Used Press-Fit Machine for sale (102,063)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Burkardroth

Burkardroth

7,903 km

Inserting machine P1S-10

PressOneP1S-10

Call

Year of construction: 2025, operating hours: 25 h, condition: as good as new (ex-display), functionality: fully functional, machine/vehicle number: P1S10_28, Electric pressing machine P1S-10 of the PRESSONE series by CoastOne from Finland with spindle drive.

Dwedpfx Ahovnrc Uj Uod

PressOne P1S-10

100kN pressing force

120mm/s feed speed

200mm/s opening speed

Tool carousel for 4 lower tools

Tool case with 22 pressing tools

Laser pointer

Work light

Side holder with color boxes

TC12 touchscreen control

36 month guarantee

Listing

Würzburg

Würzburg

7,928 km

Punching machine

Bruderer DifferenzwegpresseDWP R14 -200

Call

Condition: refurbished (used), Year of construction: 2004, operating hours: 5,000 h, functionality: fully functional, total height: 4,300 mm, ram adjustment: 100 mm, installation height: 500 mm, table height: 1,000 mm, total width: 2,200 mm, table length: 1,400 mm, pressing force: 200 t, control cabinet width: 2,000 mm, stroke length: 160 mm, clearance between the columns: 1,450 mm, working width: 1,100 mm, distance between side stands: 400 mm, overall weight: 27,000 kg, height adjustment type: electric, space requirement height: 4,500 mm, space requirement length: 2,200 mm, space requirement width: 1,800 mm, High-precision cutting and embossing press, U.T accuracy +/- 0.01, ideal for the production of fuel cell stacks or hydrogen electrolyzers.

hydrogen electrolyzers. The press is also suitable for (smooth) fineblanking, stroke rate 1 - 70 /min.

Eccentric loads are also possible without any problems thanks to 4 connecting rod rams. It is also not possible for the press to jam.

The press is completely overhauled and supplied with a new Siemens S7 control system.

Djdpfot Nf Agex Ah Uswd

Listing

Dudullu OSB

Dudullu OSB

9,692 km

Punching press

Bosporas MachineryServo Punch Press

Call

Condition: like new (used), functionality: fully functional, Year of construction: 2025, Introducing the Automatic 40 Ton Servo Punch Press Machine. Built for precision and flexibility, it boasts six tool stations, dual-servo control for dynamic X Y punching, and a powerful 22 kW hydraulic punch drive. With speeds up to 90 cycles per minute and an auto scrap conveyor, this servo punch press delivers seamless performance—quietly, efficiently, and intelligently. Watch how it adapts, executes, and excels.

Notable Features:

• Robust Punching Power

With 40 metric tons of punching force, this machine delivers consistent performance and handles a wide range of sheet materials with ease.

• Multi Tool Versatility

Equipped with 6 tool slots, it supports simultaneous loading of multiple punch tools, enabling fast tool changes and maximizing uptime.

• Precision X Y Servo Control

Dual servo motors govern the Y axis with high sensitivity and coordinate with servo feeder systems to punch at any X & Y coordinate—ideal for complex part layouts.

• Efficient Hydraulic Drive

A dedicated 22 kW hydraulic pump powers the punching mechanism, combining servo responsiveness with hydraulic force for reliable output.

• High-Speed Punching

Capable of up to 90 punches per minute, it delivers both speed and agility to meet demanding production schedules.

• Integrated Scrap Management

Outfitted with an automatic scrap conveyor, it ensures continuous operation by efficiently removing punched material waste.

_____

Why Servo Punch Press Technology Stands Out

Our machine leverages the cutting-edge advantages of servo press systems, which far surpass traditional mechanical or hydraulic presses:

• Exceptional Precision & Programmability:

Servo-driven systems offer tight control over force, speed, and position, ensuring consistent results and the flexibility to fine-tune stroke profiles.

• Energy Efficiency & Sustainability:

Power is used only during punching operations—resulting in substantial energy savings and reduced operational costs.

