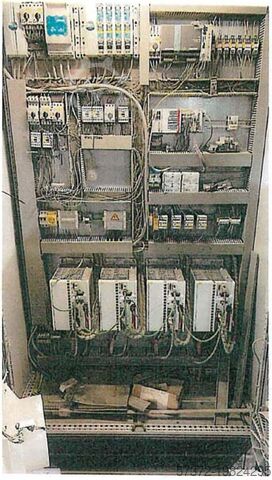

Revolving Indexing Machine

PFIFFNER HYDROMATHB 32-45/16

Call

Condition: used, Year of construction: 2013, Article: Rotary transfer machine

Manufacturer: Pfiffner

Type: Hydromat HB 32-45/16 CNC

Yob: 2013

Electro-hydraulically controlled, fully automatic

Extract from offer:

Coolant system with chip conveyor and Knoll vacuum rotation filter

High pressure pump 50 bar

Second coolant ring

Water cooler type 1600

Collets type B32-45 UP

Control: Siemens Sinumerik 840D - CNC / S7-PLC incl. modem (for teleservice)

1 bar loading magazine type IEMCA: bundle loader (yob. 2011)

1 Sawing unit: Saw blade D250mm

2 Feed unit VE 26/80-HSK: Spindle stroke max. 80mm; spindle speed max. 7200 rpm; drive power up to 2.2kW; HSK 32

2 Vertical support 26/80 with 36° angular position

2 drilling head 26/80-HSK: HSK 32

1 feed unit VE 36/100-HSK: spindle stroke max. 100mm; spindle speed max. 5430 rpm; drive power up to 2.2kW; HSK 40

4 Feed unit VE 36/100-HSK internal cooling: Spindle stroke max. 100mm; spindle speed max. 5430 rpm; drive power up to 2.2kW; HSK 40; central coolant supply

6 Drilling head 36/1000-HSK: HSK 40

2 CNC X-Y-Z turning device outside the collet disc: NC 26/100 pick-up unit; 2 deburring spindles

1 CNC horizontal cross slide 26100-HSK: X/Y stroke

1 CNC feed unit VE 36/100-HSK internal cooling: spindle stroke max. 100mm; spindle speed max. 5430 rpm; drive power up to 2.2kW; HSK 40; central coolant supply

Cpedpfjruvaqex Afnou

2 CNC turning unit 50/100-PSK: with ES-PDK-12 facing head (slide-in 2 tool holders); Z-axis 100mm; X-axis 12mm; n max. 5000 rpm; 4kW

1 turning unit WDE 30/60

1 turning tube with insertion bar

3 chip breaker valve SBV-100

Tool monitoring

Please, contact us for getting more information and pictures on mail(at) or

*

Listing

Germany

Germany

7,700 km

Round bar loader

CUCCHICMSP/CMSPF

Call

Condition: used, Bar loading magazine for multi spindle automatic lathe, new

Manufacturer: Giovanni Cucchi

Machine type: Bar loading magazine for multi-spindle

Type: CMSP/CMSPF

Cpsdpeft Ti Tsfx Afnju

Design: Side loader as surface loading magazine or bundle loading magazine

CMSP / CMSPF at a glance:

Proven technology - in use for decades

The material feed of this loader generation is carried out by the loading magazine. Bar loading magazines CMSP/CMSPF are mounted on rails, so they can be easily disconnected from the machine at any time by unlocking them at the quick release.

These magazines do not require bar tubes on the machine and are screwed directly to the machine. It is possible to work in automatic mode as well as in manual mode.

The magazine is mounted on rails, so it can be easily disconnected from the machine at any time by the operator by unlocking it on the machine. To change bar diameters, only the clamping sleeves of the magazine are changed.

The centering unit adjusts itself to the new diameter by itself. It dampens all kinds of vibrations during machining (suitable for round, square and hexagonal material!) and prevents the bar from forming an arc in the channel. This allows very high speed machining (even with larger diameters).

Quick changeover to the next diameter to be machined and a significant reduction of vibrations, due to the proven double centering, are only two of the many advantages of this system.

The advantages of CMSP/CMSPF barfeeders at a glance:

- short loading time

- optimal guiding of the bar material by double or, if necessary, triple centring device

- no oil flooding - dry running

- quick change of the diameter to be machined

- short design - space saving

- very low wear of the guide channel

- self-adjusting centring device

- significant reduction of vibrations

Please, contact us for getting more information and pictures on mail(at) or

*

Listing

Großenlüder

Großenlüder

7,854 km

Centrifugal turbine

Oliver Fritz GmbH & Co. KGSR380 ECO

Call

Condition: new, Year of construction: 2025, 2 pieces high performance centrifugal wheel Ø380 11kW. High flexibility by clockwise and counterclockwise rotation distinguishes our centrifugal wheel. Our double disc turbine

stands for a stronger bundled hotspot and more efficient blasting. The replacement of the 8

throwing blades and the inner lining is easy and without special tools, without disassembling the

turbine wheel. All wear parts are made of high quality materials for long life. A

It forms the heart of the blast machine: the efficiency and economy of the blast machine are decisively influenced by the efficiency of the centrifugal blast system.

efficiency and economy of the blast machine are decisively influenced by the efficiency of the blast wheel. The blast wheel is directly driven and

4-8 blades depending on the diameter (Ø240 4 blades, Ø380-500 8 blades). The high efficiency and

maximum utilization of the energy used is thus guaranteed at all times.

Cpjdpfx Afshvmkxjnou

We will be glad to advise you!

Listing

Madrid

Madrid

7,603 km

SIGNODE Strapping machine

SIGNODEStrapping machine

Call

Condition: used, SIGNODE AUTOMATIC STRAPPING STATION, model M400

The formed bundle is automatically transferred, by the driven rollers of the evacuation trolley, to the automatic Strapping Station. The bundle will be stopped at the programmed strapping positions to allow the automatic application of the steel strap.

Cpedpfx Aewxxz Refnju

It is composed of:

- SIGNODE automatic Strapping Machine Model M400/PA/TSM for vertical strapping,

- Pneumatic strapping floating head for steel strap of 32 mm. width (1¼") and 0,9 mm. wall thickness;

- 450 kg. jumbo coil dispenser with electrical unwinding;

- Switchboard.

SIGNODE automatic Strapping: Machine Model M400/PA/TSM for vertical strapping

Pneumatic strapping floating head: for steel strap of 32 mm. width (1¼") and 0,9 mm. wall thickness

450 kg. jumbo coil dispenser: with electrical unwinding

Switchboard: Included

We make it easier for you to find: "bundle"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Bundle (399)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you