• Quiet, Controlled Operation & Lower Maintenance:

Dwsdpew I N H Usfx Ah Usd

Compared to conventional systems, servo presses run with less noise and fewer mechanical wear parts, boosting workplace comfort and reducing downtime.

• Enhanced Safety & Monitoring:

Advanced feedback controls and real-time monitoring help detect anomalies early, minimizing risk and improving overall process reliability.

• Ultimate Flexibility with Programmable Motion:

Custom stroke profiles, dwell times, and speed modulation empower operators to adapt instantly to varied parts and production requirements.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Jonava

Jonava

8,299 km

20-26-536 Assembling press

WOODLAND MACHINERYWLM 5

Call

Condition: new, Total height 1500 mm

Total length 3000 mm

5 pneumatic cylinders

Dsdpfxodpbn Ao Ah Uswd

Compressed air pressure 8 bar

Travel of pneumatic cylinders 100 mm

Diameter of pneumatic cylinders 100 mm

Listing

Peskojai

Peskojai

8,099 km

Belt press

ProFruit MachineryPOWERPRESS 3000

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 3000 kg/h.

Dwedoq Nl Aqepfx Ah Uod

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

-The juice yield of apples using our belt press 3000 is ~75 %.

-There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

-The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

-The belt press 3000 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

-Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

-After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

-Belt tension is adjustable.

-Machine is made entirely of stainless steel and has adjustable feet for more convenient use.

-Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Discover more used machines

Listing

Ostrożne

Ostrożne

8,364 km

Punching Machine

Pressta-EiseleKTS

Call

Year of construction: 1992, condition: excellent (used), Transmission of power hydropneumatic / hydraulic

Djdpfofcbb Hsx Ah Ujwd

Listing

Burkardroth

Burkardroth

7,903 km

Inserting machine P1S-10

PressOneP1S-10

Call

Year of construction: 2025, operating hours: 25 h, condition: as good as new (ex-display), functionality: fully functional, machine/vehicle number: P1S10_26, PressOne P1S-10 is a press-in machine from Finland, which is driven by a ball screw with a servo motor.

That gives you the best of both worlds. Power, speed and accuracy.

No oil means no leakage problems, no hassle when changing the oil and no filtration problems. Pure power, accuracy and speed!

Technical data: P1S-10

Main press technology: ball screw with AC servo drive

Maximum pressing force: 100 kN

Repeatability of force setting: ± 1%

Maximum opening / approach speed: * 120 mm / s

Press speed: max 10 mm / s

Throat: 620 mm

Stroke length: 210 mm

Faster range: M2 - M10

Servo motor: 5 kW

Control: P1S TC12 touchscreen 12 "

Tool connection: Type PressOne Universal, 4-fold lower swivel base

* The maximum approach speed requires the "Fast approach speed" option.

Control features of the P1S TC12:

- Programmable press force

- Programmable lift opening

- Programmable pressing speed

Dwjdjvnrcbepfx Ah Uod

- Programmable speed change point after starting before pressing

- 2-stage cycle (start and press)

- Possibility to set the press stroke length in millimeters

- Save programs for memory control by name or number

- Piece counter, cycle stop after the last press

- Material table for material / pressing force

- Tool library

- FTP server connection

Listing

Zamość

Zamość

8,589 km

Pole milling machine

PRESSTAPRIMUS 300

Call

Condition: excellent (used), functionality: fully functional, machine/vehicle number: 9123, Year of construction: 2008, massive, rigid milling machine for large posts with a milling cutter that can be adjusted steplessly vertically

manual feed

2.2 kW 400V motor

2,800 rpm milling cutter speed

maximum milling cutter diameter 300mm

profile mounted at an angle of 20°-90°-20° (according to the scale)

Dedpfowhpk Iex Ah Uswd

maximum cut-out width 400mm (at an angle of 90°)

maximum cut-out depth 110mm

maximum profile height 190mm

stepless milling height adjustment (handwheel and scale),

adjustment range 0 - 100mm

quick cutter change system

pneumatic material clamping

cooling and lubrication system

Listing

Halilbeyli OSB

Halilbeyli OSB

9,813 km

Scrap baler

Aymas Recycling MachineryHP3 (50x50) Baling Press

Call

Condition: new, Year of construction: 2025, Also, different models are available!

IMPORTANT: MACHINE WILL BE BRAND NEW

SEE THE TECHNICAL DESCRIPTION BELOW

1. Bale Size: 500mm x 500mm x...

Dwedpfsgwa T Rsx Ah Usd

2. Container Dimensions (Width x Length x Height): 2.000mm x 2.500mm x 1.100mm

3. Capacity: 15-20 tons/hour (steel)

4. Cycle Time: 90 seconds ( Idle )

5. Top Cover Cylinder Thrust: 90 tons

6. Preliminary Compression Cylinder Thrust: 150 tons

7. Main Compression Ram Thrust: 300 tons

8. Maximum Working Pressure: 300 bars

9. Electric Motor: 2 x 75 kW = 150 kW

10. Machine Dimensions (Width x Length x Height): 10.000 mm x 10.000 mm x 4.000 mm

11. Machine Weight: 55.000 kg

12. There will be an ejection door.

13. Repairable and four-edge-usable blades.

14. Container walls will be covered with HARDOX 450 - 500 material.

15. There will be an automatic SKF liquid lubrication system integrated into the compression chamber.

16. There will be an automatic SKF greasing system that will grease the bushings.

17. Piston shafts will be induction-hardened and chrome-plated.

18. Pumps and valves used in the hydraulic system will be by PARKER or EATON VICKERS & KAWASAKI brand.

19. Bypass filter will be added to the hydraulic system.

20. There will be an AKG Hydraulic Oil Cooling System.

21. All electrical parts will be SIEMENS or SCHNEIDER Brand.

22. The machine will be fully automatic with PLC control, PLC brand and model will be SIEMENS. There will be a touch screen SIEMENS HMI Simatic Panel with emergency buttons placed on some important points.

23. There will be blades from 2767 material (hardness 55HRC) at the borders of the top cover and the sides of the scrap chamber.

24. Machine will be under AYMAS Makina San. Ve Tic. A. S. Guarantee for 1 year or 2.500 working hours whichever comes first against manufacturing defects.

Listing

Peskojai

Peskojai

8,099 km

Belt Press for Juice

ProFruit MachineryPOWERPRESS 300

Call

Year of construction: 2024, condition: new, functionality: fully functional, Belt press POWERPRESS 300 is designed for pressing fruit, berry and vegetable mash. Fruit mash is supplied on the belt which presses it against shafts.

The obtained juice flows into a small collection tank under the press with filtration sieve on top. Then the external pump or juice collection tank with pump transfers the juice from the press to a desired storage tank or straight to ROCKET pasteurizer for further processing. The pressing process is continuous.

Capacity: 300 kg/h

The most cost-efficient belt press in the market!

The most evolutionary feature of our Belt press POWERPRESS 300 is one huge pressing shaft, which lets the machine to maintain the longer pressing time (belt length is 4900 mm) and huge shaft dimensions squeezes the juice efficiently by saving the costs and space.

Dwedpfx Ahjt Rft Uo Uod

The juice yield of apples using our belt press is ~65-75 %. The yield highly depends on freshness and variety of fruits.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 300 filtrates the juice even during the pressing stage providing cleaner and purer product.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves service costs.

Adjustable fruit inlet lever lets fruit mash supply onto the shaft easily.

Crushed fruit mash can be supplied from MAXIMILL or straight from a bucket or basket.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

The machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Ostrożne

Ostrożne

8,364 km

Punching Machine

Pressta EiseleHE 10 P

Call

Year of construction: 1988, condition: excellent (used), Hydropneumatic intensifier

Foot valve operated

Max. daylight = 280 mm

Dimension 60 x 850 x 1500 mm

Weight 300kg

Dsdpfx Asfitbwoh Uewd

Listing

Zamość

Zamość

8,589 km

CUTTING MACHINE

PRESSTA EISELEPROFILMA 450

Call

Condition: excellent (used), Year of construction: 2001, functionality: fully functional, machine/vehicle number: 1015, profiles with dimensions (HxB) up to 100x195mm, 80x200 mm

automatic work cycle

driven by a 3 kW/400 V, 2850 rpm motor

cutting disc d=450x3.8x40mm, z=110

horizontal and vertical material clamping on the feed side

dosing spray system

horizontal material clamping in the feeder

moving both clamping jaws when retracting (prevents scratching of the profile)

infinitely adjustable hydropneumatic cutting disc feed

cutting disc exiting from the rear

length of cut sections adjustable in the range of 0-300mm (with reversing device 0-600 mm)

setting the cutting length by a handwheel with a mechanical counter

Dedpfewgmv Sjx Ah Ujwd

maximum width of the cut profile 200 mm

cutting range (height x width) 100x195mm, 80x200mm

automatic shutdown when material runs out

possibility of connecting a dust extractor

Listing

Halilbeyli OSB

Halilbeyli OSB

9,813 km

Briquetting press

Aymas Recycling MachineryBP 80 Chip Briquetting Press

Call

Condition: new, Year of construction: 2025, Also, different models are available!

IMPORTANT: MACHINE WILL BE BRAND NEW

SEE THE TECHNICAL DESCRIPTION BELOW

1. Briquette Diameter: Ø 80mm

2. Capacity: 700-900 kg/hour ( Copper )

3. Preliminary Compression Ram Thrust: 12.5 tons

4. Main Compression Cylinder Thrust: 250 tons ( 5 tonne / cm2 )

5. Maximum Working Pressure: 300 bars

6. Cycle Time: 12 - 14 seconds

7. Electric Motor Power: 30 kW

Dsdpfogwa Urox Ah Uewd

8. Machine Dimensions (Width x Length x Height): 2.200 mm x 2.600 mm x 2.800 mm

9. Machine Weight: 6.000 kg

10. Screw drive feeders will fill the compression chamber automatically and a built-in vibrating hopper will provide safety to the chamber by preventing the oversize material from entering the chamber.

11. Cylinder Rods are induction-hardened and chrome plated.

12. A Hydraulic Oil cooling system is implemented.

13. Pumps and valves of hydraulic systems are from worldwide reputable brands such as PARKER.

14. The machine is fully automatic by PLC control.

15. All electrical and electronic parts are by SCHNEIDER or SIEMENS Brand.

16. The machine is CE certificated. The marking certifies that a product has met European Directives regarding consumer safety, health, or environmental requirements.

17. Machine will be under AYMAS Makina San. Ve Tic. A. Ş. Guarantee against manufacturing defects for one (1) year or two thousand five hundred (2.500) working hours.

Listing

Gargždai

Gargždai

8,118 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 400

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous

Dwjdpfjflpnyox Ah Uod

Capacity: 400 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our belt press is ~75 %.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 400 filtrates the juice even during the pressing stage providing cleaner and more pure product.

The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 800, POWERPRESS 1200, POWERPRESS 1500.

Listing

Ostrożne

Ostrożne

8,364 km

Punching machine

Pressta EiseleHPS 120

Call

Year of construction: 1991, condition: excellent (used), Punching machine

Presta Eisele HPS 120

Dwsdsl H Hyqspfx Ah Ued

Listing

Halilbeyli OSB

Halilbeyli OSB

9,813 km

Scrap baler

Aymas Recycling MachineryHP3 (40x40) Baling Press

Call

Condition: new, Year of construction: 2025, Also, different models are available!

IMPORTANT: MACHINE WILL BE BRAND NEW

SEE THE TECHNICAL DESCRIPTION BELOW

1. Bale Size: 400mm x 400mm x...

2. Container Dimensions (Width x Length x Height): 1.000mm x 2.000mm x 800mm

3. Capacity: 4 tons/hour (Steel), 5 tons/hour (Copper), 2 tons/hour (Aluminium)

4. Cycle Time: 90 seconds ( Idle )

Dsdpfx Aodfc Iysh Ujwd

5. Top Cover Cylinder Thrust: 90 tons

6. Preliminary Compression Cylinder Thrust: 150 tons

7. Main Compression Ram Thrust: 210 tons

8. Maximum Working Pressure: 300 bars

9. Electric Motor: 37 kW

10. Machine Dimensions (Width x Length x Height): 3.400 mm x 6.800 mm x 3.000 mm

11. Machine Weight: 18.000 kg

12. There will be an ejection door.

13. Repairable and four-edge-usable blades.

14. Container walls will be covered with HARDOX 450 - 500 material.

15. There will be an automatic SKF liquid lubrication system integrated into the compression chamber.

16. There will be an automatic SKF greasing system that will grease the bushings.

17. Piston shafts will be induction-hardened and chrome-plated.

18. Pumps and valves used in the hydraulic system will be by PARKER or EATON VICKERS & KAWASAKI brand.

19. Bypass filter will be added to the hydraulic system.

20. There will be an AKG Hydraulic Oil Cooling System.

21. All electrical parts will be SIEMENS or SCHNEIDER Brand.

22. The machine will be fully automatic with PLC control, PLC brand and model will be SIEMENS. There will be a touch screen SIEMENS HMI Simatic Panel with emergency buttons placed on some important points.

23. There will be blades from 2767 material (hardness 55HRC) at the borders of the top cover and the sides of the scrap chamber.

24. Machine will be under AYMAS Makina San. Ve Tic. A. S. Guarantee for 1 year or 2.500 working hours whichever comes first against manufacturing defects.

Listing

Gargždai

Gargždai

8,118 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1200

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Dsdpfjflpplex Ah Uowd

Capacity: 1200 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our machine is ~75 %.

There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

Machine works automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

The washing is simple, and all machinery parts are easily removable.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 400, POWERPRESS 800, POWERPRESS 1500.

Listing

Ostrożne

Ostrożne

8,364 km

End milling machine

Pressta EiseleAKF

Call

Condition: excellent (used), Year of construction: 1992, Type: AKF 250

Dwodpfx Asucq Nwjh Usd

Motor: 400V 2,2kW

Speed: 2800 rpm

Cutter O: 250mm

Cutter holder shaft O: 40mm

Milling width: 200mm

Milling depth: 85mm

Profile height: 150mm

Listing

Halilbeyli OSB

Halilbeyli OSB

9,813 km

Scrap baler

Aymas Recycling MachineryHP3-C (40x40) Continuous Baling Press

Call

Condition: new, Year of construction: 2025, Also, different models are available!

Dwsdpfedfcqasx Ah Ued

IMPORTANT: THE MACHINE WILL BE BRAND NEW

The compression chamber walls are covered with HARDOX material for long-term life-cycle and friction resistance. A hydraulic Oil Cooling system is implemented for efficiency in hot climate conditions. Cylinder Rods are induction-hardened and chrome-plated. Pumps and valves of hydraulic systems are from worldwide reputable brands such as PARKER, and BOSCH-REXROTH. The machine is fully automatic by PLC control. It is easy to use with the help of the touch screen. All electrical and electronic parts are by SCHNEIDER and SIEMENS Brands.

The machine is CE-certified. The marking certifies that a product has met European Directives regarding consumer safety, health, or environmental requirements.

Machine will be under Aymas Makina San. Ve Tic. A. Ş. Guarantee against manufacturing defects for one (1) year or two thousand five hundred (2.500) working hours.

SEE THE TECHNICAL DESCRIPTION BELOW

Bale Size 400mm x 400mm x...

Bale Weight 120-180 kg (Steel), 50-80 kg (Aluminium),150-200 kg (Copper)

Press Box Dimensions (Width x Length x Height): 1.000mm x 2.700mm x 900mm

Loading Bunker Dimensions (Width x Length x Height): 1.650mm x 2.300mm x 800mm

Feeding Opening: 1.000mm x 1.600mm

Capacity*

Listing

Gargždai

Gargždai

8,118 km

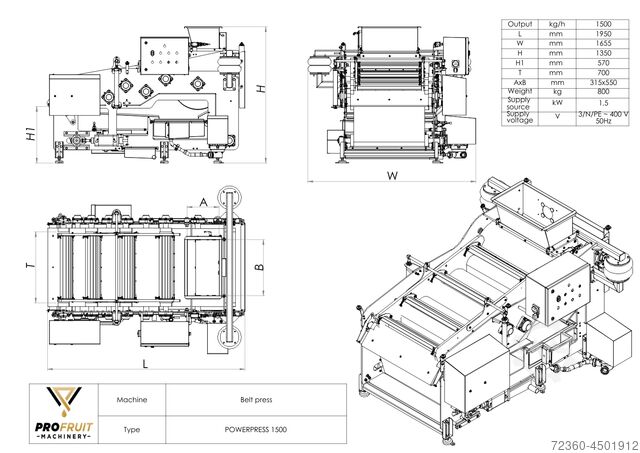

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1500 kg/h.

Dsdpfsflpp Esx Ah Uewd

- The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

- The juice yield of apples using our belt press 1500 is ~75 %.

- There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

- The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

- The belt press 1500 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

- Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

- After work, belt press should be manually washed with a water stream. - A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

- Belt tension is adjustable.

- Machine is made entirely of stainless steel and has adjustable feet.

- Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Ostrożne

Ostrożne

8,364 km

End milling machine

Pressta EiseleAKF 250L

Call

Condition: excellent (used), Year of construction: 1999, Type: AKF 250L

Motor: 400V 2,2kW

Speed: 2800 rpm

Cutter O: 250mm

Cutter holder shaft O: 40mm

Milling width: 300mm

Milling depth: 85mm

Profile height: 160mm

Dwodjtt Eb Sjpfx Ah Ujd

Weight: approx. 150kg

Dimensions W x H x D 950 x1450 x 930 mm

Trust Seal

Dealers certified through Machineseeker

Listing

Halilbeyli OSB

Halilbeyli OSB

9,813 km

Briquetting press

Aymas Recycling MachineryBP 160 Chip Briquetting Press

Call

Condition: new, Year of construction: 2025, Also, different models are available!

IMPORTANT: MACHINE WILL BE BRAND NEW

SEE THE TECHNICAL DESCRIPTION BELOW

1. Briquette Diameter: Ø 160mm

2. Capacity: 4.500 – 5.500 kg/hour (Iron & Steel)

3. Preliminary Compression Ram Thrust: 50 tons

4. Main Compression Cylinder Thrust: 600 tons

5. Maximum Working Pressure: 300 bars

6. Cycle Time: 12 - 14 sec

7. Electric Motor Power: 170 kW Overall

8. Machine Dimensions (Width x Length x Height): 5.200mm x 8.000mm x 3.100mm

9. Machine Weight: 42.000 kg

Dodpfxogv I Ihe Ah Uewd

10. Screw drive feeders will fill the compression chamber automatically and a built-in vibrating hopper will provide safety to the chamber by preventing the oversize material from entering the chamber.

11. Cylinder Rods are induction-hardened and chrome plated.

12. A Hydraulic Oil cooling system is implemented.

13. Pumps and valves of hydraulic systems are PARKER or BOSCH-REXROTH brand.

14. The machine is fully automatic by PLC control.

15. All electrical and electronic parts are by SCHNEIDER or SIEMENS Brand.

16. The machine is CE certificated. The marking certifies that a product has met European Directives regarding consumer safety, health, or environmental requirements.

17. Machine will be under AYMAS Makina San. Ve Tic. A. Ş. Guarantee against manufacturing defects for one (1) year or two thousand five hundred (2.500) working hours.

Listing

Gargždai

Gargždai

8,118 km

Belt press for juice

Profruit machineryPOWERPRESS 800

Call

Year of construction: 2023, condition: new, Belt presses POWERPRESS 800 are designed for pressing fruit, berry and vegetable mass. Fruit mass is placed on the belt which presses it against cylinders.The obtained juice flows in the collection trays under the belt presses. Pressing is continuous.

Dwsdjhu Ab Dspfx Ah Usd

Capacity: 800 kg/h

The most evolutionary feature of our belt press POWERPRESS line is integrated pump and juice collection tank into the press itself. That means that you save money and do not need an additional juice collection tank and pump which otherwise would use much space and money.

There is a filtration sieve integrated into the juice collection tank. Because of that the machine filtrates the juice even during the pressing stage providing cleaner and more pure product.

Entirely made of stainless steel.

Has adjustable feet.

The belt presses function automatically. When the tank of the mass is full, all other machines which come before belt press turn off automatically. When the juice tank is full, juice pump pumps the juice into the tanks.

Includes High pressure washer.

Has an integrated pump.

Belt tension is adjustable.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

The cleaning of the belt is automatic with high pressure cleaner, scraper and brush.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

Listing

Halilbeyli OSB

Halilbeyli OSB

9,813 km

Briquetting press

Aymas Recycling MachineryBP 200 Chip Briquetting Press

Call

Condition: new, Year of construction: 2025, Also, different models are available!

Dwjdjgv I N Uepfx Ah Uod

IMPORTANT: MACHINE WILL BE BRAND NEW.

SEE THE TECHNICAL DESCRIPTION BELOW

1. Briquette Diameter: Ø 200mm

2. Capacity: 12.000 kg/hour ( Steel)

3. Preliminary Compression Ram Thrust: 50 tons

4. Main Compression Cylinder Thrust: 850 tons

5. Maximum Working Pressure: 300 bars

6. Cycle Time: 10 - 12 sec

7. Electric Motor Power: 6x37=222 kW (Main Motors)

8. Machine Dimensions : 11.000mm x 10.000mm

9. Machine Weight: 60.000 kg

10. Screw drive feeders will fill the compression chamber automatically and a built-in vibrating hopper will provide safety to the chamber by preventing the oversize material from entering the chamber.

11. Cylinder Rods are induction-hardened and chrome plated.

12. A Hydraulic Oil cooling system is implemented.

13. Pumps and valves of hydraulic systems are PARKER or BOSCH-REXROTH brand.

14. The machine is fully automatic by PLC control.

15. All electrical and electronic parts are by SCHNEIDER or SIEMENS Brand.

16. The machine is CE certificated. The marking certifies that a product has met European Directives regarding consumer safety, health, or environmental requirements.

17. Machine will be under AYMAS Makina San. Ve Tic. A. Ş. Guarantee against manufacturing defects for one (1) year or two thousand five hundred (2.500) working hours.

Listing

Halilbeyli OSB

Halilbeyli OSB

9,813 km

Briquetting press

Aymas Recycling MachineryBP 120 Chip Briquetting Press

Call

Condition: new, Year of construction: 2025, Also, different models are available!

IMPORTANT: MACHINE WILL BE BRAND NEW

SEE THE TECHNICAL DESCRIPTION BELOW:

1. Briquette Diameter: Ø 120mm

2. Capacity: 1.800 – 2.200 kg/hour (Iron & Steel)

3. Preliminary Compression Ram Thrust: 15 tons

4. Main Compression Cylinder Thrust: 400 tons

5. Maximum Working Pressure: 300 bars

6. Cycle Time: 12 - 14 sec

7. Electric Motor Power: 75 kW

8. Machine Dimensions (Width x Length x Height): 3.200mm x 4.200mm x 3.500mm

9. Machine Weight: 13.000 kg

10. Screw drive feeders will fill the compression chamber automatically and a built-in vibrating hopper will provide safety to the chamber by preventing oversize material from entering the chamber.

11. Cylinder Rods are induction-hardened and chrome plated.

12. A Hydraulic Oil cooling system is implemented.

13. Pumps and valves of hydraulic systems are PARKER or BOSCH-REXROTH brand.

Dwodpfsdfc Iksx Ah Ued

14. The machine is fully automatic by PLC control.

15. All electrical and electronic parts are by SCHNEIDER or SIEMENS Brand.

16. The machine is CE certificated. The marking certifies that a product has met European Directives regarding consumer safety, health, or environmental requirements.

17. Machine will be under AYMAS Makina San. Ve Tic. A. Ş. Guarantee against manufacturing defects for one (1) year or two thousand five hundred (2.500) working hours.

We make it easier for you to find: "press-fit machine"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Press-Fit Machine (102,063)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month